Académique Documents

Professionnel Documents

Culture Documents

Asme Interpretations

Transféré par

ARNOUXDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Asme Interpretations

Transféré par

ARNOUXDroits d'auteur :

Formats disponibles

/.

' ..

. ._,'

ASME B31.3

INTERPRETATIONS NO. 13

1

Replies to Technical Inquiries

April 1, 1994, Through March 31, 1995

General Information

It has been agreed to publish interpretations issued by the B31 Committee concerning B31.3

as part of the update service to the Code. The interpretations have been assigned numbers in

chronological order. Each interpretation applies to the Edition or Aqdenda stated in the

interpretation, or if none is stated, to the Edition or Addenda in effect on the date of issuance of

the interpretation. Subsequent revisions to the Code may have superseded the reply. These

interpretations are not part of the Code or its Addenda.

These replies are taken verbatim from the original letters, except for a few typographical and

editorial corrections made for the purpose of improved clarity. In some instances, a review of the

interpretation revealed a need for corrections of a technical nature. In these cases, a revised reply

bearing the original interpretation number with the suffIx R is presented.

ASME .procedures provide for reconsideration of these interpretations when or if additional

information 'is available which the inquirer believes might affect the interpretation. Further, persons

aggrieved by an interpretation may appeal to the cognizant ASME committee or subcommittee. As

stated in the Statement of P o l i ~ in the Code documents, ASME does not "approve," "certify,"

"rate," or "endorse" any item, construction, proprietary device, or activity.

For detailed instructions on preparaion of technical inquiries to the B31 Committee, refer to

Appendix Z.

Code Reference and Subject Indexes

Code Reference and Subject Indexes have been prepared to assist. the user in locating

interpretations by location or by subject matter in the Code. They cover interpretations issued from

Volume 1 up to and including the present volume, and will be updated with each volume.

147

~ ,

"

i;

:~ .. '. -:

"

/" ,-

.. :; ~

t

: '. "

-: ... - ..,.

l . : . ~ ~ ~ . '

831.3

Subject

Alteration of Existing Piping and Hot Tapping ' .

Certification of a Listed Material to Another Listed Material Specification .

Paras. 301.2.1 and 302.2.5, Design Pressure .

Para. 304.1.1(a), Pressure Design of Straight Pipe .

Para 304.7.2, Pressure Design of Unlisted Components and Elements .

Paras. 304,7.2 and 304.7.2(d), Pressure Design

of Unlisted Components and Elements .

Paras. 304.7.2 and 319.3.6, Pressure Design and Flexibility Factors .

Para 319.4.1, Flexibility Analysis .

Para. 328.4, Preparation for Welding .

Para 328.5.4, Welded Branch Connections .

Chapter VI Inspection, Examination, and Testing .

Para. 341.3.4(e), Progressive Examination .

Para. 345.4.2(a), Hydrostatic Test Requirements .

Para. 345.5, Pneumatic Testing .

Para. A328.5.4, Heat Fusion Joints in Thermoplastic Piping .

Appendix X, Para. X3.2.2, Metallic Bellows Expansion Joints .

Intery,retation

13-04

13-10

13-15

13-07

13'()2

13'()3

'13-05

,13-14

13'()1

1311

:13.16

1312

13-13

13-06

,13.Q8

13-09

File No.

831-94-017

831-94.Q34

B31-94-042

831-94028

831-94015

B3194'()16

83194.()18

83194-041

83193-059

83194.()37

B3194.()59

831-94-039

83194-040

83194.Q20

831-94-029

83194-031

149

B31.3 Interpretations No. 13

Interpretation: 1301

Subject: ASME B31.3-1990 Edition, Para. 328.4, Preparation for Welding

Date Issued: November 21, 1994

File: B31-93-059

13-01, 13-62, 13-03

Question: In accordance with ASME B31.3-1990 Edition, Addenda a, does the Code require

that all transitional tapers be filled with weld metal to obtain a consistent outside diameter when

welding together two weld end components that are manufactured to include all of the following:

(1) a weld bevel to nominal wall thickness;

(2) an actual outside diameter greater than the nominal outside diameter;

(3) a taper transition from the actual outside diameter to the nominal outside diameter weld

bevel per ASME BI6.25, Fig. 1. .

Reply: No, the weld must have at least the same nominal wall thickness as the thinner of the

two components.

Interpretation: 1302

Subject: ASME B31.3-1993 Edition, Para. 304.7.2, Pressure Design of Unlisted Cqmponents

and Elements

Date Issued: 21, 1994

File: B31-94-015

Question: In accordance with ASME B31.3-1993 Edition, para. 304.7.2, may the maximum

allowable pressure of an unlisted component be greater than the manufacturer's rating?

Reply: Yes, see para. 300(c)(2).

Interpretation: 13-03

Subject: ASME B31.3-1993 Edition, Paras. 304.7.2 and 304.7.2(d), Pressure Design of Un-

listed Components and Elements

Date Issued: November 21, 1994

File: B31-94-016

Question: In accordance with ASME B31.3-1993 Edition, is a proof pressure test, in accordance

with para. 304.7.2(c), required to qualify a flange design not in with a listed standard if

the design meets the requirements of para. 304.7.2(d) as well as the introductory requirements of

para.304.7.2?

Reply: No.

151

1304, 13.05, 13-06

Interpretation: 1304

B31.3 Interpretations No. 13

r... ...

\; .'

....

,',

"

"

Subject: ASME B31.3-1993 Edition, Alterations of Existing Piping and Hot Tapping

Date Issued: November 21, 1994

File: B31-94-017

Question: Does ASME B31.3-1993 Edition and Addenda a apply to alterations of existing

piping, including tie-in branch connections, e.g., hot taps? '

Reply: No.

Interpretation: 1305

Subject: ASME B31.3-1993 Edition, Para. 304.7.2, Pressure Design qfUnlisted Components

and Elements, and Para. 319.3.6 Flexibility and Stress Intensification Factors

Date Issued: November 21, 1994

File: B31-94-018

Question (1): In accordance with ASME B31.3-1993 Edition, maya pressure containing piping

component, not manufactured in accordance with a listed standard, and for which the rules in para.

304 do not apply, be qualified in accordance with para. 304.7.2?

Reply'(1): Yes.

Question (2): In accordance with para. 319.3.6, may stress intensification factors for pressure

containing piping not manufactured in accordance with a listed standard listed in

Appendix D, be established by fatigue testing?

Reply (2): Yes.

Interpretation: 1306

Subject: ASME B31.3-1993 Edition, Para. 345.5, Pneumatic Testing

Date Issued: November 21, 1994

File: B31-94-020

Question: In accordance with ASME B31.3-1993 Edition and Addenda a, is it allowable to

pneumatically test above 110% of design pressure?

Reply: No, unless otherwise specified in the engineering design.

152

B31.3 Interpretations No. 13

Interpretation: 13-07

13-07, 13-08

Subject: ASME B31.3-1990 Edition, Para. 304.1.1(a), Pressure Design of Straight Pipe

Date Issued: November 21, 1994

File: B31-94-028

Question: In accor.dance with ASME B31.3-1990 Edition, may the minimum pipe wall thickness

determined by measurement be used to satisfy the requirements of para,. 304.1.1(a)?

Reply: Yes.

Interpretation: 13-08

Subject: ASME B31.3-1993 Edition, Para. A328.5.4, Heat Fusion Joints in Thermoplastic

Piping

Date Issued: November 21, 1994

File: B31-94-029

Question: Does ASME B31.3-1993 Edition, para. A328.5.4, apply to electrofusion bonding of

polyolefin pipe and fittings?

Reply: No. Eleetrofusion joints are not listed; see para. A304.7.2.

153

1309, 1310

Interpretation: 1309

B31.3 Interpretations No. 13

Subject: ASME B31.3-1987 Edition, Appendix X, Para. X3.2.2, Metallic Bellows Expansion

Joints

Date Issued: November 21, 1994

File: B31-94-031

Question (1): In accordance with ASME B31.3-1987 Edition, para. X3.2.2, is it required to

examine inaccessible surfaces of the bellows longitudinal seam weld after forming using liquid pen-

etrant?

Reply (1): No.

Question (2): Is a dye penetrant leak test (putting dye penetrant on :the inside surface and

developer on the weld outside surface) an acceptable alternative to liquid p ~ n e t r a n t examination of

the inside surface of bellows longitudinal seam welds?

Reply (2): No.

Question (3): Are the rules in ASME Section VIII, Division 1, Appendix 26, applicable to

bellows in ASME B31.3 piping systems?

Reply (3): No.

Interpretation: 1310

Subject: ASME B31.3-1993 Edition, Certification of a Listed Material to Another Listed

Material Specification.

Date Issued: November 21, 1994

File: B31-94034

Question: Is it permissible under the requirements of ASME B31.3-1993 Edition for an orga-

nization to recertify a listed material to another listed material specification?

Reply: B31.3 does not establish rules for materials certification other than the requirements of

the materials specifications.

154

B31.3 Interpretations No. 13

Interpretation: 1311

Subject: ASME B31.3-1993 Edition, Para 328.5.4, Welded Branch Connections

Date Issued: November 21, 1994

File: B31-94-037

13-11, 13.12, 13-13

Question: In accordance with ASME B31.3-1993 Edition, Addenda a, what is the effective weld

throat thickness required for a proprietary integrally reinforced branch 'connection fitting?

Reply: The thickness is as required by the manufacturer's design qualified in accordance with

para. 304.7.2 or MSS SP-94, and para. 328.5.4(d).

Interpretation: 1312

Subject: ASME B31.3-1990 Edition, Para. 341.3.4(e), Examination

Date Issued: November 21, 1994

File: B31-94-039

Question: In accordance with ASME B31.3-1990 Edition, para. 341.3.4(e), what is the meaning

of the phrase "all items represented by the progressive examinations."?

Reply: All items withia- the same designated lot. See para. 344.1.3 Definitions, random exami

nations.

Interpretation: 1313

Subject: ASME B31.3-1993 Edition, Para. 345.4.2(a), Hydrostatic Test Requirements

Date Issued: November 21, 1994

File: B31-94-040

Question: Does ASME B31.3-1993 Edition, Addenda a, permit a hydrostatic test pressure less

than 1.5 times design pressure?

Reply: No, unless para. 345.4.2(c) or 345.4.3(b) applies.

155

1314, 1315, 1316

Interpretation: 1314

Subject: ASME B31.3-1993 Edition, Para. 319.4.1, Flexibility Analysis

Date Issued: November 21, 1994

File: B31-94-041

B31.3 Interpretations No. 13

... ,"

\:1 ....

"'.,

Question: In accordance with para. 319.4.1, how many years of or number of operating

cycles are required to quil1ify a piping system as having a record?

Reply: Such determination is the responsibility of the designer. See para. 300(b)(2).

Interpretation: 1315

Subject: ASME B31.3-1993 Edition, Paras. 301.2.1 and 302.2.5, Design Pressure

Date Issued: November 21, 1994

File: B31-94-042

Question: When a valve isolates two process streams so that one condition on one side of the

valve occurs at the same time as another condition occurs on the other side of the valve, are the

requirements of paras. 301.2.1 and 302.2.5 met if the pressure design is based on the most severe

conditions of coincident pressure and component temperature?

Reply: Yes.

Interpretation: 1316

Subject: ASME B31.3-1993 Edition, Chapter VI Inspection, Examination, and Testing

Date Issued: November 21, 1994

File: B31-94-o59

Question (1): In accordance with ASME B31.3-1993 Edition, Addenda a, if a weld has not

penetrated to the inside comer of the root face on one side of the joint and the remainder of the

weld is sound, does ASME B31.3 classify this defect as lack of fusion?

Reply (1): No, refer to Fig. 341.3.2 sketch (c).

Question (2): Can lack of fusion occur at the root of a groove weld joint?

Reply (2): Yes.

Question (3): Is 1.5 in. of incomplete penetration in any 6 in. weld length for girth and miter

groove welds acceptable for normal fluid service?

Reply (3): Yes, per acceptance criteria listed in Table 341.3.2A.

156

Vous aimerez peut-être aussi

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Bandlock 2 Horizontal QOCDocument24 pagesBandlock 2 Horizontal QOCARNOUXPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

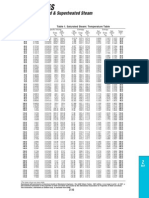

- Steam Tables: Properties of Saturated & Superheated SteamDocument11 pagesSteam Tables: Properties of Saturated & Superheated SteamARNOUXPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- PP Socket Fusion-Dimensional DataDocument21 pagesPP Socket Fusion-Dimensional DataARNOUXPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Mist Extractor - ProductCatalog PDFDocument20 pagesMist Extractor - ProductCatalog PDFStephen OgunladePas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Pipes and FittingsDocument1 pagePipes and FittingsARNOUXPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Pressure Equipment RegulationsDocument20 pagesPressure Equipment RegulationsARNOUXPas encore d'évaluation

- Arcelormittal CladDocument7 pagesArcelormittal CladARNOUXPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- AIA Technical Forum - M o M - 21-11-2013Document9 pagesAIA Technical Forum - M o M - 21-11-2013ARNOUXPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Circ LipsDocument3 pagesCirc LipsARNOUXPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Laminate SelectionDocument1 pageLaminate SelectionARNOUXPas encore d'évaluation

- Piping ModelDocument1 pagePiping ModelARNOUXPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Pipe Test Pressures TemplateDocument5 pagesPipe Test Pressures TemplateARNOUX100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Wind Pressures and Buckling of Cylindrical Steel1Document17 pagesWind Pressures and Buckling of Cylindrical Steel1ARNOUXPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Bolts TechnicalData PDFDocument48 pagesBolts TechnicalData PDFAnonymous smFxIR07Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Wind Buckling of Metal Tanks During Their ConstructionDocument7 pagesWind Buckling of Metal Tanks During Their ConstructionARNOUXPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Arcelormittal CladDocument7 pagesArcelormittal CladARNOUXPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Trunnion DetailDocument1 pageTrunnion DetailARNOUXPas encore d'évaluation

- Design Against FatigueDocument70 pagesDesign Against FatigueARNOUXPas encore d'évaluation

- Roller Bearings Selection ManualDocument4 pagesRoller Bearings Selection ManualARNOUXPas encore d'évaluation

- Steam Tables: Properties of Saturated & Superheated SteamDocument11 pagesSteam Tables: Properties of Saturated & Superheated SteamARNOUXPas encore d'évaluation

- Standard Bolt Torque Settings For Non-Metallic FlangesDocument1 pageStandard Bolt Torque Settings For Non-Metallic FlangesARNOUXPas encore d'évaluation

- AD Merkblatt CalculationsDocument13 pagesAD Merkblatt CalculationsARNOUX80% (5)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- DIN Flange Summary ChartDocument1 pageDIN Flange Summary ChartARNOUXPas encore d'évaluation

- AD Merkblatt CalculationsDocument13 pagesAD Merkblatt CalculationsARNOUX80% (5)

- Technologist ReRegistration AppFormDocument14 pagesTechnologist ReRegistration AppFormARNOUXPas encore d'évaluation

- DIN Flange Summary ChartDocument1 pageDIN Flange Summary ChartARNOUXPas encore d'évaluation

- BomDocument1 pageBomARNOUXPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Bill of QuntitiesDocument7 pagesBill of QuntitiesARNOUXPas encore d'évaluation

- Vapor PressureDocument120 pagesVapor PressureARNOUXPas encore d'évaluation

- Fermi Dirac StatisticsDocument15 pagesFermi Dirac StatisticsRiya SalujaPas encore d'évaluation

- Brochure DVE Laser Film 201505Document2 pagesBrochure DVE Laser Film 201505RDII YANMEDRSDSPas encore d'évaluation

- Astm C39Document5 pagesAstm C39Sergio Pascual50% (2)

- Material Science L-Photonic MaterialsDocument28 pagesMaterial Science L-Photonic MaterialsSaheer ShaikPas encore d'évaluation

- Unit 7 Future Home (English For Technology 2)Document2 pagesUnit 7 Future Home (English For Technology 2)Set S. Pirath0% (1)

- Ultrasonic Inspection For Shaft Inspection - by Derek Inspection PDFDocument3 pagesUltrasonic Inspection For Shaft Inspection - by Derek Inspection PDFVinothkumarPas encore d'évaluation

- Lab Name: Steam Power Plant Overview and It's Different Components (Rankine Cycle)Document19 pagesLab Name: Steam Power Plant Overview and It's Different Components (Rankine Cycle)Farhan EdwinPas encore d'évaluation

- I.Condition For The Equilibrium of A Particle: Stiffness KDocument5 pagesI.Condition For The Equilibrium of A Particle: Stiffness KJirah LacbayPas encore d'évaluation

- Adama Science and Technology University School of Applied Natural Science Department of Applied MathematicsDocument9 pagesAdama Science and Technology University School of Applied Natural Science Department of Applied MathematicsALEMAYEHUPas encore d'évaluation

- Circular beam designDocument34 pagesCircular beam designHasanuzzaman PalashPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Reinforced Masonry Engineering Handbook .6th - Ed.secDocument647 pagesReinforced Masonry Engineering Handbook .6th - Ed.secEc Ef100% (2)

- 4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFDocument500 pages4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFMittapalli SaikiranPas encore d'évaluation

- Research Paper On States of MatterDocument6 pagesResearch Paper On States of Matterefdkhd4e100% (1)

- Efunda - Plate Calculator - Clamped Circular Plate With Uniformly Distributed Loading-12.06.2017Document2 pagesEfunda - Plate Calculator - Clamped Circular Plate With Uniformly Distributed Loading-12.06.2017vinay1999Pas encore d'évaluation

- Actividad18-Cadena GarciaDocument17 pagesActividad18-Cadena GarciaSergio Cruz LopezPas encore d'évaluation

- Spark LightningDocument92 pagesSpark LightningaaPas encore d'évaluation

- Periodic Table Study Guide: How To Draw Bohr DiagramsDocument15 pagesPeriodic Table Study Guide: How To Draw Bohr Diagramsrudi_zPas encore d'évaluation

- Venturi Eductor: Nol-Tec Europe PresentsDocument2 pagesVenturi Eductor: Nol-Tec Europe PresentsJorge Luis Apaza GutierrezPas encore d'évaluation

- Case Study DELHAIZE ZELLIK ENG PDFDocument2 pagesCase Study DELHAIZE ZELLIK ENG PDFhonghai_dlPas encore d'évaluation

- Hygrophil HCDT: Product InformationDocument18 pagesHygrophil HCDT: Product InformationDavidPas encore d'évaluation

- Heat Transfer Presentation: Modes and LawsDocument16 pagesHeat Transfer Presentation: Modes and LawsmehediPas encore d'évaluation

- Shear Strength of Precast Prestressed Concrete Hollow Core SlabsDocument4 pagesShear Strength of Precast Prestressed Concrete Hollow Core SlabsMarkoGlamuzinaPas encore d'évaluation

- New Microsoft Excel WorksheetDocument8 pagesNew Microsoft Excel WorksheetAshraful HasanPas encore d'évaluation

- Ambient Vibration Testing of Historical Monuments in OhridDocument11 pagesAmbient Vibration Testing of Historical Monuments in OhridsaulolmPas encore d'évaluation

- SSC-JE Mechanical Obj. Paper 9789389269475Document23 pagesSSC-JE Mechanical Obj. Paper 9789389269475Shivam AgrawalPas encore d'évaluation

- Cambridge International General Certificate of Secondary EducationDocument20 pagesCambridge International General Certificate of Secondary Educationyuke kristinaPas encore d'évaluation

- VFR & 118Document1 pageVFR & 118Moeen Iqbal ShahPas encore d'évaluation

- Science 2010, 330, 933 (P450) PDFDocument6 pagesScience 2010, 330, 933 (P450) PDFCarlotaPas encore d'évaluation

- Syllabus MSPHYS 2020-2021-1Document67 pagesSyllabus MSPHYS 2020-2021-1mithunPas encore d'évaluation

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionD'EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionÉvaluation : 3 sur 5 étoiles3/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldD'EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Cyanide Canary: A True Story of InjusticeD'EverandThe Cyanide Canary: A True Story of InjusticeÉvaluation : 4 sur 5 étoiles4/5 (51)

- Waste: One Woman’s Fight Against America’s Dirty SecretD'EverandWaste: One Woman’s Fight Against America’s Dirty SecretÉvaluation : 5 sur 5 étoiles5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionD'Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionPas encore d'évaluation

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksD'EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksPas encore d'évaluation