Académique Documents

Professionnel Documents

Culture Documents

Meat Industry

Transféré par

Mike NiceDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Meat Industry

Transféré par

Mike NiceDroits d'auteur :

Formats disponibles

Process Biochemistry 40 (2005) 13391346 www.elsevier.

com/locate/procbio

Treatment of wastewater from the meat industry applying integrated membrane systems

Jolanta Bohdziewicz*, Ewa Sroka

Institute of Water and Wastewater Engineering, Silesian University of Technology ul. Konarskiego 18, 44-100 Gliwice, Poland Received 5 December 2003; accepted 8 June 2004

Abstract The paper presents investigations into the treatment of wastewater from the meat industry applying three hybrid processes in the following combinations: ultraltrationreverse osmosis, coagulationreverse osmosis, coagulationultraltrationreverse osmosis. Neither coagulation nor ultraltration enabled a sufcient removal of pollutants from the wastewater, which, as a result, could not be discharged into receiving water due to elevated pollution indices. However, an additional treatment by means of reverse osmosis made it possible for the wastewater to be reused in the production cycle of a plant. # 2004 Elsevier Ltd. All rights reserved.

Keywords: Membranes; Ultraltration; Reverse osmosis; Coagulant; Wastewater produced by the meat industry

1. Introduction Industrial wastewater components show different degrees of environmental nuisance and contamination hazard due to their chemical characteristics as well as excessive concentration [1]. Therefore, the treatment of wastewater, which is particularly hazardous to the environment, requires a number of complementary techniques that sufciently remove pollutants and enable the wastewater to be discharged into receiving water or be reused for industrial purposes. Membrane processes can eliminate shortcomings, which are characteristic of the traditional methods of wastewater treatment. Due to their selectivity and high effectiveness, they can replace traditional techniques or may operate together in combinations as hybrid systems [1]. The meat industry is a branch of the food industry, which causes degradation of the environment to a large extent. The wastewater produced in it contains a variety of organic and

E-mail address: ewasroka@zeus.polsl.gliwice.pl. * Corresponding author. Tel.: +48-32-237-1698; fax: +48-32-237-1047. E-mail address: jolaboh@zeus.polsl.gliwice.pl (J. Bohdziewicz), ewasroka@zeus.polsl.gliwice.pl (E. Sroka). 0032-9592/$ see front matter # 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.procbio.2004.06.023

inorganic pollutants, has a high concentration of etheric extract, suspended and biogenic matter as well as variable concentrations. In this research, we aimed at treating it, applying three systems that combined: ultraltration reverse osmosis, chemical precipitationreverse osmosis and chemical precipitationultraltrationreverse osmosis.

2. Apparatus Ultraltration was carried out applying a SEPA CF-HP pressure apparatus equipped with a plate-and-frame module produced by Osmonics, membrane active area 155 cm2. The system operated in the crossow mode. Reverse osmosis was conducted in a GH 100400 highpressure apparatus, capacity 400 cm3, produced by the same company. The system operated in the dead-end mode on at membranes whose active area was 36.3 cm2.

3. Materials The wastewater was sampled from the Meat-Processing Plant UNILANG in Wrzosowa (southern Poland), whose

1340 Table 1 Pollution indices of raw wastewater Pollution indices

J. Bohdziewicz, E. Sroka / Process Biochemistry 40 (2005) 13391346

Concentration of pollution in raw wastewater (mg/dm3) Range Mean value 4685 2500 198 32 396

Load pollution (kg/d) (mean value)

Permissible standards (mg/dm3) [2]

COD BOD5 Total nitrogen Total phosphate Total suspension

*

26506720 12003800 49287 1570 1121743

309.2 126.8 13 2.1 26.1

150 30 30 5* 50

For a wastewater treatment plant whose daily ow is below 2000 m3.

Table 2 Characteristics of ultraltration and osmotic membranes used in the tests [3] Membrane type Retention R (%) 98* Nominal molecular weight (cut-off) (K) 1050 50100 1530 2 8 Operating pressure DP (MPa) Recommended 0.35 0.17 2.76 Maximum 2.07 1.38 0.35 2.7 2.7 6.90 0.513 0.513 28 211 211 28 pH Max. temperature T (8C) 100 100 30 90 90 50

HN HZ DS-CQ DS-GH 2K DS-GH 8K SS-10

*

0.5% sodium chloride.

activity covers the slaughter and processing of pigs. It was characterized by considerable pollutant load, substantial amounts of suspended matter and high concentrations of total nitrogen and phosphorus. The values of the basic and eutrophic pollution indices ranged widely during the whole production cycle. The characteristics of the wastewater are presented in Table 1.

4. Coagulant The research employed four technical coagulants ALF (Al3+:Fe3+, 4:1); PAC (Al2O3-15.5%, Cl-20%); PAX (Al2O3, Cl-210 g/kg); PIX 113 (Fe2(SO4)3 Feog, 12.8%, Fe2+, 0.7%, H2SO4, 1%], which were added to the wastewater in the form of 1 wt.%. aqueous solution. The basic reagent dosages were calculated on the basis of a chemical reaction of phosphates. The process of coagulation with the basic dosage of the coagulant as well as its 100% and 200% excess was carried out at 1820 8C, pH of the wastewater being 6.47.6. The fast stirring time was 45 s, while the time of slow stirring and sedimentation was 30 min each. The choice of a coagulant was assessed on the basis of a decrease in COD and phosphorus concentration in the puried wastewater [7,8].

brane, two DS-GH 2K and DS-GH 8K composite membranes and one SS-10 membrane for reverse osmosis made of cellulose acetate. Table 2 shows the operating conditions and separation characteristics recommended by the manufacturer of the membranes. We also used two ultraltration membranes prepared by in this laboratory: PSf-12 and PSf-15. They were produced from casting solutions containing 12% wt. polysulphone (PSf-12) and 15% wt. polysulphone (PSf-15) applying the method of phase separation (Table 3).

6. Methods and analysis Prior to the main tests, the transport properties of the applied ultraltration and osmotic membranes and separation characteristics of PSf-12 and PSf-15 ultraltration membranes were determined. In the next stage of the research, the wastewater was treated in a system combining ultraltration and reverse osmosis. Ultraltration was used to remove organic and colloidal macromolecular substances. The processes which used HN and HZ membranes were carried out at transmemTable 3 Condition for polysulphone membranes preparation Membrane symbol PSf-12 PSf-15 Polymer concentration in casting solution (wt.%) 12 15 Amount of solvent (DMF) in casting solution (cm3) 92.6 89.4

5. Membranes The membranes used in the pressure driven membrane operations produced by American company Osmonics are as follows: two at polysulphone ultraltration membranes SEPA-H designated as HN and HZ, DS-CQ cellulose mem-

Conditions for membrane preparation: temperature of casting solution, 291 293 K; solvent evaporation time, 5 s; gelating agent, water; gelation time, 900 s; temperature of gelation, 278280 K; thickness of cast lm, 0.2 mm.

J. Bohdziewicz, E. Sroka / Process Biochemistry 40 (2005) 13391346

1341

brane pressures recommended by the manufacturer, which in the case of DSCQ, DSGH-2K, DSGH-8K, PSf-12 and PSf15 membranes, this was 0.3 MPa. The linear ow velocity of the ltered medium over the membrane surface was 2m/s each time. Next, the permeate was additionally treated by means of reverse osmosis on the SS-10 membrane removing mineral matter and low molecular organics which formed in the wastewater. The operating parameters of the process were: transmembrane pressure, 2.0 MPa; stirring rate, 200 rpm. The wastewater was also treated by replacing ultraltration with coagulation, which was additionally followed by reverse osmosis after the wastewater was ltered through a sand bed. The applied transmembrane pressure was 2.0 MPa and the stirring rate 200 rpm. In the last stage of the research, the wastewater was treated applying coagulation, ultraltration and reverse osmosis. Ultraltration of the wastewater, which followed coagulation with 200% excess of PIX, was carried out on DSCQ, DSGH-2K, DSGH-8K, PSf-12 and PSf-15 membranes using the assumed operating parameters. Ultraltration permeates were additionally treated with reverse osmosis. Each time, before it was treated, the raw wastewater was pre-treated in a fat separator. The effectiveness of the treatment in all unit processes was assessed on the basis of a decrease in pollution indices of the wastewater, such as COD, BOD5, concentration of biogenic substances and in the case of membrane operations, permeates uxes were determined. The concentrations of total nitrogen, phosphorus and COD were determined by means of the tests, which used an SQ118 photometer produced by Merck [4]. BOD5 was assayed employing the respiratory measurement method with OxiTOP measuring cylinders produced by WTW [5], the dry matter of the deposit was determined by means of the gravimetric method [6], whereas oxygen concentration, pH and temperature were measured with a microcomputer CX 315 pH/oxygen meter produced by ELMETRON.

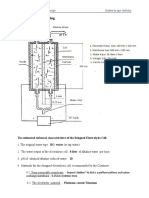

Fig. 1. Dependence of volume water ux on transmembrane pressure for ultraltration membranes.

of 0.10.3 MPa was observed for the DS-CQ ultraltration membrane whose volume water ux increased 2.2-fold under these conditions. The DSGH-2K membrane was characterized by the lowest performance for which the volume water ux was 0.31 105 m3/m2 s at D = 0.3 MPa. Before they were tested, PSf-12 and PSf-15 polysulphone membranes were preliminary conditioned which consisted in ltering deionized water at a pressure of 0.3 MPa and a temperature of 293 K until a constant volume water ux was achieved (912 h). The transport properties of the membranes are illustrated in Fig. 3. Similarly to the commercial membranes, also in the case of these membranes, the volume water ux increased with increasing pressure and was the highest for the pressure of 0.3 MPa. It was 5.3 105 m3/m2 s for PSf-12, while for PSf-15 it was higher by 43% and amounted to 2.3 105 m3/m2 s. As for the osmotic membrane, the dependence of the volume water ux on transmembrane pressure was also rectilinear and at 2.0 MPa the ux oscillated around 0.55 105 m3/m2 s. Table 4 contains equations describing the dependence of the volume water ux on the applied transmembrane pressure for all tested membranes. Determination of the separation properties of those membranes consisted of determining their cut-off, applying a

7. Results and discussion 7.1. Determination of transport and separation properties of the ultraltration and osmotic membranes used in the tests The tests started with determination of transport properties of the membranes by nding the dependence of the volume deionized water ux on transmembrane pressure. It was observed that in all cases, the water uxes increased with increasing transmembrane pressure, and the correlations obtained were rectilinear (Figs. 1 and 2). As far as ultraltration membranes are concerned, the highest increase in ultraltration rate over the pressure range

Fig. 2. Dependence of volume water ux on transmembrane pressure for SS-10 osmotic membrane.

1342

J. Bohdziewicz, E. Sroka / Process Biochemistry 40 (2005) 13391346

Fig. 3. Dependence of volume water ux on transmembrane pressure for PSf-12 and PSf-15 polysulphone membranes.

Fig. 5. Dependence of volume permeate ux on its recovery during ultraltration treatment of wastewater.

Table 4 Equations describing dependence of volume water ux on applied transmembrane pressure Membrane type HN DSGH-2K DSGH-8K DSCQ PSf-12% PSf-15% Function Jw = f(x) Jw (m3/m2 s) 23.45x 1.0857x 10.743x 2.8071x 18.171x 4.4643x Coefcient of correlation 0.976 0.9616 0.9793 0.9645 0.9727 0.998

dextran whose molecular weight and concentration were 200,000 and 5g/dm3, respectively. The samples of permeates and feed were analyzed by means of a gel permeation chromatograph produced by Shimadzu. The obtained dependence of dextran retention coefcients on their molar mass enabled the determination of cut-off values of the tested membranes. It has been found that the membrane of more compact structure (PSf-15) has a cut-off of 80,000 and PSf-12 of 90,000 (Fig. 4). 7.2. Treatment of wastewater in the hybrid system of ultraltration and reverse osmosis The rst stage of the investigations dealt with the treatment of wastewater in the system of ultraltration and reverse osmosis.

Raw wastewater was introduced into the ultraltration module after fat separation, otation and ltration through a sand lter whose grain size was 0.20.4 mm. Ultraltration was carried out on six ultraltration membranes, which differed in their polymer type and the compactness of the structure, and thus different cut-off values ranging over 2000100,000. Fig. 5 presents dependences of the volume permeate uxes on recovery during ultraltration applying different membranes. Table 5 contains equations describing the dependence of the volume permeate ux on its recovery. The equations were of logarithmic function and the high correlation coefcients indicate the proper selection of the equations for the results obtained. The HN membrane was the most efcient. Its permeate ux decreased by 12%, recovery being 50%. It was, however, four times lower in comparison with the water ux. Decisively lower ltration velocities were found for the remaining membranes. The volume permeate uxes obtained were from two to four times lower under the same conditions (50% recovery of the permeate and the same process parameters). However, the effectiveness of the processes depends not only on membrane performance but also the degree of contaminant removal. Depending on the type of membrane applied, different degrees of decrease in particular pollution indices, e.g. COD, BOD5, phosphorus and total nitrogen (Fig. 6) were found.

Table 5 Equations describing the dependence of volume permeate ux on its recovery during ultraltration treatment of wastewater Membrane type HN HZ DSGH-8K DSCQ PSf-12% PSf-15% Function Jp = f(x) Jp (m3/m2 s) 0.0678 ln(x) + 1.9169 0.1419 ln(x) + 1.6446 0.1432 ln(x) + 1.8052 0.098 ln(x) + 1.2625 0.00771 ln(x) + 1.4882 3E 06x + 0.2081 Coefcient of correlation 0.9326 0.9726 0.8965 0.9336 0.9007 0.9339

Fig. 4. Cumulative fraction of molecular weights in dextran samples.

J. Bohdziewicz, E. Sroka / Process Biochemistry 40 (2005) 13391346

1343

Fig. 6. Inuence of ultraltration membrane on removal degree of pollutants from wastewater.

the obtained ultraltration permeates obtained were additionally puried by applying reverse osmosis. Fig. 7 illustrates dependences of the changes in the volume permeate uxes on recovery in this process. The decrease in ltration velocity for HN, HZ and DSGH-8K membranes was similar and reached 11%, 11% and 13%, respectively, while for DSCQ, it decreased almost two-fold and equalled 6% (16% recovery of the permeate). PSf-12 and PSf-25 membranes also displayed a two-fold decrease in the velocity of wastewater ltration compared to the water ux. Similarly to ultraltration, the dependence of the volume permeate ux on its recovery during reverse osmosis was of logarithmic function (Table 6). The high correlation coefcients indicate the proper selection of the equations for the obtained results. Table 7 shows the nal characteristics of the wastewater treated in the hybrid system of both processes: ultraltration and reverse osmosis. In the rst process, the HN membrane was used because, while it had similar separation properties to DSCQ, it displayed a decisively better performance. The results obtained indicate that the wastewater additionally treated by reverse osmosis can be reused in the production cycle. 7.3. Treatment of wastewater in the hybrid system of coagulation and reverse osmosis Since ultraltration (see 7.2) did not produce a satisfactory degree of wastewater purication, it was replaced with coagulation. Figs. 8 and 9 show the results of the selection of a coagulant and its optimum concentration. The highest removal degree was obtained for PIX at 200% excess of its basic dosage, i.e. for the concentration of 19.0 g coagulant/g phosphorus. It enabled a decrease in COD and BOD5 by 96.5% and 62.6%, respectively, and amounted to:

Fig. 7. Dependence of volume permeate ux on its recovery during reverse osmosis of wastewater after ultraltration treatment.

The highest retention coefcients of nitrogen and phosphorus, and the highest removal degrees of COD and BOD5 were obtained when the DS-CQ membrane was applied. They were 58%, 85.9%, 84.6% and 81.5%, respectively. A similar degree of wastewater purication was achieved in ultraltration carried out on HN membrane. Nevertheless, the degrees obtained in both cases were not sufcient to allow the wastewater to be discharged into receiving water, let alone be reused in the production cycle. For this reason,

Table 6 Equations describing dependence of volume permeate ux on its recovery degree during reverse osmosis applying the SS-10 membrane Feeding solution (nadawa) Permeate Permeate Permeate Permeate Permeate Permeate after after after after after after UF on HN membrane UF on HZ membrane UFon DSGH-8K membrane UFon DSCQ membrane UF on PSf 12 membrane UF on PSf 15 membrane Function Jp = f(x) Jp (m3/m2 s) 0.0389 0.0367 0.0416 0.0212 0.0328 0.0309 ln(x) ln(x) ln(x) ln(x) ln(x) ln(x) + + + + + + 0.763 0.6763 0.6634 0.7015 0.6221 0.5574 Coefcient of correlation 0.8991 0.8461 0.8159 0.8684 0.7854 0.8372

Table 7 Pollution indices of wastewater after it was additionally treated in the system combining ultraltration (HN membrane) and reverse osmosis (SS-10 membrane) Pollution indices Unit

3

Raw wastewater

Wastewater after ultraltration process Concentration (mg/dm3) Retention R (%) 84.5 81.6 86.0 57.6

Wastewater after RO process Concentration (mg/dm3) 4.0 3.9 2.5 0 Retention R (%) 99.8 99.8 99.1 100.0

COD BOD5 Total nitrogen Total phosphate

mgO2/dm mgO2/dm3 mg/dm3 mg/dm3

2284 1900 285.0 25.5

355.0 350.0 40.0 10.6

1344

J. Bohdziewicz, E. Sroka / Process Biochemistry 40 (2005) 13391346

Fig. 8. Dependence of COD removal degree on type and dosage of coagulant.

Fig. 9. Dependence of phosphorus removal degree on type and dosage of coagulant.

662.0 mgO2/dm3 and 200.0 mgO2/dm3. The concentrations of phosphorus and total nitrogen in the puried wastewater decreased by 95.7% and 64%, and were 2.5 mg/dm3 and 150 mg/dm3, respectively. Similar removal degrees for both phosphorus and COD were obtained when using coagulant ALF with its 200% excess of the basic dosage and the concentration of 3.45 g coagulant/g phosphorus. PIX, however, was chosen for further tests because it was more efcient in removing colour and suspended matter which signicantly affected the effectiveness of reverse osmosis. The results obtained indicated that wastewater treatment through coagulation, similar to ultraltration, did not enable sufcient removal of pollutants, and the wastewater could not be discharged into receiving water. Except for phosphorus, all pollution indices exceeded permissible standards. A comparison of the effectiveness of coagulation and ultraltration showed a similar degree of pollutant removal. Thus, following coagulation, the wastewater was ltered on a sand lter in order to remove suspended matter and subsequently introduced into the osmotic module. The effectiveness of the wastewater treatment in the system of chemical precipitation reverse osmosis is presented in Table 8. The volume permeate ux obtained during reverse osmosis oscillated around 0.43 10-5 m3/m2 s and was lower by 37% compared to reverse osmosis of the wastewater after ultraltration treatment (see 7.2). 7.4. Treatment of wastewater in the hybrid system combining coagulation, ultraltration and reverse osmosis The nal stage of the research dealt with treating the wastewater in the hybrid system combining coagulation,

ultraltration and reverse osmosis. The introduction of ultraltration after the wastewater was treated chemically and before its additional treatment through reverse osmosis aimed at obtaining a satisfactory removal degree of pollutants so that the wastewater could be discharged into receiving water. The wastewater, after its preliminary coagulation with 200% excess of coagulant PIX (coagulation was carried out as in 7.3), was subsequently treated on DSCQ, DSGH-K, DSGH-8K, and PSf-12 and PSf-15 membranes. Due to technical reasons, HN and HZ membranes were not used in this system. The dependence of the volume permeate uxes on recovery (Fig. 10) were determined and described with mathematical equations (Table 9). Among the tested membranes, DSCQ displayed the highest volume permeate ux. The permeate uxes at 30% recovery egree increased by 25.7% for PSf-12 to 74.6% for DSCQ (DP = 0.3 MPa) and were 0.8 m3/m2 s and 1.3 m3/m2 s, respectively, compared to the ux obtained during ultraltration of the raw wastewater. Table 9 shows equations describing dependences of the volume uxes on the degree of permeate recovery. They were of logarithmic function. The highest removal degrees of tested contaminants were observed during ultraltration carried out on DSCQ and PSf15 membranes (Fig. 11). They were: COD, 70.6% and 65.5%; BOD5, 72.7% and 62.5%; total nitrogen, 64% and 67%; phosphorus, 98.2% and 96%, respectively. DSCQ, however, was considered as more favourable because it displayed a higher volume permeate ux. As for the remaining membranes, the degrees of contaminant removal were found to be lower by several per cent.

Table 8 Effectiveness of wastewater treatment in the system combining coagulation and reverse osmosis Pollution indices Unit

3

Raw wastewater

Wastewater after coagulation process Concentration (mg/dm3) Retention R (%) 87.5 70.0 49.0 91.0

Wastewater after RO process Concentration (mg/dm3) 4.00 3.98 1.16 0.0 Retention R (%) 99.9 99.3 98.8 100

COD BOD5 Total nitrogen Total phosphate

mgO2/dm mgO2/dm3 mg/dm3 mg/dm3

2700 1800 420.0 27.8

662.0 540.0 150.0 2.5

J. Bohdziewicz, E. Sroka / Process Biochemistry 40 (2005) 13391346

1345

Fig. 10. Dependence of volume permeate ux on its recovery during ultraltration of the wastewater coagulated by means of different ultraltration membranes. Table 9 Equations describing dependence of volume permeate ux on the degree of permeate recovery during ultraltration of wastewater after coagulation Membrane type DSGH-2K DSGH-8K DSCQ PSf-12% PSf-15% Function Jp = f(x) Jp (m3/m2 s) 0.0604 ln(x) + 0.9533 0.1546 ln(x) + 2.0314 0.407 ln(x) + 4.9369 0 0938 ln(x) + 1.6628 0.0621 ln(x) + 1.0219 Coefcient of correlation 0.811 0.8489 0.9639 0.9109 0.8524

Fig. 12. Dependences of volume permeate ux on recovery degree in the process of reverse osmosis (feed-wastewater after coagulation and ultraltration).

Fig. 11. Inuence of ultraltration membrane type on the degree of removal of contaminants from wastewater.

The puried wastewater had the following pollution indices, DSCQ: COD 159 mgO2/dm3, BOD5 130 mgO2/dm3, total nitrogen 52.7 mg/dm2, phosphorus 0.1 mg/dm3; PSf-15: COD 165 mgO2/dm3, BOD5

140 mgO2/dm3, total nitrogen 48 mg/dm3, phosphorus 0.1 mg/dm3. The remaining membranes showed even lower degrees of contaminant removal. Thus, it can be clearly noticed that the additional ultraltration treatment of the wastewater after coagulation did not produce the desired effect and the wastewater still could not be discharged into receiving water. Except for phosphorus, all determined pollution indices exceeded permissible standards. Therefore, the wastewater was additionally treated applying reverse osmosis. The process was carried out at a pressure of 2.0 MPa and a stirring rate of 200 rpm. Fig. 12 illustrates the dependences of the changes in the volume permeate uxes on the recovery degree when the wastewater treated with high-pressure ltration was pretreated via coagulation and ultraltration on different membranes. The equations describing this dependence are presented in Table 10. It has been found that the highest volume permeate ux (0.67 m3/m2 s) (16% of permeate recovery) was obtained in the process of reverse osmosis when the wastewater was ltered after coagulation and ultraltration applying the DSCQ membrane. Below is presented the compilation of results of wastewater treatment effectiveness in the hybrid system combining coagulation, ultraltration (on DSCQ) and reverse osmosis (Table 11). The obtained results showed that the wastewater puried in this system can be reused in the production cycle. Fig. 13 compares the volume permeate uxes obtained in reverse osmosis of the wastewater pre-treated by various methods: ultraltration, coagulation and in the system combining both these processes.

Table 10 Equations describing the dependence of volume permeate ux on recovery degree in the process of reverse osmosis Feeding solution (nadawa) Permeate Permeate Permeate Permeate Permeate after after after after after UF UF UF UF UF on on on on on DSGH-2K membrane DSGH-8K membrane DSCQ membrane PSf-12 membrane PSf-15 membrane Function Jp = f(x) Jp (m3/m2 s) 0.0442 0.0812 0.0173 0.0194 0.0155 ln(x) ln(x) ln(x) ln(x) ln(x) + + + + + 0.884 1.0448 0.8129 0.628 0.6368 Coefcient of correlation 0.9654 0.9128 0.8989 0.9351 0.9351

1346

J. Bohdziewicz, E. Sroka / Process Biochemistry 40 (2005) 13391346

Table 11 Effectiveness of wastewater treatment in the system combining coagulation, ultraltration (on DSCQ) and reverse osmosis Pollution indices Unit Raw wastewater Wastewater after coagulation process Concentration (mg/dm3) COD BOD5 Total nitrogen Total phosphate mgO2/dm3 mgO2/dm3 mg/dm3 mg/dm3 2839 1890 447.5 27.6 542.0 490.0 144.9 3.4 Retention R (%) 80.1 74.1 67.6 87.7 Wastewater after ultraltration process Concentration (mg/dm3) 159.0 130.0 52.7 0.1 Retention R (%) 94.4 93.1 88.2 99.6 Wastewater after RO process Concentration (mg/dm3) 3.5 3.1 0.9 0.0 Retention R (%) 99.9 99.8 99.7 100

Fig. 13. Dependence of volume permeate ux on recovery degree of permeate in the process of reverse osmosis of the wastewater pre-treated by various methods.

too low for the wastewater to be discharged into receiving water. Additional treatment with reverse osmosis enables it to be reused in the production cycle. The system combining ultraltration and reverse osmosis was found to be the most favourable. The treatment effectiveness and the volume permeate ux obtained during reverse osmosis were similar to the effectiveness and ltration velocity obtained in RO in the hybrid system of coagulation, ultraltration and reverse osmosis. The application of additional treatment of coagulation prior to ultraltration did not enable a sufcient removal of contaminant load and the wastewater could not be discharged into receiving water. In the case of both approaches, the additional treatment of the wastewater in the RO process made reuse in the production cycle possible.

It has been found that after 6 h of reverse osmosis at 16% permeate recovery the volume permeate uxes obtained during ltration of the wastewater pre-treated in the unit process of ultraltration and in the system combining coagulation and ultraltration were similar and amounted to 0.66 105 m3/m2 s and 0.68 105 m3/m2 s. It has also been observed that the decreases in volume uxes were negligible and reached 5%. A decisively lower ltration velocity was obtained in the system in which the wastewater underwent high-pressure ltration after it had been pre-treated in the process of coagulation and subsequent ltration on a sand bed. The obtained volume permeate ux was lower by 37% and oscillated around 0.43 105 m3/m2 s. This may probably be explained by the presence of suspended matter in the feed, which was not removed to a sufcient extent during ltration on the sand bed.

References

[1] Wisniewski J, Selected problems of industrial wastes purication by membran methods Conference materials Membrans and membran technics in industry: a current stage and a progress, 68 May, 2002. Jahranka, Poland, 2002. p. 23354. [2] Regulation of the Ministry of Environmental Protection, Natural Resources and Forestry, dated 5 November 1991, on the classication of waters and conditions the sewage discharged to waters and soil should satisfy, Journal of Law No. 116, item 501. [3] Performance characteristic of reserve osmosis, nonltration and ultraltration spiral wound permeates Osmonics. [4] Users manual, Photometer SQ 118, Merck. [5] Users manual, Determination of BZT using respirometric method, Oxi Top, rm WTW. [6] In: Physicochemical testing of water and sewage. Warsaw: Arkady; 1998. [7] Bohdziewicz J, obos E, Sroka E. Treatment of wastewater from meat industry using hybrid processes, XVIII EMS Summer School. In: Noworyta A, editor. Proceedings of using membranes to assist in cleaner processesAnna Trusek - Hoownia, September 914, Ladek Zdroj, Poland; 2001. p. 4753. [8] Bohdziewicz J, Bodzek M, obos E, Sroka E. Treatment of wastewater from meat industry applying the process of direct chemical precipitation combined with pressure driven membrane techniques, Conference. In: Luque S, Alwares JR, editors. Proceedings of engineering with membranesJune 36, Granada, Spain; 2001. p. 3817.

8. Conclusions The investigations showed that the pressure driven membrane operations can be applied to the treatment of the wastewater from the meat industry. It has been found that the degree of wastewater purication, both after unit ultraltration and coagulation, as well as combined together, is

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Apr 2017Document45 pagesApr 2017prasanta_bbsrPas encore d'évaluation

- Water Treatment Brochure PDFDocument8 pagesWater Treatment Brochure PDFmathesis-2Pas encore d'évaluation

- 320PRJ1201007-10-201 - O&M MANUAL - Rev 0Document164 pages320PRJ1201007-10-201 - O&M MANUAL - Rev 0Fadhil MPas encore d'évaluation

- Novel Drug Delivery SystemsDocument150 pagesNovel Drug Delivery SystemsBhavya NarangPas encore d'évaluation

- Elecrolysis Cell DrawingDocument2 pagesElecrolysis Cell DrawingRimaPas encore d'évaluation

- LG Membranes Technical ManualDocument46 pagesLG Membranes Technical Manualfarhadzaker0% (1)

- T FoskettDocument18 pagesT FoskettkuaPas encore d'évaluation

- Reverse Osmosis InstructionsDocument12 pagesReverse Osmosis InstructionsDazPas encore d'évaluation

- AN2700EN00 TFF Optimization EMDocument12 pagesAN2700EN00 TFF Optimization EMgeorgadam1983Pas encore d'évaluation

- Manual Virex Pro 3.19r2 FR - 19!04!2012Document73 pagesManual Virex Pro 3.19r2 FR - 19!04!2012Lance Johnpaul SyPas encore d'évaluation

- Aquatech India 2014Document25 pagesAquatech India 2014Gulshan MishraPas encore d'évaluation

- Caustic Recovery Using Membrane FiltrationDocument9 pagesCaustic Recovery Using Membrane FiltrationQuân Nguyễn ĐứcPas encore d'évaluation

- 1) Water TechnologyDocument11 pages1) Water TechnologyDevet ValechaPas encore d'évaluation

- Demetrius Zambaco Pasha 18321913 The 1st Leprologist in The OrientmnyorDocument1 pageDemetrius Zambaco Pasha 18321913 The 1st Leprologist in The Orientmnyorspacebaby44Pas encore d'évaluation

- Membrane Technology in Water Treatment ApplicationsDocument11 pagesMembrane Technology in Water Treatment ApplicationsleechulmiuPas encore d'évaluation

- EDI FlexAir TSeries Spec SheetDocument2 pagesEDI FlexAir TSeries Spec Sheetomega AlfaPas encore d'évaluation

- Nitrogen and Phosphorus Recovery From Wastewater: Water Pollution (S Sengupta, Section Editor)Document12 pagesNitrogen and Phosphorus Recovery From Wastewater: Water Pollution (S Sengupta, Section Editor)JohnPas encore d'évaluation

- High-Efficiency and High-Flux Hemodialysis: Sivasankaran Ambalavanan Gary Rabetoy Alfred K. CheungDocument10 pagesHigh-Efficiency and High-Flux Hemodialysis: Sivasankaran Ambalavanan Gary Rabetoy Alfred K. CheungveiaPas encore d'évaluation

- UOP Separex Membrane Technologytech PresentationDocument44 pagesUOP Separex Membrane Technologytech PresentationNam Nghĩa Hưng100% (1)

- GEI735 LEAPmbr EN PDFDocument3 pagesGEI735 LEAPmbr EN PDFlattimroPas encore d'évaluation

- Chem101 Ho8Document17 pagesChem101 Ho8Claire TaborPas encore d'évaluation

- Kent Supreme ManualDocument7 pagesKent Supreme ManualsimratsahotaPas encore d'évaluation

- Ion Exchange Research ProjectDocument66 pagesIon Exchange Research Projecthenry_tan5328100% (2)

- User Manual D - Q 3 S D - Q 3 UV S: Irect Ystem Irect YstemDocument73 pagesUser Manual D - Q 3 S D - Q 3 UV S: Irect Ystem Irect YstemEdwin Guevara RPas encore d'évaluation

- 6 - Presentation - Boiler Water ChemistryDocument100 pages6 - Presentation - Boiler Water Chemistrymuks1308100% (1)

- Water Energy Nutrient-Nexus Ruai Treatment Nairobi (Kenya)Document19 pagesWater Energy Nutrient-Nexus Ruai Treatment Nairobi (Kenya)Migwi Wa KinyuaPas encore d'évaluation

- Membrane BWRO SUEZ-AG-LDocument2 pagesMembrane BWRO SUEZ-AG-LEko SPas encore d'évaluation

- Separation and Purification TechnologyDocument12 pagesSeparation and Purification Technologyali boubakriPas encore d'évaluation

- Journal of Alloys and Compounds - 2021Document12 pagesJournal of Alloys and Compounds - 2021Eugene YiPas encore d'évaluation

- APM CatalogueDocument24 pagesAPM CatalogueSpoonful BurnsidePas encore d'évaluation