Académique Documents

Professionnel Documents

Culture Documents

Petrol Engine (Nehru Garden)

Transféré par

api-3703711Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Petrol Engine (Nehru Garden)

Transféré par

api-3703711Droits d'auteur :

Formats disponibles

Govt. Girls. Sr. Sec. School, Nehru Garden.

Jalandhar City.

PETROL ENGINE

Petrol engine was introduced by the engineers Gottlieb Daimler and Karl

Benz (both from Germany) in 1885. It is considered as one of biggest

achievement in the automotive field. It uses petrol called as gasoline in

USA as a fuel. It is made up of about 150 moving parts. Within the engine

burning of fuel mixed with air causes hot gases to expand against parts of

the engine and force them to move. So petrol engines are called internal-

combustion engines. Petrol engines are compact and light in weight for the

power they produce. The rate at which it produces work is usually

measured in horsepower or watts.

KINDS OF PETROL ENGINES

Reciprocating petrol engines are distinguished in a number of ways. Some

of them are as follows:

(1) Type of compression

(2) Valve arrangement

(3) The way they are cooled,

(4) The way they are supplied with air and fuel.

(5) Number of piston strokes per cycle,

(6) Cylinder arrangement

Classification based on number of stokes per cycle:

a) Two Stroke

b) Four Stroke

A) TWO STROKE PETROL ENGINE

From the name itself we get the idea about the functioning of the engine.

The engine ignites fuel at every upward stroke, so there are two strokes for

every ignition of fuel. They are called upward and downward stroke. As the

piston moves in upward direction from bottom to top in the first stroke the

air and fuel mixture gets compressed and ignited by spark plug as upward

stroke comes to end. This results in an explosion of mixture which forces

the piston to move downwards thereby producing power.

Since they have less moving parts they are light in weight .Also the design

is simple compared to four stroke engines. Big size bulky two-stroke cycle

engines have lubrication systems like that of four-stroke cycle engines.

B)FOUR STROKE PETROL ENGINE:

The four stroke engine is called so because the working of an internal

combustion engine is divided into four stages called four strokes of the

engine.

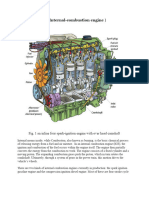

PARTS OF A PETROL ENGINE

Following are some of the important parts of petrol engine:

1) CYLINDERS - Cylinders are rigid tubes that serve as a bearing for

the pistons that move up and down inside them. They have highly polished

surfaces. This permits a close fit between piston and cylinder and prevents

gases from leaking past the piston. The cylinders in most car engines are

part of the block. Some engines have a cylinder sleeve made of specially

hardened steel or cast iron pressed into the cylinder block.

2) CYLINDER BLOCK - Cylinder block is a rigid frame that holds the

cylinders in proper alignment. If the engine is liquid cooled, the block is

jacketed, so that it can be surrounded by the liquid, or has passages for

the liquid around each cylinder. In automotive engines, the cylinder block

and crankcase form a single unit. Most cylinder blocks are made of cast

iron or aluminium.

3) PISTON AND CONNECTING RODS - There is a piston fitted in the

cylinder. This piston is connected to a connecting rod which in turn is

connected to the crank shaft. When the fuel-air mixture burns, the

expanding gases exert a force on the piston. This force is then transmitted

through a connecting rod to the crankshaft. The piston has two to six rings

to prevent the gases from escaping and to keep lubricating oil from getting

into the combustion chamber.

4) CYLINDER HEAD - Cylinder head is a casting bolted to the top of the

cylinder block. The cylinder head, together with the upper end of the

cylinder and the top of the piston, form the combustion chamber where the

fuel-air mixture burns. A cylinder head and block may be one unit.

5) CRANKCASE - Crankcase is a rigid frame that holds the crankshaft and

the crankshaft bearings. In small engines, all or part of the crankcase may

be a part of the cylinder block

6) VALVES - In a four-stroke cycle engine, each cylinder has one or two

intake valves, to let the air-fuel mixture into the combustion chamber, and

one or two exhaust valves, to let the burned gases escape. These are

called poppet valves, because they pop up and down as they open and

close. The opening in the cylinder block or head uncovered by the valve is

called the port. In many two-stroke cycle engines, the movement of the

piston takes the place of separate valves. As the piston moves, it covers

and uncovers the ports.

7) CRANK SHAFT - Crankshaft changes the reciprocating motion of the

pistons into rotary motion. The crankshaft has a number of cranks, or

throws. These cranks are displaced at angles to each other. For example,

in a six-cylinder, in-line, four-stroke cycle engine, the cranks are displaced

at 120° angles to each other. As a result, the engine delivers three equally

spaced power strokes in each revolution of the crankshaft to assure

smooth operation.

8) FLYWHEEL - Flywheel stores energy during a piston's power stroke and

releases it during other strokes. This helps to keep the crankshaft turning

at a constant speed

9) CAMSHAFT - Camshaft opens and closes the valves at the proper point

in the engine cycle. It runs the length of the engine and has one cam (lobe)

at each intake and exhaust valve. In a four-stroke cycle engine, the

camshaft is geared to the crankshaft so that it runs at half the crankshaft's

speed. The camshaft may be located in the head of an overhead valve

engine, or in the crankcase.

10) FUEL SYSTEM - Fuel system includes : (1) a storage tank for petrol, (2)

fuel lines to carry the petrol to the carburettor, (3) a carburettor to mix the

petrol with air, and (4) an intake manifold to distribute the fuel-air mixture to

the cylinders. The fuel system also includes a filter to clean dirt out of the

fuel and an air cleaner to take dirt out of the air that is mixed with the

petrol. In addition, the system may include a governor to limit the engine's

speed.

11) EXHAUST SYSTEM - Exhaust system consists of one or more parts. It

may include (1) an exhaust manifold to collect the burned gases from the

cylinders, (2) an exhaust pipe to carry the burned gases, and (3) a silencer

to silence the noise of the exhaust gases.

12) IGNITION SYSTEM - Ignition system is the electrical circuit necessary to

set fire to, or ignite, the fuel-air mixture in the different cylinders at different

times. In a car a storage battery provides electric current, which is

increased in voltage by an induction coil. The high-voltage current is

carried through a distributor, which delivers the electricity to each cylinder

at about the moment the piston reaches the top of the compression stroke.

There the electric current jumps a gap between two terminals and sets fire

to the petrol-air mixture. The terminals are encased in insulating material

and called a spark plug.

13) IGNITION SYSTEM - Ignition system is the electrical circuit necessary to

set fire to, or ignite, the fuel-air mixture in the different cylinders at different

times. In a car a storage battery provides electric current, which is

increased in voltage by an induction coil. The high-voltage current is

carried through a distributor, which delivers the electricity to each cylinder

at about the moment the piston reaches the top of the compression stroke.

There the electric current jumps a gap between two terminals and sets fire

to the petrol-air mixture. The terminals are encased in insulating material

and called a spark plug.

WORKING OF A PETROL ENGINE

The working of an internal combustion engine is divided into four stages

called four strokes of the engine and hence the engine is called a four

stroke engine.

THE INTAKE STROKE :

When the engine starts, the piston moves downwards in the cylinder,

because of which a region of low pressure is created in the cylinder, above

the piston. At this moment, the intake valve opens and the fuel

mixture(petrol vapour and air mixture) is sucked into the cylinder from the

carburetor.

THE COMPRESSION STROKE :

When the sufficient amount of the fuel mixture (petrol vapour and air

mixture) has entered the cylinder, the intake valve gets closed. The piston

is then forced to move upwards which compresses the fuel-mixture to

about one-eighth of its original volume. Higher the compression ratio, more

will be the efficiency of the engine.

THE POWER STROKE :

Before the piston completes its upward movement, compressing the petrol

vapour and air mixture, the spark plug produces a little electric spark inside

the cylinder and this spark sets fire to the petrol-air mixture. The petrol

vapour burns quickly in a little explosion, producing a large volume of

gases and enormous heat. The heat thus produced expands the gases

rapidly. The pressure of rapidly expanding hot gases pushes the piston

downward with a great force. The piston pushes the piston rod and the

piston rod pushes the crank shaft. The crank shaft is joined to the wheels

of a car. When the crank shaft turns, the wheels rotate and move the car.

THE EXHAUST STROKE:

When the piston has been pushed to the bottom of the cylinder by the hot

expanding gases in the power stroke, then the exhaust valve opens. After

that, due to the momentum gained by the wheels, the piston is pushed

upwards. The upward movement of the piston, expels the spent gases

through the exhaust valve into the atmosphere, carrying away the unused

heat. The exhaust valve then closes, the intake valve opens up, and the

above four strokes of the engine are repeated again and again.

CARBURETOR

It is the heart of gasoline engine. They meter the fuel and mix it with the air

in precise proportions. Old carburetors do spark advance by measuring the

difference in pressure between the outside and inside of the carburetor.

The amount of throttle advance is also measured. The engine's remains

which may be carbon monoxide or unburned hydrocarbons shows how

well the carburetor is working. In new engines, a small computer is used

to calculate these parameters and control one or more electric injectors.

Most of the new cars use electronic fuel injection as it allows the engine

computer to precisely control the fuel air mixture which increases energy

efficiency and reduces pollution.

APPLICATIONS:

These engines are widely used in vehicles, portable power plants to supply

the power to run pumps and other machinery on farms. Many small boats,

aero planes, trucks and buses also use it.

FUTURE SCOPE:

Continuous research is being carried to increase the fuel efficiency, reduce

the pollutants and make it more light and compact. Recently engineers at

the University of Birmingham have made the smallest petrol engine that

can replace conventional batteries. The engine is so tiny that it can be

handled on a fingertip.

Vous aimerez peut-être aussi

- Vroom! How Does A Car Engine Work for KidsD'EverandVroom! How Does A Car Engine Work for KidsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiD'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiPas encore d'évaluation

- Engine Part IDocument39 pagesEngine Part Iaashish koiralaPas encore d'évaluation

- IC EnginesDocument44 pagesIC EnginesIbrahim KhaleelPas encore d'évaluation

- Unit 1Document32 pagesUnit 1Rakeshkumarceg100% (1)

- Diesel Engine TechnologyDocument59 pagesDiesel Engine TechnologyAnonymous f2zDTm7kmPas encore d'évaluation

- On Saying Please Sanghana AmritsarDocument15 pagesOn Saying Please Sanghana Amritsarapi-3731257100% (2)

- Internal Combustion EngineDocument136 pagesInternal Combustion Enginepreethu02Pas encore d'évaluation

- 4 Stroke Petrol EngineDocument9 pages4 Stroke Petrol EngineZahid MughalPas encore d'évaluation

- Experiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineDocument6 pagesExperiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineHafeez AliPas encore d'évaluation

- Petrol EnginesoDocument7 pagesPetrol Enginesoapi-3731257Pas encore d'évaluation

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentSahil KalaPas encore d'évaluation

- Greater Noida Institute of Technology: 2-Stroke Petrol EngineDocument13 pagesGreater Noida Institute of Technology: 2-Stroke Petrol EngineEr Raghvendra SinghPas encore d'évaluation

- Lab ReportDocument14 pagesLab ReportHammad Hassan100% (5)

- Communication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Document6 pagesCommunication Lab 4-Stroke Petrol Engine: Hemanth Kumar R 07ME034Hemu723Pas encore d'évaluation

- ICE (Internal Combustion Engine)Document22 pagesICE (Internal Combustion Engine)johnlloydsantossssPas encore d'évaluation

- Internal Combustion EngineDocument46 pagesInternal Combustion EngineJoseph Rebanal AlmanzaPas encore d'évaluation

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocument9 pagesPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalPas encore d'évaluation

- Internal Combustion EnginesDocument32 pagesInternal Combustion Enginespramodkb_cusatPas encore d'évaluation

- Asi Unit 3Document21 pagesAsi Unit 3Raja RamPas encore d'évaluation

- Automative Electronics and Hybrid VehicleDocument34 pagesAutomative Electronics and Hybrid VehicleNIKHIL ASPas encore d'évaluation

- 4 Stroke Petrol Engine1699240011Document7 pages4 Stroke Petrol Engine1699240011Masoud doski100% (1)

- Study of Working Mechanisms of Important Components of Automobile EngineDocument5 pagesStudy of Working Mechanisms of Important Components of Automobile EngineNiranjana KarandikarPas encore d'évaluation

- Applications: and TheirDocument88 pagesApplications: and TheiralexPas encore d'évaluation

- Internal Combustion Engines: ApplicationsDocument88 pagesInternal Combustion Engines: ApplicationscarlosPas encore d'évaluation

- Presentation On Petrol Engine: Presented By-Mridul Mudai Sec-B4004 Roll No-B64Document12 pagesPresentation On Petrol Engine: Presented By-Mridul Mudai Sec-B4004 Roll No-B64mridulmudai1991Pas encore d'évaluation

- 1514285118329-Notes ALP InductionDocument97 pages1514285118329-Notes ALP InductionKhirod SahuPas encore d'évaluation

- Thermodynamics Lab ReportDocument49 pagesThermodynamics Lab Reportjawad60% (5)

- First Semester:-Course Title: Applied Thermodynamics TopicDocument8 pagesFirst Semester:-Course Title: Applied Thermodynamics TopicHafeez AliPas encore d'évaluation

- Lesson V Automobile Engine, and The Four-Stroke CycleDocument5 pagesLesson V Automobile Engine, and The Four-Stroke CycleNicolas AntiguaPas encore d'évaluation

- Chapter 2Document41 pagesChapter 2Ibrahim KhaleelPas encore d'évaluation

- Artifact 4 Parts Small Engines PowerpointDocument56 pagesArtifact 4 Parts Small Engines Powerpointapi-240922530Pas encore d'évaluation

- Parts of An Automobile EngineDocument16 pagesParts of An Automobile EngineEric James CatanguiPas encore d'évaluation

- At6311 Ac Lab ManualDocument78 pagesAt6311 Ac Lab Manualvivek kumarPas encore d'évaluation

- Tejay L. Tolibas BSCE - 3EDocument3 pagesTejay L. Tolibas BSCE - 3ETejay TolibasPas encore d'évaluation

- Abhay Mini InternshipDocument23 pagesAbhay Mini InternshipAbhay Raaj YadavPas encore d'évaluation

- M17-Gas and Diesel Enginesrev2 (Zadco-AHRT)Document41 pagesM17-Gas and Diesel Enginesrev2 (Zadco-AHRT)VAN VIET NGOPas encore d'évaluation

- Internal Combustion Engines: Introduction Fuels Four Stroke Engine Parts of A Four Stroke EngineDocument17 pagesInternal Combustion Engines: Introduction Fuels Four Stroke Engine Parts of A Four Stroke EnginehitulparmarPas encore d'évaluation

- Advantages and Disadvantages of Different Types of EngineDocument11 pagesAdvantages and Disadvantages of Different Types of EngineJerome BalatbatPas encore d'évaluation

- 4 Petrol EngineDocument7 pages4 Petrol Engineayesha amjadPas encore d'évaluation

- Final Project Mechanical PowerDocument163 pagesFinal Project Mechanical PowerVikrant KumarPas encore d'évaluation

- M17-Gas and Diesel Engines - Rev1 (Zadco-AHRT)Document40 pagesM17-Gas and Diesel Engines - Rev1 (Zadco-AHRT)VAN VIET NGOPas encore d'évaluation

- 4 Stroke Gasolin1Document3 pages4 Stroke Gasolin1edwinvvnPas encore d'évaluation

- Lab ReportDocument7 pagesLab Reportshah_gen89Pas encore d'évaluation

- Lab Report 12Document8 pagesLab Report 12mamoona noreenPas encore d'évaluation

- Four Stroke EngineDocument9 pagesFour Stroke Enginepawarsikander100% (3)

- Four Stroke Engine Project (2009-2010)Document47 pagesFour Stroke Engine Project (2009-2010)A K SinghPas encore d'évaluation

- Thermal Engineering 1: Lecture NotesDocument17 pagesThermal Engineering 1: Lecture NotesAndy LoPas encore d'évaluation

- Internal Combustion Engine: Chapter Learning ObjectivesDocument17 pagesInternal Combustion Engine: Chapter Learning ObjectivesRahul KhatriPas encore d'évaluation

- Mechanical KnowledgeDocument25 pagesMechanical KnowledgeJustin LowePas encore d'évaluation

- Four Stroke Petrol EngineDocument12 pagesFour Stroke Petrol EngineSyed Zaheer SajjadPas encore d'évaluation

- Theory of Engine OperationDocument19 pagesTheory of Engine OperationGabriel Dela Cruz LagmanPas encore d'évaluation

- Yy Y Yy" Y! Y YyyDocument14 pagesYy Y Yy" Y! Y YyyVenkatachalam AnnamalaiPas encore d'évaluation

- A Comparison of Two Stroke & Four Stroke EnginesDocument4 pagesA Comparison of Two Stroke & Four Stroke EnginesLubna KhanPas encore d'évaluation

- Four-Stroke Engine: From Wikipedia, The Free EncyclopediaDocument4 pagesFour-Stroke Engine: From Wikipedia, The Free EncyclopediaSam B. SucalitPas encore d'évaluation

- Marpower: Week No.1 Diesel Engine FundamentalsDocument6 pagesMarpower: Week No.1 Diesel Engine FundamentalsDarkxeiDPas encore d'évaluation

- Two and Three Wheeler NotesDocument49 pagesTwo and Three Wheeler NotesAbishek AbhPas encore d'évaluation

- Diesel EngineDocument14 pagesDiesel EngineAyşenur ÇetinPas encore d'évaluation

- CH7 ForgettingDocument29 pagesCH7 Forgettingapi-3731257100% (1)

- Govt. High. School Jhitan KalanDocument15 pagesGovt. High. School Jhitan Kalanapi-3731257Pas encore d'évaluation

- Sarojini Naidu: The Nightingale of IndiaDocument9 pagesSarojini Naidu: The Nightingale of Indiaapi-3731257Pas encore d'évaluation

- Batch:-3 Phase - I Roll No.-34 Class-12 Subject: - General English Topic: - The Death of SocratesDocument13 pagesBatch:-3 Phase - I Roll No.-34 Class-12 Subject: - General English Topic: - The Death of Socratesapi-3731257Pas encore d'évaluation

- Author:-J.L Nehru: JL Nehru Was 1 Prime Minister of IndiaDocument17 pagesAuthor:-J.L Nehru: JL Nehru Was 1 Prime Minister of Indiaapi-3731257Pas encore d'évaluation

- GSSBANDALA English)Document14 pagesGSSBANDALA English)api-3731257Pas encore d'évaluation

- General AidsDocument8 pagesGeneral Aidsapi-3731257Pas encore d'évaluation

- Indian Weavers - Tarn Taran (G) - Tarn Taran (C)Document10 pagesIndian Weavers - Tarn Taran (G) - Tarn Taran (C)api-3731257Pas encore d'évaluation

- Class 10+2Document5 pagesClass 10+2api-3731257Pas encore d'évaluation

- Lesson Plan 12 Class Topic Noun and VerbDocument18 pagesLesson Plan 12 Class Topic Noun and Verbapi-3731257Pas encore d'évaluation

- A Project Report ON: Fasting As PenanceDocument10 pagesA Project Report ON: Fasting As Penanceapi-3731257Pas encore d'évaluation

- Ghsmehma Amritsar Maori VillagesDocument10 pagesGhsmehma Amritsar Maori Villagesapi-3731257Pas encore d'évaluation

- Ghsguruwali ForgettingDocument7 pagesGhsguruwali Forgettingapi-3731257Pas encore d'évaluation

- Ghsmanawala - The School For SympathyDocument5 pagesGhsmanawala - The School For Sympathyapi-3731257Pas encore d'évaluation

- Indian Weavers - Pandori Gola - Tarn Taran (A)Document13 pagesIndian Weavers - Pandori Gola - Tarn Taran (A)api-37312570% (1)

- Daffodils - Pandori Ran Singh - Tarn Taran (A)Document11 pagesDaffodils - Pandori Ran Singh - Tarn Taran (A)api-3731257Pas encore d'évaluation

- Indian Weavers - Gaggobua) Tarn Taran (C)Document19 pagesIndian Weavers - Gaggobua) Tarn Taran (C)api-373125760% (5)

- Tolstoy's Home Sohian Khurd AmritsarDocument13 pagesTolstoy's Home Sohian Khurd Amritsarapi-3731257100% (2)

- The Lost Child Pakharpura AmritsarDocument5 pagesThe Lost Child Pakharpura Amritsarapi-3731257Pas encore d'évaluation

- No Men Are Foreign - Tarsikka - AmritsarDocument10 pagesNo Men Are Foreign - Tarsikka - Amritsarapi-3731257100% (1)

- Leisure Nagkalan AmritsarDocument11 pagesLeisure Nagkalan Amritsarapi-3731257Pas encore d'évaluation

- Tense Nagkalan AmritsarDocument17 pagesTense Nagkalan Amritsarapi-3731257100% (1)

- Diamond Necklace Pakharpura AmritsarDocument8 pagesDiamond Necklace Pakharpura Amritsarapi-3731257Pas encore d'évaluation