Académique Documents

Professionnel Documents

Culture Documents

Pigment

Transféré par

kingstonmanojDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pigment

Transféré par

kingstonmanojDroits d'auteur :

Formats disponibles

Pigment

Main article: Pigment Pigments are granular solids incorporated into the paint to contribute color, toughness, texture, give the paint some special properties or simply to reduce the cost of the paint. Alternatively, some paints contain dyes instead of or in combination with pigments. Pigments can be classified as either natural or synthetic types. Natural pigments include various clays, calcium carbonate, mica, silicas, andtalcs. Synthetics would include engineered molecules, calcined clays, blanc fixe, precipitated calcium carbonate, and synthetic pyrogenic silicas. Hiding pigments, in making paint opaque, also protect the substrate from the harmful effects of ultraviolet light. Hiding pigments includetitanium dioxide, phthalo blue, red iron oxide, and many others. Fillers are a special type of pigment that serve to thicken the film, support its structure and simply increase the volume of the paint. Fillers are usually made of cheap and inert materials, such as diatomaceous earth, talc, lime, barytes, clay, etc. Floor paints that will be subjected to abrasion may even contain fine quartz sand as a filler. Not all paints include fillers. On the other hand some paints contain very large proportions of pigment/filler and binder. Some pigments are toxic, such as the lead pigments that are used in lead paint. Paint manufacturers began replacing white lead pigments with the less toxic substitute, titanium white (titanium dioxide), even before lead was functionally banned in paint for residential use in 1978 by the U.S. Consumer Product Safety Commission. The titanium dioxide used in most paints today is often coated with silica/alumina/zirconium for various reasons such as better exterior durability, or better hiding performance (opacity) via better efficiency promoted by more optimal spacing within the paint film.

Solvent

The main purposes of the solvent are to adjust the curing properties and viscosity of the paint. It is volatile and does not become part of the paint film. It also controls flow and application properties, and affects the stability of the paint while in liquid state. Its main function is as the carrier for the non volatile components. In order to spread heavier oils (i.e. linseed) as in oil-based interior housepaint, a thinner oil is required. These volatile substances impart their properties temporarilyonce the solvent has evaporated or disintegrated, the remaining paint is fixed to the surface. This component is optional: some paints have no diluent. Water is the main diluent for water-borne paints, even the co-solvent types.

Solvent-borne, also called oil-based, paints can have various combinations of solvents as the diluent, including aliphatics, aromatics, alcohols,ketones and white spirit. These include organic solvents such as petroleum distillate, esters, glycol ethers, and the like. Sometimes volatile low-molecular weight synthetic resins also serve as diluents. Such solvents are used when water resistance, grease resistance, or similar properties are desired.

History

Cave paintings drawn with red or yellow ochre, hematite, manganese oxide, and charcoal may have been made by early Homo sapiens as long as 40,000 years ago. Ancient colored walls at Dendera, Egypt, which were exposed for years to the elements, still possess their brilliant color, as vivid as when they were painted about 2,000 years ago. The Egyptians mixed their colors with a gummy substance, and applied them separate from each other without any blending or mixture. They appeared to have used six colors: white, black, blue, red, yellow, and green. They first covered the area entirely with white then traced the design in black, leaving out the lights of the ground color. They used minium for red, and generally of a dark tinge. Pliny mentions some painted ceilings in his day in the town of Ardea, which had been done prior to the foundation of Rome. He expresses great surprise and admiration at their freshness, after the lapse of so many centuries. Paint was made with the yolk of eggs and therefore, the substance would harden and stick onto the surface it is applied to. Pigments were made from plants, sands, and different soil types.

Failure of a Paint

The main reasons of paint failure after application on surface are the applicator and improper treatment of surface. While there have been cases of paint also, but they are but rare. Application Defects can be attributed to: Dilution

This usually occurs when the dilution of the paint is not done as per manufacturers recommendation. There can be a case of over dilution and under dilution, as well as dilution with the incorrect diluent. Contamination

Foreign contaminants added without the manufacturers consent which results in various film defects.

Peeling/Blistering

Most commonly due to improper surface treatment before application and inherent moisture/dampness being present in the substrate. Chalking

Chalking is the progressive powdering of the paint film on the painted surface. The primary reason for the problem is polymer degradation of the paint matrix caused by attack by UV radiation in sunshine. Cracking

Cracking of paint film is due to the unequal expansion or contraction of paint coats. It usually happens when the coats of the paint are not allowed to cure/dry completely before the next coat is applied. Erosion

Erosion is very quick chalking. It occurs due to external agents like air,water etc. Blistering

Blistering is due to improper surface exposure of paint to strong sunshine.

Varnish is a transparent, hard, protective finish or film primarily used in wood finishing but also for other materials. Varnish is traditionally a combination of a drying oil, a resin, and a thinner orsolvent. Varnish finishes are usually glossy but may be designed to produce satin or semi-gloss sheens by the addition of "flatting" agents. Varnish has little or no colour, is transparent, and has no added pigment, as opposed to paints or wood stains, which contain pigment and generally range from opaque to translucent. Varnishes are also applied over wood stains as a final step to achieve a film for gloss and protection. Some products are marketed as a combined stain and varnish.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Comparitive of Waterproofing WorkDocument12 pagesComparitive of Waterproofing WorkReshik KannanPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- 3电气与信息系统L936L938ENGLISH PDFDocument62 pages3电气与信息系统L936L938ENGLISH PDFadelmomoura100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- PSA Nitrogen PlantsDocument4 pagesPSA Nitrogen PlantsIdo Aprilian TariganPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Nitrogen N2 - Data Class 1Document2 pagesNitrogen N2 - Data Class 1neyzaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

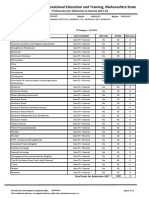

- DVET Amravati Govt ITIDocument32 pagesDVET Amravati Govt ITIVaibhav KalePas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- TechnicalExams Dec2017Document29 pagesTechnicalExams Dec2017ming_zhu10Pas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Mepoxe ANewDocument4 pagesMepoxe ANewHasbi Ashidiqi PPas encore d'évaluation

- Secadores KaeserDocument13 pagesSecadores KaeserDiego Laya PicadoPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- 2011 VND O&M ManualDocument12 pages2011 VND O&M Manualsequeira.cedric6742Pas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Materials For High Temperature High Pressure Applications andDocument28 pagesMaterials For High Temperature High Pressure Applications andDrVRKPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Samsung Fridge Manual PDFDocument0 pageSamsung Fridge Manual PDFKuldeep DidwaniaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Bezinal3000 2010Document2 pagesBezinal3000 2010tanto_deep_15Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- LGFP 2: SKF Food Compatible Bearing GreaseDocument2 pagesLGFP 2: SKF Food Compatible Bearing GreaseJurun_BidanshiPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Sample Medium Maintenance PlanDocument20 pagesSample Medium Maintenance PlanRajipah OsmanPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Process Engineering Toolkit SolutionsDocument71 pagesProcess Engineering Toolkit SolutionsTeymur RegenmaisterPas encore d'évaluation

- Samalkot Lab - (16-17 SSR) (Final)Document161 pagesSamalkot Lab - (16-17 SSR) (Final)Phani PitchikaPas encore d'évaluation

- Dokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bDocument5 pagesDokumen - Tips - Caterpillar d6 Dozer Manual d6b Crawler Tractor Ritchiewiki Caterpillar d6bjuane27Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Biomedical Waste Rule 2016 ReviewDocument5 pagesBiomedical Waste Rule 2016 ReviewRakesh VermaPas encore d'évaluation

- 100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesDocument3 pages100mm (4") BOREWELL Submersible Pumpsets: Genie SeriesPazhamalairajan KaliyaperumalPas encore d'évaluation

- InsulationDocument63 pagesInsulationSH1961Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Embuild BrochureDocument38 pagesEmbuild BrochureKawish TamourPas encore d'évaluation

- List of BIS StandardsDocument9 pagesList of BIS StandardsKumar100% (1)

- BOQ KosongDocument6 pagesBOQ Kosongkhairil mohdPas encore d'évaluation

- RI 4 Defect CausesDocument50 pagesRI 4 Defect CausesSathishkumar Srinivasan100% (1)

- Downhole Gas CompressionDocument40 pagesDownhole Gas CompressionYasir Mumtaz100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Yiheng Specifications 2020Document6 pagesYiheng Specifications 2020SAWERA TEXTILES PVT LTDPas encore d'évaluation

- Over Voltage Under Voltage RelayDocument1 pageOver Voltage Under Voltage RelayVirender RanaPas encore d'évaluation

- DPF CeramicDocument11 pagesDPF Ceramicelliott_wolfPas encore d'évaluation

- Drveni Zidovi PDFDocument35 pagesDrveni Zidovi PDFMartinJankovićPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)