Académique Documents

Professionnel Documents

Culture Documents

Tsa 100

Transféré par

Sanjay Kumar TripathiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tsa 100

Transféré par

Sanjay Kumar TripathiDroits d'auteur :

Formats disponibles

Applied Analytics - TSA-100

Page 1 of 3

Date : 9/2/2011

Site Map Resources Jobs Contact Home Search: Enter Search...

Submit

Home About Us Products OMA-300 TLG-837 H2S Analyzer TSA-100 Sampling Systems CEM ASA-400 NOx Analyzer CLT-360 Spectroscopy Accessories OMA-300CM CIP-100 Applications Press Release A Total Sulfur Analyzer Application Form Publications Information Request Register For News Letter Contact Us Branch Locations sitemap Resources Jobs

TSA-100

View AAI Demo

ePurge This week, AAI unveiled the ePurge X, a nextgeneration solution for air- purging electronic enclosures. Unlike conventional purge controllers, this new offering is entirely solid state and much more in line with the design of AAI's highly automated process analyzers. "The ePurge X has an ultra-slim profile that barely protrudes from the surface of the enclosure. It also has half as many components

http://appliedanalytics.in/index.php?page=TSA-100

9/2/2011

Applied Analytics - TSA-100

Page 2 of 3

AAI HQ Video

The TSA-100, designed for accuracy, versatility, fast-response, and ruggedness in any range of total sulfur measurement. This innovative multi-component analyzer has critical advantages over older standards such as the lead acetate tape method, a highmaintenance process with slow measurements, cumbersome adjustments, and toxic consumables. Most significantly, the TSA-100 is engineered for insusceptibility to component cross-interference, meaning that the analyzer can provide accurate total sulfur measurements when interfering compounds like H2S, SO2, and mercaptans are all present in the sample. The system consists of four major subunits: 1) a xenon light source, which sends light through fiber optic cables into the 2) flow cell, in which the unique characteristics of the sample define its interaction with the light; the light then enters a 3) holographic grating, which separates white light into its components such that the 4) diode array detector can measure the intensity of radiation at each wavelength. These measurements report on the absorption of light by the various components in the sample, and thus reveal the concentrations of the components. The analyzer is solid state (no moving parts), and since it connects to the sample through fiber optic cables, it can be installed far from any explosive or poisonous gases (making TSA-100 suitable for even the harshest industrial environments). Using the full high-resolution spectrum from the diode array, our analyzer can easily switch between extreme wavelength ranges to provide instantaneous and continuous measurements at 0-10 ppm and 0-100% all in the same instrument. The TSA-100 can be used effectively in two different methods of determining total sulfur, demonstrating the flexibility of the analyzer. In the DIRECT METHOD, the analyzer mathematically derives the concentration of each sulfur compound from the full, high-resolution absorbance spectra it obtains from the original process stream. There is no need to mechanically consolidate all sulfur into one specific component, as by combustion in the standard method. The concentrations of sulfur based components like H2S, COS, and mercaptans are computed individually from the spectrum and added together, such that the computer outputs a total sulfur reading. The direct method effectively measures total sulfur in the original process stream as multiple components. The sulfur is oxidized to SO2. The analyzer uses the absorption of the single component (SO2) to determine its concentration, and the total sulfur. The TSA-100 provides the ideal SO2-monitoring solution in case the standard method is your route.

to install as the purges that are currently available."

READ

OMA-300 Semiconductor Edition CEM product bulletin Tail gas Product bulletin TDL 506

The beauty of the TSA-100, however, is its capacity for multi-component analysis. The direct method is less expensive, requiring neither combustion nor the costs associated with it, and demonstrates the long-term benefits of incorporating AAIs flagship technology into your process. The second is the conventional standard method, which involves placing the hydrocarbon sample in a hot combustion tube in an oxygen-rich environment.

Total sulfur by conversion to SO2 (combustion sampling system)

The sulfur based compounds in the sample stream are pyrolyzed to give SO2.The flow of the sample gas and O2 are regulated to keep the correct mixture for optimal conversation. These gases are mixed in a chamber before they are injected into the furnace where all sulfur compounds are converted into SO2. The SO2 is then transferred into the analyzers flow cell where it is measured by a UV_VIS process diode

http://appliedanalytics.in/index.php?page=TSA-100

9/2/2011

Applied Analytics - TSA-100

Page 3 of 3

array spectrophotometer. The SO2 stream is returned to a waste line that can be vented or sent to the flare. The sampling system allows for automatic zero (blank) with Nitrogen at preset time intervals.

Home | About | Resources | Services | Contact Copyright 2009 Applied Analytics, India. All Rights Reserved. Contact Us Contact Us

http://appliedanalytics.in/index.php?page=TSA-100

9/2/2011

Vous aimerez peut-être aussi

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentD'EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Aanalyst 400 Aa Spectrometer: Atomic AbsorptionDocument2 pagesAanalyst 400 Aa Spectrometer: Atomic AbsorptionDara SabilaPas encore d'évaluation

- Automotive Sensor Testing and Waveform AnalysisD'EverandAutomotive Sensor Testing and Waveform AnalysisÉvaluation : 4.5 sur 5 étoiles4.5/5 (13)

- AstroUV Turbo - HACH New ProductDocument4 pagesAstroUV Turbo - HACH New ProductprannoyPas encore d'évaluation

- Liquid Sample Introduction in ICP Spectrometry: A Practical GuideD'EverandLiquid Sample Introduction in ICP Spectrometry: A Practical GuideÉvaluation : 4 sur 5 étoiles4/5 (6)

- DANI Gas ChromatographyDocument4 pagesDANI Gas Chromatographyidhem1110Pas encore d'évaluation

- The Differences Between Extractive and In-Situ Emissions MonitoringDocument7 pagesThe Differences Between Extractive and In-Situ Emissions MonitoringAniketPas encore d'évaluation

- Procal 2000 IR Emissions AnalyserDocument4 pagesProcal 2000 IR Emissions AnalyserMeindert gerssenPas encore d'évaluation

- Oxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDocument5 pagesOxygen, Nitrogen and Hydrogen Analyzer EMGA-930/EMGA-830: in Pursuit of High Performance, Speed and OperabilityDidit AndiatmokoPas encore d'évaluation

- Emerson CEMSDocument12 pagesEmerson CEMSquinteroudinaPas encore d'évaluation

- 44-74482BRO WorldLeaderAAICPMSICPMSDocument16 pages44-74482BRO WorldLeaderAAICPMSICPMSOshin ParranganPas encore d'évaluation

- Practical Approach To SOx and NOx MeasurementDocument3 pagesPractical Approach To SOx and NOx MeasurementShivPas encore d'évaluation

- Sulphur Analysis With XRF Method PDFDocument2 pagesSulphur Analysis With XRF Method PDFparsmessengerPas encore d'évaluation

- H2S & Total Sulfur AnalyzersDocument16 pagesH2S & Total Sulfur AnalyzersBryan TungPas encore d'évaluation

- ARL9900 TCA CatalogueIDocument4 pagesARL9900 TCA CatalogueIKendra TerryPas encore d'évaluation

- AVLDocument4 pagesAVLefasaravananPas encore d'évaluation

- DGA Whitepaper2Document6 pagesDGA Whitepaper2nooralhudPas encore d'évaluation

- Trace Analytics ISO 8573 White PaperDocument2 pagesTrace Analytics ISO 8573 White PaperDeepakPas encore d'évaluation

- Courier® 30SX (Outokumpu)Document8 pagesCourier® 30SX (Outokumpu)Víctor SandovskyPas encore d'évaluation

- Dumatec Solution Brochure GB PDFDocument10 pagesDumatec Solution Brochure GB PDFrani hindiPas encore d'évaluation

- AuroraDocument1 pageAuroraTHEURYSPas encore d'évaluation

- Courier® 30XPDocument4 pagesCourier® 30XPVíctor Sandovsky100% (1)

- Infra Ran For Ash Rae 110 TestingDocument2 pagesInfra Ran For Ash Rae 110 TestingMateus AquinoPas encore d'évaluation

- Aluminium Smelters: Air Quality Monitoring and Continuous Emissions MonitoringDocument4 pagesAluminium Smelters: Air Quality Monitoring and Continuous Emissions MonitoringHoang Chau TrungPas encore d'évaluation

- 28-114 UVAS Application Guide PIBDocument8 pages28-114 UVAS Application Guide PIBprannoyPas encore d'évaluation

- Analysis of Trace Elements in Petroleum NaphthaDocument5 pagesAnalysis of Trace Elements in Petroleum NaphthaEssam Eldin Metwally AhmedPas encore d'évaluation

- DescriereDocument80 pagesDescrieretitel0% (1)

- Summer Training On Ambient Air QualityDocument15 pagesSummer Training On Ambient Air Qualityakshat srivastavaPas encore d'évaluation

- Unit One This or That 1Document9 pagesUnit One This or That 1sushantPas encore d'évaluation

- Sample Handling System For AnalyzerDocument7 pagesSample Handling System For Analyzeraugur886Pas encore d'évaluation

- Product Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434Document12 pagesProduct Data Sheet ch88 in Situ Flue Gas Oxygen Transmitter Rosemount en 1508434cocot 666Pas encore d'évaluation

- E8500 Manual PDFDocument45 pagesE8500 Manual PDFAnggaraPerbawaPutraPas encore d'évaluation

- Z230 Oxygen Analysers: Hitech InstrumentsDocument2 pagesZ230 Oxygen Analysers: Hitech InstrumentsSahityan PalanichamyPas encore d'évaluation

- CEMS Primer: Automated Control Systems Inc. 122 Woodburn Drive - Dothan, AL 36301 334-792-0113 Fax 334-671-4298Document8 pagesCEMS Primer: Automated Control Systems Inc. 122 Woodburn Drive - Dothan, AL 36301 334-792-0113 Fax 334-671-4298ryan_keller_23Pas encore d'évaluation

- PK0097PEN Mass Spectrometer OmniStarThermoStarDocument8 pagesPK0097PEN Mass Spectrometer OmniStarThermoStarSichem GuerreroPas encore d'évaluation

- Foundry Master UvDocument2 pagesFoundry Master UvLucianoBorasiPas encore d'évaluation

- PDF 4 - Fence-LineDocument4 pagesPDF 4 - Fence-LineAtef GhorbelPas encore d'évaluation

- Xray ThermoDocument8 pagesXray ThermoIman Mahardika EgaPas encore d'évaluation

- Model 8066 Leak Hunter Plus Quantitative Leak DetectorDocument6 pagesModel 8066 Leak Hunter Plus Quantitative Leak Detectorsasizzo78Pas encore d'évaluation

- Total Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerDocument10 pagesTotal Nitrogen in Petroleum Products and Inorganic Materials by An Automated Micro-Dumas Nitrogen AnalyzerGuisela Carbajal RomeroPas encore d'évaluation

- MIBAROM Spectromaxxbrochure - Foundry - Eng - Rev2 - 012013 PDFDocument3 pagesMIBAROM Spectromaxxbrochure - Foundry - Eng - Rev2 - 012013 PDFCorina StanculescuPas encore d'évaluation

- A250DP PN M152 ALPHA Polymer ENDocument3 pagesA250DP PN M152 ALPHA Polymer ENpaula.bugheanuPas encore d'évaluation

- Fives Pillard Tunnel SensorsDocument6 pagesFives Pillard Tunnel Sensorsvinodjk100% (1)

- Mercury Analysis PDFDocument9 pagesMercury Analysis PDFMelinda AndersonPas encore d'évaluation

- Works-X-Supreme8000-XSAW-02.V2 - Fuels 2Document5 pagesWorks-X-Supreme8000-XSAW-02.V2 - Fuels 2md 80Pas encore d'évaluation

- 3130 ABI SystemDocument4 pages3130 ABI Systemapi-19771915Pas encore d'évaluation

- LAND FGA 900 Series EnglishDocument6 pagesLAND FGA 900 Series EnglishRaymundo CorderoPas encore d'évaluation

- New CFA BrochureDocument8 pagesNew CFA BrochureAnonymous HKuYF6kPas encore d'évaluation

- Stackfløw 400: Passionate About ParticulateDocument4 pagesStackfløw 400: Passionate About ParticulateĐặng Trung AnhPas encore d'évaluation

- Results Odour MonitoringDocument3 pagesResults Odour Monitoringl0k0tusPas encore d'évaluation

- Analyser URAS 26 50-23-80-EN-07 - 06Document6 pagesAnalyser URAS 26 50-23-80-EN-07 - 06dinhdinh1986Pas encore d'évaluation

- 5990 8053en PDFDocument36 pages5990 8053en PDFKwaku BiroPas encore d'évaluation

- Supply and Installation of Analyzer and Sampling SystemDocument17 pagesSupply and Installation of Analyzer and Sampling SystemErnesto R. Castillo100% (1)

- Testo350 (Old)Document76 pagesTesto350 (Old)cdepedroPas encore d'évaluation

- Oxygen Analyser in Coal Firing PDFDocument2 pagesOxygen Analyser in Coal Firing PDFShekhar PratapPas encore d'évaluation

- g3620 Sgoas Brochure 2012Document4 pagesg3620 Sgoas Brochure 2012Khasin FuadiPas encore d'évaluation

- Lumasense Gas Detection Limits Wall Chart PDFDocument16 pagesLumasense Gas Detection Limits Wall Chart PDFSergioPas encore d'évaluation

- AGC NovaSTREAM 6000 O2Document4 pagesAGC NovaSTREAM 6000 O2MiguelPas encore d'évaluation

- Fxe-400s Control PC: ApparatusDocument2 pagesFxe-400s Control PC: ApparatusCristian Gabriel CordaryPas encore d'évaluation

- Search Point Optima Plus BrochureDocument6 pagesSearch Point Optima Plus BrochureAdam SaufiPas encore d'évaluation

- CV - Sejal Patel - BE CompDocument2 pagesCV - Sejal Patel - BE CompSanjay Kumar TripathiPas encore d'évaluation

- Base TS-TN: Gaseous Sulfur-Nitrogen Compounds AnalyzerDocument6 pagesBase TS-TN: Gaseous Sulfur-Nitrogen Compounds AnalyzerSanjay Kumar TripathiPas encore d'évaluation

- Transportation Planning Syllabus 2016 1Document2 pagesTransportation Planning Syllabus 2016 1Sanjay Kumar TripathiPas encore d'évaluation

- 2oo3 Redundant-System PDFDocument2 pages2oo3 Redundant-System PDFSanjay Kumar TripathiPas encore d'évaluation

- Redundant Solenoid 2oo2 PDFDocument1 pageRedundant Solenoid 2oo2 PDFSanjay Kumar TripathiPas encore d'évaluation

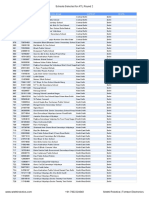

- Schools Selected For ATL Round 2: S. NO. Atl Code School Name District StateDocument3 pagesSchools Selected For ATL Round 2: S. NO. Atl Code School Name District StateSanjay Kumar TripathiPas encore d'évaluation

- VII Syllabus PDFDocument14 pagesVII Syllabus PDFSanjay Kumar TripathiPas encore d'évaluation

- Seni AnyamanDocument1 pageSeni Anyamanauni dalilah100% (1)

- Home Cure Swelling of The GumsDocument3 pagesHome Cure Swelling of The GumsSanjay Kumar TripathiPas encore d'évaluation

- 2022 AJSO Exam With AnswersDocument24 pages2022 AJSO Exam With AnswersWelly Boss HwiPas encore d'évaluation

- Roomie Dylon MannualDocument25 pagesRoomie Dylon MannualJanePas encore d'évaluation

- Integration of Nonlinear Crude Distillation Unit Models in RefineryDocument11 pagesIntegration of Nonlinear Crude Distillation Unit Models in RefineryNông DânPas encore d'évaluation

- Presentation GrihaDocument60 pagesPresentation GrihaTimila Dangol100% (1)

- Welding of P91Document37 pagesWelding of P91nishant361100% (4)

- PID Temperature Control: Proportional GainDocument5 pagesPID Temperature Control: Proportional Gainvamsikumar reddyPas encore d'évaluation

- Sustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Document4 pagesSustainable Performance in The Construction Industry: CEMEX STUDY 18/5/10 14:34 Page 1Nikhil SatavPas encore d'évaluation

- 5.1.12 TRO Unit: Part Names of Each ComponentDocument1 page5.1.12 TRO Unit: Part Names of Each ComponentMark Dominic FedericoPas encore d'évaluation

- Toyota Techdoc Continuously Variable Transaxle Fluid Adjustment 1 2 PDFDocument5 pagesToyota Techdoc Continuously Variable Transaxle Fluid Adjustment 1 2 PDFrodrivalentPas encore d'évaluation

- Thick-Walled P.V.Document23 pagesThick-Walled P.V.Erick PalladaPas encore d'évaluation

- Aac Block ReportDocument32 pagesAac Block ReportAyush Dixit100% (1)

- H1 3 6K S2 CEI 0 21 CertificateDocument7 pagesH1 3 6K S2 CEI 0 21 Certificatebeydacaltu beydacaltuPas encore d'évaluation

- Pcr2019-14 PCR Construction Products v1.0Document26 pagesPcr2019-14 PCR Construction Products v1.0marcoPas encore d'évaluation

- Segment ProtectorDocument4 pagesSegment ProtectorQuayo DeejayPas encore d'évaluation

- Combined Impact and Attrition MethodDocument7 pagesCombined Impact and Attrition MethodBernadette Beltran0% (2)

- Visual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsDocument2 pagesVisual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsrajuajiPas encore d'évaluation

- Symmetry: Tailored Workspaces-Optimized FacilityDocument7 pagesSymmetry: Tailored Workspaces-Optimized Facilityab_bn_1Pas encore d'évaluation

- Industry Cables - General Catalogue - Prysmian Group 2016 - LR PDFDocument166 pagesIndustry Cables - General Catalogue - Prysmian Group 2016 - LR PDFEmre DalgicPas encore d'évaluation

- SunPower Guideline For PVSyst Modeling - Oasis 3 - P-SeriesDocument17 pagesSunPower Guideline For PVSyst Modeling - Oasis 3 - P-Seriesvineets058100% (1)

- LV Network Calculations and Use of AmtechDocument38 pagesLV Network Calculations and Use of AmtechAbraham JyothimonPas encore d'évaluation

- Notes FlamephotometryDocument19 pagesNotes FlamephotometryKaFiAliMirzaPas encore d'évaluation

- ZRIMADocument494 pagesZRIMAأبو الأمين المغربيPas encore d'évaluation

- Nitrogen Capping Using Liquid Nitrogen - Chemical Cleaning PDFDocument3 pagesNitrogen Capping Using Liquid Nitrogen - Chemical Cleaning PDFshriya_322Pas encore d'évaluation

- Instrument System Oct 2011Document12 pagesInstrument System Oct 2011Manish GusainPas encore d'évaluation

- How To Make and Use Magic Mirrors - Nigel R. CloughDocument60 pagesHow To Make and Use Magic Mirrors - Nigel R. Cloughsrk777100% (5)

- Performance Verification For Platinum Resistance ThermometersDocument4 pagesPerformance Verification For Platinum Resistance Thermometersfawmer61Pas encore d'évaluation

- 6CH02 01 Que 20160610Document24 pages6CH02 01 Que 20160610anon_845676495Pas encore d'évaluation

- Financial Data & Ratio 2014 - SamplingDocument356 pagesFinancial Data & Ratio 2014 - SamplingeriwirandanaPas encore d'évaluation

- Gas Cutting SafetyDocument2 pagesGas Cutting SafetyTonmay MajumderPas encore d'évaluation

- Linear Screen SizingDocument4 pagesLinear Screen SizingHARIPRASADPas encore d'évaluation