Académique Documents

Professionnel Documents

Culture Documents

As QMS 003 Record Control

Transféré par

Ali ZafarDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

As QMS 003 Record Control

Transféré par

Ali ZafarDroits d'auteur :

Formats disponibles

St. Vrain Manufacturing, Inc.

SAE AS9100

QMS-003

Record Control

Record Control

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 1 of 8 Last Printed: 2/19/2008

St. Vrain Manufacturing, Inc.

SAE AS9100

QMS-003

Record Control

Document Control Revision History

Page All 5 6 All Reason for Change New Document Insert Section 5.2 Insert section 5.15.1 Revise to meet SAE AS9100 Requirements Rev. A B B C Reviewer R. Ryer R. Ryer R. Ryer R. Ryer Release Date 06/29/05 09/23/06 09/23/06 12/07/06

Signature:

Revision Approval

Date: 12/07/06

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 2 of 8 Last Printed: 2/19/2008

St. Vrain Manufacturing, Inc.

SAE AS9100

QMS-003

Record Control

1.0

Scope and Objectives 1.1 1.2 This procedure defines the activities required for establishing and maintaining a record control system. The objective of the record control procedure shall be to ensure that quality records are established and maintained to provide objective evidence of product conformance to specification, materials and process traceability, documentation retrieval for review and effectiveness of the quality management system. The result of the record control process shall ensure required documents remain legible, be readily identifiable and retrievable and have needed controls for identification, storage, protection, retrieval, retention time and disposition. Quality records shall be used to improve customer product quality and improve the overall effectiveness of the quality management system.

1.3

2.0

Applicability 2.1 This procedure applies to, but is not limited to: 2.1.1 2.1.2 2.1.3 2.1.4 2.1.5 2.1.6 all documents submitted by customers defining process and product requirements all documents submitted by customer providing objective evidence of product conformance to customer specification all documents submitted by suppliers certifying that processes and products meet specified requirements all documents created by St. Vrain Manufacturing defining processes used to meet specified requirements all documents created by St. Vrain Manufacturing providing objective evidence of product conforming to customer specification all personnel within the organization that develop, use and maintain quality records

3.0

Related Documents 3.1 3.2 3.3 3.4 QM-001, Quality Manual, Section 4.2.4, Control of Quality Records Quality records (customer, supplier, internal and external) Document Control Log SAE AS9100, Quality Management System Aerospace Requirements, Section 4.2.4, Control of Quality Records

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 3 of 8 Last Printed: 2/19/2008

St. Vrain Manufacturing, Inc.

SAE AS9100

Process Flow Chart

Process data from internal processes

QMS-003

Record Control

4.0

Process data records created and/or retained by suppliers

Process data from customers Quality data

Process data recording forms

Quality records

Legible Quality Records are:

Identifiable

Retrievable

Identification

Storage

Protection

Retrieval

Quality Record Controls are:

Retention

Disposition

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 4 of 8 Last Printed: 2/19/2008

St. Vrain Manufacturing, Inc.

SAE AS9100

QMS-003

Record Control

5.0

Procedure 5.1 In accordance with SAE AS9100, Section 4.2.4, St. Vrain Manufacturing recognizes the importance of quality records and documents and the need for control. To provide accountability and traceability on all quality records, all appropriate personnel will use initials , stamps or signatures and dates.

5.2

Requirements and Controls 5.3 Quality records that document process data are established and maintained and provides evidence of conformity to customer product requirements and the effective operation of the QMS. Quality records may be obtained from: 5.4.1 5.4.2 5.4.3 5.4.4 5.5 customers suppliers process data from internal processes any other data source that provides data that can have a direct impact on customer product quality and the effectiveness of the QMS.

5.4

Quality records shall remain legible. 5.5.1 5.5.2 data shall be recorded in ink pencil may be used for reference data

5.6

Quality records shall be readily identifiable. 5.6.1 document name and/or number shall be included in the header/footer

5.7

Quality records shall be retrievable. 5.7.1 5.7.2 5.7.3 production records are stored in the production office financial records are stored in the finance office quality records are stored in both the inspection office and in the job folder in the production office

5.8

Controls for identification. 5.8.1 5.8.2 5.8.3 5.8.4 date revision level purchase order number job number

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 5 of 8 Last Printed: 2/19/2008

St. Vrain Manufacturing, Inc.

SAE AS9100

customer chronological order (date/job number)

QMS-003

Record Control

5.9

Controls for storage. 5.9.1 5.9.2

5.10

Controls for protection. 5.10.1 plastic sleeves 5.10.2 manila file folders

5.11

Controls for retrieval. 5.11.1 person responsible for file maintenance shall perform retrieval when possible 5.11.2 others may retrieve documents when situation requires

5.12

Controls for retention time. 5.12.1 three years minimum 5.12.2 customer required

5.13

Controls for disposition of records. 5.13.1 shredding

5.14

Quality records created and retained by suppliers shall be controlled to the extent required to maintain, over a period of three years (or period designated by customer contract): 5.14.1 legibility 5.14.2 traceability 5.14.3 retrievability

5.15

All applicable quality records are available for review by customers and regulatory authorities in accordance with procedures, contract or regulatory requirements. Individual procedures that include requirements for quality records will address control requirements found in Sections 5.7 through 5.12, as appropriate.

5.16

Quality Record Definition 5.17 Quality record is any document or form that contains objective evidence (data) to support the outcome of a process and can be used to determine conformance to requirements. 5.17.1 personnel entering data shall initial, stamp or sign and date the data to provide accountability and traceability

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 6 of 8 Last Printed: 2/19/2008

St. Vrain Manufacturing, Inc.

SAE AS9100

QMS-003

Record Control

Quality Record Examples 5.18 The following are considered to be quality records, but quality records will not be limited to the examples below: 5.18.1 request for quote and response 5.18.2 purchase orders 5.18.3 customer prints, standards and specifications 5.18.4 job ticket 5.18.5 job traveler 5.18.6 inspection report 5.18.7 nonconforming material report 5.18.8 request for deviation 5.18.9 certificates of conformance Record Retention 5.19 5.20 Quality records will be stored for a minimum period of three years before disposal. Quality records will be maintained: 5.20.1 on site for a period of three years 5.20.2 after three years, offsite, according to customer or regulatory authority requirements 5.21 Customer may specify any retention period contractually.

Disposition of Quality Records 5.22 Quality records identified as being ready for disposal shall be purged from the filing system and shredded.

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 7 of 8 Last Printed: 2/19/2008

St. Vrain Manufacturing, Inc.

SAE AS9100

QMS-003

Record Control

6.0

Responsibilities 6.1 St. Vrain personnel 6.1.1 6.1.2 6.2 verify documents meet applicable requirements maintain documents as required

Quality manager 6.2.1 6.2.2 6.2.3 6.2.4 maintain document control system issue and control documents ensure documents are regularly reviewed and updated

7.0

ensure that regular internal audits, that address the continued applicability of this document, are scheduled Record Retention 7.1 Standard retention period will be three years minimum, all documents. 7.1 7.2 7.3 Customers may stipulate longer retention times.

This controlled QMS procedure shall be maintained on the server indefinitely. Any hardcopy of this controlled document shall be valid for one day after printing. 7.3.1 7.3.2 after one day has elapsed the document shall be used only as a reference document reference documents must be verified for revision level prior to use

7.4 7.5

Obsolete documents shall be removed from area of use and disposed of as appropriate. As appropriate, all quality records associated with this document are available for customer or regulatory agency review.

8.0

Document Control 8.1 8.2 Custodian: Review Activity Quality Manager Quality Manager President Operations Manager Quality Manager President Operations Manager

8.3

Approval Authority:

Revision: C Date: 12/07/06 This document expires one day after printing

Page: 8 of 8 Last Printed: 2/19/2008

Vous aimerez peut-être aussi

- The Foundations of the Process ApproachDocument34 pagesThe Foundations of the Process ApproachAli ZafarPas encore d'évaluation

- Eurolab Handbook Iso Iec 17025 2017Document32 pagesEurolab Handbook Iso Iec 17025 2017Ali ZafarPas encore d'évaluation

- SustainabilityAssessment System - AM PDFDocument35 pagesSustainabilityAssessment System - AM PDFAli ZafarPas encore d'évaluation

- Diploma Unit A Revision Cards PDFDocument72 pagesDiploma Unit A Revision Cards PDFAli Zafar100% (1)

- RCA Mini Guide PDFDocument15 pagesRCA Mini Guide PDFIldzamar Haifa WardhaniPas encore d'évaluation

- Unit Ia Exam SuccessDocument82 pagesUnit Ia Exam SuccessAli Zafar100% (8)

- The Ideology of Pakistan Javid Iqbal 1959 - 000026Document98 pagesThe Ideology of Pakistan Javid Iqbal 1959 - 000026Ali Zafar100% (1)

- ISO/IEC 17025:2017 Tutorial for UKAS StaffDocument74 pagesISO/IEC 17025:2017 Tutorial for UKAS StaffAli Zafar100% (1)

- Root Cause AnalysisDocument62 pagesRoot Cause AnalysisLintang Sekar KinanthiPas encore d'évaluation

- Victoria Compliance Framework HandbookDocument22 pagesVictoria Compliance Framework HandbookAli ZafarPas encore d'évaluation

- Examiner Reports January 2009 Unit IADocument13 pagesExaminer Reports January 2009 Unit IAElavarasan RamalingamPas encore d'évaluation

- Nebosh International Diploma Examiners Report Jan 2011 - Unit IaDocument15 pagesNebosh International Diploma Examiners Report Jan 2011 - Unit IaJack Ebiyabo Sled LawsonPas encore d'évaluation

- Annex SL Excerpt - 2015 6th Edition - Hls and Guidance Only PDFDocument23 pagesAnnex SL Excerpt - 2015 6th Edition - Hls and Guidance Only PDFalexmardukPas encore d'évaluation

- National Fire Guide Nov 14 Spec V242201634116Document67 pagesNational Fire Guide Nov 14 Spec V242201634116Ali ZafarPas encore d'évaluation

- NEBOSH Idip July 2012 Unit IA Exam PaperDocument12 pagesNEBOSH Idip July 2012 Unit IA Exam PaperNaeem Iqbal33% (3)

- Maturity AssessmentDocument228 pagesMaturity AssessmentAli ZafarPas encore d'évaluation

- COOP Risk Assessment Vulnerability AnalysisDocument8 pagesCOOP Risk Assessment Vulnerability AnalysisAli ZafarPas encore d'évaluation

- NQA ISO 14001 2015 Transition GuidanceDocument6 pagesNQA ISO 14001 2015 Transition GuidancePedroPas encore d'évaluation

- F13 SiteDailyLogDocument5 pagesF13 SiteDailyLogAli ZafarPas encore d'évaluation

- ISO 9001 Auditor Training Q&ADocument10 pagesISO 9001 Auditor Training Q&AAli Zafar71% (7)

- Evolution of a Process Flow Diagram for Farming OperationsDocument18 pagesEvolution of a Process Flow Diagram for Farming OperationsAli ZafarPas encore d'évaluation

- Costain BBS ProgrammeDocument55 pagesCostain BBS ProgrammeAli ZafarPas encore d'évaluation

- Crisis Management Manual: SampleDocument53 pagesCrisis Management Manual: SampleloveasonePas encore d'évaluation

- Costain BBS ProgrammeDocument55 pagesCostain BBS ProgrammeAli ZafarPas encore d'évaluation

- Hazop Training GuideDocument9 pagesHazop Training GuideAdyBorsosPas encore d'évaluation

- Aspect-Impact Assessments Significance Ranking Total Rank A B C D E F Impact Direct/Indir Ect Condition N/A/EDocument1 pageAspect-Impact Assessments Significance Ranking Total Rank A B C D E F Impact Direct/Indir Ect Condition N/A/EAli ZafarPas encore d'évaluation

- FIRE HYDRANT DESIGN CRITERIADocument85 pagesFIRE HYDRANT DESIGN CRITERIAhareeshrp_87515719350% (2)

- Communication, Participation & Consultation ProceduresDocument12 pagesCommunication, Participation & Consultation ProceduresAli ZafarPas encore d'évaluation

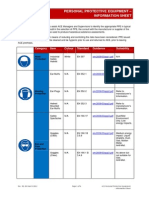

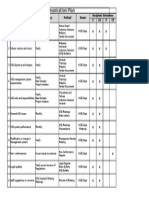

- ACE Personal Protective Equipment Information SheetDocument4 pagesACE Personal Protective Equipment Information SheetAli ZafarPas encore d'évaluation

- Communication Plan for HSSE DepartmentDocument1 pageCommunication Plan for HSSE DepartmentAli ZafarPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Calmark - Birtcher 44 5 10 LF L DatasheetDocument2 pagesCalmark - Birtcher 44 5 10 LF L DatasheetirinaPas encore d'évaluation

- IBM Release Notes - IBM SPSS Statistics 21.0 - United States PDFDocument3 pagesIBM Release Notes - IBM SPSS Statistics 21.0 - United States PDFraj sharmaPas encore d'évaluation

- Example 02 - Moment Capacity of A Concrete Beam - Reinforced Concrete Design ReviewDocument5 pagesExample 02 - Moment Capacity of A Concrete Beam - Reinforced Concrete Design ReviewJohn Michael GeneralPas encore d'évaluation

- BS (English) Dept of English University of SargodhaDocument36 pagesBS (English) Dept of English University of SargodhaFEROZ KHANPas encore d'évaluation

- An Introduction to Heisenberg Groups in Analysis and GeometryDocument7 pagesAn Introduction to Heisenberg Groups in Analysis and Geometrynitrosc16703Pas encore d'évaluation

- Sigmund Freud and His Main TheoriesDocument5 pagesSigmund Freud and His Main TheoriesNguyen HarryPas encore d'évaluation

- The Champion Legal Ads: 11-02-23Document58 pagesThe Champion Legal Ads: 11-02-23Donna S. SeayPas encore d'évaluation

- CM Group Marketing To Gen Z ReportDocument20 pagesCM Group Marketing To Gen Z Reportroni21Pas encore d'évaluation

- 8.9 Basic Maths For Well PlanningDocument9 pages8.9 Basic Maths For Well PlanningKhanh Pham MinhPas encore d'évaluation

- Arduino - Decision Making StatementsDocument20 pagesArduino - Decision Making StatementsJohn Clifford Ambaic JayomaPas encore d'évaluation

- Chalk & TalkDocument6 pagesChalk & TalkmathspvPas encore d'évaluation

- Green Screen Background Remover Using CV SystemDocument20 pagesGreen Screen Background Remover Using CV SystemSubhamPas encore d'évaluation

- Chem 361 Separation Methods IntroDocument8 pagesChem 361 Separation Methods IntroTwum SomoahPas encore d'évaluation

- Me8072 Renewable Sources of EnergyDocument13 pagesMe8072 Renewable Sources of EnergyNallappan Rajj APas encore d'évaluation

- Ajp Microproject ReportDocument9 pagesAjp Microproject ReportRushikesh KansePas encore d'évaluation

- Finimpianti Power EngDocument2 pagesFinimpianti Power EngJosip GrlicaPas encore d'évaluation

- PLC SCADA ASSIGNMENT SsDocument10 pagesPLC SCADA ASSIGNMENT SsShadab AhmadPas encore d'évaluation

- Application of EbwDocument11 pagesApplication of Ebwsuman kumarPas encore d'évaluation

- INJSO Answer Key & SolutionDocument5 pagesINJSO Answer Key & SolutionYatish Goyal100% (1)

- w5 Philo Module 5Document24 pagesw5 Philo Module 5prestonvela15Pas encore d'évaluation

- Motorship Oct 2023Document56 pagesMotorship Oct 2023Sahil PakhaliPas encore d'évaluation

- The Scientific MethodDocument4 pagesThe Scientific MethodRob LovPas encore d'évaluation

- An Introduction To Pascal Programming MOD 2010Document5 pagesAn Introduction To Pascal Programming MOD 2010Johnas DalusongPas encore d'évaluation

- Atpl Formula MergedDocument74 pagesAtpl Formula Mergeddsw78jm2mxPas encore d'évaluation

- List of Electronics Manufacturing Companies in Noida - ElectronicsmediaDocument2 pagesList of Electronics Manufacturing Companies in Noida - ElectronicsmediaBlue Oceon50% (4)

- DLP IN ICT 9 1st MeetingDocument2 pagesDLP IN ICT 9 1st MeetingHEDDA FULOPas encore d'évaluation

- Attitudes and Practices Related To Sexuality and Sexual BehaviorDocument35 pagesAttitudes and Practices Related To Sexuality and Sexual BehaviorGalvin LalusinPas encore d'évaluation

- L028 Me Dat 01 00122 001 00Document8 pagesL028 Me Dat 01 00122 001 00sivasan10006098Pas encore d'évaluation

- Report Card of Army Public School StudentDocument2 pagesReport Card of Army Public School StudentRama KrishnaPas encore d'évaluation

- Automation & Control Esst en 200804Document356 pagesAutomation & Control Esst en 200804Sveinn Rúnar JúlíussonPas encore d'évaluation