Académique Documents

Professionnel Documents

Culture Documents

Electrical and Instrmentation Design Criteria Sample

Transféré par

abdkha8644Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Electrical and Instrmentation Design Criteria Sample

Transféré par

abdkha8644Droits d'auteur :

Formats disponibles

Page

1. GENERAL ................................................................................................................................ 3

ntroduction 3

Scope 3

3 References 3

3 Outside Organizations 3

3 Other Project Design Criteria 3

33 Other Documents 3

Units 3

Working Language

Symbols and Standards

. Design Method/PhiIosophy .................................................................................................... 4

General

Engineering and Design

P&Ds

Loop and Motor Narratives

3 nstrument Specifications / Data Sheets

Plant Wide ntegration

3. ControI System ....................................................................................................................... 5

3 System Architecture

3 Fault Tolerance

33 Control Philosophy

3 Operator nterfaces

3 Motor Control and nterlocks 7

3 UPS Systems 7

4. ControI Room Layouts............................................................................................................ 7

5. Packaged Equipment.............................................................................................................. 7

6. SECURITY ................................................................................................................................ 8

UPS Systems 8

7. EQUIPMENT CONTROL PACKAGES ..................................................................................... 8

7 General 8

8. FieId Instrumentation And ControIs ....................................................................................... 8

8 nstrument and Control Signals 9

8 nstrument Power Supplies, Cabling and Grounding 9

8 Power Supplies 9

8 Field Cabling, Junction Boxes and Grounding 9

83 nstrument dentification 9

8 nstrument Selection Guidelines

8 General

8 Flow

83 Level

8 Pressure

8 Temperature

8 Density

87 Belt Scales

88 Control Valves

89 Material Selection

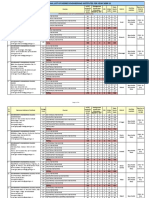

. System Architecture preIiminary bIock diagram ................................................................ 1

1.1 Introduction

The criteria will govern the development of the process control systems related to the project

This includes field instrumentation and process control hardware and software

1. Scope

This document describes the level of automation proposed for the project The scope also

includes the general guidelines for the design and selection of the process control system and

of the field instrumentation

1.3 References

1.3.1 Outside Organizations

Unless specifically stated otherwise, the instrumentation and controls will be based on the

applicable parts of the latest revision of the following codes, specifications, standards,

regulations and other documents n addition, the layouts will comply with any laws or

regulations of local authorities n the event of conflicting requirements, the most stringent will

apply:

SA nstrumentation, Systems and Automation - Standards and Practices for

nstrumentation

ANS American National Standards nstitute

NEC National Electrical Code

OSHA Occupational Safety and Health Administration

UL Underwriters Laboratory

CSA Canadian Standards Association

Local laws and codes

1.3. Other Project Design Criteria

This criteria should be read in conjunction with the following additional design criteria:

1.3.3 Other Documents

1.4 Units

1. GENERAL

All units shall be in accordance with the nternational System of Units (S units) using the "Metric

Practice GuideWhere a piece of equipment is manufactured to mperial units then the mperial

units should be shown as the primary dimensions with the metric equivalent shown in brackets

1.5 Working Language

O For the Engineering phase of the project, drawings will be in English translation

1.6 SymboIs and Standards

Piping and nstrumentation Diagram (P&D) symbols will be in conformance with SA Standard

S The Symbol and Legend P&D defines the symbols in detail

.1 GeneraI

The objective is to build a plant, which will require a minimum number of operating personnel

using essential instrumentation only The control system to be provided will be capable of fully

automatic start and stop sequences and interlocks using PLC or DCS based (hold on pending

decision) control systems and high speed communication networks

The design of the control system will be based on an hierarchical breakdown of the plant into

areas, systems and sub-systems representing logical groupings of related equipment, which can

be controlled and operated as a unit

. Engineering and Design

..1 P&IDs

The P&Ds will be developed in conjunction with the piping department based on approved

Process Flowsheets and will include the following minimum information:

Primary instrumentation

Motors and variable frequency drives (VFDs)

Connections to the control system

Control loops and critical interlocks and alarms

Air supply requirements

Valves and piping specialty items

Valve failure positions

Notes and descriptions

. DESIGN METHOD/PHILOSOPHY

.. Loop and Motor Narratives

n conjunction with the P&Ds, loop and motor narratives will be written for each loop and motor

controlled or monitored through the process control system The narratives will describe and

establish the following:

Degree of automation

Operating philosophy

Control and operation system breakdown

Process control loop description

Start/Stop sequence description

nterlocks

..3 Instrument Specifications / Data Sheets

Based on approved P&Ds, instrument specifications and data sheets will be prepared in order

to purchase instruments and related equipment

..4 PIant Wide Integration

The control system for the entire plant will be tightly integrated and transparent

This integration also applies to vendor supplied packaged equipment

3.1 System Architecture

A preliminary block diagram of the system is included at the end of this document The diagram

will be superseded by a System Architecture Block Diagram drawing as locations and /O

quantities become available

PLC's supplied with vendor equipment packages will repeat status and alarms as required to the

main plant control system via a communications protocol to be determined at a later date

Extreme care will be taken when buying equipment so that the systems supplied are fully

capable of integration with the overall plant process control system

During the development of the system architecture, other aspects such as communication with

smart devices and instruments will be considered in consultation with the Client

3. FauIt ToIerance

3. CONTROL SYSTEM

Essential equipment requiring redundancy will have a "hot back-up meaning that the stand-by

equipment will start automatically whenever a trip condition is detected Non-essential

equipment back up will be started on operator requests

Redundant controllers will be installed for continuous operation The number of control room

human-machine interfaces (HMs) will be sufficient to allow operation of the entire plant

whenever one of the HMs fails

3.3 ControI PhiIosophy

A Programmable Logic Controller (PLC) or a Distributed Control System (DCS) based plant

control system will be used to control the main processes Both process and motor control logic

will be incorporated into the control system The process and motors will be capable of being

controlled manually as well as by the control system Local start/stop stations will be provided for

all pieces of equipment nterlocks between equipment will be incorporated in the control

system Personnel safety interlocks will be hardwired

Control system controllers will be will be linked via a redundant network, allowing overall plant

monitoring and control from any control room Access to other areas would require password

access Where possible PLC's or Remote /Os will be located in Electrical Rooms or Control

Rooms

The status of the whole plant will be monitored from the main plant control room located in the

process plant building All historian, data logging and reports will be from the main plant control

room

Local HM workstations will be provided in remote areas of the plant Refer to preliminary block

system diagram (section 9)

Operator video workstations will be provided in the process plant control room, primary crusher

control room, secondary crusher control room and load out and ARD plant control room

A Data Historian system will gather data from the plant control system and other analytical

equipment

The plant control system will be capable of interfacing with a future advanced control system or

'expert' system

Separate controllers will be provided for the following areas:

O

The process plant operator will be able to monitor, and if necessary, control the **** plant PLC

or DCS based (hold on pending decision) process control system will be used to control plant

operations Both process and motor control logic will be incorporated into the control system

nterlocks between equipment will be incorporated in the control system Personnel safety

interlocks will be hardwired

3.4 Operator Interfaces

The HM workstations located in the main control room will provide:

Process indication and control interface

Motor start/stop capability and status

Process and motor failure alarms

nterlocks and sequence monitoring

Trending

Reports and logs (process plant only)

Maintenance diagnostic screens

Selected Motor runtime data

The HMs, located in the local control rooms, will display local process status and control the

plant locally Printers (colour and black and white) will be located in the main control room for

alarms, trends, graphics and reports

HMs will have brand name colour monitors, with keyboards and trackballs/mice for operator

actions The operating platform will be latest version Microsoft Windows PRO

3.5 Motor ControI and InterIocks

The control system will indicate motor status, overload trip alarm and availability to start Motor

temperature, and starts per hour will also be monitored on larger motors Pop-up faceplates for

motor control will be provided They will appear when a "pick is made on the equipment symbol

on the process graphic

3.6 UPS Systems

The control system, including operator and engineering workstations, will be powered from a

dedicated UPS source, which will keep the system operational for at least 3 minutes in the

event of a power failure The UPS units will be located in the electrical room(s) UPS 'health' will

be monitored and alarmed in the control system

Color printers, field instruments, and panels requiring VAC power will not be powered from

a UPS source unless thought to be critical to operations in the event of a power failure

Operator workstations will be desktop type and mounted on customised modular furniture

Control rooms will be pressurized and be equipped with HVAC as described in, Building

Services Design Criteria

4. CONTROL ROOM LAYOUTS

5. PACKAGED EQUIPMENT

Packaged equipment will be supplied with primary instrumentation The controls required for

these packages will normally be performed by PLC

Allen-Bradley PLC (type and model to be determined) will be used for packaged equipment

supplied with a control system

PLC's supplied with vendor equipment packages will repeat, status and alarms to the PLC or

DCS based (hold on pending decision) control system via hardwired /O signals or interface

links

The security system and CCTV will be supplied as a package system

6.1 UPS Systems

The security system will be powered from a dedicated UPS source, which will keep the system

operational for at least 3 minutes in the event of a power failure The UPS units will be located

in the electrical room(s) UPS 'health' will be monitored and alarmed in the control system

7.1 GeneraI

A number of pieces of equipment will be supplied with instrumentation and control packages,

typically:

O

mportant alarms, status and analogue values from these local panels will be wired to the control

system for display on the operator stations

Some of these packages will use PLC's for control t is intended to standardize with one PLC

manufacturer, refer to section for packaged equipment All equipment supplied PLC's will be

capable of communicating with the plant control system using a protocol as yet to be determined

6. SECURITY

7. EQUIPMENT CONTROL PACKAGES

8. FIELD INSTRUMENTATION AND CONTROLS

8.1 Instrument and ControI SignaIs

Electronic analogue signals will be isolated V, to mA DC

Pneumatic signals will be - kPa

Signals from field switches/contacts and control signals to solenoid valves will be VDC

Control voltage for motor starters and the control system /Os used for motor control will be

VAC, Hz

8. Instrument Power SuppIies, CabIing and Grounding

8..1 Power SuppIies

Two wire transmitters will be VDC powered from the control system /O card or control panel

instrument as applicable

Four wire transmitters and switches will be powered by VAC, Hz from instrument power

distribution panels A breaker will be supplied for each instrument or a related group of

instruments Disconnect type terminal blocks will be used to provide isolation between

instruments powered through the same breaker

The control system will be VAC, Hz powered from a UPS or conditioning transformer

8.. FieId CabIing, Junction Boxes and Grounding

Separate junction boxes will be used for VDC and VAC wiring

ndividual cables shall generally be used for cabling from instruments to junction boxes or

panels

Multiconductor cables will be run from field junction boxes to the control system /O or panels

Cables carrying - mA signals will have individual twisted pairs with an overall shield or drain

wire

Shields on all cables will be terminated at the control system /O rack or panel as applicable and

these will serve as the single ground point for signal wiring

Normally, separate trays will be used for instrument cables However, instrument signal cables

( - mA ) may be run in cable trays carrying electrical cables with voltages up to Volts n

this case a magnetic barrier and separate portion of the tray must be used

Fiber optic cable will be considered for long distance and/or outdoor signal transmission

8.3 Instrument Identification

All instruments will be tagged with permanent tag numbers assigned as follows:

Example: -PSL-

Area

nstrument type per P&D legend PSL

P&D sequential number (last numbers)

nstrument sequential number on P&D

Area numbers are required on a P&D only if instruments from more than one area are shown

on the P&D

Example: 3

8.4 Instrument SeIection GuideIines

8.4.1 GeneraI

Wherever possible, transmitters will be smart type and HART compatible

8.4. FIow

Magnetic flowmeters will be used for flow measurement of conductive liquids and slurries and

for fluids with corrosive properties or particulates

For local indication, line-mounted rotameters will be used for clear liquids

Vortex meters will be used for gases in small lines, or otherwise a pitot tube type primary

element, such as an "annubars, will be used with direct connected differential pressure

transmitters

Positive displacement meters will be used for local flow totalization

8.4.3 LeveI

Ultrasonic level transmitters will be used for pump box level measurement, bin levels, water

storage tanks and some reagent mix and storage tanks Where warranted by the application,

radar level instruments will be considered

Sump level switches will be conductivity type switches complete with 3 probes (ground, low and

high)

For lined vessels, transfer chute, feeder chutes etc, nuclear type transmitters or switches will be

used

Microwave or Tilt level switches will be used for plugged chute applications

8.4.4 Pressure

Direct mounted pressure transmitters will be used except where slurry, temperature or vibration

dictate the use of remote diaphragm seals

For local pressure indication bourdon tube type gauges with a minimum dial diameter of mm

will be used

8.4.5 Temperature

Sensing elements will be ohm, platinum, 3 wire RTDs or thermocouples c/w temperature

transmitters

For local temperature indication, every angle bi-metallic temperature gauges with a mm

diameter dial

8.4.6 Density

Nuclear Gamma Ray dispersion method will be used for measurement of slurry density

8.4.7 BeIt ScaIes

Belt scales will be of the load cell type

8.4.8 ControI VaIves

For control valves on lines greater than or equal to inches in diameter handling corrosive

fluids, lined butterfly valves will be used

For control valves on lines less than inches in diameter handling clear fluids, globe valves or

partial ball valves will be used

Solenoid operated ball valves will be used for on-off applications on clear liquids or non-abrasive

reagents

Solenoid operated pinch valves will be used for lime addition

Shut-off valves for low pressure slurry lines will be knife gate type

8.4. MateriaI SeIection

Materials in direct contact with the process will be selected on the basis of the Piping

Specification

END OF DOCUMENT

. SYSTEM ARCHITECTURE PRELIMINARY BLOCK DIAGRAM

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Ce5610 Assignment-2017-18 - Ce5610Document8 pagesCe5610 Assignment-2017-18 - Ce5610Fayaz HabeebPas encore d'évaluation

- DET-447 Application GuideDocument111 pagesDET-447 Application Guideabdkha8644Pas encore d'évaluation

- Work of RUMIDocument360 pagesWork of RUMIzameershah100% (3)

- DET 547 GenericDocument115 pagesDET 547 Genericabdkha8644Pas encore d'évaluation

- Gastite Di Guide PDFDocument116 pagesGastite Di Guide PDFabdkha8644Pas encore d'évaluation

- Ma Aarif E MathnawiDocument265 pagesMa Aarif E MathnawiAnwar Adam100% (1)

- Power System Protection CourseDocument269 pagesPower System Protection Courseabdkha864492% (13)

- Suggested Guidelines For Remediation of DamageDocument14 pagesSuggested Guidelines For Remediation of Damageabdkha8644Pas encore d'évaluation

- Plugging Home Drains To Prevent Sewage Back UpsDocument8 pagesPlugging Home Drains To Prevent Sewage Back Upsabdkha8644Pas encore d'évaluation

- CP2 PDFDocument40 pagesCP2 PDFHeidi VaughnPas encore d'évaluation

- Process Control System SpecificationDocument11 pagesProcess Control System Specificationabdkha8644100% (1)

- Book 4: Alternating Current Electric CircuitDocument566 pagesBook 4: Alternating Current Electric CircuitMAT JIBRUD100% (3)

- The Beauty of MathematicsDocument12 pagesThe Beauty of Mathematicsconnling100% (1)

- FS Applications PDFDocument44 pagesFS Applications PDFgs57143Pas encore d'évaluation

- BM FuseSelectiveCordinationDocument17 pagesBM FuseSelectiveCordinationabdkha8644100% (1)

- Practical Solution Guide To Arc Flash HazardsDocument143 pagesPractical Solution Guide To Arc Flash Hazardsabdkha8644100% (6)

- Lighting StandardsDocument52 pagesLighting Standardsabdkha8644Pas encore d'évaluation

- Teck 90 Cable Sizing DataDocument5 pagesTeck 90 Cable Sizing Dataabdkha8644Pas encore d'évaluation

- ITPDocument1 pageITPmaani7zeroPas encore d'évaluation

- BS en 00040-1-1992 (2006) PDFDocument14 pagesBS en 00040-1-1992 (2006) PDFShan Sandaruwan AbeywardenePas encore d'évaluation

- Assignment and Seminar Front Page Ii Year - A SectionDocument8 pagesAssignment and Seminar Front Page Ii Year - A SectionAkshayam StorePas encore d'évaluation

- Indian Electricity RulesDocument5 pagesIndian Electricity RulesP Venu Gopala RaoPas encore d'évaluation

- Assessment Rubrics for ThermodynamicsDocument16 pagesAssessment Rubrics for Thermodynamicstaufiqishak09Pas encore d'évaluation

- Maintenance Management: Assignment 1Document17 pagesMaintenance Management: Assignment 1Yogesh SharmaPas encore d'évaluation

- Chapter 2-1 FEADocument13 pagesChapter 2-1 FEAchoon yong lohPas encore d'évaluation

- Characteristics of A Good Software Requirements SpecificationDocument2 pagesCharacteristics of A Good Software Requirements Specificationmaheshraj_rPas encore d'évaluation

- K.P.Patil Institute of Technology: CertificateDocument3 pagesK.P.Patil Institute of Technology: CertificateVaibhav SPas encore d'évaluation

- Taiere Cu Flacara DIN en ISO 9013Document27 pagesTaiere Cu Flacara DIN en ISO 9013Petru AncaPas encore d'évaluation

- Provisional List of Degree Engineering Institutes For Year 2020-21Document31 pagesProvisional List of Degree Engineering Institutes For Year 2020-21Rajvi PatelPas encore d'évaluation

- Mili CVDocument3 pagesMili CVAminul Islam ShaonPas encore d'évaluation

- AP EAMCET Results 2019 - EAMCET 2019 - AP EAMCET 2019 Marks - 2019 AP EAMCET RanksDocument3 pagesAP EAMCET Results 2019 - EAMCET 2019 - AP EAMCET 2019 Marks - 2019 AP EAMCET RanksSai BabaPas encore d'évaluation

- Elite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21Document40 pagesElite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21aayush raghav (RA1811003020302)Pas encore d'évaluation

- Duct Drain Section RCC DesignDocument1 pageDuct Drain Section RCC Designhammad jagirdarPas encore d'évaluation

- How To Validate Computerized SystemsDocument31 pagesHow To Validate Computerized SystemsRahulRajGoldyPas encore d'évaluation

- ISA-TR84.00.02-2002 - Part 1Document108 pagesISA-TR84.00.02-2002 - Part 1ЮрийПонPas encore d'évaluation

- 11-Steps of Testing Process: Assess Development Plan and StatusDocument3 pages11-Steps of Testing Process: Assess Development Plan and StatusAbhinav DakshaPas encore d'évaluation

- Biju Patnaik University of Technology Odisha Grade SheetDocument1 pageBiju Patnaik University of Technology Odisha Grade SheetSangram keshari jenaPas encore d'évaluation

- CIVE 437 - Syllabus 2023 FallDocument2 pagesCIVE 437 - Syllabus 2023 FallAtifPas encore d'évaluation

- Software Requirements Spec for <ProjectDocument13 pagesSoftware Requirements Spec for <ProjectrashadulislamPas encore d'évaluation

- Analysis and Design of Shear WallDocument30 pagesAnalysis and Design of Shear Wallteguh widayat100% (1)

- Gabion Chapter 2 and 3Document10 pagesGabion Chapter 2 and 3Patrick Ray TanPas encore d'évaluation

- Trebuchet Design & Build ChallengeDocument5 pagesTrebuchet Design & Build ChallengeJohn Hayden Dela CruzPas encore d'évaluation

- UIP501C: Design of Machine Elements 04 Credits L-T-P:3-2-0Document16 pagesUIP501C: Design of Machine Elements 04 Credits L-T-P:3-2-0satishPas encore d'évaluation

- CMOS Digital Integrated Circuits Design CourseDocument2 pagesCMOS Digital Integrated Circuits Design CourseFaiq GhawashPas encore d'évaluation

- 498 07-2 MIME Ethics (Part 2)Document18 pages498 07-2 MIME Ethics (Part 2)Samer Abu ShamlehPas encore d'évaluation

- Applied Welding Engineering Lab ReportDocument4 pagesApplied Welding Engineering Lab ReportIdham DanialPas encore d'évaluation

- PI Mechanical Engineering Curriculum OverviewDocument5 pagesPI Mechanical Engineering Curriculum OverviewcommrzlPas encore d'évaluation