Académique Documents

Professionnel Documents

Culture Documents

Casting

Transféré par

Priyaanku TonkDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Casting

Transféré par

Priyaanku TonkDroits d'auteur :

Formats disponibles

247.

Skeleton Patterns

The skeleton pattern is well adapted to irregular hollow castings, such as the steam nozzle with three outlets, a drawing of which is shown in Fig. 115. The pattern is made in two parts divided along the plane of symmetry AB. In building this pattern, the three outlet flanges are built in halves of segment work, and these are joined by skeleton framing made up as a backbone, ribs and battens for each half. The marking-off table may be used to great advantage in this work. Fig. 116 is a simple form of skeleton pattern shown merely to illustrate the method of building and using this kind of pattern. This is the pattern of a plain length of cylindrical pipe. Each half is formed of a backbone, two ribs, and four battens. The lower half of the pattern is made so that the inner surfaces of the backbone and other parts are faired to the contour of the inner surface of the casting, and the upper half is made so that its outer surfaces are faired to the contour of the outer surface of the casting. The battens C occupy part of the space of the walls of the casting.

Fig. 116. In making a mould from this type of pattern, the moulder beds the lower half of the pattern in the sand of the lower half of the mould, making the parting along the line 1, 2, 3, 4, 5. The core for the casting is then formed of sand and other materials in the space enclosed between the two halves of the pattern. The core is built up as far as can be done before placing the upper half of the pattern. When this half is placed, the core surface is carried to the outline of the semi-circle 6. Non-plastic pasting sand is sprinkled over this surface (as was done over the joints 1, 2, 3, 4, 5) and the upper half of the mould is built thereon. When completed, the upper half of the mould is lifted off, and the sand is scraped from between the several battens and backbone joining the two end ribs of the upper half of the pattern by means of the small strike or strickle 8, which scrapes away the sand to the thickness of the batterns c. The upper half of the pattern is then lifted away, exposing the true surface of the upper half of the core. The core is then lifted out, and the strike T is used to scrape away the sand between the longitudinal parts of the lower half of the pattern, after which this half is lifted out. The strikes 8 and T have scraped out the sand which occupied the space for the casting. After the lower half of the pattern is lifted out, the mould is smoothed, the cavities left by the four end ribs are filled to the extent needed, and the core is replaced in the mould. The mould is now complete, ready for pouring.

Vous aimerez peut-être aussi

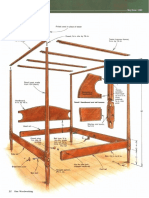

- Wood Magazine - 3 in One Bed For All Ages Part 1Document4 pagesWood Magazine - 3 in One Bed For All Ages Part 1clnieto2450% (2)

- Casting Expt 2Document5 pagesCasting Expt 2Shashank PhansikarPas encore d'évaluation

- EZSalad TongsDocument3 pagesEZSalad TongsBSulliPas encore d'évaluation

- 041 X Sa2 01 c1 QP MathematicsDocument12 pages041 X Sa2 01 c1 QP MathematicsGeetika KhuranaPas encore d'évaluation

- Make A Wood Hand Plane in An AfternoonDocument10 pagesMake A Wood Hand Plane in An AfternoonrhinorodPas encore d'évaluation

- Curtiss O-52 - A Free-Flight Model AirplaneDocument5 pagesCurtiss O-52 - A Free-Flight Model AirplaneBob KowalskiPas encore d'évaluation

- Step-By-Step Building Instructions For the B19 and B20 Gyro СoptersDocument8 pagesStep-By-Step Building Instructions For the B19 and B20 Gyro СopterspuchemPas encore d'évaluation

- Bedside Table With Breadboard Ends: Christopher SwingleyDocument2 pagesBedside Table With Breadboard Ends: Christopher SwingleyOwen MontillaPas encore d'évaluation

- Chapter 4 Surface Area and VolumeDocument49 pagesChapter 4 Surface Area and VolumeJojobaby51714100% (2)

- Junior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build DiggerDocument5 pagesJunior Backhoe: Half-Pint Sidewalk Superintendents Will Go Ape For This Boy-Size, Rugged, Easy-To-Build Diggermagatsu2099Pas encore d'évaluation

- Sa 4Document2 pagesSa 4Ari SudrajatPas encore d'évaluation

- Casting Project 1Document18 pagesCasting Project 1tamertunali100% (1)

- Gee Bee Super SportsterDocument8 pagesGee Bee Super SportsterAviation/Space History LibraryPas encore d'évaluation

- Subway Construction Using Tripled-Faced Shield Method and RC Seg-Ments in Soft GroundDocument7 pagesSubway Construction Using Tripled-Faced Shield Method and RC Seg-Ments in Soft GroundHarold TaylorPas encore d'évaluation

- Mesa Auxiliar Con CajonesDocument8 pagesMesa Auxiliar Con CajonesTETSUO111Pas encore d'évaluation

- How To Make A MicrotomeDocument2 pagesHow To Make A Microtomewoodbee2Pas encore d'évaluation

- Design For AssemblyDocument2 pagesDesign For AssemblysarbudeenddPas encore d'évaluation

- Paper 3Document10 pagesPaper 3Murthy VidyaPas encore d'évaluation

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideD'EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuidePas encore d'évaluation

- Baby DurationDocument5 pagesBaby DurationWilmer Chinomes PinzónPas encore d'évaluation

- Sand CastingDocument4 pagesSand Castingklawsis50% (2)

- The Surface Area of SolidsDocument14 pagesThe Surface Area of Solidsyarinaosu100% (1)

- Full Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Ebook PDF Integrated Advertising Promotion and Marketing Communications Global Edition 11Th Ebook PDF Docx Kindle Full Chapterhomer.owens120100% (24)

- 041 X SA2 16 B1 QP MathematicsDocument13 pages041 X SA2 16 B1 QP MathematicsDijah IsmailPas encore d'évaluation

- Lecture08-Development of SurfacesDocument57 pagesLecture08-Development of SurfacesKajal KhanPas encore d'évaluation

- Construir Moto ChopperDocument7 pagesConstruir Moto ChopperAngel Dure100% (2)

- 220 S. Torres-Garrido Et AlDocument2 pages220 S. Torres-Garrido Et AlAri SudrajatPas encore d'évaluation

- Cone DevelopmentDocument28 pagesCone Developmentprajwal86100% (2)

- Medieval Folding Stool - Popular WoodworkingDocument32 pagesMedieval Folding Stool - Popular WoodworkingplaytesteurPas encore d'évaluation

- The Pencil Post BedDocument6 pagesThe Pencil Post BedAnonymous QJ5j94luLmPas encore d'évaluation

- How Does The Ratio of Sand To Cement Affect The Strength of ConcreteDocument4 pagesHow Does The Ratio of Sand To Cement Affect The Strength of ConcreteMani Kandan ArunachalamPas encore d'évaluation

- Curtiss R-6 RacerDocument9 pagesCurtiss R-6 RacerAviation/Space History LibraryPas encore d'évaluation

- FALLING HeadDocument9 pagesFALLING Headjayantgupta28110Pas encore d'évaluation

- Arbor FinalDocument4 pagesArbor FinalAline Moser Nunes CoelhoPas encore d'évaluation

- RSW 3 - OutlineDocument7 pagesRSW 3 - OutlineJorisPas encore d'évaluation

- Chamfer PlaneDocument3 pagesChamfer PlaneFred171717100% (1)

- Shop Made SlotterDocument4 pagesShop Made Slotternevadablue100% (4)

- ### Nine Motor Boats and How To Build Them 1913Document136 pages### Nine Motor Boats and How To Build Them 1913admiradaoPas encore d'évaluation

- Krenov Style Hand Plane BuildDocument8 pagesKrenov Style Hand Plane BuildrhinorodPas encore d'évaluation

- Full Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full ChapterDocument22 pagesFull Download Original PDF Advanced Macroeconomics 4Th Edition by David Romer Ebook PDF Docx Kindle Full Chaptermary.grooms166100% (27)

- The Open Civil Engineering JournalDocument13 pagesThe Open Civil Engineering JournalPREM NAIDUPas encore d'évaluation

- 1/10 Scale Sport Hydro 1969 Notre DameDocument2 pages1/10 Scale Sport Hydro 1969 Notre Damewidian rienandaPas encore d'évaluation

- Roll Around Kitchen Cart: MLCS Items UsedDocument15 pagesRoll Around Kitchen Cart: MLCS Items UsedTETSUO111Pas encore d'évaluation

- Std 10_Math_Surface Area & Volumes_all Types Ques.Document11 pagesStd 10_Math_Surface Area & Volumes_all Types Ques.Guna DharshiniPas encore d'évaluation

- Paper - 2012 SA 2 Class - 10 Subjects - Mathematics (Areas Related To Circles and Surface Area and Volumes)Document5 pagesPaper - 2012 SA 2 Class - 10 Subjects - Mathematics (Areas Related To Circles and Surface Area and Volumes)Rahul WadhwaPas encore d'évaluation

- PepsistoveDocument5 pagesPepsistoveMark Anthony T. PadilPas encore d'évaluation

- Build A Skiff (1876) PDFDocument2 pagesBuild A Skiff (1876) PDFluisbraulinoPas encore d'évaluation

- Design and Development of Tacking and Welding Fixture For Mixing Drum of 10/7 Concrete MixerDocument5 pagesDesign and Development of Tacking and Welding Fixture For Mixing Drum of 10/7 Concrete MixerIJIRSTPas encore d'évaluation

- Wheel HubDocument12 pagesWheel HubSyafiq AlifPas encore d'évaluation

- Gasoline EngineDocument2 pagesGasoline EngineIkkasama NaguennePas encore d'évaluation

- Practice BookDocument20 pagesPractice BookWeteachPas encore d'évaluation

- Ch2 WorksheetDocument25 pagesCh2 WorksheetDheekshithaa SaravananPas encore d'évaluation

- DuctingDocument91 pagesDuctingapi-2734334210% (1)

- Digital Navy USS Arizona (2002 Ver. 1-250) PDFDocument44 pagesDigital Navy USS Arizona (2002 Ver. 1-250) PDFbamboobuckPas encore d'évaluation

- Mock-3 (Practice Paper)Document11 pagesMock-3 (Practice Paper)Sharif HossainPas encore d'évaluation

- Fundamentals of Model Airplane Part 5 PDFDocument6 pagesFundamentals of Model Airplane Part 5 PDFMarian PaunaPas encore d'évaluation

- CVP222 Falling Head Permeability TestDocument9 pagesCVP222 Falling Head Permeability Testjayantgupta28110Pas encore d'évaluation

- General Construction Tips Dagey RocksDocument23 pagesGeneral Construction Tips Dagey Rocksbiker110Pas encore d'évaluation

- Bamboo Building Material Strengths UsesDocument8 pagesBamboo Building Material Strengths UsesCyber VirginPas encore d'évaluation

- AWS CWI Part A T2Document24 pagesAWS CWI Part A T2Lala Bhai0% (1)

- Equipment Parker TallerDocument58 pagesEquipment Parker TallerHenryPas encore d'évaluation

- Three Storey Commercial Building (Concrete) - 18-009 - PinagsamaDocument21 pagesThree Storey Commercial Building (Concrete) - 18-009 - PinagsamaJohn Michael TalanPas encore d'évaluation

- SERIES 7000/8000: 3 Piece Full Port " - 12"Document8 pagesSERIES 7000/8000: 3 Piece Full Port " - 12"ErickPas encore d'évaluation

- Seminar PDFDocument12 pagesSeminar PDFTenzin WangchukPas encore d'évaluation

- Latest Company Profile of Jalmi ConstDocument11 pagesLatest Company Profile of Jalmi ConstArlyn OcampoPas encore d'évaluation

- Chapter 1 - Engineering Materials and Their Proper - 2012 - Engineering MaterialDocument12 pagesChapter 1 - Engineering Materials and Their Proper - 2012 - Engineering MaterialDavidPas encore d'évaluation

- Exercises 6.1, 7.1, 8.1 and 9.1Document2 pagesExercises 6.1, 7.1, 8.1 and 9.1peter vanderPas encore d'évaluation

- Production Technology Question BankDocument4 pagesProduction Technology Question BankShaik ShariffPas encore d'évaluation

- L&T Construction - Water & Effluent Treatment IC: Master List of Formwork ComponentsDocument21 pagesL&T Construction - Water & Effluent Treatment IC: Master List of Formwork ComponentsDheena ThayalanPas encore d'évaluation

- LAYING TECHNIQUES FOR MURAL WALL COVERINGSDocument2 pagesLAYING TECHNIQUES FOR MURAL WALL COVERINGScorzeaPas encore d'évaluation

- Comparing Quality & Yield Performance in January 2019Document7 pagesComparing Quality & Yield Performance in January 2019Aris SusantoPas encore d'évaluation

- Concrete Pipe vs HDPE Drainage Pipe: A Performance ComparisonDocument15 pagesConcrete Pipe vs HDPE Drainage Pipe: A Performance Comparisonyyanan1118Pas encore d'évaluation

- Gas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTDocument36 pagesGas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungPas encore d'évaluation

- Aluminim Welding Filler Material PDFDocument20 pagesAluminim Welding Filler Material PDFvishal bailurPas encore d'évaluation

- 3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Document22 pages3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Gaurav BedsePas encore d'évaluation

- BronzeDocument4 pagesBronzeGaurav Kumar SinghPas encore d'évaluation

- Geopolymer Ferrocement Panels Under Flexural Loading: Mohana Rajendran and Nagan SoundarapandianDocument11 pagesGeopolymer Ferrocement Panels Under Flexural Loading: Mohana Rajendran and Nagan SoundarapandianheminPas encore d'évaluation

- Sgebste1 21Document3 pagesSgebste1 21Ronnie1478Pas encore d'évaluation

- Steel-1 7131Document1 pageSteel-1 7131H. BeatsPas encore d'évaluation

- J.J.Shah PaperDocument10 pagesJ.J.Shah Paperइंजि कौस्तुभ पवारPas encore d'évaluation

- Architectural Powder - Mike WithersDocument36 pagesArchitectural Powder - Mike WithersPaulPas encore d'évaluation

- Drainage System Specifications for BuildingsDocument17 pagesDrainage System Specifications for Buildingskartick adhikaryPas encore d'évaluation

- Gyproc MF - 1 Layer Board (Rev 2) - BinderDocument19 pagesGyproc MF - 1 Layer Board (Rev 2) - BinderJanna BakeerPas encore d'évaluation

- Conventional Vs Non ConventionalDocument2 pagesConventional Vs Non Conventional3headsnakePas encore d'évaluation

- RCD 1Document25 pagesRCD 1Niña Amethyst AlivioPas encore d'évaluation

- SSH KPKNL 2021Document12 pagesSSH KPKNL 2021Taufik GeodetikPas encore d'évaluation

- SJS - DHT-Downhole Oil ToolsDocument156 pagesSJS - DHT-Downhole Oil ToolsTHUNDER KESAR1000Pas encore d'évaluation

- ASTMB917Document11 pagesASTMB917Five VanPas encore d'évaluation