Académique Documents

Professionnel Documents

Culture Documents

M357T

Transféré par

vipniDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

M357T

Transféré par

vipniDroits d'auteur :

Formats disponibles

M357T Thatcham Motorcycle Alarm/Immobiliser

Technical features_______________________________________________ Power supply:.... 12Vdc (10 V 15 V) Consumption:. Fully armed 1.9mA ..Immobiliser only 1.2mA Stop mode 0mA Operating temperature: ...-25 C - +85 C Self-supply autonomy:...5 minutes Alarm duration: ....25 seconds Remote duration: controls:....Lithium battery Combinations: ...over 7.2 x 1016 Dimensions:125 x 47 x 47 Relay contact capacity____________________________________________ Engine immobilisation relays:..10 A Direction in dicators:..5+5A Timing_________________________________________________________ Initial non-active period:..26 seconds Alarm duration:..26 seconds Passive arming delay after ignition OFF (immobilisation only): ..50 seconds Stop mode delay in unchanged state.....10 days General________________________________________________________ These instructions should be read in conjunction with the information supplied by the manufacturers/distributors training course. Alarm positioning and mounting____________________________________ -Fit the alarm control ECU in such a position that to gain access, would cause an alarm condition. -Secure the alarm in place using suitable means. -Make sure that the alarm unit is located at least 15 cm from the exhaust system. -Mount the alarm system in a reasonably dry area to minimise exposure to rain and spray. -The movement sensor of the alarm system is at its most sensitive when mounted in the horizontal position and mounted along or across the frame. Its effect is at a minimum when mounted on its side. The movement sensor is non-adjustable; therefore select the position to give suitable movement coverage.

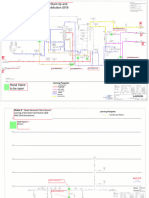

Fitting_________________________________________________________ -Disconnect the motorcycle battery negative terminal before beginning the fitting. -Make all connections following the general diagram annexed and the CD service manual. -While connecting the harness, make sure that the markings at the end of the wires are removed in order to make it impossible to identify the wire function. -Use t e M4 tester with the correct interconnection lead during a l l h installations. -The machine specific information supplied on the CD manual is a guide; always check all wiring prior to connection. Main negative and positive connections (wire No. 2 and 2 x wi re No. 3)___ Connect the 2 wires No. 3 to two independent permanent earth points. These can be frame or wire based. Caution. The frame on some machines does not provide a good earthing point so always check. Also on some machines wires that appear as negative with the machine switched off can change state when the machine is running or controls are operated. If in doubt check the wiring diagram for the specific machine. Connect wire No.2 to a permanent 12v supply via the fuse supplied in the kit. Ignition sensing wire (wire No. 1)___________________________________ Ignition Connect wire No. 1 to a wire on the machine, which is 12v ignition switched positive. Take care, on some machines the positive supply may disappear whilst the machine is being started or when certain controls are used. Always check the circuit remains ignition switched positive by testing whilst operating the controls and cranking. Immobilisation techniques________________________________________ Under no circumstances must a constant 12v positive wire be immobilised positive with the M357T alarm system. If this type of circuit is immobilised the unit will not passively immobilise and will not respond to the remote controls. DC Ignition systems (normally open method) (wires 4 and 5, 7 and 8)____ This method works by cutting the control wire of the circuit to be immobilised e.g. ignition pack, coils, side stand switch, starter, etc. The circuit will be made when the system is disarmed and the ignition is turned on. Fig.2

AC ignition systems (normally c losed method) (wires 4 and 6)___________ This method of immobilisation works by supplying a running circuit with an earth therefore stopping the trigger pulse reaching the ignition pack or coil. Fig.3

Only fit the security housing to the alarm when all functional testing has been completed. The screws are one-way only and cannot be removed. Fig.1

Direct trigger circuits (wires 17 and 44)____________ _________________ The M357T has two types of direct triggering circuits. Wire No.17 triggers the system when the alarm is armed and a negative signal is a p p l i e d to it. This wire can be used to protect the storage area of the machine via a suitable pinswitch or in certain cases, may be linked to the side stand of the machine.

Fig.4

0053WD31512SJP

Wire No.44 triggers the system when the alarm is armed and the negative connection to it is r e m o v e d . This wire must be used to protect the alarm ECU via the normally open magnetic reed switch supplied with the kit. The wire can also be extended to protect soft luggage, helmets or garages via a closed loop extension wire. Wire No.44 must end at a single earth point (i.e. be continuous from the alarm to the earth point). The addition of trigger lines taken as spurs from wire No.44 will seriously affect its performance. Fig.5

Fig.8

P O S II T II V E C O N T R O L POS T VE CONTROL

N o t e : It is a requirement of all Thatcham approved alarm systems that the alarm ECU is protected. Therefore the magnetic reed switch must be installed so that the alarm will trigger prior to access being gained to the ECU. Connecting the indicator circuits (wires 14 and 15)____________________ Connect wires 14 and 15 to the right and left hand P O S I T I V E indicator supplies of the machine. On certain machines the indicators may have the effect of powering other circuits of the machine if the indicator switch is positioned to the left or right during alarm operation. To check for this, with the ignition turned off, apply 12v to an indicator feed and switch the indicator to that side, check the other functions of the machine (e.g. headlight, horn, starter, etc) to see if they are operational. If any other system on the machine is working an inline diode (as supplied with the kit) must be installed in the indicator relay ignition switched input wire or the output wire from the indicator relay to the indicator switch. Ensure the indicators work normally when operated. If they do not the diode has most probably been installed in reverse. Connecting the LED (wires 29 and 3)_______________________________ The system is supplied with two types of LED. Select the most suitable type for the specific application and connect as per general diagram. Do not install both types of LED. Wire 29 is the pulsed positive feed from the alarm to flash the LED. Connect this to the red wire of the LED. The wire 3 running in the loom with wire 29 is the negative supply to the LED. Connect this to the black wire of the LED. Connecting the alarm s ystem to the motorcycle horn system (Wires 20 and 1 4 ) ___________________________________________________________ This is not a normal requirement of the installation and should be treated only as a customer requested extra. Establish the switching arrangement on the machine and install according to the diagrams laid out below. Fig.6

Connecting the alarm system to a supplementary siren (wire 20) The siren output is negative and has a maximum rating of 100mA. Should a supplementary siren be requested, connect as below. Fig.9

Final functional check____________________________________________ When the installation of the wiring is complete and has been checked via the M4 tester, transfer the wiring from the tester to the alarm system. The alarm will remain switched off. -Switch on the ignition to activate the alarm unit. -Once activated in this way, the alarm will be supplied from the machines battery and will be passive armed (immobilised only). -Disarm the alarm by pressing the remote control once. A single beep and flash of the indicators will be seen and heard. If a different disarm sequence is given there is a problem. Note the disarm sequence and check in the diagnostic table for the possible cause. -Within 50 seconds turn the ignition on and start the machine to check it runs. -Turn off the ignition and check the system arms passively and via the remote controls. -Next check all functions of the alarm for correct operation (see full operating instructions).

Fig.7

----------------------------

------

0053WD31512SJP

Fig.10

10A

N 1 2 3 4 5 6 7 8 14 15 17 20 29 3 44 -

Function Ignition (+15) sensing Positive supply Negative supply (2 wires) Engine immobilisation relay- C. Engine immobilisation relay- N.O. Engine immobilisation relay-N.C. Crank immobilisation relay C. Crank immobilisation relay N.O. Direction indicator Direction indicator Negative protection switch Horn/siren negative output LED Positive supply LED Negative supply ECU/Accessory loop circuit Antenna

Connection point Ignition switch positive supply (+15) 12V positive supply via 10A fuse (+30) 2 independent earth points (-31) Supply side of immobilised circuit. (See fig.2 & 3) Load side of immobilised circuit (See fig. 2) Immobilisation AC machines only (See fig. 3) Starter immobilisation Starter immobilisation To direction indicator positive feed (left) To direction indicator positive feed (right) To ECU protection switch/pannier switch (See fig. 4) See fig. 6,7,8 & 9 To red wire of the LED To black wire of the LED To negative via reed switch/accessory loop protection (see fig.5) Do not connect

Batteries are considered to be harmful waste materials and should be disposed of according t o the regulations in force

0053WD31512SJP

M357T OPERATING INSTRUCTIONS

Engine immobilisation (passive arming)___________________________ -Activation occurs 50s after the system is disarmed and the ignition is not turned on or 50 seconds after the ignition is turned off. -The system will emit a short beep and a short flash of the indicators to indicate arming. -Only the engine immobilisation circuit is active. -The LED flashes slowly. -If the system remains in this status at least 10 days, or detects that the bike battery is discharging too quickly, it goes in shut down-mode. -All systems except the immobiliser are turned off and there is no current drain from the machines battery. -To re-activate the system from the shut down mode, turn on the ignition and disarm via the remote control or via the override code. N o t e : When the system is armed only as an immobiliser the battery back up is not activated and the system will not sound if the machines battery is removed enabling servicing of the battery or other systems to take place. Fully arming the system (Alarm and Immobiliser)____________________ -Press the remote control with the ignition off before the system has passively armed (i.e. within the first 50 seconds of turning the ignition off). -The direction indicators will flash twice and the buzzer will emit two audible signals if all is correct with the machine. If there is a problem with the machine or alarm, a different arming signal will be heard (see the notes at the end of the operating instructions). -The LED will flash at an increased rate for 26 seconds. -During this 26 second initial immunity period, it is possible to test the alarm trigger inputs without triggering the alarm, an audible beep can be heard as each input is tested. -At the end of the 26-second immunity period the LED will flash at a reduced rate and the alarm will trigger when any input is activated. Note: -If on arming the machines battery or the alarms back up battery is detected as discharged, the buzzer will emit four fast bips to indicate the problem. -If on arming, one of the protection circuits is detected as active, the buzzer will emit two normal beeps followed by a boop. Disarming with remote control___________________________________ -To disarm the system whether armed passively (immobilised), as an alarm, or when sounding, press the remote control once. -The direction indicators flash once (if the machines battery is charged). -The buzzer beeps once (unless the system has been triggered) -The engine immobilisation circuits are deactivated. -The LED will be off (unless the system has been triggered). -You now have 50 seconds to turn the ignition on and start the machine. -If the ignition is not turned on within 50 seconds the machine will passively immobilise. Note: -If during the arming period the alarm was triggered, on disarming the buzzer will emit a warning boop and the LED will flash to indicate how the alarm was triggered (see the diagnostic table at the end of the operating instructions) -If the machines battery is in a low state of charge, the buzzer will emit 4 fast bips and the machines indicators will not flash. -Each time the machines ignition is turned off the LED flashes the number of times equal to the number of remote controls programmed into the system. Arming the alarm without the movement sensor____________________ -With the system fully disarmed (i.e. within 26 seconds of turning off the ignition), press and hold the remote control button for 2 seconds. -The alarm will emit 2 normal arming beeps and flashes followed by a short flash and beep after an increased pause. -The LED will flash with the same sequences as if normally armed and the system will sound to all alarm inputs except the movement sensor. -The system is only armed without the movement sensor for the period covered by that armed cycle (i.e. the next time the system is armed with the remote control it will be fully armed with the movement sensing included). Movement sensor_____________________________________________ -The sensor is integrated in the alarm -At maximum sensitivity, typical movement necessary to trigger an alarm is a change of inclination of 1.5. -It is able to detect very slow movements. -It is immune to the shocks (if short duration) and to vibrations. -Adjustment not required.

-Can be excluded for one active cycle, by arming with the remote control being pressed for more than 2 seconds. Operation of the alarm when fully armed (active phase)_____________ -This describes the status where any activation of a trigger sounds the alarm. -The LED flashes slowly and the engine immobilisation circuits are active. -The activation of one of the protective switches, or ignition, or the movement sensor (if set), generates maximum 10 alarm cycles per each setting period. -If the protective contacts or the ignition are latched, the 10 alarm cycles are generated in sequence with a gap of 5 seconds between each cycle. -Each alarm cycle lasts 26seconds. -The disconnection of the bike battery generates 9 alarm cycles with 15second intervals. Note: -If the machines battery becomes drained, the alarm switches off (shut down mode). -If the system is not disarmed/armed or is not triggered for 10 days the alarm enters shut down mode. Exiting shut down mode________________________________________ -To exit the shut down mode turn the ignition on. -If the alarm entered shut down mode from its alarmed state it gives a 5 second pre-alarm beep signal to allow disarming before sounding. -If after the 5second period the system is not disarmed, it triggers an alarm cycle. Disarming with the override code_______________________________ -Disarming is only possible when the system is armed via remote control or passive armed, but not during the 26s initial immunity period. -All systems are factory preset with a random 5-figure sequence. This code is printed on the Orange remote control code card. The owner should store this card securely as it can be used to disarm the system and also add and remove transmitters (dealer function). -To disarm the system using the override code, use t e following h procedure: 1. T u r n t h e i g n i t i o n o n ( t h e L E D w i l l b e o n ) 2. Turn the ignition off within 10s (the LED will flash with an even sequence) 3. Turn the ignition on when the LED has flashed the number of times corresponding to the first digit of the override code 4. Turn the ignition off within 10s (the LED starts a new flash sequence) 5. Turn the ignition on when the LED has flashed the number of times corresponding to the second digit of the override code 6. Continue with this procedure until the entering of the fifth digit. 7. When the fifth digit has entered, if the code is correct, the system disarms. Warning! If the three wrong override codes are entered, the system doesnt allow the disarming with the override code. At this stage is necessary to wait for 30 minutes with the ignition off before entering the correct override code. N o t e : If the alarm is armed, the entering of the override code will trigger an alarm cycle; even in case of alarm, continue with the described procedure. Remote controls______________________________________________ -Normally the system is supplied with two remote control called No.1 and No.2. -The remote controls have 7.2 x 1016 variants and are rolling code, therefore anti scan and anti grab. -An Orange code card is issued with all systems when produced. Only this card contains the remote control and pass code numbers required to introduce new remotes and override the system. It is therefore of utmost importance this card is stored securely. Should you sell the machine, please pass the code card to the new owner. -It is possible to remove a lost or stolen remote control or add one or more remote controls up to a maximum of 6. Return the machine, ignition keys and all original remote controls to the dealer along with the Orange code card issued with the system. -All extra remote controls must be pre coded to the number issued on the orange card issued with the original alarm. -The remote controls are powered by 2, 3volt, lithium batteries (CR1220) These give a normal life of around 3 years. -A remote control key conversion kit is available enabling the dealer to combine most ignition keys with the remote control. -The key conversion kit has location points to fit most types of OE ignition transponder chips. Alarm Diagnostic memories Movement sensor 1 pulse on, 3 second pause Negative input or loop circuit 2 pulses on, 3 second pause Ignition sensing 3 pulses on, 3 second pause Self powered (12volt supply 4 pulses on, 3 second pause removed)

0055WD20301SJP

Introducing and removing new remote controls to the M357T

N.B. All remote controls must be pre-coded to the number issued on the orange card supplied with prethe alarm. The override pin-code from the card is also required to access the programming routine. pinroutine. Please ensure you have these details before commencing. 1. Disarm the system either by remote control or override code. 2. Within 10s turn on the ignition 3 times and keep it on (beep on third activation). 3. Turn the ignition off within 10s. 4. Enter the override code from the Orange code card. 5. Leave the ignition on when you have entered the fifth digit of the override code. 6. The buzzer will confirm the correct entering of the code by the signal (bip-bip-bop-bop). 7. Transmit once with the new remote control to be enabled (LED lit on). 8. Transmit a second time with the same remote control for confirmation (confirmation beep). If the system emits a boop the operation was wrong; repeat the operation. 9. Now the new remote control is enabled and meanwhile all those previously stored in the memory are disabled. 10. Carry out, now, as above described, the double transmission of all other remote controls to be enabled (including the originals). 11. Turn the ignition off. The system indicates that the programming is over by the signal (bip-bipbop-bop). 12. The LED will emit the same number of flashes as the number of remote control enabled.

0035WD11011SJP

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Genset DataDocument12 pagesGenset DatagebrePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Dewatering Pump: Instruction, Installation, Operation and Maintenance ManualDocument5 pagesDewatering Pump: Instruction, Installation, Operation and Maintenance ManualDeepPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Smpling - Storage - Transportation - Installation ProcedureDocument75 pagesSmpling - Storage - Transportation - Installation ProcedurePaddyPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Design and Fabrication of Stair Climber TrolleyDocument21 pagesDesign and Fabrication of Stair Climber TrolleyAnonymous 1mMOyt9zPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- S 1514Document4 pagesS 1514bacuoc.nguyen356Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Size CalculationDocument13 pagesSize CalculationGopal DasiriPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Parts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Document87 pagesParts Catalogue: '19 ER300 AKF/AKFA (CL) (Z300)Yeison Cartagena BedoyaPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Radial Turbine Design ProcessDocument15 pagesRadial Turbine Design ProcessKamaldeep GuptaPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- (Walter J. Maciel (Auth.) ) Astrophysics of The IntDocument271 pages(Walter J. Maciel (Auth.) ) Astrophysics of The IntLuis Fernando Mejia0% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Four Bar Linkage Knee Analysis: by Michael P. Greene, B.S., M.E., C.P.ODocument10 pagesFour Bar Linkage Knee Analysis: by Michael P. Greene, B.S., M.E., C.P.ObaksoPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- AQA PHYA2 W Specimen PaperDocument13 pagesAQA PHYA2 W Specimen Paper04rchoudPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Yuri Waterbasedwindows PDFDocument26 pagesYuri Waterbasedwindows PDFRenata MansueloPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Penggantian Relay Dist Ke LCD & Progress Koordinasi Penghantar Dan PembangkitDocument11 pagesPenggantian Relay Dist Ke LCD & Progress Koordinasi Penghantar Dan PembangkitCahyo Tri HartoyoPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Dh3 Generation Lototo Plan Phase 2 RGC 08sep2023Document8 pagesDh3 Generation Lototo Plan Phase 2 RGC 08sep2023Borislav VulicPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- 三菱S4L2发动机零件图册Document111 pages三菱S4L2发动机零件图册Baiuliang BaiuliangPas encore d'évaluation

- Basic Electronic For Marine EngineersDocument45 pagesBasic Electronic For Marine EngineersŞansal DikmenerPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Stem - Physics 1 CGDocument13 pagesStem - Physics 1 CGVictoria MabiniPas encore d'évaluation

- France en Dec. 2022 v3Document37 pagesFrance en Dec. 2022 v3Tarek OsmanPas encore d'évaluation

- E510 Startup Installation ManualDocument147 pagesE510 Startup Installation Manualpermitha sariPas encore d'évaluation

- Date Tehnice 436 ZXDocument6 pagesDate Tehnice 436 ZXMB ViorelPas encore d'évaluation

- Unit Merinyu Elektrik: Application For Certificate of CompetencyDocument4 pagesUnit Merinyu Elektrik: Application For Certificate of CompetencySaff MdPas encore d'évaluation

- A Proactive 2-Stage Indoor CO2-based Demand-Controlled Ventilation Method Considering CoDocument18 pagesA Proactive 2-Stage Indoor CO2-based Demand-Controlled Ventilation Method Considering CoMariaPas encore d'évaluation

- Low-Voltage Halogen Lamps Without Reflector: Product Family DatasheetDocument13 pagesLow-Voltage Halogen Lamps Without Reflector: Product Family DatasheetparasprrmPas encore d'évaluation

- Enclosures TechnicalDocument16 pagesEnclosures TechnicalAnonymous rYZyQQot55Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Laboratorio Oficial J. M. Madariaga: Supplementary Eu-Type Examination CertificateDocument3 pagesLaboratorio Oficial J. M. Madariaga: Supplementary Eu-Type Examination CertificateDilara Azqila YasminPas encore d'évaluation

- Cusat Ec 4th Sem Question PaperDocument21 pagesCusat Ec 4th Sem Question PaperJinu Madhavan100% (1)

- Solar Based Grass CutterDocument6 pagesSolar Based Grass CutterTTPas encore d'évaluation

- SPE-188863-MS Sweet Spot Mapping in The Montney Tight Gas ReservoirDocument12 pagesSPE-188863-MS Sweet Spot Mapping in The Montney Tight Gas ReservoirarispriyatmonoPas encore d'évaluation

- All AcDocument11 pagesAll Acfb_menotifyPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Data Sheet Tcg2032 DeutzDocument3 pagesData Sheet Tcg2032 DeutzMaximiliano SanchezPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)