Académique Documents

Professionnel Documents

Culture Documents

Sample Paper: Food and Beverage Operations Semester III BHMTT

Transféré par

Ashish DigheTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sample Paper: Food and Beverage Operations Semester III BHMTT

Transféré par

Ashish DigheDroits d'auteur :

Formats disponibles

Sample Paper

Food and Beverage Operations Semester III BHMTT

by Ashish M. Dighe Exam conducted on: 12|10|2010

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 1

a. Estate Bottled: Wine that has been made and bottled at the same estate is called as an estate bottled wine. b. DOC: (Denominazione di Origine Controllata)It is the Italian equivalent of an French AOC quality standard. When DOC appears on the label it indicates that wine was made from specied grapes grown in the demarcated area. The DOC system established a method of both recognizing quality product and maintaining the international and national reputation of that product. c. Doux: Usually describes the sweetness of champagnes and sparkling wines. Normally doux wines are described as luscious, aromatic and fruity and contain around 8% and upwards of sugar in dosage. d. Demi-Sec: Usually describes the sweetness of wines. Demi-Sec means a sweet wine with around 4-6% sugar in dosage. e. Mash: In the process of making beer, the malt is milled into a ne grist and then mixed with hot water. This brewing operation last for around 1-2 hours. This process helps in breaking down the starches to more soluble sugars and is performed in a large mash tun and the resultant liquid is called as a mash. f. Punt: A punt, also known as a kick-up, refers to the dimple at the bottom of a wine bottle. It is present in a variety of wine bottles. The most commonly cited explanations for a punt have been 1) It consolidates sediment deposits in a thick ring at the bottom of the bottle, preventing much/most of it from being poured into the glass and 2) It increases the strength of the bottle, allowing it to hold the high pressure of sparkling wines/champagnes. g. Remuage: Remuage or riddling is the traditional method used to clear the wine. The bottles are taken to a holed wooden frame called puptre. This is made of two rectangular boards hinged together to form an inverted V shape. The remueur manipulates the bottles, turning and tilting each one gradually to encourage the sediment into the neck of the bottle. At the end of this operation the bottles will be almost vertical and the sediment resting on the cap. h. Refractometer: A hand held instrument or optical device used to gauge the sugar content within the grapes while they are still on the vine; it helps to assess whether the grapes are ready for plucking. i. Mulled wine: Heated wine avored with spices. In Germany it is called Glwein. j. Fino: This is a dry, pale, light and delicate sherry. This type of sherry is only obtained from casks that develop or and are considered as the ultimate amongst sherries.

:: Ashish Dighe ::

Page 2 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 2 (A)

Following is the owchart used to explain the process of making white wine. The making of the white wine encompasses : 1. Using white grapes such as a Riesling, Sauvignon Blanc or Chardonnay.

White Grapes

De-stalking

2. De-stalking - where stalks of all the grapes are removed. 3. Pressing of the grapes - The process involves passing the destalked grapes from an Archimedes press or a pneumatic press. This process squashes the grapes by breaking the skins until all the juice is released. 4. The treatment and fermentation of the must - During this process, the must is usually treated with sulphur dioxide and then cleansed of any remaining skin, pips and other suspended matter. Cultured yeast may be added and the wines are fermented slowly and cooly between temperatures of 15C and 20C to impart delicacy and fragrance. 5. Maturation - The wine is then left for maturing in casks for a short time.

Pressing

Fermentation

Maturation

Racking

6. Racking - Running the clear wine off its lees or sediment from one cask to another. 7. Fining - A further clarication of wine usually before bottling. A ning agent such as isinglass is added and this attracts the sediment suspended in the wine, causing it to coagulate and fall to the bottom of the container. 8. Filtration - The nal clarication before bottling. It removes any remaining suspended matter and leaves the wine healthy and star bright in appearance. 9. Bottling - The clear bright wine is then bottled and ready to be transported to wine cellars for sale.

Fining

Filtration

Bottling

:: Ashish Dighe ::

Page 3 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 2 (B)

Cigars are usually stored in a humidor. A humidor is, quite simply, a storage container designed to allow controlled air ow and equipped with a device that maintains the internal humidity in the range of 70 to 75 percent and its internal temperature in a narrow range of about 68 to 70 degrees Fahrenheit. The purpose of a humidor is to keep your cigars at their peak "smokability". The most crucial characteristic of a ne humidor is that it can provide a constant environment of about 68' to 70' F and 70-72% humidity. Cigars come in various sizes, some of which are explained below: Corona: 14.5 cm with a round top Petite Corona: 13 cm with a round top Tres Petite Corona: 11.5 cm Half Corona: 9.5 cm Lonsdale: as Corona but 16.5 cm in length Idealess: torpedo shaped, about 16.5 cm in length Londres: straight cigar , 12 cm in length Panatella: long and thin and open at both ends, 12.5 cm in length Stumpen: stubbier than a Panatella but slightly tapered, open at both ends. Whiff: usually small and open at both ends, about 8.9 cm in length.

:: Ashish Dighe ::

Page 4 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 2 (C)

The general requirements for labeling a French wine bottle for export are as follows: 1. Estate Information: The information of the chateau or the estate. 2. Quality Information: Grand Cru, Premier Cru etc. 3. Vintage: The year in which the grapes were harvested. 4. Appellation: The growing region, also called an appellation. 5. Quality Standards: An indication that the wine comes from a specied region and was produced from specically permitted grape varieties according to strict controls and regulations. 6. Proprietor Information: The name and address of the proprietor/ bottler. 7. Bottling Information: An indication that the wine was bottled at the estate. 8. The wine's alcohol content. 9. Quantity of wine: In this case measured in centiliters. The "e" denotes estimated volume in accordance with standard European Union measurements.

:: Ashish Dighe ::

Page 5 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 3 (A)

The word solera comes from the Italian word suelo meaning sole (as in shoes) but translated to mean casks touching the ground. The solera comprises of a group of casks placed one on top of the other, four or more scales high. The oldest wines wines are always in the bottom casks with the youngest criadera wines at the top. The solera system was introduced in 1800 and its purpose is to provide a consistent product. It is a system of blending and maturing. The wine required for sale is partially drawn off the from the bottom casks - no more than oe third of the volume is extracted per year. This is replaced by a similar amount of wine taken from the casks in the scale immediately above. And so it continues through the scales or tiers with the older wines beig continually refreshed and replenished by those from above. The younger wines take the characteristics of the old wines. Before bottling the wine is tested for strength, clarity an quality. During the manufacturing of sherry, the younger wines after the initial fermentation process are put into criaderas (small casks) in the nursery and are monitored for a yeast that forms a thick crust on the surface of some wines.This development is known as or. Flor seals the wine from harmful bacteria and prevents it from oxidising. It also contributes to the wines individual taste and character. The wines in criaderas that develop or are destined to become Finos; the ultimate in sherry. Those that do not develop or become Olorosos.

:: Ashish Dighe ::

Page 6 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 3 (B)

Wine should be stored in a wine cellar which is free from vibrations, excessive dampness, draughts and unwanted odors. The cellar should be absolutely clean, well ventilated, with only subdued lighting and a constant temperature of around 55 deg F (12 deg C) to help the wine develop gradually. The ideal orientation for wine bottles is at a slight angle, rather than completely horizontal. This allows the cork to maintain partial contact with the wine in order to stay damp but also keeps the air bubble formed by a wine's ullage at the top rather than in the middle of the bottle if the wine is lying on its side. Keeping the ullage near the top, allows for a slower and more gradual oxidation and maturation process. This is because the pressure of the air bubble that is the ullage space rises and falls depending on temperature uctuation. When exposed to higher temperatures the bubble's pressure increases (becomes positive relative to the air outside of the bottle, and if the wine is tilted at an angle, this compressed gas will diffuse through the cork and not harm the wine. When the temperature falls the process reverses. If the wine is completely on its side then this action will eject some wine through the cork. Through this "breathing" which can result from variations in temperature, oxygen may be repeatedly introduced into the bottle and as a result can react with the wine. While most wines can benet from lying on their side, Champagne and other sparkling wines tend to age better if they are kept upright. This is because the internal pressure caused by the trapped carbonic gas provides enough humidity and protection from oxygen. A study has found that Champagne stored on its side aged more quickly because oxygen was allowed to seep in after the Champagne corks lost their elasticity due to contact with the moist wine. Service temperature for various types of wines. 1. Red wine: 15C to 19C 2. White Wine: 8C to 12C 3. Sparkling Wine: 6C to 10C

:: Ashish Dighe ::

Page 7 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 3 (C)

Following are some of the obvious faults found in wines: 1. Weeping: This seeping of the wine from the cork can be caused by a faulty cork or when the secondary fermentation pushes the cork loose. 2. Acetication: The wine has ben affected by acetobacters through over exposure to air. The vinegar microbe develops a lm on the surface of the wine which produces acetic acid. The wine tastes sour, resembling vinegar (vin aigre = sour wine) 3. Cloudiness: This may be caused by extremes in storage temperature, excess protein, contact with metal or bacterial action or an unwanted continuation of fermentation. 4. Corked wine: This is a wine affected by a combination of chlorine present in cork and a fungus which results in formation of TCA (trichloroanisole) causing the wine to smell musty and rancid. 5. Sulphidization: It can be caused due to reduced oxygen supply which concentrates sulfurous smells arising from universal preservatives. 6. Crystalline deposits: Tartaric acid is soluble in water but not in alcohol, so an excess of potassium bitartrate may precipitate in very cold temperatures as crystals. The sugar-like crystals or minute akes, spoil the appearance of the wine but not the taste. 7. Foreign contamination: This may be caused when wines are stored in a badly kept cellar at incorrect temperatures or stored next to strong odors such as gasoline, vinegar or sh. Faulty bottling may also cause glass to splinter and get into the wine. 8. Oxidation: It is caused by too much absorption of air either before bottling or when bottled (loose cork). The wine may also have been stored in much too warm conditions. The wine tastes at and musty, having lost its fruit and brilliance.

:: Ashish Dighe ::

Page 8 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 4 (A)

The ingredients used in the beer making process are: 1. Water 2. Cereals 3. Yeast and 4. Hops 5. Sugar and 6. Fining Agents Water: Water is the main ingredient for beer. In brewing parlance it is called as liquor. It must be biologically pure and its mineral content assured. It can be softened or hardened. Hard water is ideal for lager whereas soft water is more suitable for heavier beers. Historically, brewers have depended for their supply on local wells where the mineral composition of the water has come through natural resources. Cereals: Cereals are the raw material most commonly used in brewing. Although wheat, rice, sorghum, millet, rye, cassava, rice, maize and even green bananas are still used to produce alcoholic drinks with some resemblance to beer, the mainstay of the brewing industry worldwide is barley. Before it can be used to brew beer, barley has to be made into malt, thereby transforming its starch content into fermentable sugars. After steeping in water, it is left to germinate in a warm environment, then heated in a process called as kilning, which gives a more or less dark color to the malt and likewise to the resulting beer. Hops: The common hop (Humulus lupulus) is a quick-growing plant reaching from 5 to 7 meters in height. It is the cone shaped female owers that are mainly used in brewing, though British producers use male hops. Small though it may be the hop cone contains a wealth of resins and essential oils; in fact more than 200 aromatic components have been identied. It is these that turn the sugary juices resulting from the brewing process into avorsome beers. Hops contain several characteristics that brewers desire in beer. Hops contribute a bitterness that balances the sweetness of the malt; they also contribute oral, citrus, and herbal aromas and avors to beer. Hops have an antibiotic effect that avors the activity of brewer's yeast over less desirable microorganisms, and hops aids in "head retention", the length of time that a foamy head created by carbonation will last. The acidity of hops acts as a preservative. Yeasts: The most important stage is undoubtedly fermentation, since it is this that dictates the type of beer that will result. There are two main types of fermentation. Top Fermentation The older of the two, is effected at 15 20C over a relatively short period (three to ve days), with yeast (Saccharomyces cerevisiae) that rises to the surface of the beer. It produces beers that are dense, full-avored and long in the mouth; Bottom Fermentation The most widely practiced method nowadays, takes between seven and ten days at lower temperatures (6 8C). The yeasts (Saccharomyces carlsbergensis) remain at the bottom of the fermentation vessel. There is also a third spontaneous - fermentation process, employed in Belgium to produce lambic and gueuze beers. It relies on yeasts which occur naturally in the atmosphere in a restricted region to the south of Brussels, Belgium. Sugar: Used basically to facilitate fermentation in the form of priming sugar and is also used to add sweetness to some brown ales and sweet stouts. Fining agents: Finings are used to clarify beer. A variety of ning agents can be used such as albumen, bentonite or isinglass.

:: Ashish Dighe :: Page 9 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 4 (B)

Aperitif means to open or drinks served at the start of a meal or before the meal to stimulate the appetite. Aperitifs can be of the following types. Bitters Fortied Wines Aromatized Wines and Absinthe and Pastis Some well known French aperitifs wines are as follows: 1. Dubonnet - Modern versions have a wine base avored with quinine and bitter herbs with additions of mistelle and spirit. This popular aperitif may be blonde (white) or rouge (red). 2. Lillet - A favorite in France, Lillet is made from white Bordeaux wine, herbs and fruit peel and fortied with Armagnac brandy. 3. Suze - Suze is a bright yellow French aperitif avored with gentian and herbs. It is bitter in avor with supposedly digestive properties and 4. Pineau des Charentes - This is an increasingly popular sweet aperitif from the Cognac area. Pineau is a heady mixture of Cognac and grape juice.

:: Ashish Dighe ::

Page 10 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 4 (C)

Malting the cereals is required for brewing. Malting has three distinct steps: 1. Steeping: The barley or other cereals are screened to remove any extraneous matter and then is put in a large tank and steeped in water till it has a moisture content of 45%. The grain absorbs water and oxygen which leads to germination. 2. Germination: This is where the starch and protein in the grains are broken down into sugars and amino acids. The moist grain is spread onto a malting oor. It is frequently turned to regulate growth and temperature and provide oxygen to assist germination. As the grain sprouts the enzymes begin to convert the starch into sugars, mainly maltose with small amounts of fructose, lavulose and glucose. 3. Kilning: When the germination has reached the desired stage, further development is stopped by kilning. The grain is dried by hot air and moisture content reduced to around 5%. Depending on the intensity and duration of kilning, different colored malts are produced. Before it can be used to brew beer, barley has to be made into malt, thereby transforming its starch content into fermentable sugars. After steeping in water, it is left to germinate in a warm environment, then heated in a process called as kilning, which gives a more or less dark color to the malt and likewise to the resulting beer. Types of malt: Pale malt the lightest kilned malt, this retains the maximum amount of sugar. It is used for many of the lighter beers. Lager malt this is lightly roasted and suited to lager production. Crystal malt Medium roasted and deep golden in color, this is used in the production of deeper colored and fuller bodied beers. Chocolate or black malt deep roasted with a chocolate color and bitter avor, this is used to produce stout and porter.

:: Ashish Dighe ::

Page 11 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 5 (A)

Madeira is made from Sercial, Verdelho, Bual and Malmsey grapes. All grape varieties are white grapes. The vinication process is pretty similar to that of other fortied wines such as port and sherry. Their fermentation is arrested by the addition of a grape spirit such as brandy. Around the 18th century it was noticed that casks of Madeira when used as ballasts on ships going to and from the East Indies had improved considerably in avor on their return. It seemed that crossing the equator on the long sea journey imparted an attractive cooked avor to the wine. What makes Madeira wine production unique is the estufagem aging process meant to duplicate the effect of a long sea voyage of the aging barrels through tropical climates. There are three main methods used to heat age the wine, used according to the quality and cost of the nished wine. 1. The most common, (Cuba de Calor) used for low cost Madeira, is bulk aging in low stainless steel or concrete tanks surrounded by either heat coils or piping that allows hot water to circulate around the container. The wine is heated to temperatures as high as 130F (55C) for a minimum of 90 days as regulated by the Madeira Wine Institute. 2. The second method (Armazm de Calor) only used by the Madeira Wine Institute, involves storing the wine in large wooden cask in a specially designed room outtted with steam producing tanks or pipes that heat the room, creating a type of sauna. This process more gently exposes the wine to heat and can last from six months to over a year. 3. The third method (Canteiro) is used for the highest quality Madeiras aged without the use of any articial heat, being stored by the winery in warm rooms left to age by the heat of the sun. In cases like vintage Madeira, this heating process can last for from 20 years to 100 years. Shippers of Madeira: 1. Averys 2. Blandy 3. Cossart Gordon 4. Faria J. & Filhos 5. Ferraz, F. F. & Co 6. Leacock & Co 7. Lomelino, Tarquinio Torquato da Camara and 8. Miles Madeira

:: Ashish Dighe ::

Page 12 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 5 (B)

Guidelines that can be followed when contemplating wine and food partnerships are as follows: Most foods can be successfully accompanied by several styles of wine. White and Rose wines are usually more versatile than red wines. This is an important consideration if one wine is being chosen to accompany the complete meal. Regional pairings are normally very successful. The simpler the food the more the wine is likely to shine. The ner the food the more it is likely to show up inferior wine. Look at the complete dish and not just the main food component. Identify the principal avors. Often the sauce will decide the wine. The weight and body of the wine should match the character and avor intensity of the food. Serve light wine with delicate food. Serve full-bodied wines with full-avored, assertive foods. Match dry with dry, rich with rich. Food avored with spices go best with aromatic or aggressively brash wines. With sweets and puddings the food nearly comes off better than the wine. Sweet wines are probably the best bet. When a particular food is served hot, it requires a more assertive wine than it does when served cold.

:: Ashish Dighe ::

Page 13 of 14

:: 12|10|2010 ::

:: Food and Beverage Service Operations ::

:: Semester 3 ::

Answer No: 5 (C)

The generic Italian term for fully sparkling wine is Spumante and slightly sparkling wine is Frizzante. Astis a sparkling white Italian wine that is produced throughout southeastern Piedmont but is particularly focused around the towns of Asti and Alba. Since 1993 the wine has been classied as a Denominazione di Origine Controllata e Garantita (DOCG) and as of 2004 was Italy's largest producing appellation. In fact, on an average vintage more than ten times as much Asti is produced in Piedmont than the more well-known Piedmontese red wine Barolo. Made from the Moscato Bianco grape, it is sweet and low in alcohol, and often served with dessert. Unlike Champagne, Asti is not made sparkling through the use of secondary fermentation in the bottle but rather through a single tank fermentation utilizing the Charmat method. It retains its sweetness through a complex ltration process. Another wine called Moscato d'Asti is made in the same region from the same grape, but is only slightly sparkling (frizzante) and tends to have even lower alcohol. XXX

:: Ashish Dighe ::

Page 14 of 14

Vous aimerez peut-être aussi

- Beverages KnowledgeDocument104 pagesBeverages Knowledgecucucucucu72Pas encore d'évaluation

- International Wines: FranceDocument18 pagesInternational Wines: FranceAshish DighePas encore d'évaluation

- International Wines: FranceDocument18 pagesInternational Wines: FranceAshish DighePas encore d'évaluation

- 40221390-Dehydrated-Onion - MarketDocument13 pages40221390-Dehydrated-Onion - MarketGourav TailorPas encore d'évaluation

- The Origins of Brewing Technology in MesopotamiaDocument20 pagesThe Origins of Brewing Technology in MesopotamiaHathor83Pas encore d'évaluation

- Microsoft Word - Kitchen Math W PDFDocument13 pagesMicrosoft Word - Kitchen Math W PDFAGPas encore d'évaluation

- The Wine BottleDocument14 pagesThe Wine BottleAshish DighePas encore d'évaluation

- Wine Knowledge Course NotesDocument26 pagesWine Knowledge Course NotesJake Porter100% (1)

- WinemakingDocument11 pagesWinemakingAshwin Babu VarghesePas encore d'évaluation

- Champagne Guide - Sotheby's Tom Stevenson BookDocument228 pagesChampagne Guide - Sotheby's Tom Stevenson BookPras_Pamungkas_4128Pas encore d'évaluation

- Alcoholic Beverages PDFDocument55 pagesAlcoholic Beverages PDFKricel Maquera0% (1)

- Lesson 3 - Introduction To WineDocument20 pagesLesson 3 - Introduction To WineMosh_CDPas encore d'évaluation

- Types of Wine GlassesDocument11 pagesTypes of Wine GlassesSharon CowanPas encore d'évaluation

- Sparkling Wine ProductionDocument6 pagesSparkling Wine ProductionblasonBourgognePas encore d'évaluation

- NA - The Bubba Gump Shrimp Co. CookbookDocument111 pagesNA - The Bubba Gump Shrimp Co. CookbookŢiţei Johnny100% (1)

- Beginning Wine - Prirucnik Za Proizvodnju Vina Namenjen Pocetnicima Na Engleskom Jeziku Napisan.Document48 pagesBeginning Wine - Prirucnik Za Proizvodnju Vina Namenjen Pocetnicima Na Engleskom Jeziku Napisan.vladimir2401Pas encore d'évaluation

- WinemakingDocument51 pagesWinemakingsorindediuPas encore d'évaluation

- Beverage Knowledge Book TwoDocument104 pagesBeverage Knowledge Book TwoAgustinus Agus Purwanto100% (4)

- EYO Scouting 14-Week CalendarDocument17 pagesEYO Scouting 14-Week Calendarjeff_cunningham_11Pas encore d'évaluation

- French WineDocument20 pagesFrench WinemaricieloPas encore d'évaluation

- Glossary of Wine TermsDocument30 pagesGlossary of Wine Termsnitin0010Pas encore d'évaluation

- CassavaKroepeck Pilar 2010Document6 pagesCassavaKroepeck Pilar 2010Anonymous yIlaBBQQPas encore d'évaluation

- What Is WineDocument11 pagesWhat Is WineAmjad KhattakPas encore d'évaluation

- Wines - An Introduction (1.1 To 1.3)Document10 pagesWines - An Introduction (1.1 To 1.3)Ashish DighePas encore d'évaluation

- 5 Stages of Wine ProcessDocument18 pages5 Stages of Wine ProcessJasmyn AgustinPas encore d'évaluation

- Storing and Serving WineDocument3 pagesStoring and Serving WineJoao RicoPas encore d'évaluation

- Week 1 - StudentDocument82 pagesWeek 1 - StudentAnny HoPas encore d'évaluation

- Basic of Wine EnglishDocument9 pagesBasic of Wine EnglishMira PranadewiPas encore d'évaluation

- Wines From ItalyDocument20 pagesWines From ItalyAshish DighePas encore d'évaluation

- IHM 2nd Year FNB Service NotesDocument163 pagesIHM 2nd Year FNB Service NotesHarsh Misra90% (29)

- Sparkling WinesDocument5 pagesSparkling WinesamanPas encore d'évaluation

- Tavern Keepers From Public Drinking in The Early Modern WorldDocument36 pagesTavern Keepers From Public Drinking in The Early Modern WorldPickering and ChattoPas encore d'évaluation

- Beverage Service Styles and Techniques: Unit 8Document33 pagesBeverage Service Styles and Techniques: Unit 8Tin PortuzuelaPas encore d'évaluation

- Hygiene Design Powder Processing PlantsDocument18 pagesHygiene Design Powder Processing Plantsthouche007Pas encore d'évaluation

- Housekeeping Department and Other Department CoordinationDocument8 pagesHousekeeping Department and Other Department CoordinationDzeiy Euhm Tan Angeles0% (1)

- Sample Paper: Food and Beverage Operations Semester III BHMTTDocument13 pagesSample Paper: Food and Beverage Operations Semester III BHMTTAshish DighePas encore d'évaluation

- Bar and LiquorDocument8 pagesBar and LiquorEkoh EndurancePas encore d'évaluation

- Sparkling Wine and Champagne HandoutsDocument10 pagesSparkling Wine and Champagne HandoutsTina Tahilyani�Pas encore d'évaluation

- Methode ChampenoiseDocument17 pagesMethode ChampenoiseShubham Sharma0% (1)

- WineDocument29 pagesWinecaldarusbiancaadelaPas encore d'évaluation

- In The Vineyard: ViticultureDocument66 pagesIn The Vineyard: ViticultureÆron DeManPas encore d'évaluation

- Wine Knowledge HandbookDocument27 pagesWine Knowledge HandbookjaePas encore d'évaluation

- Wine Production Methods15.4.24Document3 pagesWine Production Methods15.4.24mayank daultaniPas encore d'évaluation

- Food & Beverage Sekt and CavaDocument27 pagesFood & Beverage Sekt and CavaSandeep KumarPas encore d'évaluation

- Australian Wine Familiarisation AnswersDocument20 pagesAustralian Wine Familiarisation AnswersKPas encore d'évaluation

- Chapt 2.wines of WorldDocument46 pagesChapt 2.wines of Worldsahilphapale12Pas encore d'évaluation

- A Chemical IndustryDocument4 pagesA Chemical IndustryKijoci TharmapalanPas encore d'évaluation

- Wine-Distilled Beverage-Vinegar-Fermented VegetablesDocument134 pagesWine-Distilled Beverage-Vinegar-Fermented VegetablesSumit KumarPas encore d'évaluation

- Wine ProductionDocument134 pagesWine ProductionChiriac MihaelaPas encore d'évaluation

- 8 BrandyDocument13 pages8 BrandyOrkhan SchevchenkoPas encore d'évaluation

- Week 7 - StudentDocument58 pagesWeek 7 - StudentAnny HoPas encore d'évaluation

- Vinos 1Document2 pagesVinos 1Noe AmanchaPas encore d'évaluation

- Red Wine Is A Type ofDocument6 pagesRed Wine Is A Type ofgritchard4Pas encore d'évaluation

- VinificationDocument4 pagesVinificationAkhil ChandranPas encore d'évaluation

- Champagne Basic KnowledgeDocument1 pageChampagne Basic KnowledgePadu RasaPas encore d'évaluation

- Explanation of Process FlowDocument3 pagesExplanation of Process FlowKent John Labaclado DugaPas encore d'évaluation

- HJ ChampagneDocument6 pagesHJ ChampagneHemant JaluthriaPas encore d'évaluation

- c9s12 2Document9 pagesc9s12 2Babul Kumar MishraPas encore d'évaluation

- Online Wine Course 1 PDFDocument5 pagesOnline Wine Course 1 PDFVillafranca LauraPas encore d'évaluation

- Definition of WineDocument22 pagesDefinition of WineDesy RollistantiPas encore d'évaluation

- WSET L3 - 1 - Chap03 - Storage and Service of WineDocument6 pagesWSET L3 - 1 - Chap03 - Storage and Service of WineKen KaoPas encore d'évaluation

- Winery Report 13-02-2023 PDFDocument40 pagesWinery Report 13-02-2023 PDFpranay krishnaPas encore d'évaluation

- Italian Tank Fermented Sparkling WinesDocument5 pagesItalian Tank Fermented Sparkling WinesIvan ClavierPas encore d'évaluation

- History: Brandy (From Brandywine, Derived FromDocument6 pagesHistory: Brandy (From Brandywine, Derived FromКуенние ЦацхумбоPas encore d'évaluation

- Prathamesh WineDocument36 pagesPrathamesh WinePankaj ThakurPas encore d'évaluation

- Restaurant:-: Food Drink Dessert Customers Meals Take-Out Food Delivery Services Cuisines Service Inns Taverns AntiquityDocument3 pagesRestaurant:-: Food Drink Dessert Customers Meals Take-Out Food Delivery Services Cuisines Service Inns Taverns AntiquityAMAR_BANGARPas encore d'évaluation

- UntitledDocument41 pagesUntitledNichole John ErnietaPas encore d'évaluation

- Technology: Balneo MariaeDocument3 pagesTechnology: Balneo MariaehikivarvasPas encore d'évaluation

- Questions on the Bottle House and Racking Room Procedure in the Beer Brewing ProcessD'EverandQuestions on the Bottle House and Racking Room Procedure in the Beer Brewing ProcessPas encore d'évaluation

- U.I L.II The Art of WinemakingDocument11 pagesU.I L.II The Art of WinemakingDoinita DumanovPas encore d'évaluation

- Unit Test-2 AnswersDocument10 pagesUnit Test-2 AnswersAshish DighePas encore d'évaluation

- SherryDocument14 pagesSherryAshish DighePas encore d'évaluation

- Food and WineDocument9 pagesFood and WineAshish DighePas encore d'évaluation

- Wines of PortugalDocument25 pagesWines of PortugalAshish DighePas encore d'évaluation

- Practical 9Document4 pagesPractical 9Ashish DighePas encore d'évaluation

- Papers 4Document12 pagesPapers 4Ashish DighePas encore d'évaluation

- Papers 2Document12 pagesPapers 2Ashish DighePas encore d'évaluation

- Papers 3Document11 pagesPapers 3Ashish DighePas encore d'évaluation

- Practical 5Document7 pagesPractical 5Ashish DighePas encore d'évaluation

- Papers 5Document12 pagesPapers 5Ashish DighePas encore d'évaluation

- Practical No: 10 Wine Lists and Role of Sommelier:: Writing A B.O.TDocument3 pagesPractical No: 10 Wine Lists and Role of Sommelier:: Writing A B.O.TAshish DighePas encore d'évaluation

- Food and Wine - GermanyDocument6 pagesFood and Wine - GermanyAshish DighePas encore d'évaluation

- Wines of PortugalDocument25 pagesWines of PortugalAshish DighePas encore d'évaluation

- On The Ball German Wines at A GlanceDocument20 pagesOn The Ball German Wines at A GlanceAshish DighePas encore d'évaluation

- Service of Cigars: EQUIPMENT REQUIRED: Cigar Cutters, Lighter, Humidor With Cigars. ProcedureDocument4 pagesService of Cigars: EQUIPMENT REQUIRED: Cigar Cutters, Lighter, Humidor With Cigars. ProcedureAshish DighePas encore d'évaluation

- ChampagneDocument18 pagesChampagneAshish DighePas encore d'évaluation

- Setting Up Covers For Menu With Wines: Formal DinnerDocument7 pagesSetting Up Covers For Menu With Wines: Formal DinnerAshish DighePas encore d'évaluation

- Practical 6Document2 pagesPractical 6Ashish DighePas encore d'évaluation

- GermanyDocument21 pagesGermanyAshish DighePas encore d'évaluation

- Practical 9Document4 pagesPractical 9Ashish DighePas encore d'évaluation

- Wines - PresentationDocument26 pagesWines - PresentationAshish DighePas encore d'évaluation

- Practical 4Document10 pagesPractical 4Ashish DighePas encore d'évaluation

- Why Pork Is Red Meat?Document1 pageWhy Pork Is Red Meat?Ashish DighePas encore d'évaluation

- Kur KureDocument9 pagesKur KureJoly SinghPas encore d'évaluation

- Brand Audit BrandingDocument8 pagesBrand Audit Brandingcasey_d_rowePas encore d'évaluation

- CV For UAEDocument5 pagesCV For UAEfahd_lodhi8478Pas encore d'évaluation

- The Pink Rumor: Vol. 2 Issue 2Document2 pagesThe Pink Rumor: Vol. 2 Issue 2Paola Diamante BrillantePas encore d'évaluation

- Final Report Based On 60 Days Market Work As A Nilons' Army Soldier in Mumbai MarketDocument54 pagesFinal Report Based On 60 Days Market Work As A Nilons' Army Soldier in Mumbai MarketKabir SinghPas encore d'évaluation

- Case StudyDocument2 pagesCase Studyhafiz501Pas encore d'évaluation

- Red ProjectDocument30 pagesRed ProjectApoorva SrivastavaPas encore d'évaluation

- Pickering Emulsion Face Cream (O - W) With AEROSIL® R 816Document2 pagesPickering Emulsion Face Cream (O - W) With AEROSIL® R 816Yeraldine RVPas encore d'évaluation

- Marketing PlanDocument21 pagesMarketing PlanRosemarie A. EnorPas encore d'évaluation

- Pizza Hut Brief HistoryDocument2 pagesPizza Hut Brief HistoryJiingYonngPas encore d'évaluation

- Industry Visit ReportDocument11 pagesIndustry Visit ReportLovely PoacherPas encore d'évaluation

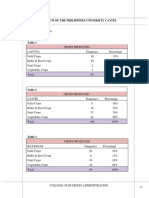

- Lyceum of The Philippines University CaviteDocument17 pagesLyceum of The Philippines University Cavitecherry valePas encore d'évaluation

- Project On BingoDocument28 pagesProject On BingoViPul50% (2)

- Individual Assignment Pricing Strategy For Mcdonald'SDocument6 pagesIndividual Assignment Pricing Strategy For Mcdonald'SfatruroziPas encore d'évaluation

- Zouq Report For Supply Chain ManagementDocument20 pagesZouq Report For Supply Chain ManagementMuhammadSaad100% (1)

- Questions To Ask On Your Restaurant Survey: The Two Most Important QuestionsDocument4 pagesQuestions To Ask On Your Restaurant Survey: The Two Most Important QuestionsNelson AindPas encore d'évaluation

- Corn Puff DPRDocument24 pagesCorn Puff DPR03 Sahithi PanchadiPas encore d'évaluation

- Brittania BiscuitDocument78 pagesBrittania BiscuitgoswamiphotostatPas encore d'évaluation

- Kitchen ToolsDocument12 pagesKitchen ToolsZie BeaPas encore d'évaluation

- Infant Formulas: Complete Packaging Handling Systems ForDocument2 pagesInfant Formulas: Complete Packaging Handling Systems Fornarras11Pas encore d'évaluation

- LBJ OctoberDocument6 pagesLBJ Octoberapi-276043152Pas encore d'évaluation