Académique Documents

Professionnel Documents

Culture Documents

Cat+Bearings PHEJ0032

Transféré par

Amjad ShahDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cat+Bearings PHEJ0032

Transféré par

Amjad ShahDroits d'auteur :

Formats disponibles

Cat Bearings

Ball Cylindrical Cylindrical Cylindrical

Tapered Roller Needle Tapered Roller

Total system design for application-driven performance

Just because two bearings have the same industry part number doesnt mean theyre the same. Outside diameter, heat treatment, surface finish, internal clearance, or profile may differand because bearings position other components, these differences are critical. Improper fit can lead to premature, expensive gear failure and damage of other components. Cat bearings are designed for specific applications based on load, operating speed, temperature range, size, and past performance. Theyre also matched to last as long as other Cat drive train components, reducing the number of repairs required, along with downtime and operating costs. Installing other brands of bearings compromises balanced wear lifewasting the extra life Caterpillar designs into its drive train components.

Caterpillar. The difference counts.

Cat Dealers define world-class product support. We offer you the right parts and service solutions, when and where you need them. The Cat Dealer network of highly trained experts keeps your entire fleet up and running to maximize your equipment investments.

Exclusive Cat technology for 2x the bearing life

Cat debris-resistant bearings provide up to twice the life of other bearings in demanding applications, thanks to proprietary heat treat processes and special material characteristics that create a high-strength surfaceblunting the stresses caused by contaminants in oil and preventing cracks from developing. Cat textured bearings feature a unique surface finish that eliminates frosting caused by the metal-to-metal contact that can occur in slow-speed, high-load applications. The result is better lubrication and twice the bearing life in Cat machine applications.

Cat BearingsGenuinely Better

Application-specific design

MODEL % SPECIAL BEARINGS

Industry number comparison

Caterpillar bearings have key quality differences most other bearings do not, including:

Special material technology

A

777D

75%

T

793C

79%

966G

65%

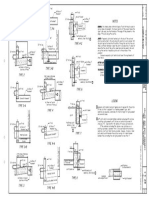

CAT BEARING INDUSTRY STANDARD Pin cage design Used in very slow speed applications Group roller design Premature wear will occur as a result of roller contact

Caterpillar spends significant amounts of time and money on research and development to ensure every Cat bearing meets specific design and application requirements. This commitment has led to new technologies like Cat debris-resistant and textured bearings available exclusively through Cat Dealers.

Cat specifications

Cat bearings are designed for specific applications and functions based on the loads, operating speeds, temperature ranges, and sizes of the Cat machines in which they operateinformation other bearing manufacturers dont have. Cat bearings designed and manufactured for Cat machines perform better and last longer.

972G

67%

X bar cage Strong design

992G

71%

Used in high speed/torque applications

Above are just a few examples of where Caterpillar utilizes highly specialized bearings.

Case-hardened heat treatment

CAT ROLLING ELEMENT

Optimized roller profile for maximum performance and life

Bearings are exposed to three types of loading conditions: standard loading in normal applications, heavy-duty loading in high-performance applications, and misaligned loading in applications where the load is distributed unequally over the bearing surface. Cat bearings feature a specialized roller profile to minimize the stresses experienced by the roller in these multiple loading conditions. Less stress leads to significantly longer life and greater reliability.

Cat bearings are manufactured using proprietary heat treat processes to ensure maximum life. Cat roller element bearings, for example, are case carburizeda highly specialized process that puts a hard shell around the bearing material, provides a tough bearing core, and extends wear life.

Optimized Load Distribution

Optimum surface finish

Cat bearings feature appropriate surface finishes to reduce rolling resistance and ensure proper oil film thickness. The result is longer bearing life matched to the life of other drive train components, reducing repair costs and downtime.

OTHER ROLLING ELEMENT

High Edge Stress

Precise tolerances

Cat bearings are designed to ensure proper alignment and precise fit, eliminating the chance of premature gear failure due to inexact tolerancesresulting in increased machine availability and lower costs.

Convenient kits for affordable repairs

To save you time and money during scheduled maintenance, we offer several bearing kits with all the parts necessary for bearing replacement. Each kit features genuine Cat bearings imprinted with the Caterpillar part number to ensure you get the correct components for your application. Available off-the-shelf worldwide, Cat bearing kits cost a fraction of what youd pay for the individual parts. For more information about Caterpillar bearings and our complete line of drive train components for all Cat machines and applications, give us a call.

PEHJ0032

www.CAT.com

Printed in the U.S.A.

2003 Caterpillar

Vous aimerez peut-être aussi

- Bottled Water Report Oct-Dec. 2016Document21 pagesBottled Water Report Oct-Dec. 2016Amjad ShahPas encore d'évaluation

- Tareekh Ibne Khaldoon - MuqaddimahDocument767 pagesTareekh Ibne Khaldoon - MuqaddimahMusalman Bhai100% (10)

- Green Chemistry Test Questions LibraryDocument8 pagesGreen Chemistry Test Questions LibraryAmjad Shah100% (4)

- Chemistry 11 TH 12 THDocument52 pagesChemistry 11 TH 12 THSudhir ChhetriPas encore d'évaluation

- Shell Mysella S2 Z 40 Old Name R-40Document2 pagesShell Mysella S2 Z 40 Old Name R-40Amjad ShahPas encore d'évaluation

- Palm ch9Document44 pagesPalm ch9Amjad ShahPas encore d'évaluation

- MATLABch 06Document58 pagesMATLABch 06Amjad ShahPas encore d'évaluation

- INTRODUCTION TO MATLAB CHAPTER No.04Document76 pagesINTRODUCTION TO MATLAB CHAPTER No.04Amjad ShahPas encore d'évaluation

- L92 InverseKinematicsDocument66 pagesL92 InverseKinematicsAmjad ShahPas encore d'évaluation

- Biogas Power PlantDocument4 pagesBiogas Power PlantAmjad ShahPas encore d'évaluation

- Manual LammpsDocument1 284 pagesManual LammpsvillettaPas encore d'évaluation

- Pipe Schedules Chart Imperial and Metric HFT50-WEB-PDocument7 pagesPipe Schedules Chart Imperial and Metric HFT50-WEB-PAmjad ShahPas encore d'évaluation

- Intrinsic and Extrinsic MotivationDocument33 pagesIntrinsic and Extrinsic MotivationAmjad ShahPas encore d'évaluation

- Plumbing, Pipe Fitting, and SewerageDocument275 pagesPlumbing, Pipe Fitting, and SewerageRob GillespiePas encore d'évaluation

- MATLABch 10Document64 pagesMATLABch 10Amjad ShahPas encore d'évaluation

- The Kile Handbook: Jonathan Pechta Federico Zenith Holger Danielsson Thomas Braun Michel Ludwig Felix MauchDocument75 pagesThe Kile Handbook: Jonathan Pechta Federico Zenith Holger Danielsson Thomas Braun Michel Ludwig Felix MauchAmjad ShahPas encore d'évaluation

- MATLABch 06Document58 pagesMATLABch 06Amjad ShahPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Crane Control and Automation: Global SolutionsDocument32 pagesCrane Control and Automation: Global SolutionsstoneminerPas encore d'évaluation

- 2003-Blanco-caron-lesca-scipDeveloping Capabilities To Create Collective IntelligenceDocument15 pages2003-Blanco-caron-lesca-scipDeveloping Capabilities To Create Collective IntelligenceWallacyyyPas encore d'évaluation

- Sachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Document5 pagesSachpazis - 4 RC Piles Cap Design With Eccentricity Example (BS8110-PART1-1997)Costas SachpazisPas encore d'évaluation

- Result - VAS - B Tech S5 (R& S) Dec 2019 PDFDocument49 pagesResult - VAS - B Tech S5 (R& S) Dec 2019 PDFGjPas encore d'évaluation

- Civil Engineering Reaction 1Document2 pagesCivil Engineering Reaction 1Angelica Joyce Muñoz100% (4)

- Roy&Shenoy - Company ProfileDocument29 pagesRoy&Shenoy - Company ProfileroyshenoyPas encore d'évaluation

- ECE Regular Syllabus CBCS 1466004199887Document150 pagesECE Regular Syllabus CBCS 1466004199887NikeshPas encore d'évaluation

- Training PDFDocument1 164 pagesTraining PDFMohammed Abdelsalam0% (1)

- ODOT CurbTypesDocument1 pageODOT CurbTypesJordan ParkerPas encore d'évaluation

- Highrise Building Design in Midas Gen - FinalDocument65 pagesHighrise Building Design in Midas Gen - Finalagusyudianto_aca100% (2)

- Choice Code: 627819110 Course Name: Civil Engineering (First Shift) Total Seats: 30 (CAP Seats: 30)Document12 pagesChoice Code: 627819110 Course Name: Civil Engineering (First Shift) Total Seats: 30 (CAP Seats: 30)Saurabh DeshmukhPas encore d'évaluation

- Intro Load PathDocument41 pagesIntro Load PathanhnguyenhaiPas encore d'évaluation

- Calculations For Slab Analysis & DesignDocument11 pagesCalculations For Slab Analysis & DesignAyoola OluwadotunPas encore d'évaluation

- FEKO Software For Automotive 2016Document2 pagesFEKO Software For Automotive 2016UdhamPas encore d'évaluation

- IABSE Symposium Report Volume 108Document4 pagesIABSE Symposium Report Volume 108w1000000Pas encore d'évaluation

- Bridge Design Manual M 23-50.06 July 2011Document1 316 pagesBridge Design Manual M 23-50.06 July 2011monolith80Pas encore d'évaluation

- 200 3PS E00x 00001 000Document30 pages200 3PS E00x 00001 000Henry MontenegroPas encore d'évaluation

- BN I CatalogDocument120 pagesBN I CatalogMujjo SahbPas encore d'évaluation

- WebtocDocument15 pagesWebtocBeurus SamaPas encore d'évaluation

- 1 Hyundai Elevator ProfileDocument10 pages1 Hyundai Elevator ProfileAndi Muhammad Nur PutraPas encore d'évaluation

- Power Electronic Inverters and Energy ConversionDocument23 pagesPower Electronic Inverters and Energy ConversionHeinzPas encore d'évaluation

- Power System Analysis SimulationDocument78 pagesPower System Analysis SimulationAkah PreciousPas encore d'évaluation

- Monterey Peninsula Engineering and Neill Engineers 04-04-16Document15 pagesMonterey Peninsula Engineering and Neill Engineers 04-04-16L. A. PatersonPas encore d'évaluation

- Electricity Bill Payment-1Document44 pagesElectricity Bill Payment-1shajanPas encore d'évaluation

- Masters in Architecture SyllabusDocument25 pagesMasters in Architecture SyllabusfruslswwwPas encore d'évaluation

- Free Download Here: Besavilla Engineering Mathematics PDFDocument2 pagesFree Download Here: Besavilla Engineering Mathematics PDFMhorien MacatangayPas encore d'évaluation

- Innovation in MEP: CPVC Sprinkler PipingDocument11 pagesInnovation in MEP: CPVC Sprinkler PipingJohn DiasPas encore d'évaluation

- Ansi - Asme B1.2-1983 (2007)Document196 pagesAnsi - Asme B1.2-1983 (2007)Thành Thái100% (1)

- Lec 1Document57 pagesLec 1Hà MaiPas encore d'évaluation

- Green EngineeringDocument27 pagesGreen EngineeringpikaPas encore d'évaluation