Académique Documents

Professionnel Documents

Culture Documents

Article Wink Elm Ann Longchuan 2008-IRB 1410

Transféré par

Jdaniel Von de LaurenDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Article Wink Elm Ann Longchuan 2008-IRB 1410

Transféré par

Jdaniel Von de LaurenDroits d'auteur :

Formats disponibles

arc welding

Easy Expansion

Efficiency Optimization

ABB robots complete in one welding process a task that traditionally took 10 to 12 workers. ABB robots free workers from contact with poisonous ammonia gas and intense lighting during welding. ABB robots ensure consistent product quality.

Text: Zhang Kun Photos: Liang Liang

Winkelmann Longchuan has achieved astounding progress over the past decade, becoming the indisputable leading producer of fuel rails in China.

By Zhang Kun Photo Liang Liang

> FA C t s

About Winkelmann Longchuan

The Winkelmann Longchuan joint venture was founded in 2005; it has 280 employees. The company produces fuel rails. Its annual revenues are USD19.1 million. Since its founding, company output has increased from 1,000 rails a month to 280,000.

In China, the rapid growth of Shanghai Winkelmann Longchuan swl Motorcomponents Co. Ltd. has surprised even the boss himself. We provide fuel rails to automobile makers, says chief engineer Guo Feng. In 1997, when the company was founded, we produced 1,000 rails a month. Today our monthly output is 280,000. Winkelmann Longchuan enjoyed this rapid growth thanks largely to the rapid development of Chinas automobile industry, which was, Guo notes, far beyond our expectations. The fuel rail is essentially a pipe delivering fuel to individual fuel injectors on combustion engines. It is an integral part of an automobile engine, and Winkelmann Longchuan is the largest manufacturer with approx 80 percent of the domestic market, says Guo. The Winkelmann Longchuan joint venture was launched in 2005 as a way for the company to reach the European market. It remains the only Chinese company to export fuel rails internationally, selling its products to Russia, Italy and Germany. Guo explains that as automakers develop new concept cars and environmentally friendly vehicles, his companys products will be in demand. Our high-pressure fuel rails disseminate the fuel in a fine spray and burn it more completely, which helps to save fuel, he says. In the next five years, Winkelmann Longchuan hopes to increase its productivity by 50 percent. Its our basic strategy to go for automation and increase production per person, Guo says. In the past two years, the company has already made strides in this

direction, doubling its productivity without increasing its workforce of 280. We have invested from usd 1.18 to 2.2 million a year in new equipment, he says. In 2008, we will introduce our third abb welding robot to the workshop. All three are irb 1410 robots. One of these robots does in a single process what has traditionally taken 10 to 12 procedures, each done by a separate worker on an assembly line. The robots save not only labor costs but wear and tear on the workers. He Jianfang, trained to be a robot operator when the first abb robot arrived at Longchuan in 2001. She explains: With the robot doing the welding, people do not have to be close to the smell of ammonia and the strong lights. This makes my work safer and much easier. abb has also been making improvements for clients, and the new robot will have a Chinese operation board, which will be much easier to operate. Guo comments: An abb robot works 24 hours a day. The product quality is so consistent that no human worker can compare. In addition, he says, a robot greets visitors as soon as they arrive at our workshop, which helps to boost our company image. Guo says he is particularly pleased with the attention abb gives his company. abb bears our requests in mind, and their products keep improving, he says. For example, the second robot from abb featured a raised welding table so that workers did not have to bend down to work. In addition, the working process was shortened. It takes half the time it did before to complete one product, says Guo. This means that we can double our productivity without consuming more electricity. Other companies produce welding robots and they do have lower prices, he admits, but we stick with abb because their product quality is stable and, like us, they continue to make improvements. Plus, their maintenance staff are always ready to help. Sometimes we buy automatic equipment from other companies because abb doesnt offer a similar product, but if its available from abb, then thats where we buy it, says Guo. We trust abb, and our cooperation with them has been very pleasant.

www.abb.com/robotics

EN_07_longchuan_abb_metal_208.indd 7

12/3/2008 11:25:04

m e ta l

>

inspection, spot welding

A strategy of inno

In todays tight auto market, innovation is the key to staying alive for U.S. auto parts maker Ogihara America Howell. In this ABB has a big role to play.

Located midway between the u.s. auto manufacturing centers of Lansing, Flint and Detroit, Michigan, the Ogihara America Howell facility stamps and assembles automotive body panels. The plant initially served the u.s. big three: gm, Ford and Chrysler. Over time the fortunes of those manufacturers have declined. Yet Ogihara has continued to thrive and maintain a prosperous business. How is that possible? To Steve Peca, the executive manager for projects and advanced engineering for Ogihara America Howell, its no mystery. Whats kept us here is innovation, he says. Were very good at inventing things. Were very creative, and our innovations keep us strong. The company has even shared a process it developed for tile manufacturing with nasa, which now makes all the space shuttle heat shield tiles using that process. That confidence can be seen throughout the bustling 800,000-square-foot Michigan factory. Here 260 employees operate a wide array of hightech robotic cells, stamping and assembling highstrength steel and aluminum into body panels and subassemblies for such car and truck manufacturers as Mercedes, Toyota and Isuzu, as well as u.s. automakers. Those parts are shipped around the world, including to China, where Ogihara is currently building a new plant. Says Peca, Weve come out with various processes and innovations that afford our customers better value than by sending jobs to low-cost countries. Its our innovation that keeps us alive, and abb plays a big role in that. abb supplies Ogihara with robots, manufacturing cells and systems for welding, material handling and quality control. The plants four assembly lines have used 20 abb robots for the past five years. abb works out very well, says Kazuaki Miura, manager of assembly engineering at the Howell plant. It has very good service. In addition, says Miura, robots pay for themselves in six months, and at half the cost

We found the ABB robot was a nice fit for us. It just snapped into place, says Steve Peca.

Text and photos by Dwight Cendrowski

www.abb.com/robotics

EN_08-09_ogihara_abb_metal_208.indd 8

12/3/2008 11:25:21

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- New Haven Union Station TOD PlanDocument45 pagesNew Haven Union Station TOD PlanNHUDLPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Erection ProceduresDocument7 pagesErection ProceduresIbrahim AlsayedPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Site Inspection Workplace Trasport ChecklistDocument6 pagesSite Inspection Workplace Trasport ChecklisttipuPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

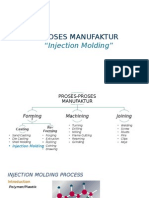

- Injection MoldingDocument23 pagesInjection MoldingAditya DhikaPas encore d'évaluation

- Company Work Execution Plan For A Long Form ContractDocument4 pagesCompany Work Execution Plan For A Long Form Contractshojaee1063Pas encore d'évaluation

- Magnetic SeparatorDocument31 pagesMagnetic SeparatorMNButt100% (1)

- Boq 103147Document39 pagesBoq 103147Rahul ChauhanPas encore d'évaluation

- Tanker Chartering and Dry Bulk CharteringDocument2 pagesTanker Chartering and Dry Bulk Charteringhwh hui57% (7)

- Sustainable Urban TransportDocument40 pagesSustainable Urban TransportDinesh PoudelPas encore d'évaluation

- NCP 23Document17 pagesNCP 23Arunashish Mazumdar100% (2)

- Sea ProtestDocument5 pagesSea ProtestenglisgoPas encore d'évaluation

- 11 Sakr Etal2010 - Pile Load Testing of Helical Piles and Driven Steel Pipes PDFDocument1 page11 Sakr Etal2010 - Pile Load Testing of Helical Piles and Driven Steel Pipes PDFAAAAAAAAAAAAAAAAAAAPas encore d'évaluation

- Vics Bol 2004Document1 pageVics Bol 2004Ghulaam RamadhanPas encore d'évaluation

- Earthwork ScopeDocument4 pagesEarthwork ScopeMax SchusterPas encore d'évaluation

- Rod Ends For The Food IndustryDocument4 pagesRod Ends For The Food IndustrycchnkvPas encore d'évaluation

- 7T SubTurbine B2176BKDocument2 pages7T SubTurbine B2176BKLuis AguirrePas encore d'évaluation

- Catalogue 2012 Rs Smell DriveDocument7 pagesCatalogue 2012 Rs Smell Driveshannon7440Pas encore d'évaluation

- NL Maritime News 28-Mar-13Document5 pagesNL Maritime News 28-Mar-13vu2jabPas encore d'évaluation

- Guide Specification Walls, Interior, Wood or Metal Studs, Cementitious Backer Unit, Latex-Portland Cement Mortar, TCNA W244C-07Document5 pagesGuide Specification Walls, Interior, Wood or Metal Studs, Cementitious Backer Unit, Latex-Portland Cement Mortar, TCNA W244C-07alex_geus5080Pas encore d'évaluation

- MS For Installation - Hypochlorination 23.10.07 HamdyDocument8 pagesMS For Installation - Hypochlorination 23.10.07 HamdyunnicyriacPas encore d'évaluation

- HBV3 Policy Certificate 30339144201501Document3 pagesHBV3 Policy Certificate 30339144201501srvbaksiPas encore d'évaluation

- Turbojet Engines - TechnologyDocument3 pagesTurbojet Engines - TechnologyzahraPas encore d'évaluation

- Indian Cement IndustryDocument27 pagesIndian Cement IndustrySubhamay Biswas100% (1)

- Monthly Progress Report For The Month of May, 2015 Double Tracking Project Between Laksam and Chinki-Astana. (NO. DCRDP/LCDL/W-1)Document6 pagesMonthly Progress Report For The Month of May, 2015 Double Tracking Project Between Laksam and Chinki-Astana. (NO. DCRDP/LCDL/W-1)linkon75Pas encore d'évaluation

- Feasibility of Bangalore Metro Rail Project (Namma Project)Document94 pagesFeasibility of Bangalore Metro Rail Project (Namma Project)vabsPas encore d'évaluation

- The Asphalt Lining of A Large Water Reservoir Near Bengazi - SchmidDocument6 pagesThe Asphalt Lining of A Large Water Reservoir Near Bengazi - Schmidmivos4Pas encore d'évaluation

- CrosbyDocument1 pageCrosbybdispoPas encore d'évaluation

- Firme America Expo ShoesDocument6 pagesFirme America Expo ShoesRodion RussuPas encore d'évaluation

- Gap Analysis ReportDocument17 pagesGap Analysis ReportVageesha Shantha Veerabhadra SwamyPas encore d'évaluation

- 35inch Concrete Median Barrier Cast-In-PlaceDocument1 page35inch Concrete Median Barrier Cast-In-PlaceSudathipTangwongchaiPas encore d'évaluation