Académique Documents

Professionnel Documents

Culture Documents

S 0000 1540 105 - C05 - 0020

Transféré par

bluelions_19Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

S 0000 1540 105 - C05 - 0020

Transféré par

bluelions_19Droits d'auteur :

Formats disponibles

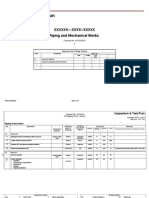

NCP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 5 of 51

5. SCOPE OF TEST & INSPECTION WITNESS BY SUBCONTR

CONTRACTOR COMPANY

SITE INSPECTION ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

1.1 Padding (1) Material (Liners) A283, A36 or equivalent Material Certificate

Check before erection

5000-102 5000-104 5000-106 5000-302 5000-304

SW

FI/P

(2) Interval (3) Loading

Max. spacing 800 mm Max. 30 kg/cm

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 6 of 51

WITNESS BY SUBCONTR

CONTRACTOR COMPANY

SITE INSPECTION ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

1.2 Verticality / Horizontally

Section 7.2

6mm/10m, not exceed 18mm/30m

5000-101 5000-103 5000-105 5000-301 5000-303 5000-305 5000-307

FW

FW

FI/P

1.3 Position / Direction

Section 7.1

Set to within 3mm of grid line

After setting

5000-101 5000-103 5000-105 5000-301 5000-303 5000-305 5000-307

SW

FW

FI/P

Nozzle Orientation

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 7 of 51

WITNESS BY

COMPANY CONTRACTOR

SUBCONTR

SITE INSPECTION ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

1.4 Elevation

Section 7.3

Within 1mm / 1m

After setting

5000-101 5000-103 5000-105 5000-301 5000-303 5000-305 5000-307

SW

FW

FI/P

1.5 Anchor Bolts

ANSI A10.13 Section 9.6

Snug tight, fully tightened by using ordinary spud wrench

After setting

5000-102 5000-104 5000-106 5000-302 5000-304 5000-306

SW

FW

FI/P

1.6 Grouting of base plate 1.7 Platform and Ladders

No Voids As per drawing

2000-010 5000-999

FW FW

FW FW

FI/P FI/P

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 8 of 51

WITNESS BY

COMPANY CONTRACTOR

SUBCONTR

SITE INSPECTION ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

1.8

Final Connection between Equipment and Piping. (1) (2) (3) (4) Flange Face Gasket Bolt and Nut Bolt Tightening

5000-001B 5000-509B

FI

1.9

Name Plate

As required

5000-999 5000-999

H H H

H H H

FI FI FI/P

1.10 Check anodes have been installed for heat exchanger. 1.11 Field Hydrostatic Test 1.12 Box Up (1) Internal cleaning (2) Final closure inspection Equipment Nozzle Face / MH Face Gasket, Bolt and Nut (3) Bolt Tightening Final closure inspection after final manway closure

If required

Comply with requirements

5000-311

5000-312 Manhole bolt, nut and gasket check 5000-312 5000-001B 5000-312 5000-509B

H H

H H

FI/P FI/P

Manhole bolt, nut and gasket check (Bolt tensioning work, if applicable)

FI/P

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 9 of 51

WITNESS BY BY COMPANY

SUBCONTR

CONTRACTOR

SITE INSPECTION ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

2. INTERNAL INSTALLATION 2.1 Distributor Pipe (1) Assembly (2) Bolt Tightness (3) Gasket 2.2 Demister (1) Assembly (2) Bolt Tightness 2.3 Tray (1) Assembly

drawings 5000-201 As per drawing After setting After setting As per drawing After setting 5000-201 After setting After setting Drawings As per drawings After setting 5000-203 5000-203A 5000-204 5000-204A

FW FW FW

FW FW FW

FI/P FI/P FI/P

FW SW

FW FW

FI/P FI/P

FI/P

(2) Support beam installation

As per drawing

After setting

5000-202 5000-202A 5000-203 5000-203A 5000-204 5000-204A

SW

FW

FI/P

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 10 of 51

WITNESS BY COMPANY

SUBCONTR

CONTRACTOR

SITE INSPECTION ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

(3) Tray Clamping

As per drawing

After setting

5000-202 5000-202A 5000-203 5000-203A 5000-204 5000-204A

SW

FW

FI/P

(4) Bolt Tightness

After setting

5000-202 5000-202A 5000-203 5000-204

SW

FW

FI/P

(5) Tack welding of nut (6) Field welding Final check for every tray (7) (8) Panel Connection Level Check Manufacturers specification or ASME Sec IX

As per drawing WPS, PQR,WQT

After setting After setting

5000-202 5000-205

SW FW

FW FW

FI/P FI/P

As per drawing Tolerance = 1/500 (unless noted otherwise)

After setting After setting

5000-203 5000-204 5000-204A

SW FW

FW FW

FI/P FI/P

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 11 of 51

WITNESS BY

SITE INSPECITON ITEM REFERENCE COMPANY

SUBCONTR

CONTRACTOR

REQUIREMENT

FREQUENCY

FORM

REMARKS

(9) Leak test (10) Check thermowell location

If required

As per drawing As per drawing

After setting After setting

5000-206 5000-202

FW FW

FW FW

FI/P FI/P

2.4 Final inspection 2.5 Check packing installation

1) Random Packing

Refer above 1.10

5000-312

As per Drawing

5000-313 5000-314 5000-316

FW

FW

FI/P

2) Structured Packing

As per Drawing

5000-314 5000-315 5000-316 5000-317

FW

FW

FI/P

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 12 of 51

WITNESS BY

COMPANY

CONTRACTOR

SUBCONT R

SITE INSPECITON ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

3. AIR FIN COOLER

As per specification

Structure Steel Work refer to Steel structure (1) Position (2) Verticality/Elevation (3) Platform and ladder (4) Bolting 3.1 Fan Hood / Fan ring (1) Verticality/Elevation 3.2 Fan & Drive Assembly Refer to Rotating ITP (1) Plumb motor shaft Check bearings for cleanliness & Lubrication

S-0000-1540-103

As per drawing As per vendor recommendation As per drawing After setting After setting After setting After setting 5000-307 5000-307 5000-310 5000-307 FW FW FW FW FW FW FW FW FI/P FI/P FI/P FI/P

As per drawing

After setting

5000-307

SW

FW

FI/P

5000-308

5000-308

FW

FW

FI/P

As per vendor recommendation

After setting

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

CP PROJECT Test and Inspection Plan For Static Equipment Erection

Company Doc. No.: Contractor Job Code: Contractor Doc. No.:

NCP-00-Q2-WS-1105 0-4848-20 S-0000-1540-105<C05> Page 13 of 51

WITNESS BY

COMPANY

SUBCONTR

CONTRACTOR

SITE INSPECITON ITEM

REFERENCE

REQUIREMENT

FREQUENCY

FORM

REMARKS

(2) Pulley alignment (3) Blade tip clearance (4) Blade Angle (5) Hub bolt torque (6) V-Belt Tension 3.3 Tube Bundle (1) Dimension / Alignment / Height (2) Tube fins damage/ cleaning 3.4 Finishing (1) Fan Guards installed (2) Air Sealing Strips Installed (3) Leak Test

IF REQUIRED Drawings

As per vendor recommendation

As per vendor recommendation As per vendor recommendation As per vendor recommendation As per vendor recommendation

After setting

After setting After setting After setting After setting

5000-308 5000-308 5000-308 5000-310 5000-308

FW FW FW FW FW

FW FW FW FW FW

FI/P FI/P FI/P FI/P FI/P

As per drawing No damage

After setting After setting

5000-309

5000-310

I/R I/R

FW FW

FI/P FI/P

As per drawing As per drawing As per Leak Test Procedure

5000-310 5000-310 5000-311

SW SW H

FW FW H

FI/P FI/P FI/P

CONFIDENTIAL INFORMATION Reproduction and use prohibited except in accordance with Saudi Polymers Company's written permission.

Field Inspection and Test

Vous aimerez peut-être aussi

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationAmair Cool88% (8)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionD'EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisD'EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerD'EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerÉvaluation : 5 sur 5 étoiles5/5 (1)

- 050-Itp For Installation of Air Intake Filter PDFDocument17 pages050-Itp For Installation of Air Intake Filter PDFKöksal PatanPas encore d'évaluation

- Tank Erection Itp & Org ChartDocument34 pagesTank Erection Itp & Org Charthasan_676489616100% (2)

- Boq Fire Fighting SystemDocument15 pagesBoq Fire Fighting SystemAnonymous VpG5VhEgGPas encore d'évaluation

- Machinery Component Maintenance and RepairD'EverandMachinery Component Maintenance and RepairÉvaluation : 5 sur 5 étoiles5/5 (1)

- FAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansD'EverandFAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansÉvaluation : 5 sur 5 étoiles5/5 (2)

- B15 e 1DDocument28 pagesB15 e 1DPaúl ÁlvarezPas encore d'évaluation

- Occidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ADocument45 pagesOccidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ASakthikumar ChandrasekaranPas encore d'évaluation

- Satip F 001 04Document4 pagesSatip F 001 04Anonymous 4e7GNjzGWPas encore d'évaluation

- A05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C DDocument14 pagesA05-004 - Inspection Test Plan - Shell & Tube Heat Exchangers - 5-210D-HA-01 A B C Dbingmin100% (4)

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Document4 pages1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnPas encore d'évaluation

- Quality Assurance For MS PipeDocument54 pagesQuality Assurance For MS PipeRam Narendra Nath100% (2)

- Volume II Technical Specifications, General Tech Requirements, Etc PDFDocument316 pagesVolume II Technical Specifications, General Tech Requirements, Etc PDFVinay YadavPas encore d'évaluation

- ITP-000 Piping Fabrication (Exemple)Document5 pagesITP-000 Piping Fabrication (Exemple)alinor_tn100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument3 pagesInspection & Testing Requirements Scope:: Test and Inspection PerbalajiPas encore d'évaluation

- Microsoft Word - F12254-CDB-W03-QUA-ITP-60053 - 06-001 PDFDocument7 pagesMicrosoft Word - F12254-CDB-W03-QUA-ITP-60053 - 06-001 PDFmuahdib100% (1)

- Fabrication of Steel Structure and Steel Equipment (Itp)Document4 pagesFabrication of Steel Structure and Steel Equipment (Itp)Javed MAPas encore d'évaluation

- P445 - Technical Proposal Rev.0Document37 pagesP445 - Technical Proposal Rev.0ArtG.EnziPas encore d'évaluation

- EXW-P015-0000-QM-LNT-IT-00066 Rev CADocument4 pagesEXW-P015-0000-QM-LNT-IT-00066 Rev CAbinunalukandamPas encore d'évaluation

- 5501 F FS For Gas Turbine0582642418Document55 pages5501 F FS For Gas Turbine0582642418pramodtryPas encore d'évaluation

- Slno 31 2012 13 Vol II RevisedDocument326 pagesSlno 31 2012 13 Vol II Revisedgvgbabu0% (1)

- (ANX-1) Inspection Test Plan (ITP) ListDocument10 pages(ANX-1) Inspection Test Plan (ITP) Listwaragainstlove50% (4)

- 026-Itp For Structural Steel PDFDocument18 pages026-Itp For Structural Steel PDFKöksal Patan100% (11)

- Inspection and Test Plan - General Civil Works at Adr&Ruwais RefineryDocument4 pagesInspection and Test Plan - General Civil Works at Adr&Ruwais RefineryJithesh.k.sPas encore d'évaluation

- Spec For Process StrainerDocument11 pagesSpec For Process StrainerHarish GundaPas encore d'évaluation

- 038-Pro Welding Consumable Control Procedure PDFDocument20 pages038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument3 pagesInspection & Testing Requirements Scope:: Test and Inspection Perkartik_harwani4387Pas encore d'évaluation

- Sample QAPDocument3 pagesSample QAPsniperiPas encore d'évaluation

- Fahu - AhuDocument6 pagesFahu - AhuHadi AbdulkaderPas encore d'évaluation

- 8382 3504 LG 8001 1 - APEM Vendor Data Register List - Rev ADocument6 pages8382 3504 LG 8001 1 - APEM Vendor Data Register List - Rev AAlphaEcc EngineeringTeamPas encore d'évaluation

- Tso PitotDocument8 pagesTso PitotElkin CuevasPas encore d'évaluation

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskPas encore d'évaluation

- SP 02G 05a 24 27028Document24 pagesSP 02G 05a 24 27028tarek_bouzayaniPas encore d'évaluation

- Consortium (Ioic) Inspection and Test Plan/Quality Control PlanDocument3 pagesConsortium (Ioic) Inspection and Test Plan/Quality Control PlanRushabh KapadiaPas encore d'évaluation

- JMS - Snuffing Pipe Installation Rev 1Document17 pagesJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriPas encore d'évaluation

- Pqp-Part 3Document9 pagesPqp-Part 3jparsbPas encore d'évaluation

- Indian Railways: S No. Date/month of Issue Revision /amendment No. Reasons of RevisionDocument24 pagesIndian Railways: S No. Date/month of Issue Revision /amendment No. Reasons of RevisionPremchand BeuraPas encore d'évaluation

- gs102 3Document9 pagesgs102 3medodedo2010100% (1)

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentRickesh NunkooPas encore d'évaluation

- 175 011000 PDFDocument2 pages175 011000 PDFAbu Anas M.SalaheldinPas encore d'évaluation

- Tell Tale HoleDocument45 pagesTell Tale HoleSingarao Katta33% (3)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarPas encore d'évaluation

- Checklist For Tank No 1Document2 pagesChecklist For Tank No 1sathi11189Pas encore d'évaluation

- Inspection and Test Record For Electric Motor - Cage-Induction Type (Including Control Unit)Document3 pagesInspection and Test Record For Electric Motor - Cage-Induction Type (Including Control Unit)karthik_egclPas encore d'évaluation

- Vacuum Breaker Valve Data SheetDocument4 pagesVacuum Breaker Valve Data SheetMathivanan AnbazhaganPas encore d'évaluation

- PS 3103Document9 pagesPS 3103JayeshPas encore d'évaluation

- ITP For Field Erected Tank Rev ADocument9 pagesITP For Field Erected Tank Rev AHoang Tuan Kiet100% (1)

- Instrumetation Report ClarificationDocument10 pagesInstrumetation Report ClarificationTayebASherifPas encore d'évaluation

- INSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFDocument7 pagesINSPECTION AND TEST PLAN (ITP) FOR TEST TANK PDM T-1001 A Rev B PDFgst ajah100% (4)

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Scope of Test & InspectionDocument9 pagesScope of Test & Inspectionbluelions_19Pas encore d'évaluation

- SAIC-A-2017 Rev 0Document3 pagesSAIC-A-2017 Rev 0bluelions_19Pas encore d'évaluation

- SAIC-A-2003 Rev 0Document3 pagesSAIC-A-2003 Rev 0bluelions_19Pas encore d'évaluation

- SAIC-A-2001 Rev 0Document3 pagesSAIC-A-2001 Rev 0bluelions_19Pas encore d'évaluation