Académique Documents

Professionnel Documents

Culture Documents

Tech Transfer by Design Tunnell White Paper

Transféré par

grobertson4519Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tech Transfer by Design Tunnell White Paper

Transféré par

grobertson4519Droits d'auteur :

Formats disponibles

IPI

International Technology Transfer By Design

By Ronald D. Snee, Ph.D. Principal, Tunnell Consulting William Reilly, Jr Managing Consultant, Tunnell Consulting Chester A. Meyers, Ph.D.Managing Consultant, Tunnell Consulting

In the relentless drive for greater operational efficiencies, market penetration, optimal capacity utilization, and global agility, more and more pharmaceutical companies face the unique challenges of international technology transfer. Government regulations, tax benefits, and mergers and acquisitions are also helping make international technology transfer a required competency for more and more companies. Whether the transfer is intra-company, inter-company, or to a contract manufacturing organization (CMO); whether it involves active pharmaceutical ingredients, in-process material, finished product or analytical methods; and whether the product is in early development, postapproval, or any stage in between in its lifecycle, the ability to perform international transfer faster, more reliably, and cost-effectively can generate significant competitive and operational advantages. Nevertheless, many companies continue to treat each international transfer of technology as a one-off event rather than as a replicable, repeatable business process that can be designed, improved, and controlled just like any other process. Technology Transfer by Design (TTbD) provides just such a systematic, repeatable method for executing international technology transfer, as well as domestic transfer. Just as at the product level where Quality by Design (QbD) depends upon an understanding of the interactions in manufacturing processes of multiple variables that keep the resulting product within specifications, TTbD at the portfolio level provides a systematic way to understand all of the elements that go into the design of a companys tech transfer process and ensure that they stay in synch to produce a successful transfer (Alaedini, Snee and Hagen 2007). Common Pitfalls in International Transfer Given the complexities of international technology transfer, including scientific as well as regulatory obstacles, challenging problems can arise at any stage of the process for any size company, from biotech start-ups to global pharmaceutical giants. For example, a pre-clinical stage biotech company seeking to bring its first recombinant therapeutic drug into Phase1 clinical trials needed to transfer a manufacturing process developed in-house at a U.S. site to a CMO in Europe. However, implementation was severely hampered by organizational, cultural and technical barriers. Cross functional project teams had been established at both sites, but the European team was not empowered to make decisions, even relatively minor, day-to-day operational decisions. Team meetings were severely hampered and unnecessary project delays occurred as post-meeting issues and recommendations were brought to the European sites senior leadership for approval, often generating further indirect feedback and additional questions. The cultural differences prevented the European team from functioning effectively. Further, the European site process scientists were unable to successfully replicate the manufacturing process developed at the U.S. site. Communication barriers, both verbal and written, frustrated attempts by the U.S. team to isolate the source of the technical difficulties encountered in the European facility. The self-confident CMO team had been introducing what they thought were process improvements with each run, never actually replicating the process being transferred. Moreover, when it was proposed that key people from the U.S. go to the CMO for several weeks to run the process side-byside with the European team, the senior management at both sites resisted, which ultimately resulted in significant project transfer delays and increased costs. The company had fallen into some of the most common pitfalls of international technology transfer. Such pitfalls include: Language: The barrier of differing languages applies not just to clear communication between sites and organizations but also to documentation. For example,

IPI

International Pharmaceutical Industry www.pharmapubs1.com January 2008

production batch records are often in a language unfamiliar to personnel at the receiving site. Translation services are expensive and need to be planned, and, in the case of transfer to a CMO, specifically addressed. People/culture/work ethic: Cultural barriers can be as formidable as language barriers. Overcoming cultural barriers requires the commitment of senior leadership on both sides of the transfer and the exchange of people between sites. Regulatory differences: Although ICH guidelines have significantly narrowed regulatory differences between the EMEA and the FDA, differences remain (ICH 2005). Site/country validation requirements after transfer: Sometimes drug substances (APIs) or drug products needs to be shipped, for example, back to the U.S. This requires shipping validation and can affect stability study design. Documentation requirements from site to site: Care must be taken with standard operating procedures (SOPs), particularly for biologics where cell bank handling and consistency can be critical. In addition, process descriptions must be site-specific. Differences in raw materials: A U.S. sourcing/supply chain can produce product characteristics that might not work in the transferred process. Even with vendor qualification and certificates of analysis, suitability of material from a new supplier may present issues that can cause delays and add costs. For example, at a receiving site for a biologic, a previously unobserved peak in an HPLC assay occurred, causing the drug substance to be out of specification. A simple change to a Tris buffer from a new supplier, which met the product specifications on a Certificate of Analysis, was nevertheless discovered to be the source of the unknown peak. Equipment dissimilarities, scale, and function: These issues may be even more pronounced for cell culture bioreactors than

10 IPI

IPI

for traditional small molecule manufacturing, but the challenges still remain if differences exist. It may not be possible to exactly replicate operating procedures. Only about 10% of biotech technology transfers to CMOs occur without need for further process development, but the expectations of management are usually much higher. In many instances of small molecule transfers, either the process is tweaked or the formulation is slightly modified (within ICH guidelines) in order to achieve a viable product. Cleaning validation/Cleaning Validation Master Plan: Does the transferred material fall within the parameters or does it create a new extreme? This is a question that the receiving site needs to address up front. Failure to understand this question will definitely affect the transfer timeline. Utilities: Because utilities would have been qualified for the equipment in the facility, at the time the facility was commissioned, they should have no impact to the transfer of a small molecule. However, there can be substantive delays, work-arounds and costs for certain utilities unique to some biologics, such as supplying water for injection (WFI) and virus containment. Deliverables, time lines, responsibility: These should be defined at the outset, especially with CMOs. Also with CMOs, how to handle failed runs, including who bears the costs, must be decided in advance it is rarely as simple as who's at fault. Executive Involvement: Organizations often underestimate the amount of time needed for key managers to manage technology transfer, especially when it involves managing CMOs. Technology transfer project demands can affect the progress of other projects involving those managers, especially in the case of small to mid-size biotech companies. As this necessarily partial list of pitfalls suggests, the challenges of international technology transfer cover virtually every aspect of the business: people, operations, technology, and regulations. Only a system-

atic, comprehensive approach to technology transfer, such as TTbD, is likely to ensure that all of these and the many additional pitfalls are addressed and ensure that organizations acquire the ability to successfully transfer technology across borders again and again. Technology Transfer by Design (TTbD) Technology Transfer by Design applies to technology transfer the advances made over the past 25 years in process understanding and improvement by such methodologies as Six Sigma and Lean (Snee and Hoerl 2003, 2005) and integrates them into a repeatable approach to transferring technology for single products or for many simultaneously. Depending upon the kind of transfer taking place, the number of process steps may vary, but in a typical site-to-site transfer there are roughly ten steps involved in creating the transfer process and investigating problems that might arise: 1.Determine scope, risks, and strategy. Determine the number of plants and products involved, the markets that the products supply, the regulatory submissions required, and the staffing and skills requirements information that should be documented and approved by senior management. Assess the regulatory, financial, and marketing risks. If the transfer entails the closing of a plant, the public relations risks should also be calculated. With an understanding of the projects scope and risks, you can then determine the optimal strategy for the transfer where, when, and, if relevant, to whom (CMO or intra-company site) to make the transfer. At all times, these analyses should be guided by an unwavering focus on the bottom line. 2. Determine overall gaps. Do executives have the time and the project management skills to manage the transfer? What gaps exist in culture, language, regulations, plant capabilities, plant capacities, and personnel in both locations? 3. Develop a governance body, champions, and mentors. The governance body should include senior management from

operations, supply chain, quality, regulatory affairs, marketing, technology/R&D, and any other functions that have a stake in the transfer. People to champion the transfer should be designated in those departments and mentors selected to counsel them throughout the process. 4. Determine communication and reporting channels. Make the reporting channels at each site and among sites absolutely clear. Include the reporting structure to senior management, the frequency of communication, the modes of communication, and the approach to addressing language barriers. 5. Determine metrics. Appropriate measures should be selected to measure the progress and success of technology transfers. These metrics could include but are not limited to: meeting the budget, meeting timelines, speed and rate of success for validation, regulatory submission approval rate, labor hours by job title, labor costs (internal and external), and opportunity costs in terms of sales as a result of delays. 6. Develop and train transfer teams. Designate the transfer teams in headquarters, in the sending plant and, if its an intra-company transfer, in the receiving plant. Ideally, teams in both the sending and receiving plants will include senior people from manufacturing, quality, technical services, engineering, and supply chain. Train the teams in troubleshooting, problem-solving, communication, and time management. 7. Determine responsibilities for each group and individual. A proven, effective method for assigning and monitoring responsibilities is RACI charting, which identifies and charts who is Responsible, Accountable, Consulted, and Informed for each activity involved in a project. 8. Conduct gap analysis for each product. Just as you conduct gap analysis of your overall transfer capability, you should also closely examine each product or group of products for your shortfalls there. Two issues are paramount: (1) the current

12 IPI

IPI

state of your product-related process understanding and (2) factors that will determine success at the receiving site, including manufacturing processes, documents, analytical methods, equipment, plant capabilities, and regulatory and safety issues. It is almost impossible to successfully transfer a process you do not understand. Six Sigma and Lean methodologies offer tools such as process mapping, value stream mapping, process capability and control, and statistical modeling, all of which are invaluable for achieving true process understanding and executing transfer using proven process design and improvement methodologies (Snee 2006). 9. Develop the technology transfer strategy and risk mitigation plan. With true process knowledge and receiving-site understanding in hand for each product or group of products, you can now develop a plan to fill the gaps, develop the transfer strategy, including knowledge transfer. All of this should be rolled up in a strategy document, accompanied by a risk assessment of the strategy and a risk mitigation plan, and approved by upper management at both the sending and receiving sites. 10. Manage, review, and follow up all activities. Conduct frequent and regular management reviews at both the level of the overall technology transfer program and at the level of the individual transfer. In the case of an intra-company or CMO transfer, make sure there is a plan in place to sustain the performance of the processes at the receiving site. Once you have completed those ten steps, all of the elements will be in place for an ongoing technology transfer capability, with increased probability of success as a result of TTbDs unique advantages: Clear bottom line focus Support and involvement of senior management leadership Structured and disciplined approach Avoidance of project delays Good manufacturability at receiving sites as a result of in-depth process under-

standing Strong supporting infrastructure with roles, responsibilities, and management systems clearly defined and understood In addition, you will have also created a key group of mangers who now have experience in international technology transfer and can repeatedly execute it rapidly, reliably, and cost-effectively. Reaping the Benefits of TTbD Companies that view technology transfer as an ad hoc event rather than a core competency are likely to find themselves plagued by costly delays, conflict and recriminations between sending and receiving sites, and, ultimately, a squandering of the benefits technology transfer is intended to produce. Meanwhile, companies that design, control, improve, and institutionalize their approach to international technology transfer through TTbD will gain significant business benefits and competitive advantages. Excellence in international technology transfer enables greater speed to market, the ability to provide uninterrupted supply of products, increased manufacturing efficiency, and significant bottom-line savings. Further, the capability in international technology transfer can be readily applied to domestic transfers as well, with similar beneficial results. With a framework in place for the increasingly crucial task of international technology transfer, forward-looking companies will be ready to respond effectively and rapidly to whatever strategic and operating challenges arise to necessitate tech transfer. And in an environment of inexorable globalization and relentless competition, the readiness is all. I References Alaedini, P R. D. Snee and B. W. Hagen ., (2007) Technology Transfer by Design Using Lean Six Sigma to Improve the Process. Contract Pharma, June 2007, 4-9. ICH Harmonised Tripartite Guideline: Pharmaceutical Development, Q8, Current Step 4 Version, November 10, 2005

Snee, R.D. (2006) Lean Six Sigma and Outsourcing Dont Outsource a Process You Dont Understand, Contract Pharma, October 2006, 4-10. Snee, R. D. and R. W. Hoerl (2003) Leading Six Sigma A Step by Step Guide Based on the Experience With General Electric and Other Six Sigma Companies, FT Prentice Hall, New York, NY, Snee, R. D. and R. W. Hoerl (2005) Six Sigma Beyond the Factory Floor: Deployment Strategies for Financial Services, Health Care and the Rest of the Real Economy, Pearson Prentice Hall, Upper Saddle River, NJ. Authors bios: Ronald D. Snee, Ph.D., is a Principal and Lean Six Sigma Initiative Leader at Tunnell Consulting in King of Prussia, PA. A leading expert on improvement methodology, he has co-authored four books and more than 175 papers in the fields of performance improvement, quality, management, and statistics for which he has been awarded the Shewhart and Grant Medals and the Deming Lecture Award. William Reilly, Jr. is a Managing Consultant in the Pharmaceutical / Life Sciences Technical Services Practice of Tunnell Consulting, where he specializes in project management and technology transfer for international product registrations and compliance remediation. His expertise includes manufacturing, research & development, and education in pharmaceutical products such as liquids, semisolids, and excipients. Chester A. Meyers, Ph.D., a Managing Consultant for Tunnell Consulting, has more than 30 years of experience in drug discovery research and pre-clinical development in all major therapeutic areas, experience with the U.S. National Institutes of Health (NIH), and as a professor of medicine. His expertise includes strategic and corporate planning, drug discovery and development, and evaluation of in-licensing opportunities and intellectual property.

IPI 13

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Satu Atap by Citra Novy PDFDocument402 pagesSatu Atap by Citra Novy PDFSsPas encore d'évaluation

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERDocument14 pagesQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual LINERKrisman SimanjuntakPas encore d'évaluation

- 2012 Land Rover VEHICLE DIAGNOSTIC REPORT - SALLSAAG6CA726588 - 2022046145024-1Document2 pages2012 Land Rover VEHICLE DIAGNOSTIC REPORT - SALLSAAG6CA726588 - 2022046145024-1Adrian Pruneda0% (1)

- Fault Codes and Scania Engine ParametersDocument8 pagesFault Codes and Scania Engine Parametersmirko coppini100% (1)

- IL-NT firmware and input/output configuration reportDocument3 pagesIL-NT firmware and input/output configuration reportBGP10Pas encore d'évaluation

- 4MDocument1 page4MTania MenesesPas encore d'évaluation

- Civil Engineer Ibrahim El-DehiDocument5 pagesCivil Engineer Ibrahim El-DehiIbrahim EldiehyPas encore d'évaluation

- DatawarehouseDocument6 pagesDatawarehouseJaveriaPas encore d'évaluation

- Trinity Institute of Professional Studies Practical FileDocument33 pagesTrinity Institute of Professional Studies Practical Filekartik aroraPas encore d'évaluation

- Tmo Sm-g386t Galaxy Avant English User Manual Nea f3Document313 pagesTmo Sm-g386t Galaxy Avant English User Manual Nea f3cozyfootrubsforuPas encore d'évaluation

- Inspeksi Mekanik Bulldozer v1Document1 pageInspeksi Mekanik Bulldozer v1kedapsayaaqPas encore d'évaluation

- Woodward GCP-30 LeoPC1 37240 PDFDocument31 pagesWoodward GCP-30 LeoPC1 37240 PDFAbdul Kurniadi100% (1)

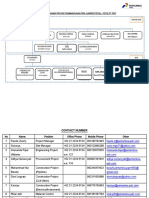

- Org ChartDocument2 pagesOrg ChartES RouzaPas encore d'évaluation

- KPRIT-Civil-C4 - 2018-19Document16 pagesKPRIT-Civil-C4 - 2018-19civil deptPas encore d'évaluation

- Laptop Voltage Requirement and Power Supply DiagramDocument5 pagesLaptop Voltage Requirement and Power Supply Diagrambong bernalbongPas encore d'évaluation

- FCI 08-ProductBrochureDocument16 pagesFCI 08-ProductBrochurepardan aksaniPas encore d'évaluation

- Rotary Actuator and Gripper Selection GuideDocument63 pagesRotary Actuator and Gripper Selection GuideAlexandre DomingosPas encore d'évaluation

- TORCH CUTTING Datasheet GEGA Bloom Billet Torch Cutting MAIL enDocument12 pagesTORCH CUTTING Datasheet GEGA Bloom Billet Torch Cutting MAIL enFahrgerustePas encore d'évaluation

- Tesks List EksportDocument19 pagesTesks List EksportcvyunaallexamedikaPas encore d'évaluation

- 12 Volt Hydraulic Pump Mte 4850 PDFDocument1 page12 Volt Hydraulic Pump Mte 4850 PDFpurnomo100% (1)

- Oracle - Prepaway.1z0 068.v2019!03!20.by - Max.96q 2Document65 pagesOracle - Prepaway.1z0 068.v2019!03!20.by - Max.96q 2sherif hassan younisPas encore d'évaluation

- Amphenol PCD Terminal Junction Module Milt81714 PDFDocument18 pagesAmphenol PCD Terminal Junction Module Milt81714 PDFramalingamPas encore d'évaluation

- C ProgrammingDocument16 pagesC ProgrammingpankajusbPas encore d'évaluation

- Jeep WK Grand Cherokee Section 08O RestraintsDocument490 pagesJeep WK Grand Cherokee Section 08O RestraintsParaskevas Stav100% (5)

- GSM-Based SCADA for Substation MonitoringDocument9 pagesGSM-Based SCADA for Substation MonitoringMoeed Iqbal100% (1)

- 0707 MoteckDocument2 pages0707 MoteckAlexander WiesePas encore d'évaluation

- Detonado Dragon Quest VIII PDF: Mirror Link #1Document4 pagesDetonado Dragon Quest VIII PDF: Mirror Link #1AllysonWaine0% (1)

- A.d.a.4 Expo ChankevinDocument56 pagesA.d.a.4 Expo ChankevinManuel Alejandro Estrella GutiérrezPas encore d'évaluation

- IMS ManualDocument66 pagesIMS Manualghafoorian_khoshgovar1488Pas encore d'évaluation