Académique Documents

Professionnel Documents

Culture Documents

Case Study

Transféré par

Jyoti SinghDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Case Study

Transféré par

Jyoti SinghDroits d'auteur :

Formats disponibles

Case study Benefits of eTracK in supply chain management Profile sundra's Farm Equipment Sector is one of largest manufacturer

r of tractors in India with sustained market leadership of over 4 years. Started in 1994, SUNDRAs tractor division has played a vital role in the mechanisation of Indian agriculture. The Farm Equipment Sector is the first tractor company in the world to win the Deming Application Prize. It designs, develops, manufactures and markets tractors as well as implements which are used in conjunction with tractors. SUNDRA has two main tractor manufacturing plants located at Mumbai and pune in Maharashtra. Both these plants have been certified for ISO 9001, QS9000 and ISO 14001. Apart from these two main manufacturing units, the Farm Equipment Sector (FES) has satellite plants located at Rudrapur in Uttarachal and Jaipur in Rajasthan. The objective of satellite plants is to produce tractors of high customisation and quality at affordable costs and facilitate quicker deliveries in local markets.

Background FES Supply Chain Management

Strategically, SUNDRA FES sources components and parts at single location at Kandivile (Mumbai) plant and send the required quantity from Mumbai to their assembling plants at Rudrapur and Pune. While pune is around 180 kms away from Mumbai, Rudrapur is around 1400 kms away and trucks have to traverse four states of Maharashtra, M.P., U.P and Chattisgarh to reach Rudrapur (Uttaranchal).FES division has enlisted 12 transporters with around 350 trucks operating on contract to these locations. With the production capacity of 9000 tractors per year in Rudrapur, ensuring the availability of raw materials on time for the remotely located plant is a challenging task. Though meticulous

planning is contemplated for the scheduling and despatch of materials, SUNDRA had encountered various problems in transportation of raw materials as per the dynamic requirements of the plants.

PAINFUL AREAS

The major problems encountered by FES Supply Chain department are as follows: Despatches delayed due to non-availability of trucks on time Absence of information on the expected time of arrival of the trucks leads to anxiety and improper planning Exact information on the current location of the trucks and status of deliveries not known as the information provided by the transporters are often unreliable eLogistics Pvt. Ltd. In-transit idle time of the trucks not known due to which deliveries are delayed SUNDRA has been continuously strived forward to implement various IT enabled measures to transform the supply chain management. In their quest for sustained competitive advantage, SUNDRA has learnt that automatic vehicle tracking services (AVTS) can be employed for solving many of their problems related to scheduling and planning of despatches.

eTracK system the right solution

In pursuit of this objective, after analyzing the performance of various companies offering vehicle tracking services, SUNDRA has enlisted eLogistics pvt Ltd, Chennai to install eTracK devices in their trucks. Initial order was to install eTracKdevices in 200 trucks of 12

transporters in the first phase and thereafter to extend it into the entire fleet. Majority of the trucks earmarked for vehicle tracking were in Mumbai Rudrapur route as this was a painful route identified by logistics managers for managing supply chain activities. eLogistics has so far installed around 150 devices and the servicing requirements are managed by their service engineers at Mumbai and Rudrapur alongwith their alliance partner, TVS Electronics Ltd at various locations. Online Vehicle location reports are provided every 2 hrs and status reports are sent on a daily and weekly basis. SUNDRA has been given access online to eTracK application software wherein they can log in with a secured Username and Password and track the current location of their trucks anytime. The weekly productivity reports comprises of the reliability of the system, distance travelled between trips, average speed of trucks, no: of kms travelled by each truck, idle time and unscheduled halts.

Benefits from eTracK

SUNDRA has derived immense benefits by employing eTracK system in their trucks which has enabled them to solve major supply chain related problems. SUNDRA has been actively involved in provding inputs regarding eTracK which has helped eLogistics in developing eTracK v3.0 with much more advanced features. We have been involved in beta testing of eTracK v3.0 and as regular eTracK users, are very satisfied with the enhanced features in v3.0 contends Sandeep Patil, FES Supply Chain Manager . The following are the major benefits accrued out of eTracK system:

Real-time information on the location of trucks for estimating the arrival time and despatch planning Idle time reduction through constant monitoring of vehicles eLogistics Pvt. Ltd. Improved productivity by reduction in turnaround time Reduction in in-transit inventory Reduced anxiety levels in managing supplies The valuable information in weekly updates from eLogistics are being incorporated in MIS reports and helps SUNDRA to measure many of the the critical performance parameters of the supply chain department. The new version of eTracK web-based software application provides almost 5000 locations plotted in the digital map with multiple layers and other user-friendly features like enabling customer to change Username and Password, generate trip-based MIS reports, display of distance between trips on the map etc SUNDRA has unequivocally expressed their satisfaction in the services offered by eLogistics and has decided to extend the system for their entire fleet. The success in supporting SUNDRAs endeavour to transform the supply chain function keeps eLogistics on a strong footing to extend eTracK system to other manufacturing companies in India.

eTracK is helping us in better co-ordination among supply chain, dispatch department and the plants with regard to availability of trucks and dispatches hence reducing our pressure on delivery commitments and better control on the transporters Sandeep Patil Manager-Logistics

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- T2K13 SeedsDocument16 pagesT2K13 SeedsRyan Thomas100% (8)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Chapter 1 Feasibility StudyDocument6 pagesChapter 1 Feasibility StudyAnonymous COBviUmh100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Celtic Britain - J. Rhys (1908)Document366 pagesCeltic Britain - J. Rhys (1908)Waterwind100% (3)

- Impact of Europeans On The Indigenous PeopleDocument13 pagesImpact of Europeans On The Indigenous PeopleDance-Off 15Pas encore d'évaluation

- The Three Strangers: and Other StoriesDocument14 pagesThe Three Strangers: and Other Storiesmojgan100% (1)

- Vedic AgeDocument8 pagesVedic AgeRamita Udayashankar100% (2)

- Pighousingstandard PDFDocument20 pagesPighousingstandard PDFJune Cruz100% (2)

- Plantation NurseryDocument6 pagesPlantation NurseryManish KumarPas encore d'évaluation

- Town and Countryside in The Age of The Black DeathDocument514 pagesTown and Countryside in The Age of The Black DeathMátyás Süket100% (1)

- Ostrich Production 1Document5 pagesOstrich Production 1fembar100% (1)

- Training ProgramDocument7 pagesTraining ProgramJyoti Singh0% (1)

- Definition of Business PolicyDocument16 pagesDefinition of Business PolicyJyoti SinghPas encore d'évaluation

- ch16 Logistics and Supply-Chain ManagementDocument24 pagesch16 Logistics and Supply-Chain ManagementLuxPas encore d'évaluation

- Technology and Banking: The Nature of Banking Harmonizes Closely With TechnologyDocument32 pagesTechnology and Banking: The Nature of Banking Harmonizes Closely With TechnologyJyoti SinghPas encore d'évaluation

- AdvertisementDocument3 pagesAdvertisementpillu9Pas encore d'évaluation

- Baddeley - The Rugged Flanks of Caucasus - Volume 2Document86 pagesBaddeley - The Rugged Flanks of Caucasus - Volume 2Oliver Urs Lenz100% (1)

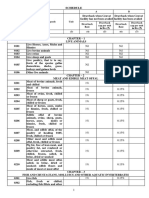

- Revised Duty Drawback Rates Schedule 2016 17 Wef 15 Nov 2016Document185 pagesRevised Duty Drawback Rates Schedule 2016 17 Wef 15 Nov 2016Emmanuel OpeyPas encore d'évaluation

- 3 HerbsDocument260 pages3 HerbsWahyu Edwin SPas encore d'évaluation

- Collective Nouns Worksheet Answers: A Brood of ChicksDocument2 pagesCollective Nouns Worksheet Answers: A Brood of ChicksGirish NagPas encore d'évaluation

- Longhorn Steakhouse NutritionDocument3 pagesLonghorn Steakhouse NutritionApril M BrownPas encore d'évaluation

- Agro-Industry TrendsDocument13 pagesAgro-Industry TrendsMuskamal EmkayPas encore d'évaluation

- Factory Farm Nation: 2015 EditionDocument50 pagesFactory Farm Nation: 2015 EditionFood and Water WatchPas encore d'évaluation

- Reproductive Condition of Some Bat Species in MT MakilingDocument28 pagesReproductive Condition of Some Bat Species in MT MakilingAllaine GarciaPas encore d'évaluation

- Ujian Diagnostik Upsr 2016: Bahasa Inggeris - PemahamanDocument6 pagesUjian Diagnostik Upsr 2016: Bahasa Inggeris - PemahamanSiti Zainon Mohd HanafiahPas encore d'évaluation

- Introduction To A Cotton GinDocument16 pagesIntroduction To A Cotton GinMohammad AbbasPas encore d'évaluation

- Critical Review of Natural History of UrbanizationDocument4 pagesCritical Review of Natural History of UrbanizationReshma GeorgiPas encore d'évaluation

- Pericarditis in Bovines A ReviewDocument9 pagesPericarditis in Bovines A ReviewDulPas encore d'évaluation

- Draught AnimalsDocument20 pagesDraught AnimalsAnnu SinghPas encore d'évaluation

- Department of Chemistry Maubin University: Comparison Between The Biogas Production of Water Hyacinth and Rice StrawDocument16 pagesDepartment of Chemistry Maubin University: Comparison Between The Biogas Production of Water Hyacinth and Rice Strawေအာင္ ေက်ာ္ စြာPas encore d'évaluation

- 084a PFDocument316 pages084a PFKelly LahtiPas encore d'évaluation

- Cetking SNAP 2009 Actual Paper With SolutionDocument30 pagesCetking SNAP 2009 Actual Paper With Solutioneva sharmaPas encore d'évaluation

- Soal-Soal Bu Ganies PDFDocument2 pagesSoal-Soal Bu Ganies PDFNur Qamar Rahmah100% (1)

- Overview of The District KachhiDocument4 pagesOverview of The District Kachhisyed waqas RehmanPas encore d'évaluation

- Veterinary DoctorDocument4 pagesVeterinary Doctorviks505Pas encore d'évaluation

- Nitrite/Nitrate Poisoning: (Cattle, Sheep)Document3 pagesNitrite/Nitrate Poisoning: (Cattle, Sheep)Syed AsifPas encore d'évaluation