Académique Documents

Professionnel Documents

Culture Documents

Learn The Basics of HRSG Inspection

Transféré par

ahmadarya0 évaluation0% ont trouvé ce document utile (0 vote)

802 vues25 pagesThe global economic downturn will impose new challenges on plant operations. One area of possible cost-cutting at some plants is in heat-recovery steam generator inspection. A plant's resident "expert" on HRSGs is likely to attend the academy a second time.

Description originale:

Titre original

Learn the Basics of HRSG Inspection

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe global economic downturn will impose new challenges on plant operations. One area of possible cost-cutting at some plants is in heat-recovery steam generator inspection. A plant's resident "expert" on HRSGs is likely to attend the academy a second time.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

802 vues25 pagesLearn The Basics of HRSG Inspection

Transféré par

ahmadaryaThe global economic downturn will impose new challenges on plant operations. One area of possible cost-cutting at some plants is in heat-recovery steam generator inspection. A plant's resident "expert" on HRSGs is likely to attend the academy a second time.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 25

2 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

T

he global economic downturn

will impose new challenges on

plant operations. Its difficult to

believe that you will be asked

to do more with a smaller budget,

but you will. However, approaching

these new challenges with a positive

mindset can yield significant ben-

efits. One might be that your junior

staff is forced to learn more about

power-generation processes, equip-

ment, and systems, thereby increas-

ing the level of expertise onsite.

An area of possible cost-cutting

at some gas-turbine-based cogen-

eration and combined-cycle plants

is in heat-recovery steam generator

(HRSG) inspection. Developing on-

staff capability to conduct base-level

HRSG inspections saves both money

and the need to schedule yet another

service organization into an already

complex outage matrix.

Most plants have considerable gas-

and steam-turbine expertise but many

do not have on-staff experts for HRSGs

and generators. Developing HRSG

know-how begins with understanding

the types of degradation/damage that

can occur and where to look

for each.

To compile the check-

list that follows, the editors

attended the HRSG Acad-

emy conducted by HRST

Inc, Eden Prairie, Minn.

The engineering services

firm focuses on inspection,

training, O&M, and redesign

projects for this special class

of steam generators. It con-

ducts two academies annu-

ally in North America and

periodically in international

locations. Each hosts up to

50 to 60 students, the max-

imum practical class size to

assure constructive interac-

tion among lecturers and

attendees while allowing all

an opportunity to have their

questions answered.

The HRSG Academy may

be the best program in the industry

for teaching plant personnel the fun-

damentals of heat-recovery steam

generators. A graduate who later

becomes his or her plants resident

expert on HRSGs is likely to attend

the Academy a second timeto dig

into specifics. Think of Shakespeare

here: You cant possibly understand

and absorb everything in one pass, or

even two.

The segment of the academy pro-

gram dealing with HRSG inspec-

tion was taught by Lester Stanley,

Scott Wambeke, and Amy Sieben,

all licensed professional engineers

with a wealth of experience in HRSG

design, inspection, and trouble-

shooting. Their course covered both

online and offline inspection. The

first encompassed data review tasks

conducted in and around the control

room and field tasks requiring a unit

walk-down. Offline inspection was

divided into gas-side, exterior, and

drums. Also included was a primer

on nondestructive examination

(NDE) techniques and on sampling of

deposits and pressure parts.

Online

inspection

Stanley opened the online segment of

the program by stating its goals:

n Identify poor operating practices.

n Identify areas requiring attention

when plant operation permits an

offline inspection and/or during

the next maintenance outage.

Data review tasks

The best place to begin your inspec-

tion, the three instructors agreed, is

in the control center where you have

access to personnel familiar with the

plants operational idiosyncrasies as

well as to historical data. This inves-

tigative work generally is done while

the unit is operating to be sure it does

not impact outage duration. HRST

uses a basic 10-point checklist for

the data-review task, but items may

be added and/or deleted depending

on plant design and other consider-

ations.

1. Feedwater control. Three

of the many questions you

should ask operations per-

sonnel are these:

n Do you see large fluc-

tuations in feedwater flow

during steady-state opera-

tion?

n Does feedwater flow start

and stop frequently during

startup?

n During overnight shut-

downs, is there frequent

topping-off of the drum to

maintain level?

A yes answer to one or

more of the questions means

theres risk of thermal-shock

damageespecially in the

coldest tube panel. These

actions cause thermal-stress

events to economizers and

feedwater heaters within

the HRSG. The number and

Learn the basics of HRSG inspection

Learned at HRST Incs

Next session: Jan 27-29, 2009

Marco Polo Beach Resort, Miami

Details at www.hrstinc.com

www.shawgrp.com

ENGINEERING DESIGN PROCUREMENT CONSTRUCTION COAL GAS

GEOTHERMAL AIR QUALITY CONTROL POWER GENERATION SERVICES

SHAW POWER GROUP, FOSSIL DIVISION

At Shaw, we build more than state-of-the-art power plants. We also build win-win

working relationships with our clients that focus on one thing: successful project

completion. As the industry turns to natural gas for clean, reliable power, you

can turn to Shaw for on-target project execution. We deliver what you expect.

You can count on it.

Count On Powerful Relationships

84M022008D

PW_Combined Cycle_Q3Ad_rev1-2.indd 1 11/14/2008 2:39:31 PM

4 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

duration of events influences how

quickly tube leaks and cracking will

occur.

2. Steam drums. First thing to

investigate is the consistency among

drum-level transmitters, level gages,

and probe indicators.

If all are not in agreement, con-

sider checking the calibration meth-

od and the pressure and

temperature compensation

settings for the level trans-

mitter.

Don t overlook asking

if the agreement among

level indicators differs at

high and low steam loads

and/or high and low drum

levels. Stanley said that

HRST often inspects high-

pressure (HP) drums with

water-level marks that are

several inches too high, yet

the operators say they are controlling

to the OEMs guidelines. This means

there is disagreement between the

indicated and actual drum levels.

Concern here is that if the opera-

tors experience a high-drum-level

event, they may think theyre operat-

ing below the high-high level (HHL)

but are actually above it and drum

water may be carrying-over into the

HP superheater.

Wambeke mentioned, You now see

that the value of a thorough annual

inspection goes well beyond identi-

fying wear and tear that requires

repair. It enables the operations

team to see whats really going on in

the HRSG and suggests fine-tuning

of controls and procedures to avoid

incidents that can damage equip-

ment unnecessarily.

Stanley continued, Ask if the

rates of pressure increase and/or

decrease during startup and shut-

down exceed OEM guidelines. If

yes, you should be concerned about

the possibility of fatigue damage at

manways and thick nozzles and care-

fully check those locations when the

unit is out of service.

HRST engineers are seeing more

and more HRSGs with crack indica-

tions on downcomer nozzle welds,

supporting what many in the indus-

try have been saying for years: HP-

drum nozzles are high on the list

of components most susceptible to

cycling stresses.

Sieben added that spin cooling

is hard on the HRSG too. Most

operations personnel dont seem to

approach shutdowns as carefully as

they do startups, she said, and a

fast cool-down can be just as damag-

ing as a fast start.

3. Desuperheaters get a significant

amount of podium time in virtually

every HRST presentation on boiler

health. Poor design, leaking valves,

ineffective spray nozzles, a lack of

instrumentation, and other factors

can wreak havoc at cogeneration

and combined-cycle plants, putting

personnel safety at risk and causing

equipment damage that should never

occur.

One of the first things to inves-

tigate is spray-valve behavior. Is

spray-valve position near constant

at steady load or does it fluctuate

sometimes closing entirely? If your

spray valve is continually hunting

that is, opening and closing dozens of

times each hourthe hot/cold cycles

eventually will stress desuperheater

nozzles to failure and possibly create

other damage as well. Control-logic

adjustments generally can rectify

this condition.

If your desuperheating stations

are properly designed and equipped

with thermocouples (TCs) upstream

and downstream, verify that both

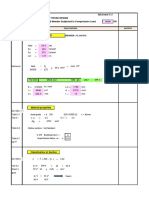

are reporting about the same steam

temperature when the control sys-

tem indicates that the spray valve is

closed (Fig 1). If this is not the case

and the downstream TC is reading

lower than the upstream one, water

probably is leaking by the closed

valve.

Give this immediate attention.

Concern is that during startups and

shutdowns, water can dribble into the

steam piping, collect along the bot-

tom of the pipe, migrate downstream

to superheater and/or reheater upper

headers, and then run down

a few tubes. Cooling effect of

the water causes those tubes

to contract. Resulting stress

can cause tube bowing and

tube-to-header weld cracks.

Also check plant data to

identify times when spraying

to less than the saturation

temperature of steam in the

pipe plus 30 deg F. Do a thor-

ough review: startup, steady-

state full load with and with-

out duct firing, steady-state

low load (less than about 120 MW

for an F-class gas turbine), and dur-

ing transients. Desuperheating to

near-saturation temperature creates

the potential for damage like that

described above for a leaking spray-

water valve.

If your data review reflects the

possibility of desuperheater prob-

lems and you are unfamiliar with the

attemperation station, walk it down

while the plant is operating to see if

design/installation deficiencies exist.

Fig 2 shows a poor desuperheater

arrangement. When Stanley flashed

this picture up on the screen, he noted

the following:

n The thermocouple is so close to the

desuperheater it gets quenched by

water droplets, thereby provid-

ing erroneous data. Specifically,

operators dont know how close to

Desuperheater

nozzle assembly

Spray water inlet

Control

valve

Block

valve

High-temperature steam Desuperheated steam

1

TC TC

Upstream elbows

Thermocouple

No drain or drip leg at low point

Desuperheater

2

6 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

saturation temperature that the

plant is operating. An improved

pipe location for the TC is needed.

n The desuperheater is too close

to both the upstream and down-

stream pipe elbows. Problems cre-

ated: Steam flow to the attempera-

tor is not uniform and spray water

is not fully evaporated before

impinging on the downstream

elbow. Latter causes fatigue dam-

age to the elbow.

n There is no drain at the low point,

allowing water to pool and to cre-

ate water events during startup.

4. Stack temperature. Recall that

high stack temperature is indicative

of inefficient operation. Compare the

actual readings at high and low loads

and compare to known benchmarks.

A large difference between the actual

and known signals a problem. Check

common causessuch as debris

accumulation on finned-tube surfac-

esand take corrective action.

5. Water temperature at economizer

outlet. Compare the water tempera-

ture at the economizer outlet to the

saturation temperature of water in

the steam drum at the exact same

time. If the two are within a couple of

degrees, Wambeke said, then water

exiting the economizer contains

steam. Avoid this condition with

startups that are as short as possible

and maintain economizer feedwater

flow. Venting appropriatedly during

filling and startup also is important.

Keep in mind that air pockets

block water flow and once a circuit

is blocked it will steam up, making

it even more difficult to clear dur-

ing startup. If the temperature of the

water at the economizer outlet makes

several sudden jumps upward during

startup from a lower-than-expected

value, this generally means a vapor

pockets are being cleared and normal

operation is being restored. However,

such clearing events, similar to water

hammer, stress the economizer

unnecessarily.

Stanley also suggested that you

compare an operating point to a

known benchmark. A large difference

is cause for concern. Check for steam-

ing, gas-side fouling, vapor locking

from trapped air, gas bypass, etc, and

take corrective action.

6. Water temperature at economizer

inlet. Review data to identify any inci-

dences of rapid temperature change

(30 deg F/min, plus or minus) when

the unit is in operation or offline.

Such rapid change is viewed as a

thermal shock to the economizer.

Also verify that the inlet tempera-

ture doesnt drop below 120F. Low

temperature is the cause of dewpoint

condensation and tube wastage.

Dont be surprised if the data you

seek are not available. Sometimes

permanent TCs are located in places

that dont indicate what actually is

happening in the tube panel and test

TCs must be installed. Fig 3 shows

what an inspection team learned

about temperatures during startup

when test TCs were installed at stra-

tegic locations within an LP econo-

mizer.

7. Economizer recirculation pump.

Verify during your inspection that the

recirculation pump is operating early

in startup and before new feedwater

is added to the LP economizer. This

allows the recirc flow to buffer the

temperature difference between the

hot tube panels and the relatively cold

water being injected into the circuit.

When the pump starts, listen for

audible signs of cavitation. HRST

engineers have been in several plants

where poor design of the recirc sys-

tem has caused recurring cavitation

and pump damagein some cases so

severe that the plants no longer use

their recirc pumps. However, this is

not a solution because the economiz-

er can be damaged by thermal shock

and/or dewpoint corrosion.

8. Superheater and reheater drains.

Proper drain operation is critical for

protecting superheaters and reheat-

ers from large thermal shocks caused

by the failure to remove condensate

prior to startup. Stanley stressed

that your inspection should, at a min-

imum, confirm the following:

n Low-point drains are open during

startup to purge water/conden-

sate prior to admitting steam to

tube panels (harps). Its relatively

easy to check the timing of motor-

operated drain valves; for manu-

ally operated valves, verify that

proper procedures are in place and

followed.

n Drains are open sufficiently early

in the startup process to ensure

that all condensate actually will be

drained prior to steam admission.

Operators at some plants where

drains open to a funnel verify drains

are clear of water by sound: A drain

discharging steam makes more

noise. A more scientific approach

is to install TCs on the drain pipe

and monitor for a reading above the

saturation temperature.

n Drains are open during a trip,

restart, and purge.

n Panels do indeed drain completely

when drains are open. The ele-

vated drain tank in Fig 4 requires

Thermal shock caused

by topping-off drum prior

to warm start

Tube flow instability

caused by low load

and original

tube-panel design

0 30 60 90 120 150 180

Time, min

300

250

200

T

e

m

p

e

r

a

t

u

r

e

,

F

3

4

IT GENERATES ENOUGH POWER FOR A CITY

AND ENOUGH PROBLEMS FOR A CRISIS.

I T S B E T T E R T O K N O W

Its no secretalong with power, your turbines generate serious problems. Fortunately, our engineers have a

serious solution. Its called VitalPoint

SM

the rst uid assessment program designed exclusively for power generation

companies. With VitalPoint, you get the most advanced condition monitoring tools in the industry. If theres a problem

that threatens your equipment or an opportunity to extend your oils lifespan, our diagnostics will nd it. To learn

more, simply call 800-655-4473 and ask for a VitalPoint specialist. VitalPointcleaner energy, from the inside out.

LOS ANGELES, CA | CHI CAGO, I L | LOUI SVI LLE, KY | ATLANTA, GA | HOUSTON, TX | MONTERREY, MEXI CO | TOKYO, JAPAN

ADVANCED FLUID ASSESSMENT

SM

8 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

sufficient pressure in the drain

system to push condensate up into

the vessel. Drain tanks located in

a pit are better because they allow

gravity draining.

Also check to see that HP, IP,

and LP drains are not combined in

a common collection pipe upstream

of the blowdown tank. Reason: Flow

through the HP drains could force

water back into the IP or LP system

if all the drains are open at the same

time. Guidelines for proper drain

system design can be found in the

HRSG Users Handbook, published

by the HRSG Users Group (details at

www.hrsgusers.org).

9. Selective catalytic reduction sys-

tem. Compare historical ammonia

consumption and outlet NO

x

read-

ings. Rapid changes to NO

x

emis-

sions or ammonia flow may iden-

tify catalyst plugging or poisoning or

ammonia supply issues. Catalyst can

be plugged by insulation released by

way of transition-duct failure; ammo-

nia injection nozzles can be plugged

by contaminants in the reagent or by

rust in lances; in oil-fired turbines,

unburned fuel sprayed on catalyst

during failed start attempts can

ignite later and sinter the catalyst.

10. Gas-side backpressure. Does

overall HRSG backpressure compare

with OEM predictions? If not, what

sections have more backpressure

than predicted? If you can determine

where backpressure is high, then

the boiler inspection can investigate

more carefully during the next out-

age. Gas-side cleaning of finned-tube

sections is one solution. More proac-

tive inlet-duct liner and insulation

maintenance may be another if foul-

ing by insulation fibers is to blame.

Online field tasks

Some key inspection tasks only

can be done while the HRSG is

operatingidentification of casing

hotspots, for example. Here are five

things Wambeke suggested that you

should be sure to accomplish during

your online walk-down:

1. Check the supplementary firing

system. Look through all view ports

to determine flame health and duct-

burner condition. Bullet points below

provide some guidance for this activ-

ity based on HRSTs experience.

n A flame length in excess of 12 ft

for an F-class HRSG is too long.

Reason: Long flames, typically

caused by low exhaust flow and/or

poor distribution of exhaust flow

across the burner, can lick tubes

in the first panel and cause local-

ized overheating.

n A bushy flame is desirablethat

is, unless it is angled upward

or downward, which indicates a

problem with exhaust flow to that

portion of the burner.

n A bright yellow flame is good; dull

orange indicates too little exhaust

flow.

n Monitor CEMS data as supple-

mental firing is initiated and shut

off. Noticeable step changes in

NO

x

and CO levels may indicate a

burner problem.

n Check the integrity of burner ele-

ments and baffles. If breakage

occurs, there is the possibility of

damage to firing-duct walls and

floors and to downstream tube

bundles.

2. Watch for deflection of superheater

and reheater floor pipe penetrations

during startup and shutdown. Tempera-

ture differentials across superheater

and reheater tube bundles can cause

the panels to bow, exacerbating

drain-line lateral movement. Drains

that collide with the floor liner or

casing often suffer stress-induced

cracking.

Stainless-steel bellows have dif-

ficulty moving laterally, while fabric

seals in high-temperature locations

typically stiffen-up. The extra motion

created by panel bowing often causes

bellows to crack and tear. On fabric

seals, bands pull lose and the fabric

kinks. Latter creates small holes

and leaks that propagate into fabric

blowouts.

Fig 5 shows a superheater drain

seal that has ripped loose from the

floor casing because of excess lateral

movement combined with the expect-

ed axial motion.

Stanley urged all attendees to also

look for stick and slip of pipes dur-

ing startupa sign of hard interfer-

ence with the floor. He said what hap-

pens is that drain lines dont move

much as the superheater warms up

and then suddenlybangthe pipe

drops an inch or so. A little while

later theres another bang and anoth-

er drop. Such hard contact/expansion

interference obviously places unnec-

essary stresses on drain lines.

3. Stop, look, listenfor vibration.

Listen carefully during your online

walk-down. When standing alongside

the transition duct connecting the GT

outlet to the HRSG, do you hear any

rattling or flapping sounds? They can

emanate from loose and vibrating (a)

internal liner sheets on walls, floor,

or ceiling, (b) flow distribution plates,

and/or (c) superheater baffles.

Recall that the perforated flow dis-

tribution plates even out flow across

the transition piece just upstream of

the duct burner; superheater baffles

prevent gas bypass around the tube

bundle.

Do you hear and/or see the casing

pulsing or vibrating? Pay particu-

lar attention to the inlet duct to the

HRSG, SCR cavity, and stack breech-

ing. Vibration can fatigue internal

liner support studs; if they fail, the

liner and insulation may be lost.

Sometimes a casing vibrates sim-

ply because it doesnt have a suf-

ficient number of stiffeners. The

inlet-duct sidewall panel in Fig 6 has

10 horizontal stiffeners. But looking

closely, note that the second, fourth,

seventh, and ninth stiffeners (moving

upward from the ground) were added

after startup to address repeat liner

failures attributed to casing vibra-

tion. The new stiffeners are larger

and painted a different color than the

originals.

Vibration of walkways and plat-

forms may be more obvious than cas-

ing vibration. If noted, look closely to

determine if the source of the vibra-

tion is the HRSG.

Stanley said to also check large-

bore piping for steady motion. If pip-

ing entering or exiting the HRSG is

constantly rocking, the source of the

disturbance could be the tube panels

vibrating in the breeze of the GT

exhaust stream. Repetitive motion

can cause fatigue damage. When the

unit is offline, push hard on tube pan-

els to see if they swing or sway. If so,

5

6

P0WLP SLPvlL

wwwa|stomcom

s a ower qenerator you exect services that will otimise

your lants short and lonqterm elliciency rawinq on a century

ol indeth exerience lstom ollers a comlete ranqe ol services

suort and solutions lor all lleet tyes worldwide lstom exerts

imrove outut and extend lant lilecycleeven when you are

oeratinq under environmental and commercial constraints

We have the serv|ces to power yoor p|ant perIormance

Fff|c|ent

Power|ng

Performance

10 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

install better tube-panel restraints

and guides.

In some cases, sophisticated analy-

sis is needed to determine the root

cause of vibration. A noise signa-

ture often can help in this regard.

Occasionally, vortex shedding in

the tube bundles can create acous-

tic resonance problems. These may

be noticed near the HRSG and/or in

nearby buildings. Comparing calcu-

lated and measured shedding fre-

quencies can give clues.

4. Identify hotspots. Begin with

a visual survey of the casing for

burned or discolored paintfor

example, the pink area in Fig 7 at

the lower portion of the inlet-duct

sidewall. Then use an infrared gun

to measure metal temperature; next,

map temperatures and prioritize

corrective action.

Stanley said that casing tem-

peratures above 350F are especially

problematic if several square feet of

casing are affected. Such high tem-

peratures combined with the affected

area cause restrained expansion

which, in turn, results in cracking

of casing steelsometimes severe.

Most paint will discolor above 350F

and cracking is a possibility, espe-

cially in areas where the casing is

stiffsuch as floors and roofs.

Dont forget to point the infrared

gun at pipe penetrations, expansion

joints, casing doors, field joints, and

duct corners. The stainless-steel bel-

lows seal under the HP superheater

in Fig 8 reveals a hot spot where the

seal attaches to the floor casing.

Probable cause is a lack of insulation

inside the bellows. High-temperature

areas of the economizer drain-pipe

penetration seals in Fig 9a pinpoint

leakage through torn fabric. R is the

reference temperature of 142F; Point

2 is at 519F, Point 3 at 390F, and

Point 4 at 589F. Wear and tear on the

seals is evident in Fig 9b.

5. Check pipe supports. First step

is a visual survey to confirm that all

supports are connected and not at

maximum travel in the hot condi-

tion. Record locations of all supports

for comparison purposes during later

inspections.

Also note damage to hangers, sup-

ports, insulation, and/or lagging that

may indicate transient phenomena

such as water hammer. Fig 10 shows

a guide for a reheater pipe that was

bent by a water-hammer event.

Spring hanger indicator in Fig 11

should be surveyed in both the hot

and cold positions. The red (hot)

and white (cold) diamonds indicate

as-designed conditions.

Offline

inspection

The HRST instructors divided the

offline inspection module into four

parts: gas side, exterior, drums, and

so-called extended scope focus-

ing on nondestructive examination

(NDE). Stanley handled the first two;

Sieben and Wambeke handled the

remaining two.

Stanley began by stating four pri-

mary goals of offline inspection:

n Document equipment condition.

n Identify items requiring immedi-

ate maintenance.

n Note emerging problems, thereby

allowing time for analysis.

n Begin planning and budgeting

maintenance activities for future

outages.

Gas side

Key to an effective gas-side inspec-

tion, the HRST instructors told the

group, are the following:

n Dedicated, meticulous inspectors.

They recommended a mixed team

consisting mainly of in-house per-

sonnel and some outside experts

with broad industry perspec-

tive. Also stressed was that any

inspection worthwhile undertak-

ing should be done properly; good

7

8

9a 9b

10

11

ALLIED POWER GROUP PUTS SALES AND SERVICE IN SYNCHRONICITY.

alliedpg.com U N I T E D F O R P E R F O R M A N C E .

Product names, logos, brands, and other trademarks mentioned herein are the property of their respective trademark holders. These trademark holders are not

affiliated with Allied Power Group, nor do they sponsor or endorse any of the products, services or methods supplied or used by Allied Power Group.

ALLIED POWER GROUP IS YOUR ONE TRUSTED SOURCE FOR FAST REPAIRS AND HIGH-QUALITY REPLACEMENT PARTS. WE HAVE ONE OF

THE LARGEST GE AND WESTINGHOUSE INVENTORIES IN THE WORLD AND CAN PROVIDE FAST, HIGH QUALITY REPAIRS FOR IGT COMPONENTS SUCH

AS HOT GAS PATH AND COMBUSTION COMPONENTS FOR MAJOR OEMS. WITH FLEXIBLE OPTIONS LIKE EXCHANGE AND LOANER PROGRAMS,

CONSIGNMENT, SALES AND LEASE, INVENTORY MANAGEMENT AND POOLING, ALLIED POWER GROUP IS YOUR ONE-STOP SHOP. BEST OF ALL, WE

PROVIDE AN UNMATCHED LEVEL OF SERVICE WHEREVER AND WHENEVER YOU NEED IT TO KEEP YOUR BUSINESS RUNNING.

15005 Mi nt z L a ne, Hous t on, T X 77014 1. 888. 830. 3535

APG 12300 CCJ_8x10.875_4C 3/18/08 11:08 AM Page 1

12 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

inspections, Stanley continued,

take days, not hours.

n A detailed record of observations

and other facts. Take plenty of pho-

tos and measurements; describe

observations in detail using a digi-

tal recorder and transcribing/edit-

ing your voice notes. Critical mea-

surements might include material

thickness in areas experiencing

FAC (flow accelerated corrosion)

attack, length of any cracks iden-

tified, distances across any cracks

found, etc.

n Organize facts logically. Link

every fact to a specific location

in the HRSG. Editors note: Per-

haps this goal can be facilitated

through use of software custom-

ized for your specific boilers. To

learn more, access www.combined-

cyclejournal.com/archives.html,

click 3Q/2007, click Knowledge

retention: New software tools help

improve plant reliability, reduce

maintenance cost on issue cover.

Your ultimate goal should be to

provide a comprehensive follow-

up checklist with detailed notes

so someone else can conduct next

years inspection having the same

knowledge you possessthat is, to

pick up where you left off without

missing a beat.

n Recommend a follow-up NDE pro-

gram for areas where problems are

suspected. This might include one

or more of the following: borescope

examination, ultrasonic (UT) sur-

veys, dye-penetrant (PT) testing,

magnetic-particle (MT) examina-

tion, hardness testing (particu-

larly where P91/T91 materials are

used), etc.

For inspection purposes, Stanley seg-

ments the HRSG into three areas:

n Access lanesincluding inlet

duct, firing duct, SCR, between

tube bundles, and stack.

n Crawl spaces under and above

tube headers.

n Exteriorincluding roof casing,

floor casing, walls.

Your inspection should go beyond

what HRST would do under its

standard HRSG contract. Engage

other experts to examine your steam

valves, safety valves, silencers,

instrumentation, piping to/from the

HRSG, etc.

Inlet-duct checklist. Inspect the

liner system for loose plates, spinning

washers, exposed insulation, and

failed studs. Fig 12 is typical of what

you might find. Here studs failed and

washers were liberated leaving liner

plates with minimal support. Once

a liner plate moves and a gap is cre-

ated between it and adjacent plates,

insulation can be sucked into the flow

stream. This creates a hot spot in the

transition duct skin and allows liber-

ated insulation to blind a portion of

the SCR catalyst.

Be aware that problems often are

experienced with flow distribution

plates. Also, check harps for corro-

sion, warped tubes, and vibration

wear from tubes contactingthat is,

banging into or rubbing against

each other when the unit is in ser-

vice. Baffles and tube ties should

be inspected for vibration damage,

wear, expansion interferences, and

weld cracks.

Figs 13, 14 show failed tube-fin tab

welds that caused rattling. Some

failed tabs rub directly on tubes.

Although no gouges were identified

in this case, if condition is left uncor-

rected, tube wear will continue (tube-

tie components are harder than the

tube material). Such wear often is

worst at lower elevations, which is

convenient because they are easier to

access for inspection. Note that the

inlet-duct superheater panel in Fig 15

is missing center baffles.

Firing-duct checklist has five focal

points for your inspection:

n Liner system. Inspect the same

way you did for the inlet duct.

n Duct burner. Look for sag in ele-

ments or baffles, nozzle plugging,

and coke buildup; verify that

burner wing condition is satis-

factory.

12

Studs broken;

washers missing

13 14 15

16 17

Visit us at POWER-GEN International, Booth #2112.

Of f i ces i n: Nor t h Amer i ca Lat i n Amer i ca Eur ope Asi a

MONI TORI NG & DI AGNOSTI C CENTER

REMOTE

EtaPRO

MONI TORI NG SERVI CE

REMOTE

EtaPRO

Bleed: 8.25 x 11.125, Trim: 8 x 10.875

Combined Cycle Journal

P E O P L E P R O C E S S E S T E C H N O L O G Y

The system allows us to respond quickly to changes in component

performance, before they impact plant heat rate.

Chung Liu, Massachusetts Municipal Wholesale Electric Company

www.etaproefficiency.com

800.803.6737

EtaPRO

Performance Monitoring and Optimization System saves money while reducing

emissions. With 600+ generating units worldwide, General Physics Corporations real-time

monitoring helps plants achieve a

and typically provides a 100% ROI in less than 12 months. From installation to operation,

our power plant experts partner with you and respond quickly whenever you need them.

Put our experience to work for you.

Energy

1% or better heat rate improvement

GPA-11 EtaPRO_ad_CyclJ_mech.indd 1 10/17/08 2:01:07 PM

Visit us at HRSG, Booth 716

EtaPro.indd 1 12/9/08 3:16:11 PM

14 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

n Tubes and fins. Inspect the same

way you did for the inlet duct. But

also check for evidence of flame

impingement or local hot spots as

well as for tubes bowed because of

desuperheater issues.

n Baffles and supports. Look for

loose or missing baffles, plus over-

heated tube ties and baffles.

n Firing-duct TCs. Be aware that

most thermocouples are too short

to read representative tempera-

tures. Also, that TCs typically

have no radiation shield and they

are influenced by cool tubes and

burner shine.

Figs 16-21 illustrate what to look

for when inspecting the firing duct.

Bowed reheater tubes in Fig 16 are

downstream of the desuperheater,

which probably allowed wet steam

to enter the tubes. A Sky Climber

or scaffolding is needed to perform a

good duct-burner inspection (Fig 17)

and repair any cracking identified

(Fig 18).

Burner coking sometimes is found

when alternative fuels are burned.

Fig 19 shows coking on a duct burner

firing refinery gas. Olefins reportedly

were the cause in this case. Coking

can occur when burning natural gas

if there is poor mixing of air and fuel

at the burner.

An overheated liner protecting the

sidewall of a firing duct is shown in

Fig 20. Hot-spot indications on tubes

downstream of duct burners are

illustrated in Fig 21.

Tube-bundle access-lane checklist.

This list begins, like the inlet- and

firing-duct checklists above, with

the liner system. Same principles

apply. Next, tubes and fins should be

inspected for corrosion, warping, and

fouling. Warping of superheater and

reheater tubes caused by poor control

of the desuperheating process is rela-

tively common (refer back to Fig 16).

Warping is also indentified with LP

and IP economizers that share com-

mon headers with HP economizers

(for more detail, access www.com-

binedcyclejournal.com/archiveshtml,

click 1Q/2008, click Module, header

replacement. . . . on issue cover.

Look carefully for tube-to-header

weld cracking (Fig 22). It can accom-

pany tube bowing, but often is found

as well on tubes that have not bowed.

Tube bowing and cracking usually

are caused by the same problem: Wet

steam entering the tube field.

Tubes downstream of the SCR are

susceptible to fouling by ammonia

salts and by rust that flakes off car-

bon-steel fin and tube surfaces (Fig

23). The amount of sulfur in the fuel,

and in the inlet air, impacts the rate

of fouling; so does the amount of time

the unit is offline, particularly in a

humid environment.

Inspect bundles for wear caused

by tube vibration. This will be found

most often where tube-tie welds are

broken and tubes are free to rattle

around (refer back to Fig 14).

Fig 24 shows where baffles are

located to avoid bypass of gas around

heat-transfer surfaces. If metal dete-

rioration is identified, make a note

for maintenance follow-up. Also iden-

18a 18b

19

20

21

22

23

16 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

tify and correct areas where expan-

sion/contraction adversely impact

baffle function (Fig 25) and where baf-

fles have slipped down tubes (often

because fins have broken off) and cre-

ated openings for gas bypass.

As you move back through the unit,

Stanley said, look over the upstream

face of the SCR catalyst for fouling

typically caused by rust and/or insu-

lation fiber entrained in the hot gas

(Fig 26). Gas bypass around the cata-

lyst limits its effectiveness and could

possibly put the plant out of com-

pliance on NO

x

. Be sure to look for

poorly installed baffling, open space

around the perimeter of the catalyst

bed, and gaps between baffling and

catalyst frames.

Finally, look for openings between

catalyst blocks and between the

bl ocks and f rames. Insul ati on

between blocks has been known to

compress over time, allowing catalyst

bricks to settle. This can create gaps

between blocks, especially in the top

row of each module (Fig 27). Insula-

tion then is free to blow downstream

and plug LP heat-transfer surfaces.

Crawl-space checklist. Inspecting

the upper and lower crawl spaces in

an F-class HRSG may not be much

fun, but it certainly is where an

inspector proves his or her value.

Virtually everyone on the plant staff

can hear casing vibration or see dis-

colored paint at a hotspot, but only a

well-trained and physically fit inspec-

tor can slither around a cramped,

dirty crawl space and identify exist-

ing and possible future problems.

Inspectors examine floor debris for

evidence of problems, the liner, liner

fit-up around piping and hanger pen-

etrations, baffles, bent piping, header

corrosion, header/tube joint condition

where visible, dripping water or cor-

rosion/rust stains from tube leaks,

etc. The photos in Figs 28 to 35 show

some of the things you can expect to

encounter.

n A bent (and binding) liner donut

around a pipe penetration in the

floor liner is shown in Fig 28. A

donut in such poor condition allows

insulation to migrate upward,

thereby creating a hotspot in the

floor casing and limiting penetra-

tion seal life. It also allows debris

to enter the seal underneath,

accelerating damage to it and

increasing corrosion risk.

n Fig 29 is a reheater pipe penetra-

tion with no liner donut, a condi-

tion that hastens degradation of

insulation. A hotspot is created

around the stainless steel bellows

below because there is no thermal

barrier between the 1050F reheat

pipe and the bellows.

n Insulation slips down and out of

stainless-steel bellows located

Exhaust flow is into page Sidewall baffles

Center (laning)

baffles

Tubes

Header (bulkhead) baffles

Lower header

Upper header

24

25

26 27 28

29 30b 30a

COMBINED CYCLE JOURNAL, Third Quarter 2008 17

C

M

Y

CM

MY

CY

CMY

K

SmartFlow3000AdFinal.pdf 12/17/2008 1:34:17 PM

18 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

above roof casing because no liner

donut is present (Fig 30a). Roof-top

photo reveals casing rust and blue

tint to bellows indicative of opera-

tional hotspots (Fig 30b).

n Drain pipes under HP superheat-

ers and reheaters are notorious

for developing stress cracks

especially at the drain pipe-to-

jumper weld (Fig 31a). Inspectors

finger points to what he believes

is a crack (Fig 31b), later confirmed

with dye-penetrant test.

n Debris accumulation on roof allows

rainwater to pool (Fig 32a), leading

to corrosion problems inside the

HRSG. The result of long periods

offline and water leakage is shown

in (Fig 32b).

n Poor condition of drain line serv-

ing an LP economizer was found

during an inspection of the lower

crawl space below this HRSG

(Fig 33a). HRST engineers recom-

mended removing the stainless-

steel bellows expansion joint

around this drain, which had lost

about 25% of its wall thickness in

five years of service (Fig 33B).

n Gas bypass: Rust is swept away in

region of high gas velocity down-

stream of the small square dark

opening in Fig 34.

n Oversize gaps, which proper baffling

should prevent, may avoid interfer-

ence problems but they adversely

impact performance (Fig 35).

Exterior inspection

By this point in the session, attendees

were catching on to what they should

be looking for when inspecting an

HRSG. The checklist presented for

this module had a familiar ring:

n Casing hotspots and cracking.

n Piping penetration seals.

n Access-door condition.

n Pipe hangers.

n Expansion joints at the round-to-

square transition and between the

HRSG and stack.

n HRSG foundations.

Of course, this isnt all you should

be inspecting on the exterior of your

HRSG. Time limitations in the class-

room and space limitations in the

magazine militate against covering

everything. When developing an

inspection program customized to

your plant, dont forget such things

as burner hardware, valves, safety

valves and silencers, drum instru-

mentation, ammonia vaporizer,

ammonia injection grid and associ-

ated piping and nozzles, etc.

Once again, photos taken during

inspections conducted by HRST engi-

neers give you a good sense of whats

important:

n Fig 36 shows hotspot on access door

and adjacent casing caused by

leaking door seal and/or problems

with the internal insulation pil-

low.

n Rust that accumulates in a fabric

seal impedes its ability to flex and

eventually the material splits (Fig

37). Liner donuts that are main-

tained in good condition help pre-

vent rust from dropping into the

seal.

n Cracked stainless-steel bellows

in Fig 38 is a casualty of excessive

drain movement as discussed ear-

31a 31b

32a 32b

33a 33b

34

Opening

35

Gap

36

37

GE Energy

Worldwide service

is in your reach.

GE Energys aeroderivative services

are located where you need them

anywhere in the world. Our service

centers are positionedaroundtheglobe,

ready toprovide afull array of services

for industrial andmarine customers.

We also have an established network

of international field service teams who

can deliver the technological expertise

you expect fromGE right to your site.

No matter where you are, the aero

energy service teamis there to help you

reach your goal.

Visit us at ge.com/energy

and find out more.

Service capabilities include contractual service agreements, engine and module exchange programs, spare parts,

modules and engines, repair and overhaul capability and engineering services both in the field and from the factory.

Aero Worldwide_CCJ.qxd:Aero Worldwide_CCJ.qxd 10/14/08 4:50 PM Page 1

20 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

lier. Mechanical seals are an alter-

native to fabric seals and bellows.

n Large casing hotspots can cause

walls and/or floors to expand more

than anticipated. Inflexible support

columns can create stress points,

cracks, and hot gas leaks at loca-

tions shown in Fig 39. One example

is foundation cracking in Fig 40,

caused by restrained expansion of

the inlet-duct support column. Such

cracking can be caused by hotspots

or by improper bolting of the col-

umn to the foundation base plate.

Drums

Amy Sieben took over for Lester Stan-

ley at the podium. First thing she

mentioned: Steam drums provide the

only non-intrusive access to the water/

steam side of an F-class HRSG. Thats

an important point. All boiler water

eventually passes through one or more

steam drums in a triple-pressure unit,

so a great deal can be learned from a

proper inspection.

Siebens checklist included the fol-

lowing:

n Inspect the drum internal sur-

face.

n Investigate any signs of distress on

steam separation equipment and

the belly pan which are caused by

thermal stress (cracks) or flow-ac-

celerated corrosion (FAC). If com-

ponents are worn, measure metal

thickness to quantify the extent of

material loss.

n Verify mechanical integrity.

n Determine if the actual waterline

is at the level designers intended.

n Scoop-up and carefully examine

drum debris. Run tests to charac-

terize the debris if necessary.

n Check the manway ring to see if

machining is necessary to restore

it to the desired flat condition.

A thorough examination of the

drum internal surface demands that

you get up close to the metal and look

for pits, nicks, cracks, tubercles, cor-

rosion, erosion, etc. Take notes and

pictures of anything that looks out

of the ordinary, Wambeke suggested

from the back of the room.

Begin with a color assessment: Red

is good in an oxidizing environment

(Fig 41), bad in a reducing environ-

ment. Next, assess overall drum con-

dition, tracking surface defects from

manufacturesuch as those created

while rolling steel for the HP drum

pictured in Fig 42. Scaling and lack of

passivation during operation is illus-

trated in Fig 43.

Has smoothness/roughness of the

drum surface changed during the

inspection interval? For example,

perhaps tubercles have formed (Fig

44). It is particularly important to

identify any pitting attack and to

inspect what the pits look like under-

neath. Keep in mind that pits may

corrode under pits, resulting in pits

larger than those at the surface.

Signs of distress to look for on

steam separators and the belly pan

include the following:

n Cracks in the belly pan (or baffle

plate), as shown in Fig 45.

n Cracks in the corners of the final

separator (Fig 46).

n Thinning caused by FAC, as evi-

denced by the loss of material on

the belly pan in Fig 47a and the

hole in the LP belly pan in Fig 47b.

Also, early FAC attack on the LP

cyclone in Fig 48a and advanced

attack (huge hole) on the Fig 48b

cyclone.

Ultrasonic (UT) thickness mea-

surements are useful for document-

ing the condition of drum internals,

as well as of tubes and piping. Keep

meticulous records to enable rate-

of- wear calculations and timely

maintenance planning. Standard UT

measurements are all thats needed

to quantify material loss.

Thickness testing of internals com-

pares original specifications of drum

components to data collected during

your inspection. More sophisticated

UTsuch as shear-wave and phased-

arrayare used to identify cracking.

The software described in last

years Outage Handbook (see itali-

cized editors note above) allows

direct capture electronically of thick-

ness measurements as the UT probe

38

Stress point (typical)

Expansion

39

40

41

42

43

44

FILTRATION

Turbine Lube Oil & EHC Solutions

Fluid Contamination Under Control with . . .

Innovative Filtration Products, Support and Solutions

Make Hy-Pro a part of your lube team and arm yourself with tools and

industry expertise to maximize reliability from your hydraulic & Lube assets.

Hy-Pro will help you develop and implement strategies to achieve and

maintain target uid cleanliness levels and extend useful uid life.

www.hyproltration.com

Fishers, Indiana USA. +1.317.849.3535

When gas turbines fall casualty to unit trips and fail-to-start

conditions, lube oil varnish is the usual suspect . . .

So how do you solve the problem? Electrostatic oil cleaners and depth lter

systems alone yield little or no long term success. While your unit is on-line and

the oil is warm, the majority of varnish-causing contaminants are in solution

and cannot be removed by electrostatic or depth ltration systems.

Hy-Pro has the solution to make varnish vanish . . .

And it doesnt require electrostatic oil cleaning! Patent-pending Ion Charge

Bonding technology removes varnish-causing contaminants while they are

still in solution whether your turbine is on-line or standing by. Hy-Pros

soluble varnish removal system is the proven solution to restore and

maintain the health of your turbine oil!

Achieve & Maintain Target Varnish

Potential Numbers in Days not Months!

Dedicated Off-Line

Gearbox Filtration

Duplex Filter, auto

kleen upgrade Vacuum Dehydration &

Turbine Oil Coalescence

EHC & Lube Oil Filter

Element Upgrades.

Non-spark & static

dissipating elements.

before after

22 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

is moved across the surfaces of

affected components. Data are stored

in a manner that allows retrieval by

clicking on a particular tube, header,

etc, on drawings of your unit incorpo-

rated into the software package.

Mechanical integrity. Look for the

obvious: Broken U bolts, missing

nuts and other hardware, plugged

chemical-feed lines and separators,

etc. Fig 49 shows a fractured chemi-

cal-feed line found in the HP drum of

one boiler inspected by HRST engi-

neers; Fig 50 reveals a bolt missing

from a secondary separator; Fig 51a

is of a mesh separator failure; Fig 51b

shows a mesh-separator pad resting

at the bottom of the steam drum.

Water level. The primary cause

of faulty level indication is instru-

mentation that is out of calibration.

Sometimes, however, water level

falsely appears lower than actual

because the level transmitter is locat-

ed too near a downcomer or pump

intake. Their suction effect pulls on

the level sensing lines (Fig 52). Plug-

ging of sensing lines is another possi-

ble cause of false readings or sluggish

response. Fig 53 shows a pencil-type

magnet with debris pulled from a

lower-level tap for an HP drum.

Debris volume, if large, suggests

possible rethinking of blowdown pro-

cedures and/or the need to check for

iron transport caused by FAC. Fig 54

is a photo of iron debris found in a

stagnant area of an HP drum at an

end beyond the baffle. Also check for

this material in the blowdown tank.

NDE basics

Sieben suggested, Depending on the

HRSGs age, number and severity

of cycles, and past issues, intrusive

inspection techniques should be con-

sidered to more accurately assess

boiler condition. This might include

one or more of the following:

n Ultrasonic testing (UT) of tubes and

piping beyond spot checks; select

optimum technology from among

A-scan, phased-array, or shear-

wave as specific tasks dictate.

n Dye-penetrant (PT) or magnetic-

45

46

47a 47b

48a 48b

49

50

51a 51b

52

53

54

Wood Group Gas Turbine Services:

Covers the world where you work, we work

Gives you OEM-equivalent MRO, cost-effectively

Knows ongoing customer satisfaction is the real

meaning of service

Delivers on its promises from beginning to end

We are centered on solving your rotating equipment

challenges and make sure your world keeps on turning.

Our solutions revolve

around a single point: You.

www.woodgroup.com/gts gts@woodgroup.com

24 COMBINED CYCLE JOURNAL, Third Quarter 2008

SPECIAL ISSUE: OUTAGE HANDBOOK HEAT-RECOVERY STEAM GENERATORS

55

particle (MT) testing of suspect

areas.

n Removal and inspection of desu-

perheaters.

n Borescope examination.

n Sampling and analysis of pres-

sure-part materials.

Ultrasonic testing. Recall how UT

works: An ultrasound transducer

connected to a diagnostic machine is

passed over the object being inspect-

ed. The transducer typically is sepa-

rated from the test object by a cou-

plant. Reflection off the back wall

or imperfection records the

wall thickness or depth of

the discontunity.

A-scan UT typically is

selected for thickness test-

ing, especially where FAC or

external corrosion has been

identified. Its easy to use, fast,

and accurate. Sieben offered an

inspection plan thats easy to

customize for your HRSGs. She

stressed that inspections should

be prioritized based on risk.

n Examine LP evaporator circuits

(plus IP circuits up to 400-psig

saturated) and HP, IP, and LP

economizer tubes that operate

between 280F and 340F, the tem-

perature range that exacerbates

FAC attack. Wall thinning gener-

ally is experienced first after tube

bends near the upper headers.

However, the risk of two-phase

FAC is just slightly higher than

single-phase FAC, so the lower-

header inlets may be more conve-

nient to check. To access the tube-

bend area, remove header baffles

as necessary.

n Check pipe elbows (jumpers) at

the apex of the elbow; and straight

runs downstream of control valves

and orifice plates, especially where

temperatures are more than 280F

and less than 340F.

n Examine headers on HRSGs with

stick-through welds on the head-

ers directly across from the tube

inlet. To review basics of tube-to-

header joints, access www.com-

binedcyclejournal.com/archives.

html, click 3Q/2004, click article

title on cover.

Phased-array UT makes use of

multiple fixed-angle transducers in

a single probe to quickly and accu-

rately characterize flaws to provide

the depth of indications, which show

up as echo blips on the instruments

screen (Fig 55). It has become the

instrument of choice in GT inspec-

tions for its ability to identify even

small flaws in complicated geome-

triessuch as compressor airfoils,

blade platforms, disks, etc.

Leading technology has its price.

Phased-array instruments and probes

are more complex and expensive than

conventional UT and technicians

require more experience and train-

ing to use it. However, compared to

radiography (RT), the old standard in

boiler work, phased-array UT offers

several advantages, including:

n No work stoppage or welder relo-

cation is required to check work

because there are no safety haz-

ards with UT as there are with RT

(radiation).

n Inspections are conduct-

ed faster.

n Better suited for the detection of

planar, crack-like indications

such as lack of fusionwhich are

conducive to premature failure.

n The exact depth of a defect is

revealed, facilitating its removal

and rework. Digital RT is making

great strides to eliminate or mini-

mize this list.

Shear-wave UT is about two to

three times less expensive, but does

not give depth of indication. Best

applications for it are straight pipe,

elbows, and circumferential welds.

PT and MT methods are used to iden-

tify cracks at the surface of the base

tube material at or near a weld. They

also are used for regular checking of

tube/header joints at the economizer

water inlet when more than 500 start/

stop cycles have been accumulated;

to verify the integrity of superheater

and reheater tube/header joints where

warped tubes have gotten worse over

time; and to pinpoint suspect leaks in

vent and drain lines.

PT is a low-cost and widely applied

inspection method for locating sur-

face-breaking defects in all non-po-

rous materials (metals, plastics, and

ceramics). For inspection of ferrous

components, however, MT often is

preferred because of its subsurface

detection capability.

Dye-penetrant inspection is used to

detect casting and forging defects,

cracks, and leaks in new products, as

well as cracks on in-service compo-

nents not visible to the naked eye. It

is simple to use: Penetrant is applied

to the surface, excess penetrant is

removed, and developer is applied to

make the crack visible. Little train-

ing is required to develop proficiency

in conducting PTs.

The red dye used most often offers

a high visual contrast against a white

developer background. The developer

draws out the penetrant from the

flaw over a wider area than the real

flaw, enhancing its visibility.

Perhaps the biggest concern in con-

ducting a dye-penetrant inspection is

surface cleanliness, offered Wambeke.

But keep in mind that some cleaning

methods are detrimental to test sen-

sitivity. Occasionally, acid etching

is required to remove metal

smearing and to reopen the

defect.

Magnetic particle inspec-

tion processes make use

of an externally applied

magnetic field or dc current

through the material. They

are based on the principle that

the magnetic susceptibility of

a defect in a ferrous material

is markedly poorerthat is,

the magnetic resistance is greater

than that of the surrounding mate-

rial.

The most common MT method relies

on finely divided iron or magnetic iron

oxide particles held in suspension in a

suitable liquid (often kerosene). This

fluid is referred to as the carrier.

The particles often are colored and

usually coated with fluorescent dyes

that are made visible with a hand-

held ultraviolet (UV) light.

The suspension is sprayed or

painted over the magnetized speci-

men to localize areas where the mag-

netic field has protruded from the

surface. The magnetic particles are

attracted by the surface field in the

area of the defect and hold on to the

56

57

26 COMBINED CYCLE JOURNAL, Third Quarter 2008

edges of the defect and define it by a

build-up of particles.

MT is used to inspect machined

parts before they are placed in service

and also to inspect parts in service for

fatigue cracking (Fig 56). The testing

method is easy to apply and takes less

time than UT and PT, but it does not

work well with complex geometries.

Attemperators in cycling service

should be inspected annually. Look

for cracking or distress on the desu-

perheater assembly; check nozzles

for plugging; confirm liner integrity

(see liner crack in Fig 57), and the

absence of pitting/wear at the down-

stream elbow. If data suggest over-

spray, inspect piping for cracks.

Borescope inspections commonly

associated with GTs, steam turbines,

and generators also find application

in some sections of HRSGs. The most

likely areas of use include the fol-

lowing:

n Economizer, cold end, when pit-

ting or cracking of the tube inter-

nal surface is of concern because

of cyclic stresses and/or water-

quality issues.

n Economizer, hot end, if damage

or deposits are suspected from

water-quality excursions in con-

junction with excessive steaming.

n HP evaporator, hot end, if water-

chemistry excursions make inter-

nal deposits a risk or iron levels

are above 1 ppm.

n LP evaporator tube rows most

susceptible to FAC damage based

on a circulation analysis or failure

history.

n First tube bundle of the super-

heater downstream of the steam

drum, if deposits from carryover

are suspected because of a steam-

separator failure.

Tube samples are taken to charac-

terize both hard scales that form in

LP boilers and magnetite and copper

deposits in HP boilers. Such deposits

reduce heat transfer and efficiency

and make the HRSG more suscepti-

ble to overheating and tube failures.

Tubes are sampled only when

available NDE methods are not able

to meet expectations. Tube sampling

is difficult, expensive, and has obvi-

ous inherent risks.

Laboratory analysis will suggest

corrections to water chemistry and

operating procedures and the most

efficient method for removing depos-

its. Base metal analysis will advise

on the condition of boiler tubes and

whether expectations of service life

must be revised downward. ccj

Visit booth 213 HRSG 2008

Vous aimerez peut-être aussi

- Advanced Temperature Measurement and Control, Second EditionD'EverandAdvanced Temperature Measurement and Control, Second EditionPas encore d'évaluation

- HRSG InspectionDocument4 pagesHRSG Inspection55312714Pas encore d'évaluation

- HRSG Final InspectionDocument8 pagesHRSG Final Inspectionmkarahan100% (1)

- AFBC BoilerDocument12 pagesAFBC BoilerNaman Sharma0% (1)

- Tube To Header JointsDocument4 pagesTube To Header Jointsshabbir626Pas encore d'évaluation

- TUBE To HEADER JOINTS PDFDocument4 pagesTUBE To HEADER JOINTS PDFRiza KhanPas encore d'évaluation

- HRSG WeldingDocument20 pagesHRSG WeldingBhargav ChaudhariPas encore d'évaluation

- HRSG Corrosion PDFDocument8 pagesHRSG Corrosion PDFJayanath Nuwan SameeraPas encore d'évaluation

- How To Identify Water Side Corrosion Problems in HRSG'S - CCJDocument7 pagesHow To Identify Water Side Corrosion Problems in HRSG'S - CCJShameer MajeedPas encore d'évaluation

- Reliability Issues With HRSGDocument93 pagesReliability Issues With HRSGAnsuman Sen Sharma100% (5)

- Heat Recovery Steam GeneratorDocument69 pagesHeat Recovery Steam GeneratorAayushi Agarwal100% (5)

- HRSG FAC Risk AssesmentDocument1 pageHRSG FAC Risk Assesmentandersonr3160Pas encore d'évaluation

- EPRI - Evaluating and Avoiding Damages To HRSG Tubes Given by Duct BurnersDocument72 pagesEPRI - Evaluating and Avoiding Damages To HRSG Tubes Given by Duct BurnersDavide Franzini100% (1)

- Challenges of Welding of Catalyst TubesDocument16 pagesChallenges of Welding of Catalyst TubesTravis SkinnerPas encore d'évaluation

- HRSG Design UpdateDocument38 pagesHRSG Design UpdateShameer Majeed100% (1)

- Boiler Materials For USC Plants IJPGC 2000Document22 pagesBoiler Materials For USC Plants IJPGC 2000pawanumarji1100% (1)

- HRSG PDFDocument248 pagesHRSG PDFaztec20100% (11)

- HRSG Handbook BrochureDocument2 pagesHRSG Handbook Brochuremahmoud_allam3Pas encore d'évaluation

- HRSG StartupDocument20 pagesHRSG Startupsujiv_sujiv1278100% (1)

- Performance HRSGDocument7 pagesPerformance HRSGalfnusi173100% (1)

- Saudi Aramco Furnace Guide150150Vertical CylindricalVertical Cylindrical5050Vertical CylindricalVertical Cylindrical15050Vertical CylindricalVertical Cylindrical150150150BoxBoxBoxDocument23 pagesSaudi Aramco Furnace Guide150150Vertical CylindricalVertical Cylindrical5050Vertical CylindricalVertical Cylindrical15050Vertical CylindricalVertical Cylindrical150150150BoxBoxBoxMohammad RawoofPas encore d'évaluation

- Boiler Life AvailabilityDocument11 pagesBoiler Life AvailabilityOkpala APas encore d'évaluation

- Optimal Hardness of P91 WeldmentsDocument50 pagesOptimal Hardness of P91 Weldmentsspamfilter02100% (2)

- Superheater and Reheater Outlet Header Inspections FailuresDocument65 pagesSuperheater and Reheater Outlet Header Inspections Failureskaruna346Pas encore d'évaluation

- Welding Filler Metals For Power Plant EngineeringDocument20 pagesWelding Filler Metals For Power Plant EngineeringgogotigPas encore d'évaluation

- HRSG Inspection TasksDocument38 pagesHRSG Inspection Tasksmkarahan100% (4)

- HRSG 2011 BrochureDocument12 pagesHRSG 2011 BrochureAndry SetiawanPas encore d'évaluation

- Remaining Life Assessment of Engineering ComponentsDocument23 pagesRemaining Life Assessment of Engineering ComponentsIndah PermataPas encore d'évaluation

- Tube Repair and Protection For DamageDocument112 pagesTube Repair and Protection For Damagesandipwarbhe1234100% (1)

- Thermal Stress Creep in HRSG Pressure PartsDocument274 pagesThermal Stress Creep in HRSG Pressure PartsAlberto Lazzaretti100% (2)

- HRSG CorrosionDocument8 pagesHRSG Corrosion5531271450% (2)

- Condition and Life Assessment of a Power Station BoilerDocument2 pagesCondition and Life Assessment of a Power Station BoilerfelramPas encore d'évaluation

- GE Frame 6FA PDFDocument4 pagesGE Frame 6FA PDFvcharlesPas encore d'évaluation

- EPRI Field Guide For Boiler Tube Failures PDFDocument215 pagesEPRI Field Guide For Boiler Tube Failures PDFkirubha_karan2000100% (2)

- Superheater Problems, Their Causes and SolutionsDocument12 pagesSuperheater Problems, Their Causes and Solutionshamirazi67% (3)

- Reformer TubeDocument16 pagesReformer TubeAgus Tri Atmanto100% (1)

- PL1083 - WHB 1 and 2 REPAIR PROCEDURE Rev 1 PDFDocument4 pagesPL1083 - WHB 1 and 2 REPAIR PROCEDURE Rev 1 PDFsarsan nedumkuzhiPas encore d'évaluation

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocument12 pages02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsivanmatijevicPas encore d'évaluation

- Tube Temperature Distribution in Water Tube Boiler - A - 2 PDFDocument14 pagesTube Temperature Distribution in Water Tube Boiler - A - 2 PDFYanuar KrisnahadiPas encore d'évaluation

- HRSG Overview PDFDocument36 pagesHRSG Overview PDF55312714100% (6)

- Boiler Codes Require Updating ToLDocument9 pagesBoiler Codes Require Updating ToLmahmoud_allam3Pas encore d'évaluation

- EPRI Sootblower WDocument13 pagesEPRI Sootblower WSiva KumarPas encore d'évaluation

- Disertation On Fmea Boiler Tube Failure AnalisisDocument65 pagesDisertation On Fmea Boiler Tube Failure AnalisisJose Gustavo Hernandez ReyesPas encore d'évaluation

- HRSG tube failures inspection techniquesDocument12 pagesHRSG tube failures inspection techniquesOwais Malik100% (1)

- HRSG Header To Stub RepairDocument54 pagesHRSG Header To Stub Repairaztec20Pas encore d'évaluation

- HRSG - Basic UnderstandingDocument30 pagesHRSG - Basic Understanding이영준100% (23)

- Training Session4 - Heat Recovery Steam GeneratorsDocument34 pagesTraining Session4 - Heat Recovery Steam GeneratorsarianaseriPas encore d'évaluation

- Heat Recovery Steam Generators Optimized For Any ApplicationDocument7 pagesHeat Recovery Steam Generators Optimized For Any ApplicationKVVPas encore d'évaluation

- CC Power PlantsDocument48 pagesCC Power PlantsSamPas encore d'évaluation

- Boiler Operation and MaintenanceDocument25 pagesBoiler Operation and MaintenanceJom BonhayagPas encore d'évaluation

- An Introduction To The Concept of Double Jeopardy in Process SafetyDocument4 pagesAn Introduction To The Concept of Double Jeopardy in Process SafetyAnonymous a4Jwz14WPas encore d'évaluation

- 205HRSGuserrev2Final PDFDocument15 pages205HRSGuserrev2Final PDFvtbkPas encore d'évaluation

- PROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalDocument6 pagesPROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalcsPas encore d'évaluation

- Specifying Shell-And-Tube Heat Exchangers (Chemical Engineering) May 2013Document7 pagesSpecifying Shell-And-Tube Heat Exchangers (Chemical Engineering) May 2013sebas_vPas encore d'évaluation

- Relief Valves in ParallelDocument5 pagesRelief Valves in ParallelJames R. Lawrence Sr.Pas encore d'évaluation

- Strategies for inspecting HRSGsDocument12 pagesStrategies for inspecting HRSGsvnchromePas encore d'évaluation

- Turbine MaintainanceDocument9 pagesTurbine Maintainanceer_sanjaypatel100% (2)

- The Design and Operation of Offshore Relief - Venting SystemsDocument24 pagesThe Design and Operation of Offshore Relief - Venting SystemsMichael HaisePas encore d'évaluation

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksPas encore d'évaluation

- Attached To Aboveground Flammable or Combustible Liquid Storage TanksDocument1 pageAttached To Aboveground Flammable or Combustible Liquid Storage TanksahmadaryaPas encore d'évaluation

- Attached To Aboveground Flammable or Combustible Liquid Storage TanksDocument1 pageAttached To Aboveground Flammable or Combustible Liquid Storage TanksahmadaryaPas encore d'évaluation

- Flow Induced Vibration CrackDocument24 pagesFlow Induced Vibration Crackantonio martelliPas encore d'évaluation

- Dew Point CorrosionDocument26 pagesDew Point CorrosionNaren C100% (2)

- Enforcing NFPA 25: Linda S. Pieczynski Attorney at Law, P.CDocument34 pagesEnforcing NFPA 25: Linda S. Pieczynski Attorney at Law, P.CahmadaryaPas encore d'évaluation

- Density Calculation ToolDocument3 pagesDensity Calculation ToolahmadaryaPas encore d'évaluation

- IRAN Archaic Signet of CivilizationDocument120 pagesIRAN Archaic Signet of CivilizationahmadaryaPas encore d'évaluation

- Nooter Eriksen PresentationDocument72 pagesNooter Eriksen Presentationahmadarya100% (4)

- Reinforced Concrete Bearing Wall Design CSA A23 3 14 v10Document29 pagesReinforced Concrete Bearing Wall Design CSA A23 3 14 v10marcob74Pas encore d'évaluation

- Romold Domestic Grease TrapDocument1 pageRomold Domestic Grease Traprajkumar_chinniahPas encore d'évaluation

- Natural Rubber VulcanizationDocument3 pagesNatural Rubber VulcanizationAbraha AbadiPas encore d'évaluation

- 5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFDocument4 pages5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFrhomadonaPas encore d'évaluation

- Thomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıDocument375 pagesThomsen, Wallace - 1995 - Displacement Based Design of Reinforced Concrete Structural Walls An Experimental Investigation of Walls With - YazıÖzlem Temel YalçınPas encore d'évaluation

- Compresssive Strength Test Concrete Hollow Block PDFDocument8 pagesCompresssive Strength Test Concrete Hollow Block PDFMohammad Tarequl AlamPas encore d'évaluation

- Asphalt DistressesDocument31 pagesAsphalt DistressesWillard Apeng100% (1)

- Las 9Document14 pagesLas 9HisokaPas encore d'évaluation

- L4 BeamsDocument10 pagesL4 BeamsFairiey Izwan Azazi100% (1)

- Working of New Design of Door Closer: Research PaperDocument7 pagesWorking of New Design of Door Closer: Research Paperabdelnabi zaghloulPas encore d'évaluation

- Alloy Steel Round BarDocument10 pagesAlloy Steel Round BarSingarao KattaPas encore d'évaluation

- Econax General CatalogueDocument28 pagesEconax General CataloguePRISHA A/P STEVEN MoePas encore d'évaluation