Académique Documents

Professionnel Documents

Culture Documents

Made To Measure: BMW in Leipzig: Case Study

Transféré par

tonisugusDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Made To Measure: BMW in Leipzig: Case Study

Transféré par

tonisugusDroits d'auteur :

Formats disponibles

Case Study Made to Measure: BMW in Leipzig

2 3

1

Photo 1: Thanks to the Leica Laser Tracker and Leica T-Probe, BMW can now probe new car series economically, as they do not have to stop the assemby line and can measure directly at the production plant. Photo 2: Chassis technicians conduct probing at a completely varnished car. Photo 3: Due to its flexibility, the Leica T-Probe can reach a wide range of surfaces and points, even those from hidden sight.

measurements can be done directly at the assembly line. In the past, a certain number of cars had to be taken off the assembly line, creating logistical problems and causing additional costs. However, the Leica Geosystems measurement system is not only used in chassis building, it is equally at home when analyzing the entire car. In order to do this, the chassis technicians conduct measurements of a completely varnished car for their colleagues a solution that is both efficient and fascinating to observe, as the mobility of the laser tracker is at full display; the vehicles do not have to be brought into a specific measuring room and are left on the assembly line instead. A real measuring machine! With a few exceptions, the Leica T-Probe is used for practically all measuring tasks; the technicians appreciate this intelligent solution and use it for analytical measurements of both small and large objects. Due to its flexibility, the Leica T-Probe can probe all kinds of points and surfaces. Therefore, it is not really surprising that the chassis measurement technicians follow their vision to further develop the Leica T-Probe and combine the system with optical sensors; it is their goal to put the Leica T-Probe into the hands of a robot and automate certain processes. The advantages of the Leica T-Probe in the automotive industry show pretty impressive results, especially at the BMW plant in Leipzig. Thanks to its multiple application areas, the Leica T-Probe has lead to some true light bulb moments. I will never forget this experienced and seasoned measurement technician who said with astonishment that the Leica T-Probe was a real measuring machine, reports Illemann with pride. Leica Tracker and Leica T-Probe proven and tested The combination of a Leica Laser Tracker and a Leica T-Probe as full-fledged coordinate measuring machines with built-in mobility and no need for dedicated space has been superbly proven and tested. Crucial for this judgement are the measurement volume and the accuracy of the system. This is an area in which the Leica Laser Tracker scores extremely well, having earned as much respect in terms of measuring accuracy as any other measuring method. All in all, a Leica Laser Tracker competently holds its ground with the best of three-axis CMMs. The handling and operation of the system are also fully impressive: unlike a photogrammetric system, the Leica Laser Tracker is independent from the position of a camera or from its configuration; the latter could be the source of errors for an unseasoned user. The laser tracker is simple to set up and is immediately ready to use. At the same time, measurement technicians can calibrate and check the system. However, the biggest advantage of a laser tracker compared to a fixed measurement machine is its mobility. Despite being fully satisfied with their Leica T-Probe system, the Leipzig team has another

By Simon Moser Thanks to the new Leica T-Probe, a WalkAround armless and wireless mobile CMM, the use of Leica Geosystems laser trackers in the automotive industry is gaining more and more momentum. In the newly constructed BMW plant in Leipzig, Germany, this combination of a laser tracker and a Leica T-Probe convinces with its mobility, its measurement volume and its accuracy, especially in chassis building. Setting up a measurement facility according to ones own ideas and visions in a newly built automotive plant, that must be the dream of every dedicated technician in measurement technology. For the 11 people of the measurement crew from quality management in chassis building, this dream has now come true in the newly constructed BMW plant in Leipzig. Within the scope of their Geometrical safeguarding in chassis building project, they purchased traditional fixed CMMs as well as innovative mobile optical measuring systems. For the flexible LTD800 Laser Tracker from Leica Geosystems, this was a perfect working environment.

If you keep in mind what the main job of the team is, namely, consultancy and support in measurement safeguarding for chassis building, our laser tracker certainly is the optimal tool for the multiple application areas due to its mobility and versatility. By using the combination of a Leica Laser Tracker and a Leica T-Probe, the Leipzig team could optimally reach its goal, as they now have a full-fledged 3D mobile coordinate measuring machine that does not block anything in the measuring area, explains Joerg Illemann, Leica Geosystems Sales Engineer responsible for BMW in Leipzig. A lot of Metes and Bounds: the Leica Laser Tracker The laser tracker from Leica Geosystems is an easy-to-transport, mobile coordinate measuring system. Thanks to its built-in laser interferometer, measurements can be carried out extremely quickly and with great precision. Regardless of whether single points or entire surfaces are being measured: from a single position, the laser tracker can measure objects with a measuring volume of up to 80 meters (131ft) in diameter and with an accuracy of +/-10 ppm (m/m), at a measuring rate of up to 3,000 points per second. Application areas for Leicas laser trackers are for example high precision tool design and construction or geometrical tests in the automotive and aerospace industries. Due to the integrated Absolute Distance Meter (ADM), periodical measurements, repetition tests and similar jobs can be carried out with full automation; the position of the laser tracker is always flexible and can adjust to the size of an object or to possible limitations of available space. On the wish list: the Leica T-Scan Leica Geosystems Walk-Around armless and wireless Leica T-Probe, which can measure practically any object anywhere with six degrees of freedom (6DoF), has played an important role for BMW when they chose the Leica system; interfering cables or

mechanical connections belong to the past. With the Leica T-Probe, even recesses and cavities can be measured with an astonishing precision: the length measurement precision is +/-0.06mm (2 Sigma) in a measuring volume of up to 15m (49ft). When the LTD800 is used together with Leica T-Scan, Leicas high-speed hand scanner, small and large objects as well as complex surfaces can be measured simply and quickly with minimal preparation times and regardless of surface material. Objects can also be digitalized for reverse engineering applications. Just having bought a Leica Laser Tracker, the Leica T-Scan is on top of the wish list for BMW Leipzig. The impressive metrology equipment amassed by the BMW plant makes a lot of sense because the construction area has to be provided with enormous amounts of accurate information. Among the teams tasks are random tests to check the production runs for a whole car series as well as analytical measurements. Also important is conducting metrology jobs quickly and efficiently, using the best-suited measuring tool available. Mobility as an unbeatable advantage Since its laser tracker purchase in mid-2004, BMW Leipzig has used its Leica Geosystems equipment in multiple application areas: during the start-up phase of the plant in which the 3 series car is being produced, the laser tracker was used to inspect the production equipment. The system will be used for this job in the future as well, for example when new production lines for upcoming BMW models are needed. This is also true for the assembly line: here, the team has used the trackers flexibility to measure specific points at each car in order to assure compliance. The Leica Laser Trackers easy mobility allows for easy verification of specific car functions, for example adjusting default gaps on car doors. In order to obtain useful measurement results, such reference measurements need to be carried out with many cars in a series. The unbeatable advantage of the Leica Laser Tracker: thanks to its mobility, these

item on its wish list other than the Leica T-Scan: namely, they wish the laser trackers were easier to install in difficult-to-reach places. Just recently the technicians had to install the laser tracker in a horizontal position when they needed to probe underneath the car, and this is something the laser tracker was not built for. However, Illemann has a solution for these applications as well: Leica Geosystems has developed an accessory into which the laser tracker can be installed so that it can operate in a horizontal positon. Good news can also be reported from Leicas service department. Thanks to their commitment to developing the necessary software interfaces, they earned additional praise. From past experience, BMW knows that Leica Geosystems service jobs are performed quickly and extremely efficiently. However, Leica Service has not made a single trip to Leipzig yet because everything has worked out according to plan and without a glitch. Leicas training concept also wins praise: it is very practice-oriented and contains more hands-on training than merely theoretical learning. Therefore, BMWs next goal is to improve their probing skills with the existing equipment and further increase their efficiency. Love at first sight Our measurement system has fully met the expectations of the BMW measurement technicians. With the Leica Laser Tracker and Leica T-Probe, they can probe new car series very economically, as they do not have to stop the assembly line and can measure directly at the production plant. On top of all, the Leica T-Probe has increased the already broad range of applications of the laser tracker considerably, and its ease of use simplifies the integration into the measurement processes, concludes Illemann, adding with a smirk: The BMW measurement team and the Leica T-Probe, that was love at first sight.

Did you know? Since March 2005, the BMW plant in Leipzig produces up to 700 vehicles a day currently the BMW 3 series sedan, the BMW 1 series three door, coup and convertible. More than 5,400 employees work in the plant which was awarded several times for its innovative architecture by Zaha Hadid.

Quelle: BMW

www.bmw-werk-leipzig.de

Jrg Illemann, Sales Engineer at Leica Geosystems: Our measurement system has fully met the expectations of the BMW measurement technicians. With the Leica Laser Tracker and Leica T-Probe, they can probe new car series very economically, as they do not have to stop the assembly line and can measure directly at the production plant.

Whether building the fastest car, the biggest plane, or the most precise tooling, you need exact measurements to improve quality and productivity. So when it has to be right, professionals trust Leica Geosystems Metrology to help collect, analyze, and present 3-dimensional (3D) data for industrial measurement. Leica Geosystems Metrology is best known for its broad array of control and industrial measurement products including laser trackers, Local Positioning Technology (LPT) based systems, hand-held scanners, 3D software and high-precision total stations. Those who use Leica Metrology products every day trust them for their dependability, the value they deliver, and the world-class service & support thats second to none. Precision, reliability and service from Leica Geosystems Metrology.

Leica Geosystems Metrology Products Moenchmattweg 5 CH-5035 Unterentfelden Switzerland Phone +41 62 737 67 68 Fax +41 62 737 68 68 www.leica-geosystems.com/metrology www.hexagonmetrology.com

2008 Hexagon Metrology. All rights reserved. 749537 Due to continuing product development, Hexagon Metrology reserves the right to change product specifications without prior notice. Printed in Switzerland. September 2008

Vous aimerez peut-être aussi

- Rep Auto VehicleDocument3 pagesRep Auto Vehicleubuntu69Pas encore d'évaluation

- For Gomaco Equipment: Leica Pavesmart 3DDocument4 pagesFor Gomaco Equipment: Leica Pavesmart 3DDonovan HarrellPas encore d'évaluation

- Custom-Built Solutions For Building Construction: Leica iCON BuildDocument6 pagesCustom-Built Solutions For Building Construction: Leica iCON Buildbbutros_317684077Pas encore d'évaluation

- Industrial Theodolites & Total Stations Brochure en PDFDocument8 pagesIndustrial Theodolites & Total Stations Brochure en PDFGiora RozmarinPas encore d'évaluation

- Leica TM6100A Brochure enDocument6 pagesLeica TM6100A Brochure enCarlos CostaPas encore d'évaluation

- Case Study In-Line Robotic InspectionDocument4 pagesCase Study In-Line Robotic InspectionKnezevic BojanPas encore d'évaluation

- For Dynapac Road Machinery: Leica Pavesmart 3DDocument4 pagesFor Dynapac Road Machinery: Leica Pavesmart 3DDonovan HarrellPas encore d'évaluation

- Leica AT960 Brochure - en PDFDocument9 pagesLeica AT960 Brochure - en PDFJDPas encore d'évaluation

- $RAQEGJODocument80 pages$RAQEGJORicardo GasparettoPas encore d'évaluation

- For G&Z Paving Equipment: Leica Pavesmart 3DDocument2 pagesFor G&Z Paving Equipment: Leica Pavesmart 3DDonovan HarrellPas encore d'évaluation

- 12.construction Catalogue en LeicaDocument44 pages12.construction Catalogue en LeicaLădaru-Baricz HajnalkaPas encore d'évaluation

- Leica Hds 6100 Brochure UsDocument4 pagesLeica Hds 6100 Brochure UsBlake WhitePas encore d'évaluation

- Leica Pegasus MapFactory BRO enDocument4 pagesLeica Pegasus MapFactory BRO enpancaPas encore d'évaluation

- Modern Monitoring System Software Development: Karl SippelDocument13 pagesModern Monitoring System Software Development: Karl SippelIustiinaa IgnatPas encore d'évaluation

- Construction CatalogueDocument76 pagesConstruction CatalogueMayre Rachel RodriguezPas encore d'évaluation

- Builder M RM PowerDocument4 pagesBuilder M RM PowerkhalidcosmosPas encore d'évaluation

- Custom-Built Solutions For Site ConstructionDocument15 pagesCustom-Built Solutions For Site Constructionbbutros_317684077Pas encore d'évaluation

- Leica NOVA TechnologyDocument60 pagesLeica NOVA Technologyciora andreeaPas encore d'évaluation

- CWfieldPipe-AustralianPipeliner PDFDocument3 pagesCWfieldPipe-AustralianPipeliner PDFpacodmxPas encore d'évaluation

- TruStories Monitoring LeicaGeoMoSDocument36 pagesTruStories Monitoring LeicaGeoMoSstat_istaPas encore d'évaluation

- Robot Measurement CellDocument1 pageRobot Measurement Cellou_tanniesPas encore d'évaluation

- NI Tutorial 11564 enDocument9 pagesNI Tutorial 11564 enpaula09Pas encore d'évaluation

- Leica DMI4000 6000Document30 pagesLeica DMI4000 6000Hakkı SaraylıkPas encore d'évaluation

- Recognize Virtually Any ShapeDocument5 pagesRecognize Virtually Any ShapeFabricePas encore d'évaluation

- Leica Viva TS15Document10 pagesLeica Viva TS15Donovan HarrellPas encore d'évaluation

- Leica Viva SmartPoleDocument6 pagesLeica Viva SmartPoleDonovan HarrellPas encore d'évaluation

- Laser-Scanning Workflow With Recap For Power-Stations Renovation ProjectsDocument15 pagesLaser-Scanning Workflow With Recap For Power-Stations Renovation ProjectsErnie ErniePas encore d'évaluation

- Leica Dm1750m-Dm750m-Dm2500m Brochure enDocument12 pagesLeica Dm1750m-Dm750m-Dm2500m Brochure enYen Ling NgPas encore d'évaluation

- Maptek Forge Mar10Document8 pagesMaptek Forge Mar10Kenny CasillaPas encore d'évaluation

- Construction Catalogue - enDocument44 pagesConstruction Catalogue - enJorge Mateus RochaPas encore d'évaluation

- Research Paper On Night Vision Technology in AutomobileDocument7 pagesResearch Paper On Night Vision Technology in AutomobilefxigfjrhfPas encore d'évaluation

- Toward Higher Automation and Flexibility in Commercial Digital Photogrammetric SystemDocument3 pagesToward Higher Automation and Flexibility in Commercial Digital Photogrammetric SystemKobalt von KriegerischbergPas encore d'évaluation

- Rimac Automobili D.O.O.: Advancing High-Performance Electric Vehicle Design With Solidworks SolutionsDocument3 pagesRimac Automobili D.O.O.: Advancing High-Performance Electric Vehicle Design With Solidworks SolutionsIllan KaprangiPas encore d'évaluation

- 022516-141 Trimble Realworks Advanced Tank TS 0315 HRDocument2 pages022516-141 Trimble Realworks Advanced Tank TS 0315 HRkurnia.imPas encore d'évaluation

- Leica Aibot: Intelligent Aerial Mapping Solution For Surveying and ConstructionDocument8 pagesLeica Aibot: Intelligent Aerial Mapping Solution For Surveying and ConstructionrogerPas encore d'évaluation

- Leica SprinterDocument9 pagesLeica Sprinterbbutros_317684077Pas encore d'évaluation

- Blue Series: BrochureDocument13 pagesBlue Series: BrochureMihail AvramovPas encore d'évaluation

- ABB Robotic Arc WeldingDocument12 pagesABB Robotic Arc Weldinganidarius301100% (1)

- CMP ProjectDocument3 pagesCMP ProjectAbusya SeydPas encore d'évaluation

- LabVIEW Multisim TutorialDocument8 pagesLabVIEW Multisim TutorialMax Marcano CamposPas encore d'évaluation

- News Release: Euroblech Award: Simufact - Welding Is Selected As One of The Most Innovative ExhibitsDocument3 pagesNews Release: Euroblech Award: Simufact - Welding Is Selected As One of The Most Innovative ExhibitsMiiss PoojaPas encore d'évaluation

- The Most Advanced Manual Total Station: Leica Viva TS11Document8 pagesThe Most Advanced Manual Total Station: Leica Viva TS11Donovan HarrellPas encore d'évaluation

- Integrated Design and Test Platform With Ni Multisim, Ultiboard, and LabviewDocument4 pagesIntegrated Design and Test Platform With Ni Multisim, Ultiboard, and LabviewMarcos CayetanoPas encore d'évaluation

- Conversion of Measurement Data Into 3 D Models and DrawingsDocument7 pagesConversion of Measurement Data Into 3 D Models and DrawingsYogeshmuley MuleyPas encore d'évaluation

- en Original 1.0 PDFDocument136 pagesen Original 1.0 PDFСтив АааPas encore d'évaluation

- Leica HxMap BRODocument2 pagesLeica HxMap BROandenetPas encore d'évaluation

- Object Tracking For Autonomous Vehicles: Project ReportDocument10 pagesObject Tracking For Autonomous Vehicles: Project ReportFIRE OC GAMINGPas encore d'évaluation

- Title:-Automatic Guided Vehicle (Agv) : IntroductionDocument4 pagesTitle:-Automatic Guided Vehicle (Agv) : IntroductionPiyush NarkhedePas encore d'évaluation

- Brochure Plastics LRDocument8 pagesBrochure Plastics LRmlucian73Pas encore d'évaluation

- Robot Simulation With RobcadDocument42 pagesRobot Simulation With RobcadMaverick SatPas encore d'évaluation

- Laser Radar Inline Inspection enDocument4 pagesLaser Radar Inline Inspection enПётр ЕживичPas encore d'évaluation

- Quick Help Acrylic WiFi HeatMaps-V2.0 (ENG)Document36 pagesQuick Help Acrylic WiFi HeatMaps-V2.0 (ENG)Tarek Tarek El-safraniPas encore d'évaluation

- IBM - Spacial and Linear AssetsDocument33 pagesIBM - Spacial and Linear AssetsDragan DragicPas encore d'évaluation

- Delmia IgripDocument6 pagesDelmia Igrip6toPas encore d'évaluation

- Abb Femap Success StoryDocument2 pagesAbb Femap Success StoryMario_A_RomeroPas encore d'évaluation

- Kode Password Database 2019Document10 pagesKode Password Database 2019Newbie BienewPas encore d'évaluation

- Measureup 3 2012 enDocument28 pagesMeasureup 3 2012 enMochammadRidwanPas encore d'évaluation

- Leica Cyclone 3DRDocument2 pagesLeica Cyclone 3DRgilangwhpPas encore d'évaluation

- Stainless Steels For Design EngineersDocument301 pagesStainless Steels For Design Engineersbookseekr67% (6)

- Results of Characterization Tests of The Surfaces of A Commercially Carburized Austenitic Stainless SteelDocument35 pagesResults of Characterization Tests of The Surfaces of A Commercially Carburized Austenitic Stainless SteeltonisugusPas encore d'évaluation

- Dassa PHD Thesis CensDocument133 pagesDassa PHD Thesis CenstonisugusPas encore d'évaluation

- Fenet d3613 Dle Advanced Finite Element Contact BenchmarksDocument62 pagesFenet d3613 Dle Advanced Finite Element Contact BenchmarkstonisugusPas encore d'évaluation

- Sap HireDocument2 pagesSap HiretonisugusPas encore d'évaluation

- Visvesvaraya Technological University Belagavi, Karnataka: Internship Report OnDocument30 pagesVisvesvaraya Technological University Belagavi, Karnataka: Internship Report OnAafaq Altaf100% (1)

- What Is A StartupDocument3 pagesWhat Is A StartupArun SoniPas encore d'évaluation

- Cybot Baseboard LCD SchematicDocument6 pagesCybot Baseboard LCD Schematicapi-584352705Pas encore d'évaluation

- 65kVA GSW65P P Pramac 2021Document1 page65kVA GSW65P P Pramac 2021RafatPas encore d'évaluation

- Keys For @emon9138: TRON Public Key (TRON Address)Document2 pagesKeys For @emon9138: TRON Public Key (TRON Address)Ifty ChowdhuryPas encore d'évaluation

- ResourcesDocument15 pagesResourcesitsyourzsinghPas encore d'évaluation

- AICE Milestone04 03.04.2024Document15 pagesAICE Milestone04 03.04.2024kevinkiprotichyegonPas encore d'évaluation

- DesktopauditreportDocument15 pagesDesktopauditreportapi-385391462Pas encore d'évaluation

- List Advantages and Disadvantages of Dynamic Memory Allocation vs. Static Memory Allocation.? AdvantagesDocument39 pagesList Advantages and Disadvantages of Dynamic Memory Allocation vs. Static Memory Allocation.? AdvantagesSajan KlPas encore d'évaluation

- HeroLab ManualDocument55 pagesHeroLab ManualColin BraddockPas encore d'évaluation

- Gambia ICT - Final - WebDocument77 pagesGambia ICT - Final - Webabey.mulugetaPas encore d'évaluation

- XDocument2 pagesXkrimo11Pas encore d'évaluation

- My Updated CVDocument5 pagesMy Updated CVSaleem UddinPas encore d'évaluation

- Role of Project Management Consultancy in ConstructionDocument4 pagesRole of Project Management Consultancy in Constructionmnahmed1972Pas encore d'évaluation

- MELFA Vision Instruction ManualDocument166 pagesMELFA Vision Instruction ManualJames JdfPas encore d'évaluation

- CV Qazim PDFDocument1 pageCV Qazim PDFUtkarsh Anand CSEPas encore d'évaluation

- Zte Mg3030 ModuleDocument27 pagesZte Mg3030 Modulesardar87Pas encore d'évaluation

- Zip Password CrackerDocument31 pagesZip Password CrackerMoTech100% (1)

- Power Electronics Question BankDocument3 pagesPower Electronics Question BankHarish SudhanPas encore d'évaluation

- T & H P A: Understanding Person AccountsDocument2 pagesT & H P A: Understanding Person AccountsPriya JuligantiPas encore d'évaluation

- 5G Transport Network Requirements, Architecture and Key TechnologiesDocument27 pages5G Transport Network Requirements, Architecture and Key TechnologiesFreedomPas encore d'évaluation

- Samsung Gb-19sen Chassis Le19r86bd LCDDocument117 pagesSamsung Gb-19sen Chassis Le19r86bd LCDAntonio CersosimoPas encore d'évaluation

- Automatic Headlight Hi-Lo Beam Using ArduinoDocument14 pagesAutomatic Headlight Hi-Lo Beam Using ArduinoMark Anthony Lluvido PlatinoPas encore d'évaluation

- How To Make Lite Versions of KONTAKT LibrariesDocument18 pagesHow To Make Lite Versions of KONTAKT LibrariesBerlinband 237Pas encore d'évaluation

- EIE412 - Lecture Modules & Contents (2021 - 22)Document18 pagesEIE412 - Lecture Modules & Contents (2021 - 22)sopuruPas encore d'évaluation

- FlucsPro Ver 6 - 0 Web Training Notes Rev1Document32 pagesFlucsPro Ver 6 - 0 Web Training Notes Rev1dharshan balajiPas encore d'évaluation

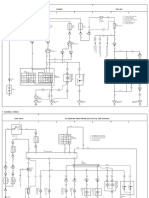

- Avanza Xenia Wiring DiagramDocument5 pagesAvanza Xenia Wiring DiagramFazri Putugerah100% (2)

- Allotted List Round 2 PDFDocument370 pagesAllotted List Round 2 PDFASHOKPas encore d'évaluation

- COTO To SendDocument37 pagesCOTO To SendHemant Singh JadaunPas encore d'évaluation

- DELTA IA-SI DIAView C EN 20190517 web-SCADADocument20 pagesDELTA IA-SI DIAView C EN 20190517 web-SCADAchandra mouliPas encore d'évaluation