Académique Documents

Professionnel Documents

Culture Documents

SPE 25630 Multiwell Application of Downhole Temperature Profiles For Crossflow Analysis

Transféré par

glsancor0 évaluation0% ont trouvé ce document utile (0 vote)

47 vues9 pagesThis paper was prepared for presentation at the SPE Middle East Oil Technical Conference and Exhibition held in Bahrain, 3-6 April 1993. Temperature profiles have been used extensively for problem diagnostics related to downhole leaks and cross-flows behind the casing. The technique presented in this paper looks at extending the single well temperature profile analysis to multi-well data-base application.

Description originale:

Titre original

00025630[1]

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThis paper was prepared for presentation at the SPE Middle East Oil Technical Conference and Exhibition held in Bahrain, 3-6 April 1993. Temperature profiles have been used extensively for problem diagnostics related to downhole leaks and cross-flows behind the casing. The technique presented in this paper looks at extending the single well temperature profile analysis to multi-well data-base application.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

47 vues9 pagesSPE 25630 Multiwell Application of Downhole Temperature Profiles For Crossflow Analysis

Transféré par

glsancorThis paper was prepared for presentation at the SPE Middle East Oil Technical Conference and Exhibition held in Bahrain, 3-6 April 1993. Temperature profiles have been used extensively for problem diagnostics related to downhole leaks and cross-flows behind the casing. The technique presented in this paper looks at extending the single well temperature profile analysis to multi-well data-base application.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 9

SPE 25630

Multiwell Application of Downhole Temperature Profiles for

Crossflow Analysis

M.F.J. Petricola and Mohamed Watfa, Schlumberger Middle East S.A.

SPE Members

Copyright 1993, Society of Petroleum Engineers, Inc.

SocIety of Petroleum Engineers

This paper was prepared for presentation at the SPE Middle East Oil Technical Conference & Exhibition held in Bahrain, 3-6 April 1993.

This paper was selected for presentation by an SPE Program Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper,

as p r e s ~ ~ t e d , have not been reviewed by the Society of Petroleum Engineers and are SUbject to correction by the author(s). The material, as presented, does not necessarily reflect

any POSItion of the Society of Petroleum Engineers, its officers, or members. Papers presented at SPE meetings are subject to publication review by Editorial Committees of the Society

of Petroleum Engineers. Permission to copy is restricted to an abstract of not more than 300 words. Illustrations may not be copied. The abstract should contain conspicuous acknOWledgment

of where and by whom the paper is presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., Telex, 163245 SPEUT.

ABSTRACT

Temperature profiles have been used extensively for

problem diagnostics related to downhole leaks and

cross-flows behind the casing. The classical

procedure is to obtain a true geothermal temperature

profile and correlate future temperature changes to

the geothermal to obtain an estimate of the location,

magnitUde and direction cf the cross-flow anomalies.

This single well technique was limited by the

availability of a representative geothermal gradient,

local and time-lapse variations in this geothermal

gradient, coupled with the absolute accuracy

required from the temperature readings.

The technique presented in this paper looks at

extending the single well temperature profile analysis

to multi-well data-base application. Here the

temperature profiles for a selected number of wells

in a field are loaded in a database. The geothermal

variations across the field can then be quantified at

any given period of time from the median reading for

the wells in that area. This allows for data

normalizations for all the wells, which improved the

accuracy of the temperature readings. The net effect

is an order of magnitude improvement in accuracy,

which facilitated the detection of small leaks and

cross-flow of fluids behind the casing. In essence,

this technique overcomes all the shortcomings and

errors that are normally associated with the single

well temperature profile evaluation.

The examples presented show the classical

applications of temperature profile evaluation in a

variety of behind the casing cross-flow environment.

The results also show how a geothermal gradient

can be obtained from a family of wells where no

representative geothermal gradient is available over

the intervals of interest. The resultant improvement

295

in resolution also highlight the presence of very slow

leaks, that would otherwise have not been detected.

INTRODUCTION

Temperature profiling can be used for a variety of

problem diagnostics in producing and shut down

wells (ref-1). Essentially, the deviations of the

measured temperature-depth profiles (temp) from

the established geothermal temperature profiles, for

the interval under evaluation, are used to evaluate

for casing leaks and for behind casing cross-flow.

The temperature derivative with respect to depth

(.1temp) can be used in combination with the temp

profile which acts as a magnifier of anomalies- This

is essentially similar to the derivative of the pressure

- time profiles in pressure transient analysis.

The interpretation procedure of the temp and .1temp

profiles are complicated by a variety of factors.

These may include the following:

The original "undisturbed" geothermal

temperature profiles are not linear function of

depth. The temp profiles have characteristic

signatures for each formation, reflecting

endothermic and exothermic reactions that may

be taking place.

If fluid injection is taking place, then formation

cooling may take place resulting in regional

modification of the original temp profiles.

In gas cap reservoirs, gas expansion caused by

production may also result in a modified temp

profile.

In flowing wells, small deviation temp may be

swamped by the flowing fluid temperature in the

casing or annulus, masking small anomalies

related to cross-flows and leaks.

* Mark of Schlumberger

MULTI-WELL APPLICATIONS OF DOWNHOLE TEMPERATURE

PROFILES FOR CROSS-FLOW ANALYSIS

SPE 25630

In faulted reservoirs, the temperature profiles,

and absolute values of temperatures, can vary

from one block to another.

Where gas fluid movement is taking place, the

flow profile is complicated by the cooling effects

of the gas caused by expansion. Thus, if gas

is channeling upward, then the increase in the

temp caused by the vertical movement of the

gas is balanced by the cooling effect due to

expansion.

It is apparent from the aforementioned that the

interpretation of temp is not a routine non -

interactive procedure. A good knowledge of the

geothermal gradient is necessary for a

representative interpretation.

The applications of temp for problem diagnostics has

been in practice for a long time in the oil industry.

The following are typical applications:

Fluid cross-flow, upward or downward, behind

the casing or between casings in multiple

casing configurations. This applications is

normally made in shut down wells which were

left to stabilize over a long period of time to

achieved geothermal equilibrium.

Fluid cross-flow behind the casing under

production conditions. This technique could

yield inconclusive results if the magnitude of the

anomaly under investigation is small.

Zone Isolation: Fluid is normally injected in the

zone to be isolated and time-lapse temperature

profiles are obtained. The signature of these

profiles is an excellent indication of the

presence of cross-flow (Fig-1).

Fluid Leaks into I from the production string :

The signature of the flowing temperature

profile will change because of the change in

both the fluid temperature (if fluid is entering

the mainstream) and the volume of fluid

flowing (Fig-2).

Gas entry into the well bore: The production of

gas, and the change in pressure, normally

results in a cooling effect (Fig-3). The

magnitude of the change in temperature is a

function of the pressure change,volume of gas

entering the flow string, and the initial

temperature conditions of both the gas and

borehole fluids. Under normal conditions, this

feature is relatively easier to detect.

296

Data AcQuisition for Correct Temperature Profile

Special logging techniques are necessary to obtain

representative temperature profiles. This is because

the anomalies are of the order of a fraction of one

degree Fahrenheit. Fluid mixing and the associated

temperature convection resulting from that caused

by the tool movement in the borehole, and the

dynamic response of the temperature changes,

could be a major limiting factor. Fig-4 shows the

ideal procedure for accurate temp data which can

be summarized as follows:

The well should allowed to stabilize for the

longest period conveniently possible.

Logging is made with the tool descending on its

first run.

Across zones of interest , logging should be

made at very slow speed of the order of 900

ftlhour.

Initial runs in the borehole to do depth

correlations, or to check the bottom of the hole,

should not be made before the temperature

temp log is obtained.

Normally, temperature logs are made for the

objective of obtaining bottom hole temperatures for

pressure corrections. In such case, errors of the

order of 2F caused by convection are not critical

for the pressure correction.

Temperature Signatures in Fluid Cross - Flow

Environments.

ConditiQns fQr cross-flQW

There. has been a wealth of technical papers on the

subject of temp analysis. In layered and producing

reservoirs cross-flows can take place behind the

casing. The vQlume of crQss-flQw is a functiQn of the

following:

Pressure differences between the layers.

FIQwing or shut-in conditiQns that can create

additiQnal pressure differences between the

layers.

Cement quality behind the casing and between

the layers.

Relative permeability of the twQ layers.

Casing .cQrrosiQn which will increase the flow

path behind the casing.

In almost all cases, all the conditions controlling the

IQcatiQn and cross-flQw rates between layers, as

defined above, are nQt knQwn. It is therefQre

SPE25s30 MARIOJ. C. PETRICOLA and MOHAMED WATFA 3

impossible to predict the location and the volume of

cross-flow between the layers. Moreover, since the

flow takes place behind the casing, traditional

flowmeter surveys can't be used to indicate the

location or volume of the cross-flow behind the

casing.

The procedure has been to run temperature surveys

in the casing, in flowing and shut-in conditions, in

order to locate the position of cross-flows. The

deviation of the recorded temperature logs from the

normal geothermal temperature gradient, together

with the derivative of the temperature with respect to

depth, are used effectively to locate the location and

direction of the cross-flow behind the casing.

Shown are eight diagrams representing different

conditions of cross-flow between layers and the

predicted temperature profiles - these diagrams are

representations and were constructed from a

data-base of temperature logs. The objectives is to

establish a family of type curves for correlation.

These diagrams were constructed assuming that

one of the layers is producing; this is normally the

condition under which most of the temperature

surveys are made. Each diagram shows the

following:

Well sketch and zone locations.

Standard Geothermal gradient (No flow or

cross-flow) .

Standard Temperature gradient under flowing

condition (no cross-flow).

Temperature anomaly caused by cross-flow,

superimposed on geothermal gradient.

Combined temperature profiles for flowing and

behind casing cross-flow conditions.

Differential temperature ( ~ t e m p ) which is the

rate of change of temperature with depth. This

is made for the condition of flow plus behind

casing cross-flow.

The presented temperature trends and profiles for

the flowing conditions, for the cross-flow conditions

and for the temperature derivatives are not unique.

The magnitude by which each of these curves

departs from the standard geothermal temperature

gradient profile will depend on the volume of both the

flow in the casing and the volume of cross-flow

behind the casing. The important thing about these

curves are the signatures and shapes of these

curves for the different flow and cross-flow

conditions; these signatures can be considered

unique and can be used to locate cross-flows behind

the casing, and to be compared with standard

297

conditions. It is also worth noting here that the

shape of the signatures with respect to the position

of the producing interval (perforations) is also

important to identify the various cross-flow

conditions.

Examples of Inter-Layer Cross-Flows

Example-1 (Fig-5): Well flowing into casing, In

this case there are no cross-flow between the

layers. The fluid saturations for water, oil and

gas (Sw, Soil and Sgas respectively), are

representative of fluid conditions of the whole

field for all the layers logged by the Thermal

Decay Time Tool (TDr) in that well.

Example-2 (Fig-6): Well flowing into the casing,

with a downward cross-flow between two layers

above the perforation; In this case the TDT

saturations obtained for the two flowing zones;

the zone producing into the casing (2) and the

zone producing the cross-flow (4), are

representative of field conditions. The TDT

saturation evaluations for the thief zone (3)

receiving the cross-flow will normally be

representative of conditions adjacent to the

borehole and not field conditions for that zone.

The saturation evaluations if the initial;

saturation conditions in the thief zone and in the

zone producing the cross-flow are the same.

Example-3 (Fig-7): Well flowing into casing, with

an upward cross-flow between two layers above

the perforations; This case is very similar to

example-2, with similar conclusions with

regards to the saturations, with the exception

that zone 3 and 4 are swapped; the

uncertainty with regards to representative

saturations of field conditions will be that of

zone-4, instead of zone-3 as in example-2.

Example-4 (Fig-B): Well flowing into casing, with

an upward cross-flow between two layers below

the perforations; This again is very similar to

Example-2, with all the TDT saturation

evaluations representative of field conditions

except for the layer receiving the flow (zone-2

in this case).

Example-5 (Fig-9): Well flowing into casing, with

an downward cross-flow between two layers

below the perforations; Similarly here, the

TDT saturation evaluations will be

representative of field conditions for all the

zones, except for the thief zone receiving the

4

MULTI-WELL APPLICATIONS OF DOWNHOLE TEMPERATURE

PROFILES FOR CROSS-FLOW ANALYSIS

cross-flow (zone-1 in this example).

SPE 25630

Example-6 (Fig-10): Well flowing into casing,

with an upward cross-flow into the producing

zone from a layer below it. In this configuration,

the TOT saturation evaluations for all the zones

are representative of field conditions.

Example-7 (Fig-11): Well flowing into casing,

with a downward cross-flow into the producing

zone from a layer above it. Similar to

example-6, the TOT saturation evaluations for

all the zones are representative of field

conditions.

Example-8 (Fig-12): Well flowing into casing,

with an upward orland downward cross-flow

from the producing zone into zone below it or

above it; In both cases the TOT saturation

evaluation is representative of field conditions

for all the zones except for the thief zone

receiving the cross - flow. However, by

increasing the flow rate, this cross-flow can be

reduced and possibly eliminated, because of

the reduction in the pressure differences.

It is clear from the preceding discussions that:

Only the thief zones receiving the flow could

have TOT saturation values not representative

of field conditions.

Other zones Which includes; zones producing

into the casing, zones not producing at all, or

zones producing the cross-flow behind the

casing, will have TOT saturation evaluations

representative of field conditions.

If the thief zone is also producing into the

casing, the TOT saturation evaluations will still

be representative of field conditions. The

cross-flow is generally assumed to flow

straight into the casing through the

perforations.

It is apparent from this discussion that TOT

interpretation in wells with behind casing cross-flow

is still valid for most of the logged interval. The

availability of temperature logs will help in locating

the interval of the cross-flow as well as the direction

of the flow. This will help in evaluating the saturation

trends on a field wide basis.

pata Base Applications

298

Multi-Well Data-Base applications have been

effective in evaluating geological and petrophysical

variations both spatially and by zone by zone (ref-2).

The data-base approach was also used here to

evaluate temp data. The procedure used in

Data-base applications is outlined in the chart of

Fig-13. This may be summarized as follows:

a- Obtain all the log data for a maximum number

of wells. This data should be representative of

potential regional variations across the field.

b- For each well with temp data, obtain all the

formation tops, Zones, sub-zones, etc.. Of

particular interest are loss circulation zones,

zones of injection, hydrodynamically active

zones, and zones where natural or induced

temperature anomalies are expected.

c- Lateral averaging on a 1/2 foot basis are then

used to obtain a representative geothermal

temperature gradient. Regional and zonal

variations in the geothermal temperature

gradient can be identified from the Data-base

displays. Fig-14 is such an application, and this

technique is critical where geothermal

temperature gradients are either not

established, or are changing with time.

d- The variation of the temp from the geothermal

can be obtained. Fig-15 shows the variations

from the geothermal for the family of wells

presented in Fig-14..

e- Likewise, the variation in the ~ t e m p can be

obtained. This will magnify the magnitude of the

anomaly for correlations and identifications.

The two figures (14 & 15) show the applications of

this technique to a five well Multi-well Data-Base.

The results highlight the locations of two cross-flow

leaks that are taking place behind the casing.

The temperature variations from the median can be

used to quantify the volume of fluid cross-flow

(ref-3). The following equation for mass flow rate can

be applied:

Wf =9-

A

47 [Ln{ r c ~ S}+ 0.29] tons/da}

. 2 (kt) .

with t the total production time, k the thermal

SPE 25630 MARIOJ. C. PETRICOLA and MOHAMED WATFA 5

diffusivity of the formation and rce the external

casing radius. This equation also assumes that the

fluid specific heat is 1Btu/day-ft-oF. A is the

relaxation distance which can be derived from the

temperature log. In the case where the asymptote

has been reached, A is simply:

where gG is the geothermal gradient, and Dg the

temperature increase attributed to fluid flow.

CONCLUSIONS

The temperature profiles in a well are an excellent

tool for diagnosing production anomalies. The

validity of the data is conditional on acquiring this

data under ideal conditions; since the temperature

anomalies considered are of the order of few

degrees, the quality of acquisition is therefore

essential.

The application of the Multi-Well Data-Base to the

evaluation of field temperature profiles has

essentially improved the resolution of the interpreted

data, and highlighted regional variations in these

profiles. Well and field geothermal gradients can be

re-constructed, and small flow rates, which would

otherwise not being recognized, can now be

identified and quantified using this technique.

NOMENCLATURE

temp: Temperature profile which varies with

depth (Degrees Fahrenheit-OF)

Atemp: The derivative of temp with depth. (OF 1ft)

t = Production time (hours)

k = Thermal diffusivity

ree = External Casing Radius (inches)

A = Relaxation distance

L1g = Temperature difference caused by fluid flow

(OF)

gG = geothermal gradient (OFIft).

wf = Fluid mas flow (tons/day)

REFERENCES

1- A. Poupon and J. Loeb: "Temperature logs in

Production and Injection wells." Schlumberger

Publications.

2- A.F. Abed and M. Watfa: " A Dynamic

Multi-Well Data-Base". Journal of Petroleum

Technology, November 1988.

299

3- M. B. Curtis and E. J. Witterholt: "Use of the

Temperature Log for Determining Flow Rates in

Producing Wells". SPE 16864-Dallas Sept.

27-30,1987.

.c

-

Q.

(1)

C

Temperature

Rg-1: The use of Time-Lapse Temperature profiles

to detect zone isolation.

Temperature

Rg-2: The effect of fluid leak on the Temperature

Profiles

.c

-

Q.

(1)

C

Flow ( No Gas Entry)

I

Flow ( + Gas Entry

Temperature

Rg-3: The effect of Free Gas entry on the Temperature

Profiles

300

Stabilize the well

to Reach geothermal

conditions

Determine Zone/Layers

of Interest

Log Slowly down.

Log 900 ftlhour over Zone

of Interest

+

Make repeat section

Make other log passes

over zone of Interest.

+

Make Depth check.

Shift the depth on main

Log If necessary

Rg-4: Data Acquisition flow chart to

obtain temperature profiles.

SPE256

Rg-l: Thl. ohow. Ih. oIfect 01 bohlnd cooing cro...flow on Ih.

tempel'llture gl'lldienl and Ihi depth derivative. The cro...flow

I, abovi tha producing Interval and I, downward.

Increasing Temperature

Flg-5: Exemple ahowIng tha geothenMl tempel1lture gradlen' and

the effect of flow on tIM gradlen' and Ita: derivative

CR.to 01 chong. 01 _poro\uFO with doplh dC_p)/d(doplh)

IncraeBlng Tamperature

t

1(.....1,.(,.11

IncreasiDI

Ible of Chase

Flg..7: me show. the effect of behind casing croflow on the

temperatura gradient end It. depth derivative. The crofIow

la .bov. the producing Interval and I, upward.

Fig-8: Thl. ,hows the effect of behind caalng cro...flow on the

temp.ratu... gradient end lte depth derivative. The croflow

I. below the producing Interval and I. upward.

IncreasIng Temperature

IzonesJ

._-- --

--T-'-==---"<

301

Rg.8: lbl. ohowo th. '-101 bohlnd ....ng ._flowon tho

.........ture gradient and Ita depth derivaUv. The croa.flow

I. _ tho pracluclng Intorvol .nd I. _.Id.

Flg-10: This shows the effect of behind c.,lng cro..ftow on the

temperature gradient and 1t8 depth derivative. The cro...flow

I. bolow tho pracluclng Intorvol ond I. flowing upw.rd. Inlo th.

producing In....v.l.

(temp.)1d (depth)

Increasing Temperature

Temperature

.cr

'E.

.!l

Increealng Temperatur.

~ . - - 1 - - 1 - - - - _ . _ - - - _ . _ - ~

Incre8slng Temperature

Zones

Flg-12: Thle ,h0W8 the etr.ct of behind cuing oro....... on the ...._ g...dlant ond Ito dopIh __ Tho era__

10 II'om producing I....... ond 10 downw'" Into ....

zone below It.

302

SPE256 }O

ICollect all the data aVallablel

In a data-base

Ildantlfy Formatlona, layara I

and sub-layers 01 Interest

Lateral averaging to obtain a rapresentatlve

Geothemal Gradient.

Depth shlflthe data eo that tha layer Tops &

BollOms lor the various wells are on depth.

Median Averaging

Discard data with high divergence

IIdentify Regional changes I

In geothermal gradient II

it exlata.

Obtain Variance from

Geothermal gradient.

lemp. (true) temp (Geothermal)

+

Obtain variance from the Differential

temperature profiles.

tJ.temp. (true) tJ.tamp (Geothermal)

Flg13: Ollla-ba.. application lor Interpreting temperature

proIII...

Temponllure Proll'.. lor 5 Wella

10 of

Tempereture Deviation (Temp-Med'an)

o

.)

: Down flow

1,000----t----..

Up!FIOW

3000 -.---+---.--.-t-----r----

I I I

ii'T

4000 __._._4-. -;---.----.-

I ~ - -i---...-....

~ o o o ---i------- ,-t'---,

~

Flg-14: An Exomple 01 01 live wellafrom a land field u_

to oblaln a llald gaothennal gradient.

303

Vous aimerez peut-être aussi

- Spe 176089 MS PDFDocument11 pagesSpe 176089 MS PDFatilio martinezPas encore d'évaluation

- Experimental and Numerical Assessment of Cold Restart Process of Heavy 7 WHOC12 - 277Document5 pagesExperimental and Numerical Assessment of Cold Restart Process of Heavy 7 WHOC12 - 277han.velthuis431Pas encore d'évaluation

- Modeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsDocument8 pagesModeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsInternational Journal of Innovative Science and Research Technology100% (1)

- Modeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsDocument8 pagesModeling and Simulation of The Temperature Profile Along Offshore Pipeline of An Oil and Gas Flow: Effect of Insulation MaterialsInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- PGI2003 FastStartup&DesignForCyclingDocument20 pagesPGI2003 FastStartup&DesignForCyclingscarrion80100% (1)

- Fluid Movement: Temperature SurveysDocument13 pagesFluid Movement: Temperature SurveysAG YPas encore d'évaluation

- Rack PDFDocument8 pagesRack PDFWan Norain Awang LongPas encore d'évaluation

- CFD Studies in The Prediction of Thermal Striping in An LMFBRDocument12 pagesCFD Studies in The Prediction of Thermal Striping in An LMFBRjofredjosephPas encore d'évaluation

- Bahrami 2007Document15 pagesBahrami 2007Fjgff RkffyrPas encore d'évaluation

- Deepwater Well Temperature Prediction Using MWD DataDocument8 pagesDeepwater Well Temperature Prediction Using MWD DataBrucePas encore d'évaluation

- Temperature Effects For High-Velocity Gas FlowDocument5 pagesTemperature Effects For High-Velocity Gas FlowkronafPas encore d'évaluation

- Cooling Technology Institute: Design and Operation of A Counterflow Fill and Nozzle Test Cell: Challenges and SolutionsDocument12 pagesCooling Technology Institute: Design and Operation of A Counterflow Fill and Nozzle Test Cell: Challenges and SolutionsScribdakiotto100% (1)

- Thermal Fatigue Due To Statification in PipingDocument16 pagesThermal Fatigue Due To Statification in PipinghamadaniPas encore d'évaluation

- 3013 PDFDocument42 pages3013 PDFOlbira Dufera100% (1)

- Iec 60041Document10 pagesIec 60041João Marcos Monteiro BernardesPas encore d'évaluation

- Thermosiphon Reboilers: Characteristics and Design ParametersDocument7 pagesThermosiphon Reboilers: Characteristics and Design ParametersAlwin James100% (1)

- Computerized Temperature Decay - An Asset To Temperature LoggingDocument9 pagesComputerized Temperature Decay - An Asset To Temperature LoggingLulut Fitra FalaPas encore d'évaluation

- Flare Sweep GasDocument5 pagesFlare Sweep GasChem.EnggPas encore d'évaluation

- Refrigerant in Capillary Tube PDFDocument6 pagesRefrigerant in Capillary Tube PDFMayank Kumar100% (2)

- O S T I Rf-H/33 I: ReceivedDocument10 pagesO S T I Rf-H/33 I: ReceivedAnonymous CLoxXdABPas encore d'évaluation

- Comparative Study of The Packing Design (Comparative Study of The Packing Design)Document14 pagesComparative Study of The Packing Design (Comparative Study of The Packing Design)Johnathan Ortega MenesesPas encore d'évaluation

- 31 - Temperature in WellsDocument7 pages31 - Temperature in WellsAgus AlexandriPas encore d'évaluation

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringD'EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringPas encore d'évaluation

- Fired Heater Process GasDocument9 pagesFired Heater Process GasWendellReeceFrankPas encore d'évaluation

- Johnson 2010Document24 pagesJohnson 2010Franciani GoedertPas encore d'évaluation

- On The Design of Thermal BreathingDocument6 pagesOn The Design of Thermal BreathingLizbeth Fiallos AvilaPas encore d'évaluation

- Determination of OD cooling parametersDocument12 pagesDetermination of OD cooling parametersmpu682Pas encore d'évaluation

- GT2008 50103finalDocument10 pagesGT2008 50103finalkanbur.191Pas encore d'évaluation

- Hydrate Formation in ValvesDocument6 pagesHydrate Formation in ValvesChem.EnggPas encore d'évaluation

- Fuel NozzlesDocument3 pagesFuel Nozzlesfrancisco_navas4479100% (1)

- Cooling Tower Performance Test Code ComplianceDocument12 pagesCooling Tower Performance Test Code ComplianceFouzan AbdullahPas encore d'évaluation

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoPas encore d'évaluation

- Thermosiphon ReboilersDocument7 pagesThermosiphon Reboilerssj_scribd100% (1)

- Thermal Analysis of Exposed Pipeline Under Natural ConvectionDocument6 pagesThermal Analysis of Exposed Pipeline Under Natural ConvectionSyahrizalYusoffPas encore d'évaluation

- Models - Heat.shell and Tube Heat ExchangerDocument26 pagesModels - Heat.shell and Tube Heat ExchangerLuis Esteban Vela DonosoPas encore d'évaluation

- The Cooling Process in Gas Quenching: N. LiorDocument8 pagesThe Cooling Process in Gas Quenching: N. LiorananthakumarPas encore d'évaluation

- Factors Affecting Fuel Availability and Composition During in Situ CombustionDocument11 pagesFactors Affecting Fuel Availability and Composition During in Situ CombustionBahman MatouriPas encore d'évaluation

- NitrogenoDocument139 pagesNitrogenoEmanuelLopezPas encore d'évaluation

- Somali National University: Mechanical Measurement (MM 3609)Document28 pagesSomali National University: Mechanical Measurement (MM 3609)Omari AdamPas encore d'évaluation

- Direct Temperature Measurements Error SourcesDocument12 pagesDirect Temperature Measurements Error Sourcesalenyxcv3217Pas encore d'évaluation

- The CFD Simulation of Temperature Control in A Batch Mixing TankDocument6 pagesThe CFD Simulation of Temperature Control in A Batch Mixing TankRodolfo BrandaoPas encore d'évaluation

- Thermodynamics Lap 11 FinalDocument8 pagesThermodynamics Lap 11 Finalaquib14125Pas encore d'évaluation

- Heat Transfer in a Horizontal Coiled Pipe at Near-Critical PressureDocument5 pagesHeat Transfer in a Horizontal Coiled Pipe at Near-Critical PressureM. SukarmanPas encore d'évaluation

- SPE 87227 Thermal Modeling of Shut-In Well After Multiphase Hydrocarbon ProductionDocument9 pagesSPE 87227 Thermal Modeling of Shut-In Well After Multiphase Hydrocarbon ProductionJohn DoePas encore d'évaluation

- OGJ Hot Vapor Bypass DesignDocument6 pagesOGJ Hot Vapor Bypass DesignJesse Haney III100% (2)

- HAZOP Footprint - UC Riverside, CHE175A, Chemical Process DesignDocument9 pagesHAZOP Footprint - UC Riverside, CHE175A, Chemical Process DesignGabriel S. Gusmão (Freddie)Pas encore d'évaluation

- Exp. 5 Heat Transfer Study On Plate Heat ExchangerDocument6 pagesExp. 5 Heat Transfer Study On Plate Heat ExchangerElaine PuiPas encore d'évaluation

- Temperature Correction of Falling-Weight-Deflectometer MeasurementsDocument10 pagesTemperature Correction of Falling-Weight-Deflectometer MeasurementsIvanStanicPas encore d'évaluation

- Blowdown Onshore and Offshore InstallationDocument16 pagesBlowdown Onshore and Offshore InstallationRonny AjaPas encore d'évaluation

- Spe 50581 MSDocument14 pagesSpe 50581 MSmade hPas encore d'évaluation

- Blow DownDocument15 pagesBlow DownRenato BenintendiPas encore d'évaluation

- Blowdown of Vessels and Pipelines: S.M. Richardson & G. SavilleDocument15 pagesBlowdown of Vessels and Pipelines: S.M. Richardson & G. SavillefaisalmuradPas encore d'évaluation

- Testing of Thermocouples For InhomogeneityDocument5 pagesTesting of Thermocouples For Inhomogeneityliam15111981Pas encore d'évaluation

- Liquid Holdup in Geothermal Wells: Sabodh K. Garg, John W. Pritchett, and James H. AlexanderDocument7 pagesLiquid Holdup in Geothermal Wells: Sabodh K. Garg, John W. Pritchett, and James H. AlexanderIrwan JanuarPas encore d'évaluation

- Chapter Four Tubing Well Performance and Sizing: Hydrocarbon BehaviorDocument14 pagesChapter Four Tubing Well Performance and Sizing: Hydrocarbon Behaviorfuaad IbraahimPas encore d'évaluation

- CBE 362L 1 Double PipeDocument8 pagesCBE 362L 1 Double PipeDodOng GwapoPas encore d'évaluation

- TEMPERATURE LOGGING TECHNIQUES REVEAL DOWNHOLE CONDITIONSDocument18 pagesTEMPERATURE LOGGING TECHNIQUES REVEAL DOWNHOLE CONDITIONSsaeed65Pas encore d'évaluation

- Advanced Temperature Measurement and Control, Second EditionD'EverandAdvanced Temperature Measurement and Control, Second EditionPas encore d'évaluation

- Working Guide to Reservoir Rock Properties and Fluid FlowD'EverandWorking Guide to Reservoir Rock Properties and Fluid FlowÉvaluation : 3 sur 5 étoiles3/5 (1)

- 1969 - Dic - 00002464 Romero-JuarezDocument3 pages1969 - Dic - 00002464 Romero-JuarezglsancorPas encore d'évaluation

- Zolotukhin Reservoir Engineering 002Document217 pagesZolotukhin Reservoir Engineering 002Anttonio Gómez86% (14)

- Acronyms Used in The Oil & Gas IndustryDocument48 pagesAcronyms Used in The Oil & Gas IndustryharoldalconzPas encore d'évaluation

- SPE 125031 (Ilk) Decline Curve Analysis HPHT Gas Wells Theory y ApplDocument23 pagesSPE 125031 (Ilk) Decline Curve Analysis HPHT Gas Wells Theory y ApplglsancorPas encore d'évaluation

- Spe 116575 Ms P Tim WhiitleDocument9 pagesSpe 116575 Ms P Tim WhiitleglsancorPas encore d'évaluation

- SPE 152878 South Sen Field Dynamic Analysis, Mexico South RegionDocument0 pageSPE 152878 South Sen Field Dynamic Analysis, Mexico South RegionglsancorPas encore d'évaluation

- Amyx J. Petroleum Reservoir Engineering Physical PropertiesDocument634 pagesAmyx J. Petroleum Reservoir Engineering Physical PropertiesYorman Azocar Ibarra100% (3)

- Empirical Method of Oil Recovery Using The API EquationDocument2 pagesEmpirical Method of Oil Recovery Using The API EquationglsancorPas encore d'évaluation

- SPE 26647 Application of Variable Formation Compressibility For Improved Reservoir AnalysisDocument16 pagesSPE 26647 Application of Variable Formation Compressibility For Improved Reservoir AnalysisglsancorPas encore d'évaluation

- Curtis H. WhitsonDocument18 pagesCurtis H. WhitsonglsancorPas encore d'évaluation

- 26060Document10 pages26060glsancorPas encore d'évaluation

- Romero JuarezDocument3 pagesRomero JuarezglsancorPas encore d'évaluation

- Romero JuarezDocument3 pagesRomero JuarezglsancorPas encore d'évaluation

- Level Measurement (RADAR Trasnmitter)Document17 pagesLevel Measurement (RADAR Trasnmitter)febri_bontangPas encore d'évaluation

- Overview of Boiler Drum Level MeasurementDocument36 pagesOverview of Boiler Drum Level Measurementrarundivya83% (6)

- Wild Well Technical Data BookDocument78 pagesWild Well Technical Data BookFabio ParceroPas encore d'évaluation

- Arena-Flow Software For Sand Core EngineeringDocument71 pagesArena-Flow Software For Sand Core Engineeringpatrones. valerio cPas encore d'évaluation

- Function: ProcemeDocument25 pagesFunction: ProcemeGAYATHRI CHIPPALAPas encore d'évaluation

- Optimization of Frac:Pack Completions Based On Field Experience by Morales2003Document9 pagesOptimization of Frac:Pack Completions Based On Field Experience by Morales2003Bangsawan AriefPas encore d'évaluation

- Manual de Parte Godwin CD100M PDFDocument19 pagesManual de Parte Godwin CD100M PDFkamana7Pas encore d'évaluation

- Packer & Exp. JTDocument21 pagesPacker & Exp. JTMohammad shahheidarPas encore d'évaluation

- PG0010 Home Blood Pressure MonitorsDocument4 pagesPG0010 Home Blood Pressure Monitorsl0l21Pas encore d'évaluation

- Es Acv 1116fmDocument4 pagesEs Acv 1116fmMedia ThxPas encore d'évaluation

- PVC Water Pumps PDFDocument26 pagesPVC Water Pumps PDFYulidar Wahyu RachmawanPas encore d'évaluation

- Ch. 18 - Thermal Properties of MatterDocument72 pagesCh. 18 - Thermal Properties of MatterMark Ronald SuaisoPas encore d'évaluation

- Wind DesignDocument68 pagesWind DesignJames MellanPas encore d'évaluation

- Valve Leakage Rates Test STDDocument5 pagesValve Leakage Rates Test STD윤병택Pas encore d'évaluation

- The Universe On A Tee ShirtDocument26 pagesThe Universe On A Tee ShirtJohn WindersPas encore d'évaluation

- Gaspropertiesactivity Ms All Pages 1Document6 pagesGaspropertiesactivity Ms All Pages 1api-233194737Pas encore d'évaluation

- Conteo de Particulas en Aire ComprimidoDocument2 pagesConteo de Particulas en Aire ComprimidoSalvador NegretePas encore d'évaluation

- Physics KSSM F5 (Chapter - Pressure)Document6 pagesPhysics KSSM F5 (Chapter - Pressure)abc zzzPas encore d'évaluation

- 3.2.3.a FluidPowerPracticeProblemsEdittedDocument6 pages3.2.3.a FluidPowerPracticeProblemsEdittedOlusoga AdeyigaPas encore d'évaluation

- Steel Plates Weight D 1561Document3 pagesSteel Plates Weight D 1561Armando DuartePas encore d'évaluation

- Control Valve Data SheetDocument3 pagesControl Valve Data SheetgrabettyPas encore d'évaluation

- TDC - EDC 7" FaultcodesDocument268 pagesTDC - EDC 7" FaultcodesJason KozminskaPas encore d'évaluation

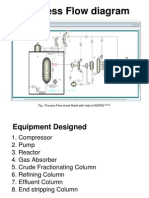

- Process Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENDocument42 pagesProcess Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENSwarnim RajPas encore d'évaluation

- 3.5 Pseudo Steady StateDocument6 pages3.5 Pseudo Steady StateAndrei IvanovichPas encore d'évaluation

- Introduction to MagnetohydrodynamicsDocument36 pagesIntroduction to MagnetohydrodynamicsFilip KesteliPas encore d'évaluation

- Ideal and Real Gas LawsDocument74 pagesIdeal and Real Gas LawsAlex LeePas encore d'évaluation

- TR 3 2012Document91 pagesTR 3 2012منير أحمدPas encore d'évaluation

- Calculation Method For The Analysis and Prevention of Overpressure During Refilling of Cryogenic Tanks With Rupture Disk (S)Document51 pagesCalculation Method For The Analysis and Prevention of Overpressure During Refilling of Cryogenic Tanks With Rupture Disk (S)najiruddinshaikPas encore d'évaluation