Académique Documents

Professionnel Documents

Culture Documents

MTD 4661 Is1608

Transféré par

arunas1081Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MTD 4661 Is1608

Transféré par

arunas1081Droits d'auteur :

Formats disponibles

Doc: MTD 8 (4661)

For BIS use only

BUREAU OF INDIAN STANDAD Draft Indian Standard FREE CUTTING COPPER BARS, RODS AND SECTIONS SPECIFICATION (First Revision of IS 8328) ICS 77.150.30 Not to be reproduced without permission Of BIS or used as Standard FOREWORD (Formal clause will be added later on). This standard was first published in 1977. In the present revision, following modifications has been made: 1) 2) 3) 4) 5) A new clause on references has been incorporated Clauses for condition of delivery, freedom from defects, chemical composition, sampling, retest and criteria for conformity have been modified. One more grade of phosphorised high residual phosphorous-tellurium copper alloy which is most suitable and widely used for gas welding nozzles has been added. Mechanical properties and electrical properties have been modified. The requirement of test certificate is added. Last date for receipt of comments is 15 11 2005

For the purpose of deciding whether particular requirement of this standard is complied with the final value, observed or calculated, expressing the result of a test or analysis, shall be rounded off in accordance with IS 2:1960 'Rules for rounding off numerical values (revised)'. The number of significant places retained in the rounded off value should be the same as that of the specified value in this standard. 1 SCOPE

This standard covers the requirements for free cutting leaded-copper and tellurium-copper bars, rods and sections. 2 REFERENCES

The following standards contain provisions which through reference in this text, constitute provision of this standard. At the time of publication, the editions indicated were valid. All standards are subject to revision and parties to agreements based on this standard are encouraged to investigate the possibility of applying the most recent editions of the standards indicated below: IS No. 440:1964 1387:1993 1608:2005 1817:1961 Title Method of chemical anlysis of copper (revised) General requirements for the supply of metallurgical materials (second revision) Metallic materials - tensile testing at ambient temperature (third revision) Methods of sampling non-ferrous metals for chemical analysis

Doc: MTD 8 (4661)

2826:1986 3288 (Part 1):1986 (Part 3):1986 3863:1966 3 TERMINOLOGY Dimensions and tolerances for copper and copper alloy, rods and bars for general engineering purposes (third revision) Glossary of terms relating to copper and copper alloys Part 1 Materials (third revision) Part 3 Wrought forms Method of chemical analysis of copper-tellurium alloy

For the purpose of this standard, the definition of terms given in IS 3288 (Part 1 and Part 3) shall apply. 4 SUPPLY OF MATERIAL

General requirements relating to the supply of material shall be as laid down in IS 1387. 5 FREEDOM FROM DEFECTS

The material shall be clean, smooth free from surface defects like blisters, silvers, scales, fins, spills, cracks and internally sound free defects like porosity piping etc. 6 CONDITION OF DELIVERY

The material shall be supplied in any one of the following conditions as specified by the purchaser: 1) Half hard (HB) 2) Hard (HD) 7 DIMENSIONS AND TOLERANCES

7.1 Sizes The material shall be supplied in sizes as specified in IS 2826 or as required by the purchaser. 7.2 Tolerances The tolerances on sizes of bars/rods shall be as specified in IS 2826. 7.2.1 The tolerances for sections shall be as agreed to between the purchaser and the supplier/manufacturer and shall be stated in the order. 8 8.1 CHEMICAL COMPOSITION The material shall conform to the chemical composition as specified in Table 1.

8.2 The chemical analysis of leaded copper and tellurium copper shall be carried out in accordance with IS 440 and IS 3863 respectively or any other established instrumental/chemical method. In case of dispute the procedure specified in the latest version of IS 440 and IS 3863 for chemical analysis, shall be the referee method. However when the method is not given in IS 440 and IS 3863, the referee method shall be as agreed to between the purchaser and manufacturer. 8.3 Alternatively the methods specified in relevant ISO/IEC Standard may be used.

Doc: MTD 8 (4661)

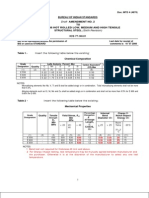

Table 1 Chemical composition (Clause 8.1)

ELEMENTS

(1) Copper & Silver, Min Tellurium Lead Phosphorous Total impurities, Max 9

PERCENTAGE _______________________________________________ Grade 1 Grade 2 Grade 3 (2) (3) (4) 99.05 0.5 to 0.8 0.015 to 0.050 0.10 99.20 0.3 to 0.7 0.10 98.40 0.80 to 1.50 0.10

MECHANICAL PROPERTIES

9.1 The material when tested for tensile test in accordance with IS 1608 shall conform to the requirements given in Table 2. Table 2 Tensile Properties (Clause 9.1)

Condition (Common to all alloys (1) Half hard (HB)

Size in mm Over Upto and including (2) (3) 6 10 32 50 6 10 32 50 10 32 50 10 32 50 -

Tensile Elongation on Gauge Strength Length5.65A, Min min, MPa Percent (4) (5) 260 260 240 230 315 305 275 260 10 10 15 18 6 8 10 12

Hard (HD)

NOTE 1N/mm2 = 0.102 Kgf/mm2 = 1MPa ________________________________________________________________ 9.1.1 The tensile test shall be made on test pieces machined to shape and largest dimensions practicable as specified in IS 1608 from the samples selected in accordance with 11.4. 9.1.2 Up to and including 32 mm rods/bars, the material longitudinal axis of the test pieces shall be the same as that of the rods/bars. 9.1.3 In case of rods/bars over 32 mm the central longitudinal axis of the test piece shall be at least 16 mm from the nearest face/surface. 9.1.4 The fractured test piece shall be free from pipe and other surface defects.

Doc: MTD 8 (4661)

9.1.5 Should a tensile test piece break outside the middle third of the gauge length and the elongation percentage obtained be lower than minimum specified, the test may be discarded and another test made. 10 ELECTRICAL RESISTIVITY

10.1 The electrical resistivity of Grade 2 and Grade 3 shall not exceed to 0.0203 ohm/mm2/meter. The equivalent conductivity will be 85 percent IACS minimum. 10.2 Grade 1 is not intended for electrical application requirement. and therefore has no resistivity

10.3 Electrical resistivity test need not be made except when indicated by the purchaser at the time of placing the order. 11 SAMPLING AND CRITERIA FOR CONFORMITY

11.1 Unless otherwise agreed to between the purchaser and the supplier/manufacturer the following sampling procedure and criteria for conformity shall hold good. 11.2 Lot

In any consignment, all the material of same grade, size and temper manufacturer from the same raw material, produced at the same place, shall be grouped together to constitute a lot. 11.3 Material shall be examined for freedom from defects and for tolerances on diameter/dimensions. Any bar/rod/section found defective shall be rejected. 11.4 From the material found satisfactory in 11.3 one sample shall be selected from each lot of part thereof to provide necessary test pieces for all the tests (chemical analysis, tensile test and electrical resistivity). Mass of each not vary with the size of material and is given in Table 3. NOTE The material required for chemical analysis from the selected bar/rod/section shall be taken in accordance with IS 1817. Table 3 Lot Size (clause 11.4) Specified size (Diameter of width across Flats of material _______________________________________ Over Upto and including mm mm (1) (2) 12 12 50 50 -

Mass of each lot

kg (3) 1000 2000 4000

NOTE When the order does not permit forming lots in the above quantity the lot size shall be as agreed to between the supplier and the purchaser. 11.5 The lot shall be accepted if the samples tested meet all the chemical composition, tensile, properties and electrical resistivity (if required by the purchaser) requirements to the specification.

Doc: MTD 8 (4661)

12

RETEST

12.1 If a result of chemical analysis fails to satisfy the requirements for any of the constituents two more tests for that constituents shall be done on the same sample in order to confirm that the analysis has been done properly. If both the test results satisfy the relevant requirements, the lot shall be considered as conforming to this specification, otherwise not. 12.2 If any of the test pieces first selected fails to pass the requirements of tensile properties and electrical resistivity test, two further sample from the same lot shall be selected for testing, one of which shall be from the same piece of material from which the original sample was taken, unless it is withdrawn by the supplier. 12.2.1 If the test piece from both these additional samples pass the lot represented by the test samples shall be deemed to comply with this standard. If the test piece from either of these additional samples fail the lot represented by the test samples shall be rejected. 13 PACKING

The material shall be packed in bundles, boxes, cases or crates or as required by the purchaser, so as to ensure the safe transportation of the material and avoid damage in transit. 14 MARKING

14.1 Each package tagged with suitable metal tag with shall be marked with the following details: a) b) c) d) e) f) g) h) 14.2 Dimensions Mass Grade/chemical composition Temper Lot number Date of manufacture Name and/trade mark of manufacturer Any other information required by the purchaser

BIS Certification Marking

The material may also be marked with the Standard Mark. 14.2.1 The use of Standard Mark is governed by the provision of the Bureau of Indian Standards Act, 1986 and the Rules and Regulations made there under. The details of the conditions under which the licence for the use of Standard Mark may be granted to manufacturers or producers may be obtained from the Bureau of Indian Standards. 15 TEST CERTIFICATE

The supplier shall provide the test certificate for each consignment giving information like lot number, size, grade and temper of the material with corresponding chemical composition, tensile properties and electrical resistivity test result. 16 INFORMATION TO BE GIVEN BY THE PURCHASER

This standard contains a number of clauses in which the purchaser is allowed to exercise an option. The purchaser should provide following information at the time of placing the order:

Doc: MTD 8 (4661)

a) Whether the purchaser wished to inspect the material at the suppliers works (see 3) b) Grade and temper of the material (see 8 and 6) c) Dimensions and tolerances (see 7) d) Sampling and criteria for conformity(see 11) e) Packing details (see 13) f) Marking details (see 14) g) Whether test certificate required by the purchaser (see 15)

Vous aimerez peut-être aussi

- Ferrous Alloy Types and PropertiesDocument72 pagesFerrous Alloy Types and PropertiesSneha Kriti100% (3)

- Is 2004Document7 pagesIs 2004shanrama100% (1)

- F138Document4 pagesF138Gustavo SuarezPas encore d'évaluation

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsD'EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsPas encore d'évaluation

- Astm B 124 PDFDocument5 pagesAstm B 124 PDFweltwind100% (1)

- Astm B75M.11Document8 pagesAstm B75M.11Tiago SucupiraPas encore d'évaluation

- Metal Recycling: Opportunities, Limits, InfrastructureDocument32 pagesMetal Recycling: Opportunities, Limits, InfrastructureFarooq MuhammadPas encore d'évaluation

- Corrosion: Corrosion ControlD'EverandCorrosion: Corrosion ControlL L ShreirÉvaluation : 5 sur 5 étoiles5/5 (1)

- 000000000001011273Document190 pages000000000001011273Dante FilhoPas encore d'évaluation

- Astm F 136 - 02Document6 pagesAstm F 136 - 02Marcos Verissimo Juca de PaulaPas encore d'évaluation

- 4454 1 PDFDocument12 pages4454 1 PDFJessica Harrington0% (1)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingD'EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingPas encore d'évaluation

- Is 2708 - Manganize Steel CastingDocument6 pagesIs 2708 - Manganize Steel CastingJanak MistryPas encore d'évaluation

- Astm B705Document4 pagesAstm B705Maram NasraweenPas encore d'évaluation

- Astm B150 & B150M - 03Document6 pagesAstm B150 & B150M - 03jtek01Pas encore d'évaluation

- List of StandardDocument126 pagesList of Standardarunas10810% (1)

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekPas encore d'évaluation

- ASTM B427-09 (Reapproved 2015)Document4 pagesASTM B427-09 (Reapproved 2015)Gabriel Perez CruzPas encore d'évaluation

- Evans Ancient Bronze Implements 1881Document540 pagesEvans Ancient Bronze Implements 1881alexdavies56100% (2)

- Doc: MTD 8 (4660) : (Fifth RevisionDocument8 pagesDoc: MTD 8 (4660) : (Fifth RevisionAnonymous TjdHCuPas encore d'évaluation

- Astm B476-06Document4 pagesAstm B476-06Srinivasan KrishnamoorthyPas encore d'évaluation

- Astm f136 Rev ADocument4 pagesAstm f136 Rev AAhmad BrianPas encore d'évaluation

- Is 737Document16 pagesIs 737amitava_198450% (2)

- Is 2856 1999 Carbon Steel Castings For Pressure Containing Parts Suitable For Fusion WeldingDocument11 pagesIs 2856 1999 Carbon Steel Castings For Pressure Containing Parts Suitable For Fusion WeldingpsewagPas encore d'évaluation

- Iron-Phosphorus Powder Metallurgy (P/M) Parts For Soft Magnetic ApplicationsDocument6 pagesIron-Phosphorus Powder Metallurgy (P/M) Parts For Soft Magnetic ApplicationsJosé Ramón GutierrezPas encore d'évaluation

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)mulong83Pas encore d'évaluation

- Astm A874Document3 pagesAstm A874DendePas encore d'évaluation

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDocument4 pagesA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterPas encore d'évaluation

- Wrought Titanium-6Aluminum-7Niobium Alloy For Surgical Implant Applications (UNS R56700)Document6 pagesWrought Titanium-6Aluminum-7Niobium Alloy For Surgical Implant Applications (UNS R56700)masoudPas encore d'évaluation

- I S 613 - 2000Document11 pagesI S 613 - 2000Hariprasad gantyalaPas encore d'évaluation

- Is 2004Document7 pagesIs 2004raghav248Pas encore d'évaluation

- B551 07Document10 pagesB551 07Srinivasan KrishnamoorthyPas encore d'évaluation

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)pablitochoaPas encore d'évaluation

- Is 2041 2009Document12 pagesIs 2041 2009Katie RamirezPas encore d'évaluation

- Wrought Cobalt - 28chromium - 6molybdenum Alloys For Surgical Implants (UNS R31537, UNS R31538, and UNS R31539)Document3 pagesWrought Cobalt - 28chromium - 6molybdenum Alloys For Surgical Implants (UNS R31537, UNS R31538, and UNS R31539)Gustavo SuarezPas encore d'évaluation

- Astm B688 (1996)Document6 pagesAstm B688 (1996)ElmerPas encore d'évaluation

- Electronic Grade Alloys of Copper and Nickel in Wrought FormsDocument3 pagesElectronic Grade Alloys of Copper and Nickel in Wrought Formsjamaljamal20Pas encore d'évaluation

- F 364 - 96 - RJM2NC05NGDocument3 pagesF 364 - 96 - RJM2NC05NGjamaljamal20Pas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationRishith Ellath Meethal VadakaraPas encore d'évaluation

- B 373 - 00 - QJM3MWDocument5 pagesB 373 - 00 - QJM3MWmalika_00Pas encore d'évaluation

- B477-1997 (2008)Document3 pagesB477-1997 (2008)Srinivasan KrishnamoorthyPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To Informationanand.bharadwajPas encore d'évaluation

- Asme Section II A Sa-181 Sa-181mDocument4 pagesAsme Section II A Sa-181 Sa-181mAnonymous GhPzn1xPas encore d'évaluation

- F 1058 - 97 - RjewntgtukveDocument8 pagesF 1058 - 97 - RjewntgtukvePrakash MakadiaPas encore d'évaluation

- C K201 PDFDocument21 pagesC K201 PDFManoj KumarPas encore d'évaluation

- B932-2004 (2010)Document3 pagesB932-2004 (2010)Srinivasan KrishnamoorthyPas encore d'évaluation

- B815 PDFDocument3 pagesB815 PDFROHITPas encore d'évaluation

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Ajesh Kumar MuraleedharanPas encore d'évaluation

- Is 1897 2008Document12 pagesIs 1897 2008Santosh KumarPas encore d'évaluation

- Nickel-Iron-Chromium-Silicon Alloys (UNS N08330 and N08332) Seamless Pipe and TubeDocument3 pagesNickel-Iron-Chromium-Silicon Alloys (UNS N08330 and N08332) Seamless Pipe and TubeSrinivasan KrishnamoorthyPas encore d'évaluation

- B167 1207649-1Document9 pagesB167 1207649-1allanromarioPas encore d'évaluation

- Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)Document10 pagesCartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)luis_may22Pas encore d'évaluation

- Astm B 398Document4 pagesAstm B 398vadmanh100% (1)

- Ni-Fe-Cr-Mo-Cu-N Low-Carbon Alloys (UNS N08925, UNS N08031, UNS N08354, and UNS N08926), and Cr-Ni-Fe-N Low-Carbon Alloy (UNS R20033) Bar and Wire, and Ni-Cr-Fe-Mo-N Alloy (UNS N08936) WireDocument7 pagesNi-Fe-Cr-Mo-Cu-N Low-Carbon Alloys (UNS N08925, UNS N08031, UNS N08354, and UNS N08926), and Cr-Ni-Fe-N Low-Carbon Alloy (UNS R20033) Bar and Wire, and Ni-Cr-Fe-Mo-N Alloy (UNS N08936) WireSrinivasan KrishnamoorthyPas encore d'évaluation

- Is 1148 2009 PDFDocument10 pagesIs 1148 2009 PDFchepurthiPas encore d'évaluation

- F138 1479757-1Document5 pagesF138 1479757-1Thaweekarn ChangthongPas encore d'évaluation

- B729Document3 pagesB729LambertWaynePas encore d'évaluation

- Standard Specification For Wrought Copper-Alloy Bearing and Expansion Plates and Sheets For Bridge and Other Structural UseDocument5 pagesStandard Specification For Wrought Copper-Alloy Bearing and Expansion Plates and Sheets For Bridge and Other Structural UseHugoStiglicPas encore d'évaluation

- Zirconium and Zirconium Alloy Sheet, Strip, and Plate For Nuclear ApplicationDocument6 pagesZirconium and Zirconium Alloy Sheet, Strip, and Plate For Nuclear ApplicationSrinivasan KrishnamoorthyPas encore d'évaluation

- ASTM-B693-17-2022-Document2 pagesASTM-B693-17-2022-Dip MPas encore d'évaluation

- Is 5522 1992Document6 pagesIs 5522 1992psewagPas encore d'évaluation

- Standard Specification For Aluminum-Alloy 5005 Drawing Stock For Electrical Purposes1Document3 pagesStandard Specification For Aluminum-Alloy 5005 Drawing Stock For Electrical Purposes1HugoStiglicPas encore d'évaluation

- Standard Specification For Copper-Zinc-Aluminum-Cobalt Alloy, Copper-Zinc-Tin-Iron Alloy Plate, Sheet, Strip, and Rolled BarDocument5 pagesStandard Specification For Copper-Zinc-Aluminum-Cobalt Alloy, Copper-Zinc-Tin-Iron Alloy Plate, Sheet, Strip, and Rolled BarLorena JimenezPas encore d'évaluation

- F1713 1479757-1Document5 pagesF1713 1479757-1Thaweekarn ChangthongPas encore d'évaluation

- Standard Specification For: Designation: B167 11Document9 pagesStandard Specification For: Designation: B167 11mahfuzPas encore d'évaluation

- MTD 4730 Is1079Document7 pagesMTD 4730 Is1079arunas1081Pas encore d'évaluation

- Guide To Selection of Sus Surface FinishDocument15 pagesGuide To Selection of Sus Surface FinishTun Chit FooPas encore d'évaluation

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081Pas encore d'évaluation

- SAE1018Document1 pageSAE1018arunas1081Pas encore d'évaluation

- mtd4670 IS513Document10 pagesmtd4670 IS513arunas1081Pas encore d'évaluation

- MTD4 (4937)Document1 pageMTD4 (4937)arunas1081Pas encore d'évaluation

- MTD4 (4939)Document10 pagesMTD4 (4939)arunas1081Pas encore d'évaluation

- MTD32 (5079) WDocument11 pagesMTD32 (5079) Warunas1081100% (1)

- MTD4 (4919)Document3 pagesMTD4 (4919)arunas1081Pas encore d'évaluation

- INDIAN STANDARDS FOR METALLURGICAL ENGINEERINGDocument8 pagesINDIAN STANDARDS FOR METALLURGICAL ENGINEERINGSasi KumarPas encore d'évaluation

- MTD4 (4855) Is8910Document8 pagesMTD4 (4855) Is8910arunas1081Pas encore d'évaluation

- MTD4 (4671) 3803Document8 pagesMTD4 (4671) 3803arunas1081Pas encore d'évaluation

- MTD4 (4870)Document2 pagesMTD4 (4870)Muthu KumarPas encore d'évaluation

- HR Standards IS8500Document3 pagesHR Standards IS8500Ravindra Rao SPas encore d'évaluation

- Thickness TolerancesDocument1 pageThickness Tolerancesarunas1081Pas encore d'évaluation

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- October 2016 2Document16 pagesOctober 2016 2Tanvika AroraPas encore d'évaluation

- Terex Crane Ac80 2 Technical Training ManualDocument23 pagesTerex Crane Ac80 2 Technical Training Manualmarkgregory170387rwb100% (106)

- C83600 PDFDocument2 pagesC83600 PDFboccareddyPas encore d'évaluation

- Scheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFDocument6 pagesScheme of Testing and Inspection For Certification of Carbon Steel Cast Billet Ingots Billets Blooms and Slabs For Re Rolling Into Seel For General Structural Purpose PDFbipinagarwalPas encore d'évaluation

- 1-Bimetal Technology PDFDocument32 pages1-Bimetal Technology PDFUdit SharmaPas encore d'évaluation

- Aluminum The Wiring Material of The FutureDocument7 pagesAluminum The Wiring Material of The FuturevkmsPas encore d'évaluation

- Characterization of Low Cost P-Cu2On-CuO JunctionDocument6 pagesCharacterization of Low Cost P-Cu2On-CuO JunctionbongtongPas encore d'évaluation

- Grade 7 Pre Techn NotesDocument22 pagesGrade 7 Pre Techn NotesAhmed Hassan100% (1)

- Hds Erico CadweldDocument12 pagesHds Erico CadweldIván Tadeo MoralesPas encore d'évaluation

- Ch22-Materials Selection and Design ConsiderationDocument29 pagesCh22-Materials Selection and Design ConsiderationBryan de GuiaPas encore d'évaluation

- 2016-6um Pitch High Density Cu-Cu Bonding For 3d Ic StackingDocument8 pages2016-6um Pitch High Density Cu-Cu Bonding For 3d Ic Stacking湯晴羽Pas encore d'évaluation

- Heavy Metal Contents of Livestock Feeds and Animal Manures in England and WalesDocument9 pagesHeavy Metal Contents of Livestock Feeds and Animal Manures in England and WalesCiobanu ConstantinPas encore d'évaluation

- A6163 ConnectabilityTestingDocument63 pagesA6163 ConnectabilityTestingJorgePas encore d'évaluation

- Omega Product Price List PDFDocument10 pagesOmega Product Price List PDFVCPas encore d'évaluation

- Principales Minas en Mexico: HistoriaDocument5 pagesPrincipales Minas en Mexico: HistoriaJunior VasquezPas encore d'évaluation

- 2 TS Maintenance Free Earthpit R1Document5 pages2 TS Maintenance Free Earthpit R1sandeepbhallaPas encore d'évaluation

- 10 Copper Facts - Https://egyptiansorcery - ComDocument2 pages10 Copper Facts - Https://egyptiansorcery - ComAravenaPas encore d'évaluation

- Kobe Steel Misconduct ReportDocument111 pagesKobe Steel Misconduct ReportJo K ErPas encore d'évaluation

- LoveUrns® 2014 HumanDocument29 pagesLoveUrns® 2014 HumanshimacherPas encore d'évaluation

- United States Patent Office: Patented Nov. 26, 1963Document2 pagesUnited States Patent Office: Patented Nov. 26, 1963Bharata BadranayaPas encore d'évaluation

- ELE-3COP-361: Title - Application of Raybraid and Instalite Braid To Hand Laid CablesDocument3 pagesELE-3COP-361: Title - Application of Raybraid and Instalite Braid To Hand Laid Cablesmurat degirmenciPas encore d'évaluation

- Cu (+2) - Citrate Dimer Complexes in Aqueous SolutionsDocument8 pagesCu (+2) - Citrate Dimer Complexes in Aqueous SolutionsDemigodPas encore d'évaluation

- Copper Alloy Data for Heat ExchangersDocument9 pagesCopper Alloy Data for Heat ExchangersNut AssanaiPas encore d'évaluation