Académique Documents

Professionnel Documents

Culture Documents

How To Disassemble The Turret Clamp Unclamp

Transféré par

angeldorta2002Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

How To Disassemble The Turret Clamp Unclamp

Transféré par

angeldorta2002Droits d'auteur :

Formats disponibles

CNC Repair Procedure: How to Disassemble the Turret Clamp/ Unclamp Piston on a Fuji HM-30 CNC Milling Machine

(Alarm 1002 Turret Clamp/ Unclamp Time Over)

Posted on May 2, 2011 by pinpoint1

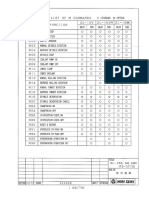

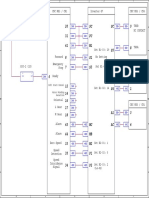

BUILDER: FUJI MODEL: HM-30 CONTROL: FANUC 21iM TITLE: TURRET INDEX TIME OVER ALARM. TURRET NOT FULLY UNCLAMPING. SUMMARY: CORROSION IN THE BORE FOR THE TURRET UNCLAMP PISTON PREVENTED FULL UNCLAMPING. CLAMPING CYLINER NEEDED TO BE REMOVED. ALARMS: 1002 DETAILS: 1. Index turret to station 1 and make sure its clamped. If the motor will not rotate the turret, you can look at the tool-driver to make sure you are in the correct location. The friver should be centered on the hole at the turret station at the 9 oclock position. You can then use the solenoid valve to clamp.

2. Mark and remove all holders from turret

3. Remove the front-end covers upper and lower sections

4. Disconnect the coolant pump at connector 1M2 at the rear of the machine.

5. Remove the split-ring guard on the turret. It makes it easier to handle when the turret comes off.

6. Remove the outer bolt pattern (M10 screws) that hold the turret on. Remove the eccentric pin prior to taking the turret off.

7. Remove the back section of the way-cover.

8. Remove the (2) M6 screws holding the clamp/unclamp proximity switches. Mark the bracket mounting location. Remove the (2) M8 screws holding the electrical connection box in place. You will need to move this out of the way.

9. Remove the (4) hex bolts that mount the turret-index motor. Set the motor and the box down inside the back area.

10. Remove the air hose for the oil-air mist.

11. Loosen the (3) set-screws and then remove the KMT nut from the back of the shaft. Remove the switch dog. Suggestion: take and record several measurements to make sure you get everything back the way it was to begin with when you re-assemble.

12. Loosen the M8 screws in the face of the Mecha-lock. Remove the Mecha-lock from the bore in the gear.

13. Push the shaft forward about inch to make some room on the back side for the removal of the gear and the back cover.

14. Remove the M8 screws from the back cover. Be careful not to lose the small lock washers on the screws. The cover must be pulled straight back as there are (2) pins in the bottom edge. Take off the large gear.

15. Remove the front disk and shaft from the front side. This will expose the machine-side coupling and the front end of the piston. Set it carefully on the floor. Watch that you catch the bearings on the back as the shaft comes out.

16. Remove the M8 screws that hold on the back cylinder flange. You can put a small screw in one of the tapped holes and gently pry the flange out of the bore.

17. The piston can now be removed. It will probably be necessary to hammer it out. Care must be taken to avoid damaging the piston or the cylinder bore. A tool can be made from scrap round-stock for this purpose.

Check out www.fanucmanual.com for our CNC troubleshooting book For Machine Tool Parts and Accessories, go to www.globalmachineparts.com Free cnc repair and troublshooting info at www.pinpointcncblog.com For information on Toyooki products, go to www.toyookivalve.blogspot.com Go to www.industrialfanslink.com for information on Industrial Fans for Machines. For machine scraping, alignment and repair check out Geometric Specialties Go to www.industrialoilcooler.com for information on Industrial Oil Coolers and Chillers

Vous aimerez peut-être aussi

- Vt-1150 User ManualDocument22 pagesVt-1150 User ManualAnne RodriguesPas encore d'évaluation

- CNC MitshibushiDocument394 pagesCNC MitshibushiMathi AlaganPas encore d'évaluation

- Operação M64Document347 pagesOperação M64Luciano MalheiroPas encore d'évaluation

- Fanuc Fanuc Fanuc Fanuc Fanuc: Series 16 Series 18 Series 20 Series 21 Series 0Document612 pagesFanuc Fanuc Fanuc Fanuc Fanuc: Series 16 Series 18 Series 20 Series 21 Series 0CLAUDIOPas encore d'évaluation

- 1 Program Errors Alarms On Program and OperationDocument78 pages1 Program Errors Alarms On Program and Operationsssf-doboj100% (2)

- 63505en PDFDocument397 pages63505en PDFSang Nguyễn BáPas encore d'évaluation

- ADI4Document79 pagesADI4Rudi CasmitaPas encore d'évaluation

- Mazak Detector Alarm MalfunctionDocument1 pageMazak Detector Alarm MalfunctionArturo LopezPas encore d'évaluation

- Gauging Manual PDFDocument311 pagesGauging Manual PDFsekhon875115Pas encore d'évaluation

- F400 Instruction Manual PDFDocument414 pagesF400 Instruction Manual PDFДТМ-Інжиніринг. Вестати з ЧПК, Південна КореяPas encore d'évaluation

- BNP b2215 (Eng) ZDocument138 pagesBNP b2215 (Eng) ZRuslanPas encore d'évaluation

- Mori Seiki ZLM Codes ListDocument3 pagesMori Seiki ZLM Codes ListDragosPas encore d'évaluation

- Mitsubishi Manuals 1351Document21 pagesMitsubishi Manuals 1351Roohollah TavassoliPas encore d'évaluation

- Oporation and Maintinace ManualDocument187 pagesOporation and Maintinace ManualChristian RollinsPas encore d'évaluation

- Mori Seiki ZT 1000 y enDocument16 pagesMori Seiki ZT 1000 y enOswald muñoz100% (1)

- Oprawki - Mazak Schite DeseneDocument32 pagesOprawki - Mazak Schite DeseneStoian Valentin50% (2)

- CNC Tapping Center: TC-S2D TC-22B TC-20B TC-R2B TC-32B TC-31BDocument15 pagesCNC Tapping Center: TC-S2D TC-22B TC-20B TC-R2B TC-32B TC-31BFodor Attila BotondPas encore d'évaluation

- Doosan BMT65 ToolingDocument28 pagesDoosan BMT65 Toolingmarcos lemosPas encore d'évaluation

- Manual FanucDocument6 pagesManual FanucWermeson SousaPas encore d'évaluation

- Parameter Manual: Fanuc Ac Spindle Motor @ Series Fanuc Ac Spindle Motor # SeriesDocument939 pagesParameter Manual: Fanuc Ac Spindle Motor @ Series Fanuc Ac Spindle Motor # SeriesTony AntonyPas encore d'évaluation

- Genos-En CNC OkumaDocument13 pagesGenos-En CNC Okumahggil380250% (2)

- IOLINK2-Connection Manual PDFDocument192 pagesIOLINK2-Connection Manual PDFSebautomatismePas encore d'évaluation

- Seicos 21l IntrustionDocument61 pagesSeicos 21l IntrustionkhoaPas encore d'évaluation

- Gfke 0218a en - 050120Document229 pagesGfke 0218a en - 050120giuseppe abatiPas encore d'évaluation

- OkumaDocument509 pagesOkumaMarijan Perković100% (1)

- B-62114en 03 050120Document183 pagesB-62114en 03 050120CONG TRAN NGOCPas encore d'évaluation

- 64113EN1Document1 224 pages64113EN1João Paulo Moreira Santos BarbosaPas encore d'évaluation

- LH-630 服務手冊Document378 pagesLH-630 服務手冊LndIngenieria50% (2)

- Maza Trol M 2 Operator ManualDocument5 pagesMaza Trol M 2 Operator Manualcamb2270100% (1)

- ES400 F 21iMB Mag Zero Set 033007Document3 pagesES400 F 21iMB Mag Zero Set 033007Julián MorelosPas encore d'évaluation

- Doosan TT Series CNCDocument7 pagesDoosan TT Series CNCRevolusiSoekarnoPas encore d'évaluation

- Datasheet Monitor Mazak ControlDocument1 pageDatasheet Monitor Mazak Controlzotya54Pas encore d'évaluation

- VMC Maintenance Manual (Alarm) : (Mynx 6500/)Document156 pagesVMC Maintenance Manual (Alarm) : (Mynx 6500/)Sagar HankarePas encore d'évaluation

- 0i - D Parameter B64310EN - 01 PDFDocument591 pages0i - D Parameter B64310EN - 01 PDFKen FitzpatrickPas encore d'évaluation

- Mori - ATC38 - 50 Installation - Maintenance Manual PDFDocument54 pagesMori - ATC38 - 50 Installation - Maintenance Manual PDFTheo SouzaPas encore d'évaluation

- Tsugami B0205 206 III Focus BrochureDocument8 pagesTsugami B0205 206 III Focus BrochureBakhtiar Permana50% (2)

- Mitsubishi M64 Control Corrupt User Program Memory SymptomsDocument1 pageMitsubishi M64 Control Corrupt User Program Memory SymptomsPham LongPas encore d'évaluation

- Fanuc Series 16 Backup ProcedureDocument4 pagesFanuc Series 16 Backup ProcedureYael Abraham GutiérrezPas encore d'évaluation

- Yasnac J50L Upgrading Function ManualDocument76 pagesYasnac J50L Upgrading Function ManualsunhuynhPas encore d'évaluation

- Fanuc 16i 210i Ts AlarmsDocument109 pagesFanuc 16i 210i Ts AlarmstugskulPas encore d'évaluation

- Programming Manual - Mazatrol Preview 3 - H763PA0017EDocument224 pagesProgramming Manual - Mazatrol Preview 3 - H763PA0017EIvan YordanovPas encore d'évaluation

- M100741H MAI Memex Memory Upgrade For Fanuc 16 182Document32 pagesM100741H MAI Memex Memory Upgrade For Fanuc 16 182Nica BogdanPas encore d'évaluation

- Re Initialise t32 mc116Document5 pagesRe Initialise t32 mc116GopiPas encore d'évaluation

- Mori Seiki MV-65 ParametrosDocument258 pagesMori Seiki MV-65 Parametrosfrancisco sandovalPas encore d'évaluation

- BNP b2267 (Eng) CDocument317 pagesBNP b2267 (Eng) CibraheemPas encore d'évaluation

- 19av550y ManualDocument36 pages19av550y ManualAre GeePas encore d'évaluation

- 17 HK63Document39 pages17 HK63faqall0% (1)

- 38M21C-1809EN Instruction ManualDocument396 pages38M21C-1809EN Instruction ManualCoptil NicolaePas encore d'évaluation

- 20ab - Operation Manual PDFDocument103 pages20ab - Operation Manual PDFNormaudettegmailcomPas encore d'évaluation

- A-53866E-387 - 02 - 050120 Startup SpindleDocument44 pagesA-53866E-387 - 02 - 050120 Startup SpindleAntonio LucasPas encore d'évaluation

- DNC Operation Management Package PDFDocument120 pagesDNC Operation Management Package PDFVìAi0% (1)

- File - 20210920 - 111340 - G7 YasnacDocument1 pageFile - 20210920 - 111340 - G7 YasnacPhong HuynhPas encore d'évaluation

- Fanuc 6 Alarm Codes System Fanuc 6 AlarmsDocument16 pagesFanuc 6 Alarm Codes System Fanuc 6 AlarmsPham LongPas encore d'évaluation

- 54765e PDFDocument152 pages54765e PDFCristobal PerezPas encore d'évaluation

- Fan Uc CNC Dual Check 01Document124 pagesFan Uc CNC Dual Check 01yogiboobooPas encore d'évaluation

- Mazak Mazatech v-515 en v1Document8 pagesMazak Mazatech v-515 en v1Mauricio A. Tamayo RamirezPas encore d'évaluation

- CNC - Sfy-Aem680atx-Im-M-0 M720XP 380VDocument211 pagesCNC - Sfy-Aem680atx-Im-M-0 M720XP 380VРоман ДупликPas encore d'évaluation

- Volvo Penta Md5A Diesel Marine Engine Workshop Manual (REPARACION de MOTORES)Document38 pagesVolvo Penta Md5A Diesel Marine Engine Workshop Manual (REPARACION de MOTORES)todogif100% (1)

- 70 070 Autocreaser 50 Service ManualDocument31 pages70 070 Autocreaser 50 Service ManualWilliam John DavisonPas encore d'évaluation

- DataBase Management Systems SlidesDocument64 pagesDataBase Management Systems SlidesMukhesh InturiPas encore d'évaluation

- Wilo49608 Wilo Ge LeafletDocument46 pagesWilo49608 Wilo Ge LeafletJair Jimenez HerreraPas encore d'évaluation

- Data MiningDocument721 pagesData MiningAuly Natijatul AinPas encore d'évaluation

- Subsistence and Travel FormsDocument3 pagesSubsistence and Travel FormsAnonymous YRLhQY6G6jPas encore d'évaluation

- BSDC CCOE DRAWING FOR 2x6 KL R-1Document1 pageBSDC CCOE DRAWING FOR 2x6 KL R-1best viedosPas encore d'évaluation

- Agile Marketing Reference CardDocument2 pagesAgile Marketing Reference CardDavid BriggsPas encore d'évaluation

- Summative-Test-3-5 Tve ExploratoryDocument3 pagesSummative-Test-3-5 Tve ExploratoryMjnicole MartejaPas encore d'évaluation

- Hyflow: Submersible PumpsDocument28 pagesHyflow: Submersible PumpsmanoPas encore d'évaluation

- A Case Study From The: PhilippinesDocument2 pagesA Case Study From The: PhilippinesNimPas encore d'évaluation

- Nxivm: 2nd Superseding IndictmentDocument32 pagesNxivm: 2nd Superseding IndictmentTony Ortega100% (2)

- Instructions For The Safe Use Of: Web LashingsDocument2 pagesInstructions For The Safe Use Of: Web LashingsVij Vaibhav VermaPas encore d'évaluation

- Supply DemandProblems With Solutions, Part 1Document16 pagesSupply DemandProblems With Solutions, Part 1deviPas encore d'évaluation

- Quiz1 2, PrelimDocument14 pagesQuiz1 2, PrelimKyla Mae MurphyPas encore d'évaluation

- Bali Hai LawsuitDocument14 pagesBali Hai LawsuitLas Vegas Review-JournalPas encore d'évaluation

- PCU CalculationDocument2 pagesPCU CalculationMidhun Joseph0% (1)

- 2 1 PDFDocument18 pages2 1 PDFالمهندسوليدالطويلPas encore d'évaluation

- Imp121 1isDocument6 pagesImp121 1isErnesto AyzenbergPas encore d'évaluation

- CV Najim Square Pharma 4 Years ExperienceDocument2 pagesCV Najim Square Pharma 4 Years ExperienceDelwarPas encore d'évaluation

- Orthopanton Villa System MedicalDocument61 pagesOrthopanton Villa System MedicalOscarOcañaHernándezPas encore d'évaluation

- Leadership Style SurveyDocument3 pagesLeadership Style SurveyJanelle BergPas encore d'évaluation

- UNECE-Turkey-TCDO-Rail Freight Traffic in Euro-Asian LinksDocument20 pagesUNECE-Turkey-TCDO-Rail Freight Traffic in Euro-Asian LinksArsenePas encore d'évaluation

- Dolby Atmos Specifications PDFDocument24 pagesDolby Atmos Specifications PDFVanya ValdovinosPas encore d'évaluation

- O-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisDocument11 pagesO-CNN: Octree-Based Convolutional Neural Networks For 3D Shape AnalysisJose Angel Duarte MartinezPas encore d'évaluation

- Laser Security System For HomeDocument19 pagesLaser Security System For HomeSelvakumar SubramaniPas encore d'évaluation

- Legal Environment of Business 7th Edition Kubasek Solutions Manual Full Chapter PDFDocument34 pagesLegal Environment of Business 7th Edition Kubasek Solutions Manual Full Chapter PDFlongchadudz100% (12)

- International Business EnvironmentDocument5 pagesInternational Business EnvironmentrahulPas encore d'évaluation

- MGT 201 Midterm Exam, Version BDocument8 pagesMGT 201 Midterm Exam, Version BCybelle TradPas encore d'évaluation

- Newton Gauss MethodDocument37 pagesNewton Gauss MethodLucas WeaverPas encore d'évaluation

- 25 - Marketing Channels - Value Networks.Document2 pages25 - Marketing Channels - Value Networks.zakavision100% (1)

- Tankguard AR: Technical Data SheetDocument5 pagesTankguard AR: Technical Data SheetAzar SKPas encore d'évaluation