Académique Documents

Professionnel Documents

Culture Documents

ESP Technical Specification

Transféré par

RameshBMDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ESP Technical Specification

Transféré par

RameshBMDroits d'auteur :

Formats disponibles

NAME OF PROJECT :2 X 600 MW COAL BASED POWER PLANT MAHAN, DIST :SINGRAULI, MADHYA PRADESH

ENQUIRY DOCUMENT

ESSAR CONSTRUCTIONS (INDIA) LIMITED

ELECTRO STATIC PRECIPITATOR

ANNEXURE V: TECHNICAL SPECIFICATION 1. SCOPE OF WORK This specification, in general, comprises of technical specification to be followed during ERECTION OF ELECTRO STATIC PRECIPITATOR (ESP) for 2 X 600 MW Coal Based Power Plant, Mahan, Singrauli, Madhya Pradesh. 2.

2.1

DESCRIPTION OF ESP An Electro static precipitator is a large, industrial emission control unit. It is designed to trap and remove dust particles from the exhaust gas. These dust laden gases pass through an electrostatic precipitator that collects the dust. Clean gas then passes out of the precipitator and through a Stack to the atmosphere

2.2

The main component of ESP consist of the following : Collecting & Emitting System Collecting & Emitting Rapping Casing & Structure Hopper Staircase & Platform Electrical System

2.3

The base plate shall be fixed with foundation bolt. The geometrical center line of the base plate shall match with the corresponding axis of foundations and the deviation in base plates center line shall not be more than 3mm.

2.4

Secondary grouting to be done after completing erection of the first tier structure.

NAME OF PROJECT :2 X 600 MW COAL BASED POWER PLANT MAHAN, DIST :SINGRAULI, MADHYA PRADESH

ENQUIRY DOCUMENT

ESSAR CONSTRUCTIONS (INDIA) LIMITED

ELECTRO STATIC PRECIPITATOR

3.

3.1 3.2

CODES AND STANDARDS

IS 800 : 2007 General Construction in Steel - Code of Practice. IS 816 : 1969 Code of Practice for Use of Metal Arc Welding for General Construction in Mild Steel. IS 823 : 1964 Code of procedure for Manual Metal Arc Welding of Mild Steel. IS 2062 : 2006 Hot Rolled Low, Medium and High Tensile Structural Steel. IS 814 : 2004 Covered Electrodes for Manual Metal Arc Welding of Carbon and Carbon Manganese Steel - Specification IS 1363 : 2002 Hexagon Head Bolts, Screws and Nuts of Product Grade `C' Part 1 : Hexagon Head Bolts (Size Range M 5 to M 64) 4. GENERAL NOTES

3.3 3.4 3.5

3.6

4.1 4.2 4.3 4.4 4.5

Plant reduced level of 0.00 corresponds to finished floor level of ground floor of Main Power House Building. All dimensions are in millimeters and elevations and coordinates in meters, unless noted otherwise. Drawings shall not be scaled. Figured dimensions shall be followed. Contractor shall check and verify all dimensions before execution of work. All works shall be carried out as per respective specifications. In the absence of specification for a particular type of work the same shall be carried out as per the relevant IS standards and as directed by Engineer.

4.6 4.7

All IS standards referred shall be the latest IS edition including all official amendments. Any particular note given on the drawing shall override the notes given herein. 5. PREPARATION BEFORE CONSTRUCTION

NAME OF PROJECT :2 X 600 MW COAL BASED POWER PLANT MAHAN, DIST :SINGRAULI, MADHYA PRADESH 5.1

ENQUIRY DOCUMENT

ESSAR CONSTRUCTIONS (INDIA) LIMITED

ELECTRO STATIC PRECIPITATOR

All the drawings shall be checked by related personnel before assembling of steel structures. All technical explanation from technical person as per the requirements of construction drawings and related technical documents to be clearly explained to the erection gang.

5.2

5.3

Various measuring tools like steel tape, ruler, bare L-square and level bar shall be calibrated before using to ensure accurate measurement.

6.

6.1

ASSEMBLY OF EQUIPMENTS

Arrangement should be made to do pre-assembly of parts on the ground before erecting to reduce erection time. The supporting of platforms and stairs shall be welded on the assembly components as per drawings. Prior to the installation, the technician shall explain Technical requirements and safety measures to be followed to all the workers. The quality standard of erection must be within allowable deviation. 7.

7.1 7.2 7.3

6.2

6.3

6.4

TECHNICAL SPECIFICATION

Welding in general shall conform to IS 816 and IS 823. Electrodes used shall generally conform to IS 814 or equivalent and shall be amendable to radiographic tests. Erection bolts shall be black hexagonal headed conforming to IS 1363 of grade C and property class 4.6. The exact length of bolts shall be decided on the basis of grip length required.

7.4 7.5 7.6

Connections may be welded or bolted as indicated on construction drawings. Minimum size of fillet weld shall be equal to the lowest thickness of the connected member or 8 mm whichever is less, unless specified otherwise. All butt welds shall be full strength Butt Welds.

NAME OF PROJECT :2 X 600 MW COAL BASED POWER PLANT MAHAN, DIST :SINGRAULI, MADHYA PRADESH

ENQUIRY DOCUMENT

ESSAR CONSTRUCTIONS (INDIA) LIMITED

ELECTRO STATIC PRECIPITATOR

7.7 7.8

Intermittent weld shall not be permitted unless specified in the drawing. All erection bolts shall be 16 mm dia. black M.S. bolts in 17.5 mm dia. holes unless otherwise noted. Erection bolts shall be retained in position even after the structure is welded.

7.9

Where bolted connection is specified, each member meeting at the joint shall have at least 2 bolts in one line. A minimum of one bolt shall be used at the crossing of the angle cross bracings.

7.10

Anchor bolts at column bases shall be thoroughly tightened to develop full fixity at the base. The nut shall be tack welded to base plate after tightening. A locknut shall also be provided.

7.11 7.12 7.13 7.14

7.15

Column base plates shall be grouted as soon as possible after erection of columns ensuring that columns are perfectly plumb. Erection tolerances as per detailed specifications shall be strictly adhered to. A sequence of erection of members shall be prepared and submitted by erector for approval by Engineer before actual erection commences. Contractor shall take extra care to check the straightness of all members and get them inspected / approved before erection. Portion of steel structure to be encased in concrete shall not be painted.

********

Vous aimerez peut-être aussi

- Solar Tree Structure DetailsDocument4 pagesSolar Tree Structure Detailsdsengineeringsolutions120987Pas encore d'évaluation

- Table of Contents PageDocument15 pagesTable of Contents PageEr Nizar AhamedPas encore d'évaluation

- Technical Specification For Module Mounting StructureDocument4 pagesTechnical Specification For Module Mounting Structurepankaj tyagiPas encore d'évaluation

- Checklist For Lighting Mast Structure Design & DrawingDocument4 pagesChecklist For Lighting Mast Structure Design & DrawingRupesh KhandekarPas encore d'évaluation

- Technical Specification Section: StructureDocument10 pagesTechnical Specification Section: StructurePremBhushanPas encore d'évaluation

- Technical Specification Section StructureDocument10 pagesTechnical Specification Section StructurePremBhushanPas encore d'évaluation

- Fabrication Beam Structure Design DrawingDocument4 pagesFabrication Beam Structure Design DrawingRupesh KhandekarPas encore d'évaluation

- Checklist For BPI Structure Design & DrawingDocument4 pagesChecklist For BPI Structure Design & DrawingRupesh KhandekarPas encore d'évaluation

- 33kV Bus Duct Structure Design DrawingDocument4 pages33kV Bus Duct Structure Design DrawingRupesh KhandekarPas encore d'évaluation

- Checklist For 33kV HG Fuse Structure Design & DrawingDocument4 pagesChecklist For 33kV HG Fuse Structure Design & DrawingRupesh KhandekarPas encore d'évaluation

- Checklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingDocument4 pagesChecklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingRupesh KhandekarPas encore d'évaluation

- Checklist For 33kV DP Structure Design & DrawingDocument4 pagesChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarPas encore d'évaluation

- Ethane Furnace Erection SequenceDocument5 pagesEthane Furnace Erection SequenceAleem QureshiPas encore d'évaluation

- Checklist For Wave Trap Structure Design & DrawingDocument4 pagesChecklist For Wave Trap Structure Design & DrawingRupesh KhandekarPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument21 pagesDisclosure To Promote The Right To InformationgovimanoPas encore d'évaluation

- 3-Bid Document Volume-III-Substation Specifiations - 1Document126 pages3-Bid Document Volume-III-Substation Specifiations - 1KaminiSurendraReddyPas encore d'évaluation

- Fabrication of Structural Steel WorkDocument16 pagesFabrication of Structural Steel WorkyogeswaranPas encore d'évaluation

- Is Standard ListDocument5 pagesIs Standard ListbalramkinagePas encore d'évaluation

- MOS Roof Truss InstallationDocument19 pagesMOS Roof Truss InstallationMohammad Hadoumi Saldan100% (9)

- CivilStructures HVPNLDocument11 pagesCivilStructures HVPNLHeather CarterPas encore d'évaluation

- Eaton Guidespec Metal Enclosed Non Segregated Bus Duct MV 26 18 29Document6 pagesEaton Guidespec Metal Enclosed Non Segregated Bus Duct MV 26 18 29JeyakumarPas encore d'évaluation

- Bored Cast in Situ Method LogyDocument77 pagesBored Cast in Situ Method LogySujan RajkumarPas encore d'évaluation

- 55 Samss 001Document7 pages55 Samss 001Vahid KosariPas encore d'évaluation

- 26 13 13 Mvcircuitbreakerswitchgear (Gas Insulatedvacuum)Document19 pages26 13 13 Mvcircuitbreakerswitchgear (Gas Insulatedvacuum)Md Rodi BidinPas encore d'évaluation

- Microsoft Word - A927-000-81-41-46052 - 1Document9 pagesMicrosoft Word - A927-000-81-41-46052 - 1bondsivamaniPas encore d'évaluation

- General Notes & SpecificationsDocument6 pagesGeneral Notes & SpecificationsDon Santos100% (1)

- Bren DBR 15-04-2023Document18 pagesBren DBR 15-04-2023preethiPas encore d'évaluation

- Technical Specifications Section-Iv 1.0 Transmission Tower 1.1 General Description of The TowerDocument29 pagesTechnical Specifications Section-Iv 1.0 Transmission Tower 1.1 General Description of The TowerKy TaPas encore d'évaluation

- LWT Workshop Elevations: Department of Defence: Renovation and Refurbishment: Upington 8sai BattalionDocument1 pageLWT Workshop Elevations: Department of Defence: Renovation and Refurbishment: Upington 8sai BattalionAndrewSwanepoelPas encore d'évaluation

- RMC Technical Material Specification SummaryDocument27 pagesRMC Technical Material Specification Summarysat palPas encore d'évaluation

- I Girder Prestressing Methodology DRNDocument11 pagesI Girder Prestressing Methodology DRNAkarsh KorishettarPas encore d'évaluation

- ARKON - Updated Steel Fabrication Methodology 08162021Document5 pagesARKON - Updated Steel Fabrication Methodology 08162021Yvan Glendell MangunePas encore d'évaluation

- General notes and design parameters for construction projectDocument4 pagesGeneral notes and design parameters for construction projectRinaldi DwiyantoPas encore d'évaluation

- SEC Porcelain Insulator SpecificationDocument25 pagesSEC Porcelain Insulator SpecificationpcelisPas encore d'évaluation

- PROPOSED LT PANEL WORKS FOR ARG ANANTA-1 AT JAIPURDocument23 pagesPROPOSED LT PANEL WORKS FOR ARG ANANTA-1 AT JAIPURARG ANANTAPas encore d'évaluation

- LM Tech SpecDocument7 pagesLM Tech SpecSUSOVAN BISWASPas encore d'évaluation

- LV Panel Boards - SpecificationDocument7 pagesLV Panel Boards - SpecificationduleepabowattePas encore d'évaluation

- Prestressing Works SpecsDocument30 pagesPrestressing Works SpecsVladimir Simeunovic100% (1)

- Suryadev T.S.for STRL FinalDocument46 pagesSuryadev T.S.for STRL Finalkrmcharigdc100% (1)

- Annex-05 PAC Synergy InstaconDocument43 pagesAnnex-05 PAC Synergy InstaconRishabhPas encore d'évaluation

- Specifications:: 1 Project Site Information & Intent of SpecificationDocument8 pagesSpecifications:: 1 Project Site Information & Intent of Specificationardee pashamylaramPas encore d'évaluation

- TS - LGSS MARRIED OFFICER Living Shelter 17 CORPS SINGLE STOREYDocument20 pagesTS - LGSS MARRIED OFFICER Living Shelter 17 CORPS SINGLE STOREYdesignPas encore d'évaluation

- 4 - Electrical SpecificationsNIT39 PDFDocument69 pages4 - Electrical SpecificationsNIT39 PDFDileep ChintalapatiPas encore d'évaluation

- Method Statement For Structural Fabrication & ErectionDocument11 pagesMethod Statement For Structural Fabrication & ErectionBinay93% (14)

- Methodology Well Foundation at Yamuna RiverDocument18 pagesMethodology Well Foundation at Yamuna RiverSambit NayakPas encore d'évaluation

- Addendum-Additional Special Conditions Yamuna Bridge TenderDocument42 pagesAddendum-Additional Special Conditions Yamuna Bridge TenderAshish VermaPas encore d'évaluation

- Structural Design Basis ReportDocument31 pagesStructural Design Basis ReportRajaram100% (1)

- IS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)Document17 pagesIS 9417 - 2018 Welding of High Strength Steel Bars For Reinforced Concrete Construction - Recommendations (Second Revision)bala subramanyam100% (2)

- Steel Project ReportDocument5 pagesSteel Project ReportMariappan .PPas encore d'évaluation

- 2 TS SS STR R8 030309 060213Document16 pages2 TS SS STR R8 030309 060213dkshtdkPas encore d'évaluation

- Indian Standard For ConnectorsDocument11 pagesIndian Standard For Connectorsm khPas encore d'évaluation

- Is 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocument10 pagesIs 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDebajani DekabaruahPas encore d'évaluation

- Low Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationDocument16 pagesLow Voltage Metal Enclosed Drawout Arc Resistant Switchgear: MNS-SG Guideform SpecificationSanj PandeyPas encore d'évaluation

- Specification For Hollow Metal Pressed Steel Doors PDFDocument7 pagesSpecification For Hollow Metal Pressed Steel Doors PDFChetan ToliaPas encore d'évaluation

- Electrical BOQ Plot C LPSDocument5 pagesElectrical BOQ Plot C LPSAgrawal PrajaktaPas encore d'évaluation

- Is - 816Document30 pagesIs - 816mmkatta100% (1)

- Section 461 Multirotational Bearings 461-1 DescriptionDocument3 pagesSection 461 Multirotational Bearings 461-1 Descriptionl_aguilar_mPas encore d'évaluation

- Spot Welding Interview Success: An Introduction to Spot WeldingD'EverandSpot Welding Interview Success: An Introduction to Spot WeldingPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Donich Water Hydro Scheme CMSDocument14 pagesDonich Water Hydro Scheme CMSRameshBMPas encore d'évaluation

- Donich Water Hydro Scheme CMSDocument14 pagesDonich Water Hydro Scheme CMSRameshBMPas encore d'évaluation

- Donich Water Hydro Scheme CMSDocument14 pagesDonich Water Hydro Scheme CMSRameshBMPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsidePas encore d'évaluation

- Mepw 379Document4 pagesMepw 379RameshBMPas encore d'évaluation

- Mechanical EquipmentDocument3 pagesMechanical EquipmentRameshBMPas encore d'évaluation

- Ansi b36.10 Pipe SizeDocument9 pagesAnsi b36.10 Pipe SizeSpoonful BurnsidePas encore d'évaluation

- Ansi Pipe ScheduleDocument1 pageAnsi Pipe ScheduleRameshBMPas encore d'évaluation

- Astm A 53Document1 pageAstm A 53RameshBMPas encore d'évaluation

- Ansi Pipe ScheduleDocument1 pageAnsi Pipe ScheduleRameshBMPas encore d'évaluation

- 28096Document25 pages28096RameshBMPas encore d'évaluation

- PRAGYADocument2 pagesPRAGYARameshBMPas encore d'évaluation

- Abu Dhabi Useful Information1Document16 pagesAbu Dhabi Useful Information1RameshBMPas encore d'évaluation

- Information About Machine UnbalanceDocument2 pagesInformation About Machine UnbalanceRameshBMPas encore d'évaluation

- Great Plains Turbo-Cisel TC-5111Document112 pagesGreat Plains Turbo-Cisel TC-5111Vasile PopoviciPas encore d'évaluation

- 0324 - L - KaMeWa Controllable Pitch Main PropellersDocument290 pages0324 - L - KaMeWa Controllable Pitch Main Propellersvmike6350% (6)

- Service Parts List: M18™ Fuel™ Power Unit 2825-21 K49A 54-49-2810Document7 pagesService Parts List: M18™ Fuel™ Power Unit 2825-21 K49A 54-49-2810Amjad AlQasrawiPas encore d'évaluation

- 32 McNeilus Mixer Parts Section Revised 1 PDFDocument59 pages32 McNeilus Mixer Parts Section Revised 1 PDFLuis Cuentas100% (1)

- A. Cataloge Book MSR AC16Document56 pagesA. Cataloge Book MSR AC16parahu arief100% (1)

- Huck C50LDocument4 pagesHuck C50LchristianPas encore d'évaluation

- YOIKOTO Electrical and Industrial Supplies Trading: The Good ChoiceDocument12 pagesYOIKOTO Electrical and Industrial Supplies Trading: The Good ChoicePeter Tee Jay AlvarezPas encore d'évaluation

- BC03 Fire DamperDocument20 pagesBC03 Fire DamperabhishekPas encore d'évaluation

- Samsung UE40EH5000WDocument49 pagesSamsung UE40EH5000WjokersuPas encore d'évaluation

- HM1203C PBDocument3 pagesHM1203C PBJose SanchezPas encore d'évaluation

- TAS Steering Gear Service Manual: TRW AutomotiveDocument0 pageTAS Steering Gear Service Manual: TRW AutomotiveJulio Ramirez100% (1)

- Technical Manual Fulcrum ENG Op004 Rev03!09!2016Document8 pagesTechnical Manual Fulcrum ENG Op004 Rev03!09!2016Robert ClevelandPas encore d'évaluation

- Column-Base Plate Foundation Design Report, How To Design Base Plate Connections, Sample Design Report, ColumnBase Software, PCEESoft Inc.Document5 pagesColumn-Base Plate Foundation Design Report, How To Design Base Plate Connections, Sample Design Report, ColumnBase Software, PCEESoft Inc.ircivilcivilPas encore d'évaluation

- Sliding Gate Operator Manual (WJKMB201&202)Document13 pagesSliding Gate Operator Manual (WJKMB201&202)Ricardo FajardoPas encore d'évaluation

- Manual Book KeboDocument42 pagesManual Book KeboUlwan FianiPas encore d'évaluation

- bp2036 Piezoelectric Charge Accelerometer Types 4371Document2 pagesbp2036 Piezoelectric Charge Accelerometer Types 4371ategPas encore d'évaluation

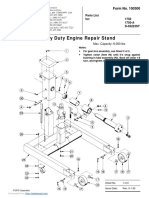

- Heavy Duty Engine Repair Stand: Form No. 100300Document4 pagesHeavy Duty Engine Repair Stand: Form No. 100300Mouayed TalbiPas encore d'évaluation

- Gasketing Design Guide-Final2-1Document23 pagesGasketing Design Guide-Final2-1Joy BhattacharyaPas encore d'évaluation

- List of Companies With MakeDocument10 pagesList of Companies With MakeforexPas encore d'évaluation

- Instruction Manual Juki LK-1900ADocument124 pagesInstruction Manual Juki LK-1900AMaskusyani100% (2)

- SAILOR 6110 Mini-C GMDSS: Installation ManualDocument112 pagesSAILOR 6110 Mini-C GMDSS: Installation ManualcristianocalheirosPas encore d'évaluation

- Ef1000b 7XD2 2003Document25 pagesEf1000b 7XD2 2003CRISTIAN BARRIOSPas encore d'évaluation

- Building A Drawer Slide CNC Machine For Under 200Document6 pagesBuilding A Drawer Slide CNC Machine For Under 200Deiver MurciaPas encore d'évaluation

- Module 6Document104 pagesModule 6rabih87Pas encore d'évaluation

- Lokotrack LT1213S Parts ListDocument634 pagesLokotrack LT1213S Parts ListFabian Cortes Serrano100% (13)

- Ring Mill Manual Rock Labs PDFDocument48 pagesRing Mill Manual Rock Labs PDFCuchito Miraval100% (2)

- Bettis Service Instructions For Hd732-s HydraulicDocument27 pagesBettis Service Instructions For Hd732-s Hydraulicrangga advPas encore d'évaluation

- Service Manual: Spring Brake ActuatorDocument24 pagesService Manual: Spring Brake ActuatorPatricio G. ArrienPas encore d'évaluation

- Texas Flange Product CatalogDocument76 pagesTexas Flange Product CatalogVicky GautamPas encore d'évaluation