Académique Documents

Professionnel Documents

Culture Documents

Detecting Susceptibility To Intergranular Corrosion: Seminar ON

Transféré par

Devashish JoshiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Detecting Susceptibility To Intergranular Corrosion: Seminar ON

Transféré par

Devashish JoshiDroits d'auteur :

Formats disponibles

SEMINAR ON

DETECTING SUSCEPTIBILITY TO INTERGRANULAR CORROSION

PREPARED BY: NAME: TRUSHIT K. NASHIKKAR ROLL NO. : 913

INTERGRANULAR CORROSION

The microstructure of metals and alloys is made up of grains, separated by grain boundaries. Intergranular corrosion is localized attack along the grain boundaries, or immediately adjacent to grain boundaries, while the bulk of the grains remain largely unaffected. This form of corrosion is usually associated with chemical segregation effects (impurities have a tendency to be enriched at grain boundaries) or specific phases precipitated on the grain boundaries. Such precipitation can produce zones of reduced corrosion resistance in the immediate vicinity.

MECHANISM

Microscope view of a polished cross section of a material attacked by intergranular corrosion What causes intergranular corrosion?

This type of attack results from local differences in composition, such as coring commonly encountered in alloy castings. Grain boundary precipitation, notably chromium carbides in stainless steels, is a well recognized and accepted mechanism of intergranular corrosion. The precipitation of chromium carbides consumed the alloying element - chromium from a narrow band along the grain boundary and this makes the zone anodic to the unaffected grains. The chromium depleted zone becomes the preferential path for corrosion attack or crack propagation if under tensile stress.

CHROMIUM PROFILE ACROSS GRAIN:

In nickel alloys and austenitic stainless steels, where chromium is added for corrosion resistance, the mechanism involved is formation of chromium carbide at the grain boundaries, forming chromiumdepleted zones (this process is called sensitization).

Around 12% chromium is minimally required to ensure passivation, mechanism by which a thin invisible layer forms at the surface of stainless steels. This layer protects the metal from environments and it is, thus, stainless.

corrosive boundary

Selective leaching often depletion mechanisms.

involve

grain

These zones also act as local galvanic couples, causing local galvanic corrosion.

This condition happens when the material is heated to temperature around 700 C for too long time, and often happens during welding or an improper heat treatment.

When zones of such material form due to welding, the resulting corrosion is termed weld decay.

Stainless steels can be stabilized against this behavior by addition oftitanium, niobium, or tantalum, which form titanium carbide, niobium carbide and tantalum carbide preferentially to chromium carbide, by lowering the content of carbon in the steel and in case of welding also in the filler metal under 0.02%, or by heating the entire part above 1000 C and quenching it in water, leading to dissolution of the chromium carbide in the grains and then preventing its precipitation.

Another possibility is to keep the welded parts thin enough so that, upon cooling, the metal dissipates heat too quickly for chromium carbide to precipitate.

Other related kind of intergranular termed knifeline attack (KLA).

corrosion

is

Knifeline attack impacts steels stabilized by niobium, such as 347 stainless steel.

Titanium, niobium, and their carbides dissolve in steel at very high temperatures.

At some cooling regimes, niobium carbide does not precipitate, and the steel then behaves like unstabilized steel, forming chromium carbide instead.

This affects only a thin zone several millimeters wide in the very vicinity of the weld, making it difficult to spot and increasing the corrosion speed. Structures made of such steels have to be heated in a whole to about 1950 F, when the chromium carbide dissolves and niobium carbide forms. The cooling rate after this treatment is not important, as the carbon that would otherwise pose risk of formation of chromium carbide is already sequestered as niobium carbide.

The photos above show the microstructure of a type 304 stainless steel. The figure on the left is the normalized microstructure and the one on the right is the "sensitized" structure and is susceptible to intergranular corrosion or intergranular stress corrosion cracking.

Figure : Intergranular corrosion of a failed aircraft component made of 7075-T6 aluminum

Many aluminum base alloys are susceptible to intergranular corrosion on account of either phases anodic to aluminum being present along grain boundaries or due to depleted zones of copper adjacent to grain boundaries in copper-containing alloys. High strength aluminium alloys, especially when extruded or otherwise subjected to high degree of working, can undergo exfoliation corrosion. Here the corrosion products build up between the flat, elongated grains and separate them, resulting in lifting or leafing effect and often propagating from edges of the material through its entire structure. Intergranular corrosion is a concern especially for alloys with high content of copper.

Other kinds of alloys can undergo exfoliation as well; the sensitivity of cupronickel increases together with its nickel content. A broader term for this class of corrosion is lamellar corrosion. Alloys of iron are susceptible to lamellar corrosion, as the volume of iron oxides is about seven times higher than the volume of original metal, leading to formation of internal tensile stresses tearing the material apart.

Similar effect leads to formation of lamellae in stainless steels, due to the difference of thermal expansion of the oxides and the metal. Copper-based alloys become sensitive when depletion of copper content in the grain boundaries occurs.

Anisotropic alloys, where extrusion or heavy working leads to formation of long, flat grains, are especially prone to intergranular corrosion. Intergranular corrosion induced by environmental stresses is termed as stress corrosion cracking.

Intergranular corrosion can be detected by ultrasonic and eddy current methods.

SENSITIZATION EFFECT

Sensitization of metals involves the creation of galvanic corrosion cells within the microstructure of an alloy. Certain alloys when exposed to a temperature characterized as a sensitizing temperature become particularly susceptible to intergranular corrosion.

In a corrosive atmosphere, the grain interfaces of these sensitized alloys become very reactive and intergranular corrosion results.

This is characterized by a localized attack at an adjacent to grain boundaries with relatively little corrosion of the grains themselves.

The alloy disintegrates (grains fall out) and/or loses its strength.

Intergranular corrosion is generally considered to be caused by the segregation of impurities at the grain boundaries or by enrichment or depletion of one of the alloying elements in the grain boundary areas. Thus in certain aluminium alloys, small amounts of iron have been shown to segregate in the grain boundaries and cause intergranular corrosion. Also, it has been shown that the zinc content of a brass is higher at the grain boundaries and subject to such corrosion.

High-strength aluminium alloys such as the Duralumintype alloys (Al-Cu) which depend upon precipitated phases for strengthening are susceptible to intergranular corrosion following sensitization at temperatures of about 120C. Nickel-rich alloys such as Inconel 600 and Incoloy 800 show similar susceptibility. Die-cast zinc alloys containing aluminum intergranular corrosion by steam in a atmosphere. exhibit marine

Cr-Mn and Cr-Mn-Ni steels are also susceptible to intergranular corrosion following sensitization in the temperature range of 400-850C. In the case of the austenitic stainless steels, when these steels are sensitized by being heated in the temperature range of about 500 to 800C, depletion of chromium in the grain boundary region occurs, resulting in susceptibility to intergranular corrosion. Such sensitization of austenitic stainless steels can readily occur because of temperature service requirements, as in steam generators, or as a result of subsequent welding of the formed structure. Several methods have been used to control or minimize the intergranular corrosion of susceptible alloys, particularly of the austenitic stainless steels.

Thus a high-temperature solutionheat treatment, commonly termed solution-annealing, quenchannealing or solution-quenching, has been used.

The alloy is heated to a temperature of about 1,060 to 1,120C and then water quenched.

This method is generally unsuitable for treating large assemblies, and also ineffective where welding is subsequently used for making repairs or for attaching other structures.

Another control technique for preventing intergranular corrosion involves incorporating strong carbide formers or stabilizing elements such as niobium or titanium in the stainless steels.

Such elements have a much greater affinity for carbon than does chromium; carbide formation with these elements reduces the carbon available in the alloy for formation of chromium carbides.

Or the stainless steel may initially be reduced in carbon content below 0.03 percent so that insufficient carbon is provided for carbide formation.

These techniques are expensive and only partially effective since sensitization may occur with time.

The low-carbon steels also frequently exhibit lower strengths at high temperatures.

REFERENCES: 1. en.wikipedia.org/wiki/Intergranular_corrosion 2. corrosion-doctors.org/FormsIntergranular/intergranular.htm 3. www.corrosionclinic.com

Vous aimerez peut-être aussi

- Intergranular CorrosionDocument4 pagesIntergranular CorrosionMecha EngrPas encore d'évaluation

- Intercrystalline CorrosionDocument24 pagesIntercrystalline Corrosionlu190765Pas encore d'évaluation

- W-2&3 Corrosion and Its TypesDocument46 pagesW-2&3 Corrosion and Its TypesUsamaPas encore d'évaluation

- ChirayuDocument15 pagesChirayuDevashish JoshiPas encore d'évaluation

- Corrosion and Its TypesDocument68 pagesCorrosion and Its TypesBilal AhmadPas encore d'évaluation

- Corrosion and Its TypesDocument68 pagesCorrosion and Its Typeshafiz ahmedPas encore d'évaluation

- TrushitDocument22 pagesTrushitDevashish JoshiPas encore d'évaluation

- Intergranular Corrosion 05Document32 pagesIntergranular Corrosion 05Tayyab Ahsan100% (1)

- Prevention From Inter-Granual CorrosionDocument7 pagesPrevention From Inter-Granual CorrosionDevashish JoshiPas encore d'évaluation

- Corrosion ModuleDocument26 pagesCorrosion ModuleRamakrishnan AmbiSubbiahPas encore d'évaluation

- Materials Degradation: Understanding Corrosion and its FormsDocument18 pagesMaterials Degradation: Understanding Corrosion and its FormsAustin Okoth OmondiPas encore d'évaluation

- Corrosion and Corrosion ControlDocument26 pagesCorrosion and Corrosion Controlahmedhammad7838Pas encore d'évaluation

- Forms of Corrosion: CHE-545-172 DR Ime B.ObotDocument17 pagesForms of Corrosion: CHE-545-172 DR Ime B.ObotAnonymous NxpnI6jCPas encore d'évaluation

- Corrosion Failures: Thirunavukarasu.H 13MY12Document47 pagesCorrosion Failures: Thirunavukarasu.H 13MY12soundrapandianPas encore d'évaluation

- Corrosion Protection Methods for SteelDocument21 pagesCorrosion Protection Methods for SteelShruti SinhaPas encore d'évaluation

- 02 Forms of CorrosionDocument41 pages02 Forms of CorrosionNino AngobPas encore d'évaluation

- Sensitization Definition - Loss of Alloy Integrity from Chromium DepletionDocument2 pagesSensitization Definition - Loss of Alloy Integrity from Chromium DepletionKanzul FadhilPas encore d'évaluation

- Stainless SteelsDocument16 pagesStainless SteelsGnobelPas encore d'évaluation

- Chapter 3. Corrosion of MetalsDocument48 pagesChapter 3. Corrosion of MetalsEjaj Siddiqui100% (2)

- Metal Corrosion and Its Prevention: Material ScienceDocument49 pagesMetal Corrosion and Its Prevention: Material Sciencedr nfPas encore d'évaluation

- Types of CorrosionDocument53 pagesTypes of CorrosionFelix Julio Céspedes Soto100% (3)

- Intergranular CorrosionDocument26 pagesIntergranular CorrosionIvan RiansaPas encore d'évaluation

- Nidhi Shah ContentDocument6 pagesNidhi Shah ContentDevashish JoshiPas encore d'évaluation

- Study Material - CorrosionDocument10 pagesStudy Material - CorrosionIScourse materialPas encore d'évaluation

- Super AlloysDocument17 pagesSuper AlloysMohamed WahidPas encore d'évaluation

- ENVIRONMENTAL DEGRADATION OF MATERIALSDocument30 pagesENVIRONMENTAL DEGRADATION OF MATERIALSSanketDesai100% (1)

- Jenis Korosi Berdasarkan BentuknyaDocument52 pagesJenis Korosi Berdasarkan Bentuknyaari195Pas encore d'évaluation

- Electrochemistry XIDocument30 pagesElectrochemistry XISalma RasyidahPas encore d'évaluation

- Types of Corrosion 1Document30 pagesTypes of Corrosion 1Lion ManabatPas encore d'évaluation

- Intergranular CorrosionDocument20 pagesIntergranular CorrosionD'yana RusdiPas encore d'évaluation

- Stainless SteelDocument40 pagesStainless SteelHarshita DabasPas encore d'évaluation

- Corrosion and TypesDocument34 pagesCorrosion and Typesparamaguru vPas encore d'évaluation

- Cswip, NotesDocument2 pagesCswip, NotesYuvaraja kPas encore d'évaluation

- Defects in GalvanizingDocument10 pagesDefects in GalvanizingSreedhar Patnaik.M75% (4)

- Proteksi InggrisDocument9 pagesProteksi Inggrisbo_lankPas encore d'évaluation

- Designing Aluminium-Bronze Castings for Strength & Corrosion ResistanceDocument17 pagesDesigning Aluminium-Bronze Castings for Strength & Corrosion Resistancepoom2007100% (1)

- Inclusions in SteelsDocument31 pagesInclusions in SteelsJatin BangaliPas encore d'évaluation

- Case Study Forms of Corrosion: Chemical Engineering DeptDocument41 pagesCase Study Forms of Corrosion: Chemical Engineering DeptBAKRPas encore d'évaluation

- CorrosionDocument16 pagesCorrosionالGINIRAL FREE FIREPas encore d'évaluation

- Thermal Spray Coating For Steel ProcessingDocument5 pagesThermal Spray Coating For Steel ProcessingRamkiyengarPas encore d'évaluation

- Corrosion Mechanisms and Prevention MethodsDocument32 pagesCorrosion Mechanisms and Prevention MethodsSWAGATAM BAZPas encore d'évaluation

- TYPES OF CORROSION: PITTING, GALVANIC, INTERGRANULAR & MOREDocument8 pagesTYPES OF CORROSION: PITTING, GALVANIC, INTERGRANULAR & MORENiranjana SivaPas encore d'évaluation

- Ss Wire Properties / Orthodontic Courses by Indian Dental AcademyDocument79 pagesSs Wire Properties / Orthodontic Courses by Indian Dental Academyindian dental academyPas encore d'évaluation

- Corroision TypesDocument27 pagesCorroision Typesmohsin razaPas encore d'évaluation

- Scaling in BoilersDocument12 pagesScaling in BoilersVikneswaran BalakrishnaPas encore d'évaluation

- Uniform CorrosionDocument33 pagesUniform CorrosionImmalatulhusnaPas encore d'évaluation

- Corrosion of Orthopedic MaterialsDocument21 pagesCorrosion of Orthopedic MaterialsWasim R. IssaPas encore d'évaluation

- Corrosion Analysis of Stainless Steel: Seifedine KadryDocument9 pagesCorrosion Analysis of Stainless Steel: Seifedine KadryMarcos GonzalezPas encore d'évaluation

- Stainless SteelDocument24 pagesStainless SteelsmrutiPas encore d'évaluation

- Casting of AluminiumDocument36 pagesCasting of AluminiumRezza RuzuqiPas encore d'évaluation

- 1-Introduction To CorrosionDocument112 pages1-Introduction To Corrosionazerai2000Pas encore d'évaluation

- Hot Dip GalvanizingDocument38 pagesHot Dip Galvanizingtmmsekar100% (1)

- Corrosion: IntroducingDocument29 pagesCorrosion: Introducingkeval patelPas encore d'évaluation

- Types of CorrosionDocument25 pagesTypes of CorrosionPandia RajanPas encore d'évaluation

- Stainless Steel Corrosion in Acidic EnvironmentsDocument10 pagesStainless Steel Corrosion in Acidic EnvironmentsPrateep UntimanonPas encore d'évaluation

- RM01 - 17 18 Case Study Welding of Aluminium AlloyDocument12 pagesRM01 - 17 18 Case Study Welding of Aluminium AlloyAnonymous cgcKzFtXPas encore d'évaluation

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkD'EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkPas encore d'évaluation

- Why Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksD'EverandWhy Do Metals Rust? An Easy Read Chemistry Book for Kids | Children's Chemistry BooksPas encore d'évaluation

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelD'EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelPas encore d'évaluation

- Seminar ON Significance of H - H O-O Lines in Pourbaix DiagarmDocument10 pagesSeminar ON Significance of H - H O-O Lines in Pourbaix DiagarmDevashish JoshiPas encore d'évaluation

- Vipul Mevasiya ContentDocument15 pagesVipul Mevasiya ContentDevashish JoshiPas encore d'évaluation

- A Seminar On Cathodic Protection TechniquesDocument9 pagesA Seminar On Cathodic Protection TechniquesDevashish JoshiPas encore d'évaluation

- Mitesh ContentDocument18 pagesMitesh ContentDevashish JoshiPas encore d'évaluation

- Krunal Vora ContentDocument14 pagesKrunal Vora ContentDevashish JoshiPas encore d'évaluation

- Sumit ContentDocument6 pagesSumit ContentDevashish JoshiPas encore d'évaluation

- Ronak Mehta ContentDocument12 pagesRonak Mehta ContentDevashish JoshiPas encore d'évaluation

- Nidhi Shah ContentDocument6 pagesNidhi Shah ContentDevashish JoshiPas encore d'évaluation

- Types of Methods of Powder Production:: Physico Chemical Processes Are As UnderDocument11 pagesTypes of Methods of Powder Production:: Physico Chemical Processes Are As UnderDevashish JoshiPas encore d'évaluation

- Parth ContentDocument9 pagesParth ContentDevashish JoshiPas encore d'évaluation

- Electric Discharg Machining: Parikh Krutik R. ROLL NO.931Document6 pagesElectric Discharg Machining: Parikh Krutik R. ROLL NO.931Devashish JoshiPas encore d'évaluation

- Metallic Coatings For Corrosion PreventionDocument9 pagesMetallic Coatings For Corrosion PreventionDevashish JoshiPas encore d'évaluation

- Ankur ContentDocument6 pagesAnkur ContentDevashish JoshiPas encore d'évaluation

- A Seminar On Electrolytic Production of Metallic Powder: Prepared By: Darshit Fadadu ROLL NO: 938Document13 pagesA Seminar On Electrolytic Production of Metallic Powder: Prepared By: Darshit Fadadu ROLL NO: 938Devashish JoshiPas encore d'évaluation

- Gaurav Chudasama ContentDocument11 pagesGaurav Chudasama ContentDevashish JoshiPas encore d'évaluation

- TrushitDocument22 pagesTrushitDevashish JoshiPas encore d'évaluation

- Dinkar Kokje ContentDocument8 pagesDinkar Kokje ContentDevashish JoshiPas encore d'évaluation

- Corrosion in Various Environments and Their RoleDocument9 pagesCorrosion in Various Environments and Their RoleDevashish JoshiPas encore d'évaluation

- VaishaliDocument15 pagesVaishaliDevashish JoshiPas encore d'évaluation

- Arjun ContentDocument13 pagesArjun ContentDevashish JoshiPas encore d'évaluation

- Electrometallurgy and Corrosion Seminar On Fuel Cells: Name: Anirudh Gupta ROLL NO.: 902 YEAR: 2011Document10 pagesElectrometallurgy and Corrosion Seminar On Fuel Cells: Name: Anirudh Gupta ROLL NO.: 902 YEAR: 2011Devashish JoshiPas encore d'évaluation

- Prevention From Inter-Granual CorrosionDocument7 pagesPrevention From Inter-Granual CorrosionDevashish JoshiPas encore d'évaluation

- Anil Vaghamshi ContentDocument6 pagesAnil Vaghamshi ContentDevashish JoshiPas encore d'évaluation

- Tushal KyadaDocument11 pagesTushal KyadaDevashish JoshiPas encore d'évaluation

- Seminar Topic On Galvanic Corrosion ParametersDocument6 pagesSeminar Topic On Galvanic Corrosion ParametersDevashish JoshiPas encore d'évaluation

- SUMITDocument27 pagesSUMITDevashish JoshiPas encore d'évaluation

- VibhanshuDocument21 pagesVibhanshuDevashish JoshiPas encore d'évaluation

- Fe-H2O System in Pourbaix Diagram: Seminar Topic OnDocument21 pagesFe-H2O System in Pourbaix Diagram: Seminar Topic OnDevashish JoshiPas encore d'évaluation

- Ronak MehtaDocument17 pagesRonak MehtaDevashish JoshiPas encore d'évaluation

- Victron MultiPlus 48 1200-13-16 Datasheet enDocument1 pageVictron MultiPlus 48 1200-13-16 Datasheet enBAHJARI AMINEPas encore d'évaluation

- AAU5243 DescriptionDocument30 pagesAAU5243 DescriptionWisut MorthaiPas encore d'évaluation

- Obiafatimajane Chapter 3 Lesson 7Document17 pagesObiafatimajane Chapter 3 Lesson 7Ayela Kim PiliPas encore d'évaluation

- Application D2 WS2023Document11 pagesApplication D2 WS2023María Camila AlvaradoPas encore d'évaluation

- ExpDocument425 pagesExpVinay KamatPas encore d'évaluation

- The Changing Face of War - Into The Fourth GenerationDocument5 pagesThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozPas encore d'évaluation

- Spsi RDocument2 pagesSpsi RBrandy APas encore d'évaluation

- Cinema 4D ShortcutsDocument8 pagesCinema 4D ShortcutsAnonymous 0lRguGPas encore d'évaluation

- Ali ExpressDocument3 pagesAli ExpressAnsa AhmedPas encore d'évaluation

- Control SystemsDocument269 pagesControl SystemsAntonis SiderisPas encore d'évaluation

- Judge Vest Printable PatternDocument24 pagesJudge Vest Printable PatternMomPas encore d'évaluation

- Rheology of Polymer BlendsDocument10 pagesRheology of Polymer Blendsalireza198Pas encore d'évaluation

- Easa Ad Us-2017-09-04 1Document7 pagesEasa Ad Us-2017-09-04 1Jose Miguel Atehortua ArenasPas encore d'évaluation

- Ground Water Resources of Chennai DistrictDocument29 pagesGround Water Resources of Chennai Districtgireesh NivethanPas encore d'évaluation

- S2 Retake Practice Exam PDFDocument3 pagesS2 Retake Practice Exam PDFWinnie MeiPas encore d'évaluation

- May, 2013Document10 pagesMay, 2013Jakob Maier100% (1)

- Roadmap For Digitalization in The MMO Industry - For SHARINGDocument77 pagesRoadmap For Digitalization in The MMO Industry - For SHARINGBjarte Haugland100% (1)

- Henny Penny 500-561-600 TM - FINAL-FM06-009 9-08Document228 pagesHenny Penny 500-561-600 TM - FINAL-FM06-009 9-08Discman2100% (2)

- Programming Language Foundations PDFDocument338 pagesProgramming Language Foundations PDFTOURE100% (2)

- Digital Communication Quantization OverviewDocument5 pagesDigital Communication Quantization OverviewNiharika KorukondaPas encore d'évaluation

- Newcomers Guide To The Canadian Job MarketDocument47 pagesNewcomers Guide To The Canadian Job MarketSS NairPas encore d'évaluation

- Unit 1 Writing. Exercise 1Document316 pagesUnit 1 Writing. Exercise 1Hoài Thương NguyễnPas encore d'évaluation

- Liber Chao (Final - Eng)Document27 pagesLiber Chao (Final - Eng)solgrae8409100% (2)

- Sieve Shaker: Instruction ManualDocument4 pagesSieve Shaker: Instruction ManualinstrutechPas encore d'évaluation

- Translation EquivalenceDocument6 pagesTranslation EquivalenceJamal Anwar TahaPas encore d'évaluation

- BMS Technical ManualDocument266 pagesBMS Technical Manualiago manziPas encore d'évaluation

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis VinoPas encore d'évaluation

- NameDocument5 pagesNameMaine DagoyPas encore d'évaluation

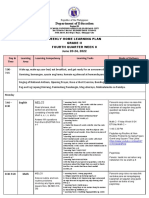

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Document8 pagesDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIOPas encore d'évaluation

- Distinguish Between Tax and FeeDocument2 pagesDistinguish Between Tax and FeeRishi Agarwal100% (1)