Académique Documents

Professionnel Documents

Culture Documents

6.mohammed Aman Ogeto - FinalPaper 81 88http://www - Iiste.org International Journal Call For Paper

Transféré par

iisteTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

6.mohammed Aman Ogeto - FinalPaper 81 88http://www - Iiste.org International Journal Call For Paper

Transféré par

iisteDroits d'auteur :

Formats disponibles

Determinants of Technical Efficiency of Rose Cut-Flower Industries in Oromia Region, Ethiopia

Mohammed Aman School of Agricultural Economics and Agribusiness, Haramaya University P.O.Box +251 138, Dire Dawa, Ethiopia Email: rosemuhe@gmail.com or muhecristy@gmail.com Jema Haji School of Agricultural Economics and Agribusiness, Haramaya University P.O.Box +251 233, Haramaya, Ethiopia Email: jemmahaji@gmail.com or jema.haji@ekon.slu.se Abstract The objective of this study is to measure and identify input use efficiency level of 28 rose cut flower industries in three districts of Oromia Regional state (Ethiopia) using a two stage approach. . In the first stage, a non-parametric (DEA) method was used to determine the relative technical, scale and overall technical efficiencies. In the second stage, a Tobit model was used to identify sources of efficiency differentials among industries. The results obtained indicated that the mean technical, scale and overall technical efficiency indices were estimated to be 92%, %61 and 58%, respectively for the cut flower industries. This Implies, major source of overall technical inefficiencies was scale of operation rather than pure technical inefficiency. Besides, the estimated measures of technical efficiency were positively related with Farming experience, formal schooling years of managers and negatively related with age of farms. No conclusive result was obtained for the relation between size and efficiency. Key words: Technical Efficiency, Scale Efficiency, DEA, Tobit, Rose cut flowers, farming experience, Oromia, Ethiopia. 1. Introduction Diversification of agricultural production is seen as a priority for least developing countries to reduce dependence on primary commodities. The main reason is, despite high dependence on these commodities for their livelihood, declining trend of prices for primary agricultural commodities (Humphrey 2006). Accordingly, floriculture sector is chosen for enhancing farm incomes and reducing poverty in developing countries. In particular, African countries have a comparative advantage in rose flower varieties production. Fewer economies of scale and labour-intensive nature of production in cut flower industries are major sources comparative advantage for these countries (Labaste 2005). Due to suitable climatic conditions and natural resources; high level of support by the government; favorable investment laws and incentives; proximity to the global market (mainly Europe) and availability of abundant and cheap labour, Ethiopia is the second largest producer of rose cut flowers in Africa following Kenya (Habte 2007). Moreover, the cut-flower industry in Ethiopia has emerged as one of the biggest sources of foreign exchange earning

in recent years. This is mainly because of increased demand for cut-flowers, in the world market, by countries like Netherlands, Germany, Italy, United States, United Kingdom and Switzerland (Belwal & Chala 2007). Despite above opportunities, the high costs of technology, knowledge intensity of production, lack of access to capital, strict market regulations and standards; and demanding infrastructural requirements along with non existence of diversity in cut flower exports i.e. more than 80 % are a single rose variety, made the country not to benefit much (Melese 2007). To achieve simultaneous cost reduction and higher yield level of rose cut flowers, improving the resource use efficiency of these industries is relevant. And hence, this study is designed to estimate technical efficiency level and to identify its main determinants in the production of rose cut flowers in Awash Melkassa, Bishoftu and Ziway districts, respectively. These study areas are chosen due to relative similarity in terms of their geographic characteristics, market conditions, production practices and type of rose cut flowers grown. In particular, this study tries to answer following questions; what is the existing level of efficiency of rose cut flower industries in the study areas? Is there any room for improvement in the level of efficiency for rose cut flower industries? What are the main causes for the existing level of efficiency? What are the main possible solutions to improve the existing level of efficiency in rose cut flowers production? By what level will input(s) be reduced to obtain the existing yield level of rose cut flower stems? The rationales for this study are, identifying the technical efficiency level of the rose cut flower industries, will help business owners as to what extent they can reduce scarce resource use while maintaining current yield level of rose cut flower stems. Moreover, due to recent development of the sector in Ethiopia, checking for technical efficiency of these farms will also help policy makers in future policy design. 2. Materials and Methods 2.1. Sources and Types of Data Primary data on the industry features, characteristics and production processes are collected through an interview with farm managers using a semi-structured questionnaire from the 28 rose cut flower industries. Whereas, the secondary cross sectional data on input and output for one growing season (45 days) were collected from each daily input use records in order to calculate the variables required for the empirical analysis. The data used in this study was drawn from a survey conducted from December 7, 2010-January, 2010/11, in the three districts. 2.2. Methods of Data Analysis Given decision making units (DMUs) producing and products (outputs) using inputs, input and output vectors as input

may be represented by matrix (X) and

, respectively. For each DMU, all data may be written in terms of

as output matrix ( ). Under the assumption of

, the linear programming model for

measuring the technical efficiency of rose cut flower farms can be given as follows according to Coelli et al. (1998)is: Subject to

Where, -( ) Vector of rose cut flower stems by the -( )Vector of inputs of the industry

rose cut flower industry. )for ( ) cut flower industries. )for rose cut farms. .

- Rose cut flower stems output matrix ( - Rose cut flower production input matrix (

- The input oriented technical efficiency score having value If -(

, the industry will be technically efficient; otherwise inefficient. And industry.

)Vector of weights which defines the linear combination of peers of the is only suitable when all

The specification of

work at optimum scale. Otherwise, measures of model is reformulated by imposing a

technical efficiency can be mistaken for scale efficiency. Therefore, the efficiency, as it is free of scale effects. Thus, technical efficiency ( from following linear programming: Subject to ) with

convexity constraint. Technical efficiency measure obtained with VRS model is also named as pure technical in DEA model could be obtained

And Where, model. When there is a difference in efficiency score values between and models, scale inefficiency is confirmed, is a convexity constraint ( is an vector of ones) and other variables are as defined in the

indicating that the return to scale is variable, i.e. it can be increasing or decreasing (Fre & Grosskopf 1994). Scale efficiency values for each analyzed with and can be obtained by the ratio between the scores for technical efficiency are scale efficient and a value less than 1 imply ) is operating under super) are assumed to operate under suboperating with Decreasing Returns to Scale (

. If the ratio value equals to 1, it indicates

scale inefficiency. Furthermore,

optimal condition while those operating with increasing Returns to scale ( optimal conditions.

After efficiency scores are obtained, to identify the determinants of efficiency, a Tobit model is used for the secondstage relationship between efficiency measures and suspected correlates of inefficiency (Binam et al. 2003; Irizoz et al. 2003; Chavas et al. 2005; Barnes 2006). The reason for using Tobit model for DEA efficiency scores is the bounded nature of efficiency level between 0 and 1. In this case, estimation with OLS would lead to biased parameter estimates (Green 1991; Dhungana et al. 2004). Rather a two-limit Tobit regression is estimated using commonly used statistical software STATA version 10.

2.3. Definition of Variables The dependent variable, in first stage, is given by total number of rose cut flower stems produced. While, the independent variables included in this stage are: land measured by total hectare of land under greenhouse, the total labour (total number of temporary and permanent), water (the total amount of water (m 3) used in the greenhouse rose cut flower farms), the rose plant seedlings (estimated by the total number of rose flower plant seedlings stems used by the farms.), nitrate, sulphate and acid fertilizers measured by (kg) used. In the second stage, however, the dependent variable is the technical efficiency score level of the rose cut flower industries. Then this dependent variable is regressed over the following farm specific socio-economic variables. Average area per greenhouses; location of the farm in KM (distance from the Bole International airport); Ownership (measured by dummy values of 1 if the rose cut flower farm is domestically owned and 0 if owned by foreign investors.); Age of the farm (years since the establishment of the rose cut flower farm); Managers education level (formal schooling years spent by the farm managers) and Managers farming experience (total years of farming experience by the farm managers in same or related farming). The output and inputs data, from the twenty-eight rose cut flower industries, are used to estimate the technical efficiency levels in the production of rose cut flowers by using DEAP version 2.1 with an input orientation option i.e. since the industries are targeted at minimization of input use. 3. Results and Discussion 3.1. Descriptive statistics The mean land size holding, under greenhouses, in the study areas was 19.17 hectares, with minimum and maximum sizes of 4.98 and 42 hectares, respectively. While, the mean employment level was 536 workers. The mean amount of nitrate, sulphate and acid fertilizers used in greenhouses were 12.82 kg, 26.46 kg and 1.98 kg, respectively. Furthermore, the mean, water, rose flower plant seedlings and cut flower yield levels were 47,300 m 3, 1,066,500 and 9,671,800 stems, respectively. 3.2. Efficiency (DEA) Results In this section, district as well as industry level technical efficiency results are discussed. For the sake of comparison, technical efficiency indices are estimated both under and type of returns to scale. The district level technical efficiency results indicate that, industries at Awash Melkassa, Bishoftu and Ziway districts could reduce their input use by 24%, 64% and 22% without any loss of rose cut flower stems. While, the mean technical efficiencies, using districts, respectively (Table 1). , were 100, 90 and 94 percent for Awash Melkassa, Bishoftu and Ziway and along with scale efficiency level

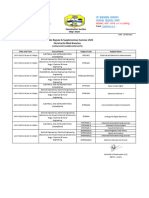

Table 1. Descriptive statistics of the technical efficiency scores of districts Case Districts N Mean S.dev Awash Melkassa 1 0.76 CRS Bishoftu 13 0.36 0.22 Ziway 14 0.78 0.34 Total 28 0.58 0.35 Awash Melkassa 1 1.00 VRS Bishoftu 13 0.90 0.11 Ziway 14 0.94 0.10 Total 28 0.92 0.11 Source: Author survey, 2011.

Min 0.76 0.14 0.15 0.14 1.00 0.71 0.64 0.64

Max 0.76 1.00 1.00 1.00 1.00 1.00 1.00 1.00

Range 0.00 0.86 0.85 0.86 0.00 0.29 0.36 0.36

Furthermore, results obtained indicate statistically significant difference in mean technical efficiency level for rose cut flower industries in case of CRS i.e. farms in Ziway district were performing well followed by farms in Awash Melkasa and Bishoftu districts. However, the difference was not statistically significant in case of VRS. This may be due to similar technologies of production used by rose cut flower industries. Frequency distribution of the technical efficiency scores in both CRS and VRS are given in Table 2. Accordingly 8 industries under CRS and 16 under VRS are technically efficient and the remaining technically inefficient. Table 2. Frequency distribution of technical efficiency scores (VRS, CRS and SE) Frequency of Technical Efficiency TE scores CRS Percent VRS Percent 1.00 8 28.57 16 57.14 0.91- 0.99 2 7.14 2 7.14 0.81- 0.90 1 3.57 5 17.86 0.71- 0.80 1 3.57 4 14.28 0.61- 0.70 1 3.57 0.51- 0.60 0.41- 0.50 3 10.71 0.31- 0.40 5 17.86 0.21- 0.30 4 14.28 0.11- 0.20 4 14.28 Mean 0.58 0.92 Minimum 0.14 0.64 Maximum 1.00 1.00 S.dev 0.35 0.11 Source: Author survey, 2011.

SE 8 3 1 1 2 6 5 2 0.61 0.19 1.00 0.33

Percent 28.57 10.71 3.57 3.57 7.14 21.43 17.86 7.14

3.3. Returns to Scale of Industries The majority,19 (67.85%), of scale inefficient rose cut flower industries were operating under IRS with only one farm operating under CRS. Those operating under IRS are small industries that need to increase their size of operation. While, those operating under DRS are large industries operating above their optimal scale and thus could be better-off by reducing their size of operation. Accordingly, most of the scale inefficient industries, in the three districts, need to expand their size of holding to efficiently utilize their resources (Table 3).

Table 3. Efficiency and returns to scale distribution of rose cut flower industries Technical Efficiency Returns to Scale CRS CRS SE IRS CRS Industries Efficient 8 16 8 Inefficient 20 12 20 Total 28 28 28 19 8 Mean 0.58 0.92 0.61 Source: Own (Authors) calculation

DRS

The mean SE was 0.61 This result imply that , the average size of the greenhouse rose cut flower industries in the study areas is far from the optimal scale and an additional 39 % productivity gain could be feasible, provided they adjusted their farms operation to an optimal scale. The causes of inefficiency for the industries could be either inappropriate scale or misallocation of resources. Inappropriate scale suggests that industries are not taking advantage of economies of scale in rose cut flower production process. While, misallocation of resource refers to inefficient input combination. As shown in Table 3, the mean SE and TE (VRS) score were 0.61 and 0.92, respectively. This relatively low scale efficiency mean value indicates the main cause of technical inefficiency, for the rose cut flowers industries, is inappropriate scale (scale inefficiency) rather than misallocation of resources (pure technical inefficiency). In this study, input slacks are also estimated. The input slacks, using the VRS technical efficiency measure (pure technical efficiency), indicate excess use of that input(s) relative to other peer farms. The mean slack values for land, labour, water, nitrate, sulphate and acid fertilizers and rose plant seedling inputs are 0.76 hectares, 478 workers,1,810 m3,1.3 kg,1.76 kg,0.22 kg and 130041 stems, respectively. Among fertilizers, smallest mean input slack value is obtained for acids followed by nitrates. The reason is that, acid fertilizers are used to clean the drip pipes and less frequently applied than the two fertilizers. The rose cut flower industries can reduce costs, incurred on inputs, by the amount of slacks without reducing production level of rose cut flower stems. 3.4. Determinants of Technical Efficiency In order to examine the effect of relevant technological, farm specific and socio-economic factors on technical efficiency of rose cut flower farms, the input oriented VRS technical efficiency scores are regressed on the selected explanatory and farm specific variables using a two-limit Tobit model since efficiency scores are bounded between 0 and 1 (Table 4).

Table 4. Determinants of technical efficiency in rose cut flowers production The log likelihood estimates The Robust standard estimates Variables Parameters Efficiency effect Parameters Efficiency effect b0 -0.976 b0 -0.976 Constant( ) (0.667) (0.258) b1 -0.020 b1 -0.020 (0.023) (0.016) b8 -0.004 b8 -0.004 (0.012) (0.009) b9 0.259 b9 0.259 (0.101) (0.093) b10 -0.009* b10 -0.009** (0.035) (0.022) b11 0.104** b11 0.103*** (0.039) (0.028) b12 0.048** b12 0.048*** (0.023) (0.014) Log likelihood 0.937 Log 0.937 Pseudo likelihood Sigma 0.133 0.133 *** Significant at 1%; ** significant at 5%; * significant at 10%. Standard errors were shown in parenthesis, (x1= Average land area, x8 =location, x9 = ownership, x10 = age of industry, x11= managers education and x12= managers experience). The result obtained for age of the industry shows a negative and significant effect on technical efficiency of rose cut flower production implying older rose cut flower farms are less technically efficient than new ones. While, the formal education schooling years and experience in same or related business of farm managers has positive and significant effect on technical efficiency level of the farms. Furthermore, the marginal effects for the determinants of technical efficiency were also estimated. And hence, for a unit percentage increase in years rose cut flower farms, technical efficiency decreases by 1 %. While, a one percent additional formal schooling years of the farm mangers will improve technical efficiency of the industry by 10.3 %. Finally, a one percent additional farming experience of the farm manager will improve technical efficiency by 4.8 % (Table 5). Table 5. Marginal effects of efficiency variables after Tobit regression The log likelihood estimates The Robust standard estimates Variables Parameters dy/dx Parameters dy/dx b1 -0.020 b1 -0.020 (0.023) (0.016) b8 -0.004 b8 -0.004 (0.012) (0.009) b9 0.259 b9 0.259 (0.101) (0.093) b10 -0.01* b10 -0.01* (0.035) (0.022) b11 0.103*** b11 0.103*** (0.039) (0.028) b12 0.048** b12 0.048*** (0.023) (0.014) Source: authors own calculation

4. Conclusion Results obtained indicated that there is a room to improve technical efficiency level of rose cut flower industries in the study areas. For instance, the mean scale efficiency value of 0.61 implying, on average, rose cut flower industries in the three study districts are not operating at their optimal farm size. Among the factors that are assumed to affect technical efficiency level, experience in same or related farming activities as well as more years of formal schooling by the farm manager increased technical efficiency level Whereas, age of the farm, along with rose cut flowers grown inside, decreased the technical efficiency level. As far as marginal gain in technical efficiency is concerned, formal years of schooling dominates that of farm manager farming experience in same or related farming activities. References Barnes, A.P. (2006), Does multi-functionality affect technical efficiency? A non-parametric analysis of the Scottish dairy industry, Journal of Environmental Management 80,287-294. Belwal, R., & Chala, M. (2007), Catalysts and barriers to cut flowers export: A case study of Ethiopian floriculture industry, International Journal of Emerging Markets 3(2), 216-235. Binam, JN., Sylla, K., Diarra, I., & Nyambi G. (2003), Factors affecting technical efficiency among coffee farmers in Cote dIvoire: Evidence from the centre west region, African Development Review 15, 66-76. Chavas, J-P., Petrie, R., & Roth, M. (2005), Farm household production efficiency: Evidence from the Gambia, American Journal of Agricultural Economics 87(1), 160-179. Coelli, T.J., Rao, D.S.P., ODonnell, C.J., & Battese, G.E. (1998), An introduction to productivity and efficiency analysis (2nd edition), Springer Science, New York. Dhungana, B.R., Nuthall, P.L., & Nartea, G.V. (2004), Measuring the economic inefficiency of Nepalese rice farms using data envelopment analysis, The Australian Journal of Agricultural and Resource Economics 48 (2), 347-369. Fre, R., Grosskopf, S., & Lovell, C.A.K. (1994), Productivity frontiers, Cambridge: Cambridge University Press. Green, W. (1991), LIMDEP: Users manual and reference guide, New York: Econometric software, Inc. Habte, S. (2007), Ethiopia cut flower export industry and international market: Investment opportunity profile in Ethiopia. Humphrey, J. (2006), Horticulture: Responding to challenges of poverty reduction and global competition, Acta Horticulture 69(9), 1938. Irizoz, B., Rapn, M., & Zabaleta, I. (2003), Assessing the technical efficiency of horticultural production in Navarra, Spain Agricultural Systems78, 387-403. Labaste, P. (2005), The European horticulture market. Opportunities for Sub- Saharan African exporters. Working Paper NO. 63, Washington: The World Bank. Melese, A. (2007), Triple role of the Dutch in the growth of the cut-flower industry in Ethiopia. Unpublished Thesis for partial fulfillment of masters of arts in development studies, The Hague, The Netherlands.

List of Tables Table Page Table 1. Descriptive statistics of the technical efficiency scores of districts .................................................................5 Table 2. Frequency distribution of technical efficiency scores (VRS, CRS and SE) ....................................................5 Table 3. Efficiency and returns to scale distribution of rose cut flower industries ........................................................6 Table 4. Determinants of technical efficiency in rose cut flowers production...............................................................7 Table 5. Marginal effects of efficiency variables after Tobit regression .......................................................................7

Appendices Appendix Table A 1.Name and location of DMUs (rose cut flower farms) DMUs Name of the rose cut flower farm 1 AQ Roses Plc 2 Exp. Incorporated Chibo Flowers 3 Sher flowers 8 4 Braam Flowers PLC 5 Ziway Roses PLC 6 Sher Ethiopia PLC 7 Rainbow Colors PLC 8 Yassin Legesse J. Flower Farm 9 Dugda Floriculture Dev't PLC 10 Joytech PLC 11 Bukito Agro Industry 12 Friendship Flowers 13 ZK Flower 14 Eyasu Sirak Workineh Flowers PLC 15 Olij Flowers PLC 16 Minaye Flowers PLC 17 Roshanara Rose PLC 18 Super Arsity Flower PLC 19 Sher flowers 1 20 Sher flowers 2 21 Sher flowers 3 22 Sher flowers 4 23 Experience Flowers PLC 24 Evergreen Roses PLC 25 Zubka General Business Flower Farm Plc 26 Sher flowers 5 27 Sher flowers 6 28 Sher flowers 7

District (location ) Ziway Ziway Ziway Ziway Ziway Ziway Bishoftu Bishoftu Bishoftu Bishoftu Bishoftu Bishoftu Bishoftu Bishoftu Bishoftu Bishoftu Bishoftu Awash Melkasa Ziway Ziway Ziway Ziway Ziway Bishoftu Bishoftu Ziway Ziway Ziway

10

Vous aimerez peut-être aussi

- Determinants of Technical Efficiency of Rose Cut-Flower Industries in Oromia Region, EthiopiaDocument8 pagesDeterminants of Technical Efficiency of Rose Cut-Flower Industries in Oromia Region, EthiopiaiistePas encore d'évaluation

- Ahumada-Villalobos2011 Article ATacticalModelForPlanningThePrDocument20 pagesAhumada-Villalobos2011 Article ATacticalModelForPlanningThePrmaria teresa barriosPas encore d'évaluation

- Economies: Technical E Developing Countries: The Case of EthiopiaDocument27 pagesEconomies: Technical E Developing Countries: The Case of EthiopiaGirmaTeklehanaPas encore d'évaluation

- Parametric Estimation of Technical and Scale Efficiencies in Italian Citrus Farming Fabio A. MadauDocument21 pagesParametric Estimation of Technical and Scale Efficiencies in Italian Citrus Farming Fabio A. MadauTamash MajumdarPas encore d'évaluation

- Technical Efficiency of Resource-Conserving Technologies in Rice - Wheat Systems The Case of Bihar and Eastern Uttar Pradesh in IndiaDocument10 pagesTechnical Efficiency of Resource-Conserving Technologies in Rice - Wheat Systems The Case of Bihar and Eastern Uttar Pradesh in IndianirajpjoshiPas encore d'évaluation

- Estimation of Technical Efficiency and Investigation of Efficiency Variables in Wheat Production: A Case of District Sargodha (Pakistan)Document8 pagesEstimation of Technical Efficiency and Investigation of Efficiency Variables in Wheat Production: A Case of District Sargodha (Pakistan)kmillatPas encore d'évaluation

- Efficiency and Productivity of Textile Industries and Products in Central JavaDocument5 pagesEfficiency and Productivity of Textile Industries and Products in Central Javagizex2013Pas encore d'évaluation

- The Technical EfficientlyDocument5 pagesThe Technical EfficientlySarah YeoPas encore d'évaluation

- Vol10 No1 pp95Document15 pagesVol10 No1 pp95Lena BastianPas encore d'évaluation

- Analyzing The Technical Efficiency of SMDocument24 pagesAnalyzing The Technical Efficiency of SMmichael okekePas encore d'évaluation

- Web Based Recommendation System For FarmersDocument5 pagesWeb Based Recommendation System For FarmersEditor IJRITCC100% (1)

- Can Rice Yield Gaps Be Closed? A Theoretical Framework To Explain Yield Gaps at Farm Level With A Case Study For Central Luzon, PhilippinesDocument29 pagesCan Rice Yield Gaps Be Closed? A Theoretical Framework To Explain Yield Gaps at Farm Level With A Case Study For Central Luzon, Philippinesirri_social_sciences0% (1)

- Estimation of Technical Efficiency in Production Frontier ModelsDocument53 pagesEstimation of Technical Efficiency in Production Frontier ModelskPas encore d'évaluation

- Jurnal 1 Perbedaan Sfa Dan DeaDocument35 pagesJurnal 1 Perbedaan Sfa Dan DeaegsantyaPas encore d'évaluation

- Technical Efficiency of Macedonian Pig FarmsDocument10 pagesTechnical Efficiency of Macedonian Pig FarmsArah OpalecPas encore d'évaluation

- Bach Che 2015Document29 pagesBach Che 2015alagar krishna kumarPas encore d'évaluation

- 1-Technical Allocative Cost and Scale Effi-Bangladesh PDFDocument20 pages1-Technical Allocative Cost and Scale Effi-Bangladesh PDFRiadul Islam NasimPas encore d'évaluation

- A Stochastic Frontier and Corrected Ordinary Least Square Models of DETERMNING EFICIENCYDocument5 pagesA Stochastic Frontier and Corrected Ordinary Least Square Models of DETERMNING EFICIENCYHerwan GalinggingPas encore d'évaluation

- The Cost of Producing Potted Orchids Hawaiian Agricultural ProductsDocument4 pagesThe Cost of Producing Potted Orchids Hawaiian Agricultural ProductsStefana LnPas encore d'évaluation

- Frontier Production Functions and Technical Efficiency: Ifpri: Migration and TeDocument5 pagesFrontier Production Functions and Technical Efficiency: Ifpri: Migration and TeHijas MVPas encore d'évaluation

- Siraj ProposalDocument11 pagesSiraj ProposalAbdul-Ghafoor MangiPas encore d'évaluation

- AS3021 Operational Research 2011/2012 CourseworkDocument4 pagesAS3021 Operational Research 2011/2012 CourseworkRobert TaylorPas encore d'évaluation

- Career Planning and Management1111Document6 pagesCareer Planning and Management1111David Fluky FlukyPas encore d'évaluation

- Salinization PDFDocument9 pagesSalinization PDFMauro FerraresePas encore d'évaluation

- Greenhouse Mechanization - State of The Art and Future PerspectiveDocument16 pagesGreenhouse Mechanization - State of The Art and Future PerspectiveamandasilvaamandaPas encore d'évaluation

- 7IJAERS 09202060 Economic PDFDocument14 pages7IJAERS 09202060 Economic PDFIJAERS JOURNALPas encore d'évaluation

- Efficiency, Yield Gaps, and Profitability of Potato (Solanum Tuberosum) Production in Kombolcha District, Oromia National Regional State, EthiopiaDocument6 pagesEfficiency, Yield Gaps, and Profitability of Potato (Solanum Tuberosum) Production in Kombolcha District, Oromia National Regional State, EthiopiaAlem M. HailuPas encore d'évaluation

- 03 Capacity and Scale-UpDocument29 pages03 Capacity and Scale-UpNadiaPas encore d'évaluation

- Sustainability 10 04218Document14 pagesSustainability 10 04218Andrikopoulou ChristinaPas encore d'évaluation

- PDF 162769 89224Document10 pagesPDF 162769 89224Prateek IngolePas encore d'évaluation

- Using Technology in The Conduct of SurveyDocument14 pagesUsing Technology in The Conduct of SurveyCatherine SanchezPas encore d'évaluation

- 1 s2.0 S0925527310004792 MainextDocument12 pages1 s2.0 S0925527310004792 MainextAnelisa Lima das MercesPas encore d'évaluation

- Natural Rubber in NigeriaDocument19 pagesNatural Rubber in NigeriaDonald rayPas encore d'évaluation

- Efficiency of Ethiopian Garment FactoriesDocument13 pagesEfficiency of Ethiopian Garment Factoriesashenafi solomonPas encore d'évaluation

- Challenges of Scale and Specificity in Greenhouse Gas CalculatorsDocument7 pagesChallenges of Scale and Specificity in Greenhouse Gas CalculatorsAzhari RizalPas encore d'évaluation

- An Optimization Approach For Scheduling Wine Grape HarvestDocument17 pagesAn Optimization Approach For Scheduling Wine Grape Harvestmileva_lukicPas encore d'évaluation

- Profit Efficiency Among Bangladeshi Rice FarmersDocument22 pagesProfit Efficiency Among Bangladeshi Rice FarmersAtif NaeemPas encore d'évaluation

- Veri Analizi Son Hali.Document13 pagesVeri Analizi Son Hali.emrePas encore d'évaluation

- D2 Paperon Exportandproductivityfor WB2018 ConferenceDocument72 pagesD2 Paperon Exportandproductivityfor WB2018 ConferenceFriday Tube (Tango)Pas encore d'évaluation

- 02 ShanmugamDocument17 pages02 ShanmugamTushar ChaudhariPas encore d'évaluation

- Analysis of Technical Efficiency and The Influence of Socioeconomic Factors On Oil Palm Farming in Muaro Jambi District - IndonesiaDocument7 pagesAnalysis of Technical Efficiency and The Influence of Socioeconomic Factors On Oil Palm Farming in Muaro Jambi District - IndonesiaMamta AgarwalPas encore d'évaluation

- Jaae 667Document19 pagesJaae 667Zadicus CreightonPas encore d'évaluation

- Technical, Allocative and Economic Efficiencies in Swine Production in Hawaii: A Comparison of Parametric and Nonparametric ApproachesDocument14 pagesTechnical, Allocative and Economic Efficiencies in Swine Production in Hawaii: A Comparison of Parametric and Nonparametric ApproachesKumay MarzukiPas encore d'évaluation

- Agricultural Robots For Field OperationsDocument4 pagesAgricultural Robots For Field OperationsAman WattsPas encore d'évaluation

- Productivity Change Using Growth Accounting and Frontier-Based Approaches - Evidence From A Monte Carlo AnalysisDocument11 pagesProductivity Change Using Growth Accounting and Frontier-Based Approaches - Evidence From A Monte Carlo AnalysisGeorge NunesPas encore d'évaluation

- International Journal of Engineering Research and Development (IJERD)Document8 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDPas encore d'évaluation

- A Multi-Objective Analysis For Import Quota Policy Making in A Perishable Fruit and Vegetable Supply Chain: A System Dynamics ApproachDocument10 pagesA Multi-Objective Analysis For Import Quota Policy Making in A Perishable Fruit and Vegetable Supply Chain: A System Dynamics ApproachHadi P.Pas encore d'évaluation

- Technical Efficiency in Agriculture in Ghana Analyses of Determining FactorsDocument10 pagesTechnical Efficiency in Agriculture in Ghana Analyses of Determining FactorsAlexander DeckerPas encore d'évaluation

- Design of A Process Layout PomDocument12 pagesDesign of A Process Layout PomHendi HendriansyahPas encore d'évaluation

- Methods of Data AnalysisDocument6 pagesMethods of Data AnalysistemesgenPas encore d'évaluation

- Factors Affecting Software Maintenance Productivity: An Exploratory S T U D Y 1Document16 pagesFactors Affecting Software Maintenance Productivity: An Exploratory S T U D Y 1nidhinsPas encore d'évaluation

- 2017 Purshase and Storage ModelDocument16 pages2017 Purshase and Storage ModelMichelle RuizPas encore d'évaluation

- Tomato Cultivation EconomicsDocument9 pagesTomato Cultivation EconomicsMaes SamPas encore d'évaluation

- Coelii EfikasnostDocument22 pagesCoelii Efikasnostsladjanapaunovic11Pas encore d'évaluation

- SSRN Id4034034Document19 pagesSSRN Id4034034tegenuzewde2018Pas encore d'évaluation

- Smart RefineryDocument22 pagesSmart RefineryVeeramuthu100% (1)

- Developing Bankable Business Plans: A Learning Guide for Forest Producers and Their OrganizationsD'EverandDeveloping Bankable Business Plans: A Learning Guide for Forest Producers and Their OrganizationsPas encore d'évaluation

- Earned Value Management: A Global and Cross-Industry Perspective on Current EVM PracticeD'EverandEarned Value Management: A Global and Cross-Industry Perspective on Current EVM PracticePas encore d'évaluation

- Synergies and Trade-Offs in Climate-Smart Agriculture: An Approach to Systematic AssessmentD'EverandSynergies and Trade-Offs in Climate-Smart Agriculture: An Approach to Systematic AssessmentPas encore d'évaluation

- Operations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationD'EverandOperations Management in Automotive Industries: From Industrial Strategies to Production Resources Management, Through the Industrialization Process and Supply Chain to Pursue Value CreationPas encore d'évaluation

- (39-47) Consumerism A Pillar of Social Welfare Indian PerspectiveDocument9 pages(39-47) Consumerism A Pillar of Social Welfare Indian PerspectiveiistePas encore d'évaluation

- (21-27) Role of Right To Information Act 2005 in The Human DevelopmentDocument7 pages(21-27) Role of Right To Information Act 2005 in The Human DevelopmentiistePas encore d'évaluation

- (10-15) A Relationship Between Emotional Intelligence and Self EsteemDocument6 pages(10-15) A Relationship Between Emotional Intelligence and Self Esteemiiste100% (1)

- Study The Rheological and Mechanical Properties of PVADocument7 pagesStudy The Rheological and Mechanical Properties of PVAiistePas encore d'évaluation

- 861 2048 1 SMDocument9 pages861 2048 1 SMkhaliddarwish1962Pas encore d'évaluation

- Study of Ground Water in Perungudi Area of ChennaiDocument9 pagesStudy of Ground Water in Perungudi Area of ChennaiiistePas encore d'évaluation

- Stock Market Volatility and Macro Economic Variables Volatility in Nigeria An Exponential GARCH ApproachDocument15 pagesStock Market Volatility and Macro Economic Variables Volatility in Nigeria An Exponential GARCH ApproachiistePas encore d'évaluation

- 4th Sem Electrical AliiedDocument1 page4th Sem Electrical AliiedSam ChavanPas encore d'évaluation

- Apm p5 Course NotesDocument267 pagesApm p5 Course NotesMusumbulwe Sue MambwePas encore d'évaluation

- Convention On The Rights of Persons With Disabilities: United NationsDocument13 pagesConvention On The Rights of Persons With Disabilities: United NationssofiabloemPas encore d'évaluation

- Phase 1: API Lifecycle (2 Days)Document3 pagesPhase 1: API Lifecycle (2 Days)DevendraPas encore d'évaluation

- BCG - Your Capabilities Need A Strategy - Mar 2019Document9 pagesBCG - Your Capabilities Need A Strategy - Mar 2019Arthur CahuantziPas encore d'évaluation

- Interruptions - 02.03.2023Document2 pagesInterruptions - 02.03.2023Jeff JeffPas encore d'évaluation

- BMA Recital Hall Booking FormDocument2 pagesBMA Recital Hall Booking FormPaul Michael BakerPas encore d'évaluation

- STM - Welding BookDocument5 pagesSTM - Welding BookAlvin MoollenPas encore d'évaluation

- DC Servo MotorDocument6 pagesDC Servo MotortaindiPas encore d'évaluation

- Everlube 620 CTDSDocument2 pagesEverlube 620 CTDSchristianPas encore d'évaluation

- Digital LiteracyDocument19 pagesDigital Literacynagasms100% (1)

- Introduction To Motor DrivesDocument24 pagesIntroduction To Motor Drivessukhbat sodnomdorjPas encore d'évaluation

- Perkins 20 Kva (404D-22G)Document2 pagesPerkins 20 Kva (404D-22G)RavaelPas encore d'évaluation

- Use of EnglishDocument4 pagesUse of EnglishBelén SalituriPas encore d'évaluation

- Hexoskin - Information For Researchers - 01 February 2023Document48 pagesHexoskin - Information For Researchers - 01 February 2023emrecan cincanPas encore d'évaluation

- Anaphylaxis Wallchart 2022Document1 pageAnaphylaxis Wallchart 2022Aymane El KandoussiPas encore d'évaluation

- 06-Apache SparkDocument75 pages06-Apache SparkTarike ZewudePas encore d'évaluation

- Epidemiologi DialipidemiaDocument5 pagesEpidemiologi DialipidemianurfitrizuhurhurPas encore d'évaluation

- Using Boss Tone Studio For Me-25Document4 pagesUsing Boss Tone Studio For Me-25Oskar WojciechowskiPas encore d'évaluation

- Arduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash GuptaDocument3 pagesArduino Based Voice Controlled Robot: Aditya Chaudhry, Manas Batra, Prakhar Gupta, Sahil Lamba, Suyash Guptaabhishek kumarPas encore d'évaluation

- Engineering Notation 1. 2. 3. 4. 5.: T Solution:fDocument2 pagesEngineering Notation 1. 2. 3. 4. 5.: T Solution:fJeannie ReguyaPas encore d'évaluation

- Week 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student HandoutDocument3 pagesWeek 8: ACCG3001 Organisational Planning and Control Tutorial In-Class Exercise - Student Handoutdwkwhdq dwdPas encore d'évaluation

- Continue: Rudolf Bultmann Theology of The New Testament PDFDocument3 pagesContinue: Rudolf Bultmann Theology of The New Testament PDFpishoi gerges0% (1)

- Low Cost Building ConstructionDocument15 pagesLow Cost Building ConstructionAtta RehmanPas encore d'évaluation

- On CatiaDocument42 pagesOn Catiahimanshuvermac3053100% (1)

- Lending OperationsDocument54 pagesLending OperationsFaraz Ahmed FarooqiPas encore d'évaluation

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDocument27 pagesSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunPas encore d'évaluation

- Cic Tips Part 1&2Document27 pagesCic Tips Part 1&2Yousef AlalawiPas encore d'évaluation

- MRT Mrte MRTFDocument24 pagesMRT Mrte MRTFJonathan MoraPas encore d'évaluation

- Shahroz Khan CVDocument5 pagesShahroz Khan CVsid202pkPas encore d'évaluation