Académique Documents

Professionnel Documents

Culture Documents

E179 BD 01

Transféré par

Cù Hoàng TuầnDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

E179 BD 01

Transféré par

Cù Hoàng TuầnDroits d'auteur :

Formats disponibles

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Benefits for your application

The oils meet the requirements according to DIN 51 517 03, CLP. Corresponding gears can be switched to Klbersynth GH 6 oils without prior consultation with the gear manufacturer provided the general application notes are observed. As of ISO VG 220 the scuffing load stage API GL 5 is achieved. Gears are sufficiently protected against scuffing even under high peak loads. Much longer service life than mineral oils due to the excellent ageing and oxidation resistance of the base oil; thus maintenance intervals can be extended and in certain cases even lifetime lubrication is possible Owing to the wide service temperature range a single viscosity grade can cover both low and high temperatures in many applications The optimum friction behaviour of the polyglycol base oil reduces power losses and improves efficiency The good wear protection of both gears and rolling bearings ensures that the service life calculated for the lubricated components is achieved The excellent viscosity-temperature behaviour supports the formation of a sufficient lubricating film even at elevated and high temperatures Seals made of 72 NBR 902, 75 FKM 585 and 75 FKM 170055 are resistant to Klbersynth GH 6 oils. Leakage and contamination are prevented.

Approved by Flender, SEW Eurodrive, Getriebebau Nord, Stber Antriebstechnik, Lenze, ZAE Antriebstechnik, Bonfiglioli, Rossi Motoriduttori, Motovario, Moventas, etc.

Description Klbersynth GH 6 oils are gear oils on a polyglycol basis. They have a high scuffing load capacity and micro-pitting resistance. These oils have also proved their good wear protection in rolling bearings on the FAG FE 8 test rig for gear oils. Klbersynth GH 6 oils stand out for their excellent ageing and oxidation resistance, good viscosity-temperature behaviour and very good thermal stability. Application Klbersynth GH 6 oils were especially developed for the lubrication of worm gears with steel/bronze pairings.

The polyglycol base oils and special additives reduce the friction coefficient and provide low wear values, which is a clear advantage in these applications. Klbersynth GH 6 oils achieve a particularly low wear intensity according to DIN 3996 (calculation of load capacity of worm gears). Klbersynth GH 6 oils are also used for the lubrication of bevel and spur gears, rolling and plain bearings as well as all types of denture couplings, especially when exposed to high temperatures. Klbersynth GH 6 oils can also be used for the lubrication of lifting, drive and transport chains.

Klbersynth GH 6-32, 46, 80, 100, 150, 220, 320, 460, 680, 1000 Article numbers: 012157/012009/012158/012159/012160/012161/012162/012163/012164/012165, 012281 en

Edition 10.08, replaces edition 05.08 MA-TM/HSi

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Application notes Klbersynth GH 6 oils can be applied by immersion, immersion/circulation and injection. Klbersynth GH 6 oils are not miscible with mineral oils and synthetic hydrocarbons. We recommend cleaning the lubrication points or rinsing gears with the Klbersynth GH 6 oil which will be used after conversion. Klbersynth GH 6 oils are neutral towards ferrous metals and almost all nonferrous metals. There may be increased wear when the contact surfaces of design elements made of aluminium or aluminium alloys are exposed to dynamic loads. If necessary, preliminary tests should be carried out. For permanent temperatures up to 80 C seals made of 72 NBR 902 may be used. For higher temperatures, we recommend to use seals made of 75 FKM 585 or 75 FKM 170055. It should be noted that elastomers from one or several manufacturers can behave differently; therefore tests should be performed. When applying Klbersynth GH 6 oils we recommend the use of two-component paints (reaction paints) for interior coating. Oil gauge glasses should preferably be made of natural glass or polyamide materials. Other transparent plastics, e.g. Plexiglas, have a tendency to crack under stress. The suitability of materials used in contact with Klbersynth GH 6 oils should be tested, especially prior to series application.

Viscosity selection When determining the oil viscosity for gears, the manufacturer's instructions take priority. In cases where there are no gear manufacturer's instructions, the viscosity can be selected in accordance with the enclosed worksheet "Klbersynth GH 6 oils selection of oil viscosity for gears". To determine the correct oil viscosity for bearings, please observe the bearing manufacturer's instructions. For determining the actual viscosity, please refer to the enclosed viscosity-temperature diagram indicating the differing viscositytemperature behavior of Klbersynth GH 6 oils as compared to mineral oils.

Minimum shelf life The minimum shelf life is approx. 36 months if the product is stored in its unopened original container in a dry, frost-free place.

Pack sizes 20 l canister 200 l drum

Material Safety Data Sheets Material safety data sheets can be downloaded or requested via our website www.klueber.com. You may also obtain them through your contact person at Klber Lubrication.

Klbersynth GH 6-32, 46, 80, 100, 150, 220, 320, 460, 680, 1000 Article numbers: 012157/012009/012158/012159/012160/012161/012162/012163/012164/012165/012281 en

Edition 10.08, replaces edition 05.08 MA-TM/HSi

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Product data

Klbersynth GH 6- ISO VG DIN 51 519 Density, DIN 51 757, at 15 C, [kg/m], approx. Kinematic viscosity, DIN 51 561 at 20 C, [mm2/s], approx. 2 at 40 C, [mm /s], approx. at 100 C, [mm2/s], approx. Viscosity index, DIN ISO 2909 Flash point COC, DIN ISO 2592, [C] Pour point, DIN ISO 3016, [C] Lower service temperature range*, [C] Upper service temperature range*, [C] Corrosion protection on steel, DIN ISO 7120 Ageing characteristics, ASTM D 2893, increase in viscosity, [%] FZG gear test rig, A/8.3/90, DIN 51354-2, scuffing load stage API scuffing load capacity Rolling bearing test rig FE 8, D 7,5/80-80, DIN 51 819-3, wear of rolling elements, [mg] wear of cage [mg]

*

32 32 984

46 46 1035

80 1040

100 100 1043

150 150 1050

220 220 1060

320 320 1067

460 460 1074

680 680 1075

1000 1000 1075

1500 1500 1080

88 32 6,5 > 150 > 220 < -45

113 46 9

205 80 15

270 100 20

400 150 29

630 220 40

880 320 54

1240 460 71

1900 680 110

3000 1000 167 250 250 -25

4300 1500 231 > 250 > 250 < -10

> 190 > 190 > 190 > 210 > 220 > 220 > 220 > 220 > 250 > 250 > 250 > 250 > 250 > 250 > 250 > 250 < -40 < -40 < -35 < -35 < -35 < -30 < -25 < -25

-45

-40

-35 160 0A

-30

-25

-10

> 14 API GL 5

30 200

Service temperatures are guide values which depend on the lubricant's composition, the intended use and the application method. Lubricants change their consistency, apparent dynamic viscosity or viscosity depending on the mechano-dynamical loads, time, pressure and temperature. These changes in product characteristics may affect the function of a component.

Klbersynth GH 6-32, 46, 80, 100, 150, 220, 320, 460, 680, 1000 Article numbers: 012157, 012009, 012158,012159, 012160, 012161, 012162, 012163, 012164, 012165, 012281 en

Edition 10.08, replaces edition 05.08 MA-TM/HSi

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Viscosity-temperature diagram

kinematic viscosity in mm2/s

temperature in C

Lubrication is our world With more than 2000 products available around the world, you can be sure that Klber has the right product for your application. Please contact Klber Lubrication specialists worldwide to assist you in all matters regarding lubrication. www.klueber.com

Klber Lubrication Mnchen KG, Geisenhausenerstrae 7, 81379 Mnchen, Germany, phone +49 89 7876-0, fax +49 89 7876-333. The data in this product information is based on our general experience and knowledge at the time of printing and is intended to give information of possible applications to a reader with technical experience. It constitutes neither an assurance of product properties nor does it release the user from the obligation of performing preliminary tests with the selected product. We recommend contacting our Technical Consulting Staff to discuss your specific application. If required and possible we will be pleased to provide a sample for testing. Klber products are continually improved. Therefore, Klber Lubrication reserves the right to change all the technical data in this product information at any time without notice. Klber Lubrication, a company of the Freudenberg Group Publisher and Copyright: Klber Lubrication Mnchen KG. Reprints, total or in part, are permitted only prior consultation with Klber Lubrication Mnchen KG and if source is indicated and voucher copy is forwarded.

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Worksheet: selection of oil viscosity for gears The manufacturer's instructions on oil viscosity take priority in any case. If the viscosity is not calculated e.g. on the basis of the EHD theory, it can be selected in accordance with this worksheet. Selection is based on DIN 51509, pt. 1 "Selection of lubricants for toothed gears". All information in this worksheet applies only to Klbersynth GH 6 oils. The differing viscositytemperature behaviour of these synthetic oils as compared to mineral oils has been taken into account. The correct viscosity must be selected independently for every gear stage, and a compromise is required for multi-stage gears. The selection of the correct viscosity in accordance with this worksheet is based on the oil's expected operation temperature, i.e. the oil sump temperature or the temperature of the injected oil. This temperature is calculated by determining the gear's thermal economy, taking into account the produced losses, or, in the case of gears already installed, by measuring the temperature. It might be required to select a lower viscosity to ensure lubricant supply during a cold start and at low ambient temperatures. In the individual case it is necessary to check the viscosity at the existing starting temperature (especially in the case of oil circulation lubrication), or to test the components at the expected starting temperature (especially in the case of immersion lubrication). The viscosity grade of the Klbersynth GH 6 oils required for a gear stage is determined by means of the Klber viscosity index and the expected oil operating temperature using the diagram of the last page.

Klbersynth GH 6-32, 46, 80, 100, 150, 220, 320, 460, 680, 1000 Article numbers: 012157, 012009, 012158, 012159, 012160, 012161, 012162, 012163, 012164, 012165, en

Edition 10.08, replaces edition 05.08 MA-TM/HSi

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Determination of the Klber viscosity index for a spur gear stage The required Klber viscosity index for a spur gear stage is calculated using the force-speed factor in accordance with table 1. Table 1

MPa s Force-speed factor KS/v m 0.02 > 0.02 to 0.08 > 0.08 to 0.3 > 0.3 to 0.8 > 0.8 to 1.8 > 1.8 to 3.5 > 3.5 to 7.0 > 7.0

v KS = Peripheral speed at the reference circle [m/s] = Rolling pressure acc. to Stribeck [N/mm, MPa] Ft U +1 2 2 = Z H Z K A N / mm 2 , MPa b d1 U = Nominal peripheral force [N] = Tooth width [mm] = Diameter of reference circle [mm] = Gear ratio = Z2/Z1; Z2 > Z1 *1 = Distribution factor *1 = Contact ratio *2 = Application factor

Klber viscosity index KVZ 1 2 3 4 5 6 7 8

KS

Ft b d1 U ZH Z KA

*1 *2

2 Note: Determination of ZH and Z according to DIN 3990, pt. 2. For a rough calculation: ZH Z 2 3 Note: Guide values for KA are listed in DIN 3990, pt. 6.

Example 1 Single-stage spur gear driving a fan Drive: Nominal peripheral force: Tooth width: Diameter of reference circle: Gear ratio: 2 2 ZH Z : KA: Peripheral speed: Rolling pressure acc. to Stribeck: Force-speed factor: Acc. to table 1, Klber viscosity index: Expected oil sump temperature: Electric motor Ft = 3000 N b = 25 mm d1 = 230 mm U = 2.5 3 1 v = 4 m/s KS = 2.2 MPa MPa s KS/v = 0.55 m KVZ = 4 90 C

For this application we selected Klbersynth GH 6-150 in accordance with the diagram on page 4.

Klbersynth GH 6-32, 46, 80, 100, 150, 220, 320, 460, 680, 1000 Article numbers: 012157, 012009, 012158, 012159, 012160, 012161, 012162, 012163, 012164, 012165, en Edition 10.08, replaces edition 05.08 MA-TM/HSi

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Determination of the Klber viscosity index for a worm gear stage The required Klber viscosity index for a worm gear stage is calculated in accordance with table 2. Table 2

N min Force-speed factor KS/v m2 60 > 60 to 400 > 400 to 1800 > 1800 to 6000 > 6000

Force-speed factor KS/v =

T2 n1 a KA Note: = = = = N min K A 2 n1 a m Output torque [Nm] -1 Worm speed [min ] Centre distance [m] Application factor Guide values for KA are listed in DIN 3990, pt. 6. T2

3

Klber viscosity index KVZ 5 6 7 8 9

Example 2

Worm gear stage of a gear motor driving a circular conveyor Drive: Output torque: Worm speed: Centre distance: Application factor: Force-speed factor Klber viscosity index acc. to table 2: Expected oil sump temperature: Electric motor T2 = 300 Nm -1 n1 = 350 min a = 0.063 m KA = 1

K S / v = 3427,9

KVZ = 8 85 C

N min m2

For this application Klbersynth GH 6-460 was selected in accordance with the diagram on page 4.

Klbersynth GH 6-32, 46, 80, 100, 150, 220, 320, 460, 680, 1000 Article numbers: 012157, 012009, 012158, 012159, 012160, 012161, 012162, 012163, 012164, 012165, en

Edition 10.08, replaces edition 05.08 MA-TM/HSi

Product information

Klbersynth GH 6 oils

Synthetic gear and high temperature oils

Viscosity selection diagram

Klber viscosity index

Klbersynth GH 6-32, 46, 80, 100, 150, 220, 320, 460, 680, 1000 Article numbers: 012157, 012009, 012158, 012159, 012160, 012161, 012162, 012163, 012164, 012165, en Edition 10.08, replaces edition 05.08 MA-TM/HSi

Oil operating temperature [ C]

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- ME5506 Make-Up Quiz 2Document6 pagesME5506 Make-Up Quiz 2Wai-Yen Chan100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Permeability of Concrete - tcm45-346751Document3 pagesPermeability of Concrete - tcm45-346751abualamalPas encore d'évaluation

- Fluid Applied WaterproofingDocument8 pagesFluid Applied WaterproofingHamza MamiPas encore d'évaluation

- File 40 - Doors and WindowsDocument44 pagesFile 40 - Doors and WindowsdvduronPas encore d'évaluation

- Australian Standard Automatic Fire Sprinkler SystemsDocument26 pagesAustralian Standard Automatic Fire Sprinkler SystemsNatarajan RavisankarPas encore d'évaluation

- Parker O RingDocument0 pageParker O RingRazvan C GoranPas encore d'évaluation

- Engineering Glass ProjectsDocument3 pagesEngineering Glass ProjectshanstephPas encore d'évaluation

- Specification Sheet: High-Pressure, High-Temperature Thread Compound For Casing, Tubing, and Line PipeDocument1 pageSpecification Sheet: High-Pressure, High-Temperature Thread Compound For Casing, Tubing, and Line PipeCù Hoàng TuầnPas encore d'évaluation

- Advanced Circulating & Bearing Oil for MachinesDocument2 pagesAdvanced Circulating & Bearing Oil for MachinesCù Hoàng TuầnPas encore d'évaluation

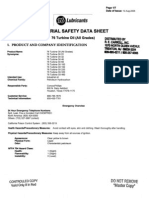

- 76 Turbine Oil (All Grades)Document7 pages76 Turbine Oil (All Grades)Cù Hoàng TuầnPas encore d'évaluation

- Omega 71Document2 pagesOmega 71Cù Hoàng TuầnPas encore d'évaluation

- Surface treatments for automotive applicationsDocument7 pagesSurface treatments for automotive applicationsSasiKumar PetchiappanPas encore d'évaluation

- Heatshrinkable Sheets: Manufacturer Statement & Product Data SheetsDocument15 pagesHeatshrinkable Sheets: Manufacturer Statement & Product Data SheetsariyamanjulaPas encore d'évaluation

- Salamander Plumbago Ladle Bowls: Product InformationDocument2 pagesSalamander Plumbago Ladle Bowls: Product InformationVinay RajputPas encore d'évaluation

- PDS - Sikaflex®-68 TFDocument4 pagesPDS - Sikaflex®-68 TFFran GVPas encore d'évaluation

- Leucophor BMB 2000 PowderDocument5 pagesLeucophor BMB 2000 PowderTahir IqbalPas encore d'évaluation

- Epoqua 2Document4 pagesEpoqua 2pravi3434Pas encore d'évaluation

- Flow Chart of Proto Sample Development in Apparel IndustryDocument22 pagesFlow Chart of Proto Sample Development in Apparel Industrysabber100% (1)

- List of Job Titles - Construction Trades Helpers and Labourers (NOC 7611-D) - Job BankDocument7 pagesList of Job Titles - Construction Trades Helpers and Labourers (NOC 7611-D) - Job BankAlex Punzalan100% (1)

- Design and Development of Plastic Parts For Car Interior: Project TitleDocument56 pagesDesign and Development of Plastic Parts For Car Interior: Project TitleJyoti KalePas encore d'évaluation

- Flowable-Fill Final 03-2006Document22 pagesFlowable-Fill Final 03-2006Hector Alberto Garcia LopezPas encore d'évaluation

- Bba Drilyner RFDocument11 pagesBba Drilyner RFLidijaSpaseskaPas encore d'évaluation

- Yanam PSR 2010-11 Book Schedule of RatesDocument869 pagesYanam PSR 2010-11 Book Schedule of RatesSaurabh Kumar SharmaPas encore d'évaluation

- NGO Monthly Progress ReportDocument94 pagesNGO Monthly Progress ReportRishiram MukhiyaPas encore d'évaluation

- Study On Properties of Polymer Modified Mortars Used As Repair MaterialsDocument6 pagesStudy On Properties of Polymer Modified Mortars Used As Repair MaterialsIJSTE100% (1)

- Art 12 Ceramic MaskDocument3 pagesArt 12 Ceramic Maskapi-272348756Pas encore d'évaluation

- ESR 2538 ChemofastDocument14 pagesESR 2538 ChemofastEduardo Antonio Duran SepulvedaPas encore d'évaluation

- A 02 1064Document4 pagesA 02 1064Marliton SalinasPas encore d'évaluation

- Sunanda PDFDocument3 pagesSunanda PDF9821694825100% (1)

- Penguard Pro: Technical Data SheetDocument5 pagesPenguard Pro: Technical Data SheetSyed Mahmud Habibur RahmanPas encore d'évaluation

- Nitoseal MS600 sealant for immersed conditionsDocument4 pagesNitoseal MS600 sealant for immersed conditionsmilanbrasinaPas encore d'évaluation

- Norma A 153 (Ingles)Document4 pagesNorma A 153 (Ingles)Ivo GecelePas encore d'évaluation

- Twyfords SpecDocument116 pagesTwyfords SpecjasonsinnottPas encore d'évaluation