Académique Documents

Professionnel Documents

Culture Documents

700htp Iseng0100 Fluke Hydraulic Pump Tester

Transféré par

Dineros NievaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

700htp Iseng0100 Fluke Hydraulic Pump Tester

Transféré par

Dineros NievaDroits d'auteur :

Formats disponibles

3. 4. 5.

Connect the input of the pressure instrument under test to the test pressure port (item B). Unscrew the pressure release knob (item I) to vent pressure from the pump. Zero the pressure module. The zeroing procedure depends on which pressure module and calibrator you are using. Turn the fine adjustment knob (item D) to mid-range. Tighten the pressure release knob finger tight. Turn the PRIME / HIGH selector counter-clockwise to the PRIME position. Squeeze the handles repeatedly until resistance increases (about 10 strokes). The hydraulic cylinder is now primed.

Fluke-700HTP Hydraulic Test Pump Instruction Sheet

6. 7. 8. 9.

Introduction

The Fluke 700HTP Hydraulic Test Pump (hereafter called the pump) is a portable source of high pressure. The pump has the following specifications: Maximum pressure: 700 bar (10,150 psi) Hydraulic media: distilled water or mineral based hydraulic oil Wetted materials: 303 stainless steel, brass, polyurethane, PTFE, nitrile, and nylon Weight: 3.53 lb (1.6 kg) Dimensions: length 9.29 in (236 mm), width 6.26 in (159 mm), depth 2.76 in (70 mm)

10. Squeeze the handles together and turn the PRIME / to the HIGH position. In HIGH selector clockwise the HIGH position, the length of the hanle stroke is shortened for proper resolution per stroke. Caution Pressure may rise rapidly if the pressurized volume is small. 11. Compress the handles to apply incrementally higher pressure. 12. Adjust the pressure using the fine adjustment knob.

Box Contents Replacement Parts

Pressure release valve stem, Fluke PN 689346 Seal kit, Fluke PN 689361 Handle and main piston assembly, Fluke PN 2029208 Fine control knob, Fluke PN 689349 Hydraulic fluid reservoir, Fluke PN 689353 Model 700HTP Hydraulic Test Pump with 3/8-in BSP male to 1/4-in. NPT female adapter and 1/4-in. BSP male to 1/4-in. NPT female adapter installed 3/8-in. BSP male to 1/4-in. NPT male adapter Replacement seal kit for the pump Instruction Sheet

Limited Warranty & Limitation of Liability

This Fluke product will be free from defects in material and workmanship for one year from the date of purchase. This warranty does not cover fuses, disposable batteries or damage from accident, neglect, misuse or abnormal conditions of operation or handling. Resellers are not authorized to extend any other warranty on Flukes behalf. To obtain service during the warranty period, send your defective calibrator to the nearest Fluke Authorized Service Center with a description of the problem. THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of liability may not apply to you.

How to Contact Fluke

To contact Fluke, call one of the following numbers:

USA: 1-888-99-FLUKE (1-888-993-5853) Canada: 1-800-36-FLUKE (1-800-363-5853) Europe: +31 402-675-200 Japan: +81-3-3434-0181 Singapore: +65-738-5655 Anywhere in the world: +1-425-446-5500

Visit us on the World Wide Web at: www.fluke.com

Fluke Corporation P.O. Box 9090 Everett, WA 98206-9090 U.S.A.

Fluke Europe B.V. P.O. Box 1186 5602 B.D. Eindhoven The Netherlands

PN 688728 December 1997, Rev.1, 8/02

1997,2002 Fluke Corporation. All rights reserved. Printed in U.S.A. All product names are trademarks of their respective companies.

Features of the Test Pump

2 1 3 (other side)

Using the Test Pump

Pressure Module

4 9

6 mm

743

DOCUMENTING PROCESS CALIBRATOR

8

Recommended fluid level

HYDRAULIC TEST PUMP DO NOT EXCEED 10000 psi -700 bar

5 6

MEAS SOURCE

mA

SETUP

TC RTD

V Hz

8 5 2 0

9 6 3

CLEAR

(ZERO)

RANGE

4 1

.

mA RTD

CAT

ENTER

Pump shown with selector and handles in "Prime" position.

pk01f.eps

V RTD

mA

S I G N A L

30V MAX

SOURCE

30V MAX

MEAS

30V MAX

300V MAX

TC

+

T E S T

No. A

Item Master instrument port Test pressure port Pressure relief valve port Fine adjustment knob Hydraulic fluid reservoir Fluid inlet tube PRIME / HIGH selector Reservoir filler plug Pressure release knob

Function Port for Fluke 700 Series Pressure Module. Supplied with 3/8-in. BSP to 1/4-in. NPT female adapter installed. Port for pressure instrument under test. Supplied with 1/4-in. BSP to 1/4-in. NPT female adapter installed. Port for an optional Fluke 700PRV Pressure Relief Valve (plugged). Allows you to precisely adjust the applied pressure. Holds 100 cc of hydraulic fluid: mineral based hydraulic oil or distilled water. Feeds hydraulic fluid to the hydraulic cylinder. Selects priming mode or pressurizing mode. Remove this to fill hydraulic fluid reservoir. Reseal before you pump. Allows you to release pressure in a controlled manner. 1.

Red

Black

pk02c.eps

Warning To avoid a violent release of pressure, always depressurize the system slowly using the pressure release knob (item I, left) before you detach any pressure line from the pump. Do not connect the pump to an external pressure source. Caution If you are using the pump with a pressure module or pressure instrument that will be damaged by pressures of 700 bar (10,150 psi), you can protect the equipment by installing a properly set relief valve in the system or an optional Fluke 700PRV Pressure Relief Valve on the pump. Attach a 700 Series Pressure Module (hereafter called "pressure module") to the master instrument port A for all modules except the 700P High Pressure Modules. To adapt to the 700P Series High Pressure Modules, first remove the installed input adapter and replace it with the male -in NPT Adapter. The threads in the Master Instrument port are BSP. Use only a bonded seal (supplied), never use thread sealing tape with the BSP parallel threads. Connect the pressure module to the calibrator as shown in the figure

F G

H I

2.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Dimensional Information For Hot TappingDocument3 pagesDimensional Information For Hot TappingCarlos ShuntaPas encore d'évaluation

- Technical Note Two Phase FlowDocument3 pagesTechnical Note Two Phase FlowAnonymous MB5YbaLrBEPas encore d'évaluation

- Diaphragm Valve How It WorksDocument3 pagesDiaphragm Valve How It Worksthouche007Pas encore d'évaluation

- Fire Fighting Pumps: FeaturesDocument3 pagesFire Fighting Pumps: FeaturesReyza PrasetyoPas encore d'évaluation

- Check Valve and Throttle/Check Valve With SAE Flanged Ports: RE 64 548/06.03 1/6 Replaces: 03.94Document6 pagesCheck Valve and Throttle/Check Valve With SAE Flanged Ports: RE 64 548/06.03 1/6 Replaces: 03.94Enayat IzadiPas encore d'évaluation

- PICV-Fig1932 IOM-Hatts PDFDocument4 pagesPICV-Fig1932 IOM-Hatts PDFSujit RajanPas encore d'évaluation

- Centrifugal Compressor Surge and Surge ControlDocument32 pagesCentrifugal Compressor Surge and Surge ControlMoustafa HelmyPas encore d'évaluation

- Smoke & Ventilation CalculationsDocument7 pagesSmoke & Ventilation CalculationsAhmedPas encore d'évaluation

- Narol, Ahmedabad ,: Air Compressor Air DryerDocument6 pagesNarol, Ahmedabad ,: Air Compressor Air DryerMahendra ShahPas encore d'évaluation

- Building Renovation Quote BreakdownDocument7 pagesBuilding Renovation Quote BreakdownMEGAWATT CONTRACTING AND ELECTRICITY COMPANYPas encore d'évaluation

- Installation & Start Up of Axial Piston PumpDocument14 pagesInstallation & Start Up of Axial Piston Pumpmrkadu_61Pas encore d'évaluation

- Compressor Bendix BA-921 CAT 385 - 0936Document40 pagesCompressor Bendix BA-921 CAT 385 - 0936Prajna SatyaPas encore d'évaluation

- Coiled TubingDocument31 pagesCoiled TubingAndres Anchicoque100% (3)

- CPOC-GS-PI-0004 Rev 0 PDFDocument19 pagesCPOC-GS-PI-0004 Rev 0 PDFPCHAN@TOMPas encore d'évaluation

- Hydraulic CalculationsDocument12 pagesHydraulic CalculationsIsmid Maulana100% (1)

- Pre Commissioning ChecklistsDocument13 pagesPre Commissioning Checklistsmehul10941Pas encore d'évaluation

- RE 25402 - 2021-08 Editado (Valvula Limitadora de Presion BOSCH)Document24 pagesRE 25402 - 2021-08 Editado (Valvula Limitadora de Presion BOSCH)nenuchoPas encore d'évaluation

- Dredge Sled Hydraulic 4in v2.1Document3 pagesDredge Sled Hydraulic 4in v2.1JonesPas encore d'évaluation

- Chapter 3 - Wellbore Performance AnalysisDocument56 pagesChapter 3 - Wellbore Performance AnalysisTu Dang TrongPas encore d'évaluation

- Plant Water List: Plant P14 Project 10000 TPD CiteureupDocument3 pagesPlant Water List: Plant P14 Project 10000 TPD Citeureupabdullah amanullahPas encore d'évaluation

- The Impact of Surface Roughness On Axial Compressor Performance DeteriorationDocument11 pagesThe Impact of Surface Roughness On Axial Compressor Performance DeteriorationAlozie OgechukwuPas encore d'évaluation

- Overhaul Procedure ValveDocument4 pagesOverhaul Procedure ValveRansley Tong100% (1)

- Tanjung Jati B Training: SootblowersDocument26 pagesTanjung Jati B Training: SootblowersKaremBenzema100% (3)

- International Well Control Forum Surface BOP Kill Sheet - Deviated Well (S.I. Units)Document3 pagesInternational Well Control Forum Surface BOP Kill Sheet - Deviated Well (S.I. Units)Kenaouia Bahaa100% (1)

- IITB Aerospace Engineering Courses Autumn 2022Document1 pageIITB Aerospace Engineering Courses Autumn 2022Vishnu SankarPas encore d'évaluation

- Transportasi Fluida (Compressible Fluid-Fan Blower)Document36 pagesTransportasi Fluida (Compressible Fluid-Fan Blower)Evia Salma ZauridaPas encore d'évaluation

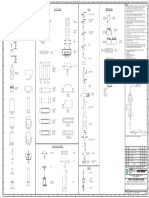

- Legend Sheet P&ID For As-Built - Drafting On 20210722-1Document1 pageLegend Sheet P&ID For As-Built - Drafting On 20210722-1Ludi D. LunarPas encore d'évaluation

- Spare Parts Catalogue - January 2015Document17 pagesSpare Parts Catalogue - January 2015Yury KovalevPas encore d'évaluation

- L1 Water HammerDocument19 pagesL1 Water HammerOPOPas encore d'évaluation

- Drawing performance characteristics of centrifugal compressor and finding surge lineDocument17 pagesDrawing performance characteristics of centrifugal compressor and finding surge lineankit kushwahaPas encore d'évaluation