Académique Documents

Professionnel Documents

Culture Documents

Champion Model CV Brochure - CV04-2010

Transféré par

Sunil BajpaiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Champion Model CV Brochure - CV04-2010

Transféré par

Sunil BajpaiDroits d'auteur :

Formats disponibles

CHAMPION WAFER CHECK VALVES SIZE RANGE 2" 72" ASME CLASS 125 2500

MATERIALS: IRON CARBON STEEL STAINLESS STEEL ALUMINUM BRONZE ALLOY 20 MONEL NICKEL

CHAMPION VALVES, INC.

DUAL DISC S PRING L OADED WAFER C HECK VALVES

FEATURES

Light weight, versatile design 80% to 90% less than conventional full-body swing check valves

BENEFITS

Simplifies piping Reduces thermal and seismic considerations Optimizes space utilization Lowers installation costs Reduces pipe supports Requires less number of man-hours Low cracking pressure and overall pressure drop Ensures positive closure Alleviates water hammer and resultant damaging effects

Dual Discs open to 85 degrees

Spring-loaded discs calculated to increase the responsiveness of the discs Extended long-leg spring

Prevents seat wear caused by scrubbing

GENERAL APPLICATION General service piping systems Water, oil, gasoline, chemicals Gas (compressible gases) Air (compressed air and blower) INSTALLATION

Champion wafer check valves are designed for installation in flanged piping systems, between two flanges. Valves may be installed in vertical or horizontal piping. Care must be taken to always install the valves with the shafts in a vertical position when installing in a horizontal pipeline. Vertical up flow is always a good installation. Consult factory for vertical down flow. Champion wafer check valves are designed to provide long service life if the velocity is kept within the flow rate shown in the table on page 7 and if a minimum of 5 pipe diameters of straight pipe in front of the valve is maintained downstream from a likely cause of turbulence (i.e., pump discharge, reducers or elbows).

INDUSTRY STANDARDS

ASME B16.1, B16.5, B16.34, B16.47 and B31.1 API 594 and 598 MSS-SP-25, MSS-SP-55 API 6A and 6D (as applicable) MSS-SP-61 (standard for the resilient seated, metal seated when required)

FIGURE NUMBER INFORMATION

DUAL DISC - WAFER BODY STYLE

CV - Standard Wafer CVR - Retainerless Wafer

ORDERING LETTER MATERIAL

BODY & DISCS

SPECIFICATION

ASME/API SERIES

12 15 25 30 40 60 90 150 250 = 125 Class = 150 Class = 250 Class = 300 Class = 400 Class = 600 Class = 900 Class = 1500 Class = 2500 Class

A B C D F G H J K L M N S T

Aluminum Bronze Bronze Carbon Steel Duplex Alloy 20 Cast Iron Hastelloy C276 410 Stainless Steel 317 Stainless Steel Ductile Iron Monel Nickel 316 Stainless Steel 304 Stainless Steel

ASTM B148, Alloy 952; BS 1400, Alloy AB2 ASTM B62, C83600 ASTM A216, Gr. WCB ASTM A351, Gr. CD4MCu ASTM A351, Gr. CN7M ASTM A126; Gr.B ASTM A494, Gr. CW12MW ASTM A217, Gr. CA15 (12% Cr) ASTM A351, Gr. CG8M ASTM A536; Gr. 65-45-12 ASTM A494, Gr. M-35-1 ASTM A494, Gr. CZ-100 ASTM A351, Gr. CF8M ASTM A351, Gr. CF8

SEAT

ORDERING LETTER MATERIAL OPERATING TEMPERATURE

C F

SPRING

ORDERING LETTER MATERIAL OPERATING TEMPERATURE

C F

B E H J L N P S T V

Buna-N EPDM Silicone 410 SS

Stellite Neoprene Integral Metal 316 SS Teflon Viton

- 57 to 120 -18 to 135 -18 to 260 - 267 to 537 -267 to 537 - 40 to 120 - 267 to 537 - 267 to 537 - 40 to 149 - 40 to 204

- 70 to 250 0 to 300 0 to 500 - 450 to 1000+ - 450 to 1000+ - 40 to 250 - 450 to 1000+ - 450 to 1000+ - 40 to 300 - 40 to 400

S M W X

316 SS Monel Inconel Inconel X-750

260 232 371 593

500 450 700 1100

END CONNECTION

ORDERING CONNECTIONS LETTER ORDERING LETTER

BODY CONFIGURATION

CONFIGURATION

P R RJ

Plain Face Serrated Raised Face Ring Joint

None(Blank) 1 2 3

Wafer style, inserted between mating flanges with studs spanning entire length Lug design with threaded holes bolted from each end Lug design with through-bolt holes to protect studs Double flanged design with valve flanges bolted to individual like flanges

EXAMPLE: Specifications Call for 6(150mm), Wafer Style Retainerless; ASME 300 Champion Wafer Check; 316 Stainless Steel Body; 316 SS Discs; Metal Seat; & Inconel X-750 Spring; Raised Face End Connection; Through Bolt Lug Body

6CVR30-SSPX-R2

SIZE STYLE PRESSURE CLASS BODY DISC SEAT SPRING END CONNECTION BODY CONFIGURATION MODIFICATION NUMBER

Assigned by Factory

6"

CVR

30

STYLE CV & CVR INSTALLATION DIMENSIONS*

*

Dimensions for lug and double flange body styles and bolting requirements are available upon request.

4 Champion Valves, Inc.

*Approximate weights and dimensionsApply for certified drawings. Dimensions available with DIN, JIS, AS and ISO. Sizes above 24 per ASME B16.47 Series A. Series B available if required.

STYLE CV & CVR INSTALLATION DIMENSIONS* (Continued)

*

*Approximate weights and dimensionsApply for certified drawings. Dimensions available with DIN, JIS, AS and ISO. Sizes above 24 per ASME B16.47 Series A. Series B available if required.

Champion Valves, Inc. 5

STYLE CV & CVR INSTALLATION DIMENSIONS* (Continued)

*Approximate weights and dimensionsApply for certified drawings. Dimensions available with DIN, JIS, AS and ISO. Sizes above 24 per ASME B16.47 Series A. Series B available if required.

PRESSURE DROP CALCULATIONS FOR GAS

Pressure drop for gas media across Champion Valves Wafer Check (in horizontal installation) can be determined using the following equation and Cv and Cracking Pressure shown for each valve size. Additional equations may be necessary in order to calculate the pressure drop.

6 Champion Valves, Inc.

NOTE: Contact Champion Valves, Inc. for Vertical Installation

TECHNICAL DATA

Application specific spring torques are available.

PRESSURE DROP CHART. This chart is based on flow of clean water at ambient temperature. Consult our engineering department for pressure drop information for steam, gases or viscous fluids. Consult factory for pressure drop of sizes larger than 48 inches.

GOOD PIPING PRACTICE recommends placement of check valves a distance equal to 5 pipe diameters from any turbulence producing device such as elbows, pumps, etc.

RECOMMENDED FLOW RATE RANGES

(Horizontal Installation)

Champion Valves, Inc. 7

EXCEPTIONAL QUALITY, SERVICE & RELIABILITY

Champion Valves, Inc.

P.O. Box 12901 Wilmington, N.C. 28405 USA phone: 910.794.5547 fax: 910.794.5581 email: sales@wafercheck.com visit our website at: www.WaferCheck.com

Please Contact Champion Valves, Inc. for the Following Check Valve Designs: Dual Disc Wafer Style Single Disc Wafer Style Nozzle Check

represented by:

cvi-cv 04.2010 printed in the usa

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- WCE5 SeriesDocument12 pagesWCE5 SeriescatalineulaPas encore d'évaluation

- PL 01-09-2020 Investment Casting Ball ValveDocument2 pagesPL 01-09-2020 Investment Casting Ball ValveSunil BajpaiPas encore d'évaluation

- Tax Invoice: Details of Receiver (Buyer Details)Document1 pageTax Invoice: Details of Receiver (Buyer Details)Sunil BajpaiPas encore d'évaluation

- AI ISO CertificateDocument1 pageAI ISO CertificateSunil BajpaiPas encore d'évaluation

- Ball Valve 6000 Psi Comes in NPT - BSP Male or Female. Size From 1 - 8 - To 2Document10 pagesBall Valve 6000 Psi Comes in NPT - BSP Male or Female. Size From 1 - 8 - To 2Sunil BajpaiPas encore d'évaluation

- Data Chart For Threads by MARYLANDDocument71 pagesData Chart For Threads by MARYLANDN.Palaniappan100% (6)

- PL 01-02-2020 Casted Valve PDFDocument7 pagesPL 01-02-2020 Casted Valve PDFSunil BajpaiPas encore d'évaluation

- 3", 4" and 6" 151/301 Wafer Ball ValvesDocument4 pages3", 4" and 6" 151/301 Wafer Ball ValvesSunil BajpaiPas encore d'évaluation

- Wcenim0027-01 en V53 V54Document16 pagesWcenim0027-01 en V53 V54Sunil BajpaiPas encore d'évaluation

- PL 01-02-2020 Casted Valve PDFDocument7 pagesPL 01-02-2020 Casted Valve PDFSunil BajpaiPas encore d'évaluation

- PBV Unibody and Two-Piece Flanged Floating Ball Valves: Smart Solutions. Powerful ProductsDocument28 pagesPBV Unibody and Two-Piece Flanged Floating Ball Valves: Smart Solutions. Powerful ProductsSunil BajpaiPas encore d'évaluation

- Aug2017/zip/24425456 TD Gseb 25Document54 pagesAug2017/zip/24425456 TD Gseb 25Sunil BajpaiPas encore d'évaluation

- C4 C44 C51 Cryogenic Service Valves PDFDocument12 pagesC4 C44 C51 Cryogenic Service Valves PDFTaylor RamirezPas encore d'évaluation

- PL 01-02-2020 Casted Valve PDFDocument7 pagesPL 01-02-2020 Casted Valve PDFSunil BajpaiPas encore d'évaluation

- Aug2017/zip/24425456 TD Gseb 30Document51 pagesAug2017/zip/24425456 TD Gseb 30Sunil BajpaiPas encore d'évaluation

- CertificateOfCompletion - Time Management FundamentalsDocument1 pageCertificateOfCompletion - Time Management FundamentalsDesiree HendersonPas encore d'évaluation

- 5Document1 page5Sunil BajpaiPas encore d'évaluation

- SS Invetment Casting Pipe Fittings CF8 (304) : Sr. Item Description 1/4" 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"Document2 pagesSS Invetment Casting Pipe Fittings CF8 (304) : Sr. Item Description 1/4" 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2"Sunil BajpaiPas encore d'évaluation

- Seat Temp RatingDocument12 pagesSeat Temp RatingVinothkumarPas encore d'évaluation

- Valve Body Material GradeDocument4 pagesValve Body Material GradeMdsr HasanPas encore d'évaluation

- Aug2017/zip/24425456 TD Gseb 29Document50 pagesAug2017/zip/24425456 TD Gseb 29Sunil BajpaiPas encore d'évaluation

- Aug2017/zip/24425456 TD Gseb 28Document50 pagesAug2017/zip/24425456 TD Gseb 28Sunil BajpaiPas encore d'évaluation

- Aug2017/zip/24425456 TD Gseb 26Document49 pagesAug2017/zip/24425456 TD Gseb 26Sunil BajpaiPas encore d'évaluation

- Steel Pipe Flanges ASME B 16.5 RF (Raised Face)Document3 pagesSteel Pipe Flanges ASME B 16.5 RF (Raised Face)Sunil BajpaiPas encore d'évaluation

- Aug2017/zip/24425456 TD Gseb 31Document55 pagesAug2017/zip/24425456 TD Gseb 31Sunil BajpaiPas encore d'évaluation

- Jindal Pipes PRICE List PDFDocument12 pagesJindal Pipes PRICE List PDFajkuagra50% (2)

- Led BillsDocument1 pageLed BillsSunil BajpaiPas encore d'évaluation

- ABO BoucherDocument6 pagesABO BoucherSunil BajpaiPas encore d'évaluation

- Jindal Pipes PRICE List PDFDocument12 pagesJindal Pipes PRICE List PDFajkuagra50% (2)

- ABO Ball ValveDocument6 pagesABO Ball ValveSunil BajpaiPas encore d'évaluation

- Generator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling SystemDocument2 pagesGenerator Set Pre-Start-Up Checklist: Open & Enclosed Generator Sets Cooling Systemarkan1976Pas encore d'évaluation

- Technip Ethylene ProcessDocument31 pagesTechnip Ethylene ProcessHabli Mawardi100% (4)

- Hydraulics Intro PDFDocument81 pagesHydraulics Intro PDFavinash babuPas encore d'évaluation

- 3 Phase Power CalculationDocument5 pages3 Phase Power CalculationChris Osea AlvarezPas encore d'évaluation

- 30B - Liquefaction Processes FundamentalsDocument31 pages30B - Liquefaction Processes FundamentalsPutu Indra MahatrisnaPas encore d'évaluation

- PCP (Progressive Cavity Pump)Document7 pagesPCP (Progressive Cavity Pump)SHOBHIT KUMAR100% (1)

- LOESCHE CGP Mobile Grinding Plant For Solid Fuels EDocument12 pagesLOESCHE CGP Mobile Grinding Plant For Solid Fuels EgugPas encore d'évaluation

- OFITE Filter Press With Nitrogen Cylinder 140-35Document9 pagesOFITE Filter Press With Nitrogen Cylinder 140-35HenryPas encore d'évaluation

- Thermal Cracking:: Stream Number Stream Make SourceDocument3 pagesThermal Cracking:: Stream Number Stream Make SourcejohnPas encore d'évaluation

- Material Selection Data For UpstreamDocument1 pageMaterial Selection Data For UpstreamAzazmohammadPas encore d'évaluation

- Kinney LR PumpsDocument20 pagesKinney LR Pumpsnarupv100% (1)

- Caterpillar Olympian GEH 220-2 - Technical SheetDocument4 pagesCaterpillar Olympian GEH 220-2 - Technical Sheetbobi15667% (6)

- 32-44cr v2.7 Imo Tier II MarineDocument531 pages32-44cr v2.7 Imo Tier II MarineSergey100% (2)

- ZJ70DBS Drilling Rig User Manual PDFDocument48 pagesZJ70DBS Drilling Rig User Manual PDFnobodymagdesignPas encore d'évaluation

- Motor Perkins 750 KVA PDFDocument2 pagesMotor Perkins 750 KVA PDFDuda CorrêaPas encore d'évaluation

- Mattco Pulsation Dampener OMM PDFDocument5 pagesMattco Pulsation Dampener OMM PDFpr_oil100% (4)

- Curriculum Vitae: Mohamed Saber Mohamed Gad Nemat AllaDocument5 pagesCurriculum Vitae: Mohamed Saber Mohamed Gad Nemat Allamohamed aliPas encore d'évaluation

- Below Grade Spill Containment Manholes - Franklin Fueling SystemsDocument8 pagesBelow Grade Spill Containment Manholes - Franklin Fueling Systemswarung1bensinPas encore d'évaluation

- Oil and Fat Assignment PDFDocument21 pagesOil and Fat Assignment PDFM Asrar SidonPas encore d'évaluation

- Annexure 11 - Safety HandbookDocument50 pagesAnnexure 11 - Safety Handbookmanu2020Pas encore d'évaluation

- Variable Speed Fluid Coupling - SCDocument7 pagesVariable Speed Fluid Coupling - SCRavikanth AluriPas encore d'évaluation

- API 5L QuesDocument33 pagesAPI 5L QuesRavindra S. Jivani100% (1)

- GasketDocument45 pagesGasketSathish RajanPas encore d'évaluation

- Asian Paints LTD, Patancheru - Vamiq Modified Compressor ProposalsDocument122 pagesAsian Paints LTD, Patancheru - Vamiq Modified Compressor ProposalsRaja RamachandranPas encore d'évaluation

- Islamiya English School, Abu Dhabi.: Grade: 9 Using Money 16Document1 pageIslamiya English School, Abu Dhabi.: Grade: 9 Using Money 16everly.Pas encore d'évaluation

- Wang 2007Document10 pagesWang 2007sri murti astutiPas encore d'évaluation

- Critical Velocity FarazDocument15 pagesCritical Velocity FarazAvinav KumarPas encore d'évaluation

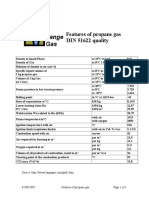

- Features of Propane Gas DIN 51622 QualityDocument1 pageFeatures of Propane Gas DIN 51622 QualityShijo PodiyanPas encore d'évaluation

- Oxidative Processes of Desulfurization of Liquid FuelsDocument12 pagesOxidative Processes of Desulfurization of Liquid FuelsMNButtPas encore d'évaluation

- 026 PDFDocument11 pages026 PDFMEHDIPas encore d'évaluation