Académique Documents

Professionnel Documents

Culture Documents

SA Buhler

Transféré par

Andreea BenteaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SA Buhler

Transféré par

Andreea BenteaDroits d'auteur :

Formats disponibles

Separator Classier

MTRB

Excellent separating efciency. High quality.

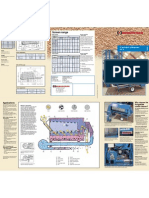

Separator MTRB with aspiration channel MVSH.

Application This machine, designed to meet high demands, is typically applied in our mills and elevators (silos) for grain cleaning. Other sites and elds of application include: feed mills, seed cleaning plants, oilseed cleaning installations, cocoa bean and cocoa nibs grading systems in chocolate factories, etc. Design The sieve box assembly, which is mounted on rubber springs supported by the machine frame, moves back and forth by two vibrators arranged at either side of the machine. The slope of the sieve box is adjusted to the specic application of the machine. The stroke and the angle of throw can be adjusted to suit special needs. The two sieve decks end at the front drawers and each are securely locked in place in the sieve box by two clamps. The second separating section for the coarse impurities is attached to the lateral outlet (top sieve). The machine outlet is matched to the various outlet aspiration systems available.

Excellent separating efciency High capacity Versatile applications Easy changing of sieves

High capacity. Low power requirement.

A C F

E B A Product inlet B Product outlet C Aspiration connection D Lateral outlet for the coarse impurities Mode of operation The separator separates the grain from coarse and ne impurities by sifting. Low-density (light) particles in the grain can also be reliably removed by additionally applying an aspiration channel or an air-recycling aspirator. The product is fed to the machine through the central integral inlet. The adjustable distribution device in the inlet allows uniform spreading of the product to be achieved across the top sieve deck. The overs (tailings) of this sieve are directed to the lateral outlet, where an additional separation is made into coarse, nonusable impurities and ne, usable particles. After further grading on the second sieve deck, the overs (main product fraction) are fed either to the attached aspiration channel or air-recycling aspirator, or to a simple aspiration box, depending on the machine version. (large kernels, strings, straw particles, etc.) E Outlet for the ne impurities (brokens, sand, etc.) F Coarse sieve G Sand sieve

Wide range of applications. Aspiration combinations.

Machine combinations with various outlet aspiration systems

Separator with aspiration box

Features Sturdy construction Easy operation Quick and easy changing of the sturdy sieves Adjustable stroke and angle of throw Low power requirement Minimum maintenance Easy-to-replace wear parts No lubrication points

Separator with aspiration channel MVSH

Separator with air-recycling aspirator MVSQ

Grading and classifying. Efcient cleaning.

A B D

Technical data Type Capacity in t/h * Cleaning MTRB-100/100 MTRB-100/100 S MTRB-100/200 MTRB-100/200 S MTRB-150/200 MTRB-150/200 S 24 100 16 66 8 33 Silo Dimensions in mm Approx. weight in kg Volume seap. m3 5.5

A

1780 1780 2745 2625 2745 2625

B

1610 1610 1610 1610 2180 2180

C

1630 1630 1730 1930 1730 1930

D

70 70 70 110 70 110

net 810

gross 990

by sea 1080

1030

1260

1380

10

1340

1650

1820

12

* The specied capacity data refers to wheat and rye with normal amount of impurities (2 to 3%). Capacities for corn (maize) 90% Capacities for barley 80%

The specied capacity data for storage elevator (silo) cleaning systems refers to peak values that are achieved with uniform product feed to the separator, maximum moisture of 15% and normal amount of impurities.

In the case of dirty wheat with a high moisture content and a high degree of impurities, the following approximate capacities will apply: 1518% H2O 6570% 1822% H2O 5560% above 22% H2O maximum 50%

Bhler AG CH-9240 Uzwil, Switzerland T +41 71 955 11 11 F +41 71 955 66 11 www.buhlergroup.com

MU 16030 en

1005

3000 DF

Vous aimerez peut-être aussi

- Chain Conveyor PDFDocument2 pagesChain Conveyor PDFDiego Alejandro Briceño RangelPas encore d'évaluation

- Buhler PDFDocument20 pagesBuhler PDFMoco DocoPas encore d'évaluation

- Trior BuhlerDocument6 pagesTrior BuhlerCobraCMM100% (1)

- High Impurity Requires Accurate Cleaning.: Peter StrieglDocument26 pagesHigh Impurity Requires Accurate Cleaning.: Peter StrieglPablo Ezequiel Rossa100% (1)

- BEHN + BATES Valve Bag Filling Systems PDFDocument20 pagesBEHN + BATES Valve Bag Filling Systems PDFJoão BaptistaPas encore d'évaluation

- Vortx Tornado f3 EnglishDocument2 pagesVortx Tornado f3 EnglishLiliann CabelloPas encore d'évaluation

- Brochure Conveying Systems en 001Document15 pagesBrochure Conveying Systems en 001jack-bc100% (1)

- Large Sifting Quadro Plansifter Provides High Capacity ClassificationDocument4 pagesLarge Sifting Quadro Plansifter Provides High Capacity ClassificationManuel Javier G'Pas encore d'évaluation

- Hammer-Mill Spare-Parts enDocument2 pagesHammer-Mill Spare-Parts enRogerio100% (1)

- Creatbot User Manual V7.0 enDocument34 pagesCreatbot User Manual V7.0 enPeporro LopezPas encore d'évaluation

- Reverse Vending Machine Pilot ProjectDocument4 pagesReverse Vending Machine Pilot ProjectICT WalaPas encore d'évaluation

- Instruction and Operation Manual: Manual de Instrucción Y Operación Guide D'Instruction Et D'OperationDocument13 pagesInstruction and Operation Manual: Manual de Instrucción Y Operación Guide D'Instruction Et D'OperationglizamabPas encore d'évaluation

- MSDG - SPL 7974-1-En-0410Document72 pagesMSDG - SPL 7974-1-En-0410Midias SangatiPas encore d'évaluation

- Pasteur IzerDocument12 pagesPasteur Izerkhaoula100% (1)

- CF1500Series PDFDocument2 pagesCF1500Series PDFالبتلة اللطيفPas encore d'évaluation

- Pegasus en Lauter TunDocument13 pagesPegasus en Lauter TunVũ Văn PhúPas encore d'évaluation

- TechSpec MistralDocument4 pagesTechSpec MistralScarab SweepersPas encore d'évaluation

- Gaga 2006 MKZM Drum SieveDocument6 pagesGaga 2006 MKZM Drum SievelrbolPas encore d'évaluation

- Mixing:: Basic Tasks of Blow RoomDocument9 pagesMixing:: Basic Tasks of Blow RoommohitPas encore d'évaluation

- Purifier PuromatDocument4 pagesPurifier PuromatbasisjohnPas encore d'évaluation

- MVSG-H Mu16034 enDocument4 pagesMVSG-H Mu16034 enCesarPas encore d'évaluation

- WWT Catalogue EN 1116Document24 pagesWWT Catalogue EN 1116Ramona FenolPas encore d'évaluation

- 1T/H Sesame Processing Plant Turnkey SolutionDocument14 pages1T/H Sesame Processing Plant Turnkey SolutionDidier SanonPas encore d'évaluation

- Washing Brochure TerexDocument21 pagesWashing Brochure TerexWashington HuallpaPas encore d'évaluation

- Vacuum CollectionDocument4 pagesVacuum CollectionLoganBohannonPas encore d'évaluation

- Cosechadora Serie 7000Document20 pagesCosechadora Serie 7000Secreto SecretosPas encore d'évaluation

- Savi General CatalogueDocument8 pagesSavi General CataloguecristyryePas encore d'évaluation

- Mobile Grain CleanerDocument2 pagesMobile Grain CleanerDulguunkherlen BudkhandPas encore d'évaluation

- Cimbria Mega CleanerDocument12 pagesCimbria Mega CleanerMohammad AinuddinPas encore d'évaluation

- SideDraft Product Bulletin PDFDocument1 pageSideDraft Product Bulletin PDFkalaiPas encore d'évaluation

- REMU XO CrossoverBucketDocument6 pagesREMU XO CrossoverBucketScott GuimondPas encore d'évaluation

- Agrimir Catalog 2Document14 pagesAgrimir Catalog 2agrimir_machinePas encore d'évaluation

- Allmineral Productinfo GBDocument16 pagesAllmineral Productinfo GBTitanicPas encore d'évaluation

- Komptech CribusDocument12 pagesKomptech CribusbaleizaobzPas encore d'évaluation

- Card Sliver Brochure PDFDocument8 pagesCard Sliver Brochure PDFVenkatesh Gogineni100% (1)

- Batching Plant PDFDocument8 pagesBatching Plant PDFfakhli bisaPas encore d'évaluation

- Pre-Cleaner DELTA 142: Data Sheet 142Document1 pagePre-Cleaner DELTA 142: Data Sheet 142Madalina MenteaPas encore d'évaluation

- Sand Filtration Units150Document3 pagesSand Filtration Units150Smriti PrasadPas encore d'évaluation

- Irtmm 2019 Chapter 3Document31 pagesIrtmm 2019 Chapter 3Abhishek SinghPas encore d'évaluation

- CornWetMilling BrochureDocument8 pagesCornWetMilling BrochureAndrea HernandezPas encore d'évaluation

- Vibroscreen BrochureDocument12 pagesVibroscreen BrochureVarun MalhotraPas encore d'évaluation

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009Pas encore d'évaluation

- Rice Mill MachinesDocument7 pagesRice Mill MachinesPraise K PremonPas encore d'évaluation

- 1 Terminator BrochureDocument12 pages1 Terminator BrochureDiogo_23Pas encore d'évaluation

- Types of Screens: Primary TreatmentDocument20 pagesTypes of Screens: Primary TreatmentMadhuri GuptaPas encore d'évaluation

- MT 3000 2 Offset VogeleDocument8 pagesMT 3000 2 Offset VogeleRobinson GuanemePas encore d'évaluation

- 4082WWT Grit RemovalDocument21 pages4082WWT Grit Removalahmedmagdi2009Pas encore d'évaluation

- Eurovac High Volume Collector PackageDocument15 pagesEurovac High Volume Collector PackageDaniel AustinPas encore d'évaluation

- Noggerath Combi Units - Efficient and Compact PretreatmentDocument4 pagesNoggerath Combi Units - Efficient and Compact PretreatmentAngele IvanovskiPas encore d'évaluation

- Mec Blasting ProcessDocument9 pagesMec Blasting Processapcd electrothermPas encore d'évaluation

- Textile Technology Internship ReportDocument24 pagesTextile Technology Internship Reportgunashekarkalluri100% (1)

- Batching PlantDocument12 pagesBatching PlantPratik LikharPas encore d'évaluation

- Introduction To BlowroomDocument21 pagesIntroduction To Blowroomsujal jha100% (1)

- BrocherDocument12 pagesBrochermustaqeem khanPas encore d'évaluation

- CONDUX Universal-Mill CUM E-4cb06fDocument12 pagesCONDUX Universal-Mill CUM E-4cb06fAndrea Hernandez100% (1)

- Mag. AgitatorDocument12 pagesMag. AgitatorGanesh.Mahendra100% (1)

- Ammann Asphalt Mixing-Plant EasyBatch en PDFDocument12 pagesAmmann Asphalt Mixing-Plant EasyBatch en PDFWillian MazaPas encore d'évaluation

- 3-Vertical Cuttings Dryer System GNCD930Document12 pages3-Vertical Cuttings Dryer System GNCD930GeorgePas encore d'évaluation

- Pannevis Brochure FinalDocument20 pagesPannevis Brochure FinalAnonymous XFK4lezBvPas encore d'évaluation

- Screening ConsiderationsDocument23 pagesScreening ConsiderationsJames MPas encore d'évaluation

- Bloating, Acidity & Constipation - DearistDocument13 pagesBloating, Acidity & Constipation - DearistRobert DsouzaPas encore d'évaluation

- Inorganic Chemistry ReviewDocument25 pagesInorganic Chemistry ReviewPj Declarador100% (3)

- Oral Health Care Tips (Final Infographic)Document1 pageOral Health Care Tips (Final Infographic)Audrey Ann AcobPas encore d'évaluation

- HealTea Co Business PlanDocument26 pagesHealTea Co Business PlanKenneth SottoPas encore d'évaluation

- Leon's StoryDocument94 pagesLeon's StoryTomaPas encore d'évaluation

- Stardew Valley Character Gift GuideDocument8 pagesStardew Valley Character Gift GuideBryan LagosPas encore d'évaluation

- Tempting Season's Greetings - 2010Document1 pageTempting Season's Greetings - 2010JurgenJanssensPas encore d'évaluation

- Convert and Calculate Volume of Liquids in Litres and MillilitresDocument24 pagesConvert and Calculate Volume of Liquids in Litres and MillilitresMazlina AliPas encore d'évaluation

- Karly Lane - Tallowood Bound (Extract)Document31 pagesKarly Lane - Tallowood Bound (Extract)Allen & UnwinPas encore d'évaluation

- Count Nouns and Non-Count Nouns. Simple Present VS Present Continuous.Document3 pagesCount Nouns and Non-Count Nouns. Simple Present VS Present Continuous.Blanca CamposPas encore d'évaluation

- A.S AddictDocument41 pagesA.S AddictRimsha Ansari67% (3)

- Global Business Technology - Version 1.0Document6 pagesGlobal Business Technology - Version 1.0Prasenjit PradhanPas encore d'évaluation

- Kaiser Katalog Engl 2014Document39 pagesKaiser Katalog Engl 2014mmm_gggPas encore d'évaluation

- GDM Thanksgiving RecipesDocument3 pagesGDM Thanksgiving RecipesWGMEPas encore d'évaluation

- Soyinka, Wole - Aké (Vintage, 1983)Document239 pagesSoyinka, Wole - Aké (Vintage, 1983)AyAjetomobi100% (6)

- Essential Oils N OleoresinDocument32 pagesEssential Oils N Oleoresinasokmithra100% (2)

- Americas 20 Worst Restaurant MealsDocument20 pagesAmericas 20 Worst Restaurant MealsBrianW100% (5)

- Amm Presentation-120811224207-Phpapp01Document28 pagesAmm Presentation-120811224207-Phpapp01irfankhan007Pas encore d'évaluation

- Plath's "InitiationDocument10 pagesPlath's "InitiationMerry CorvinPas encore d'évaluation

- Slyman S Restaurant MenuDocument3 pagesSlyman S Restaurant MenueatlocalmenusPas encore d'évaluation

- Fast Food Linked to Teen Health RisksDocument9 pagesFast Food Linked to Teen Health RisksZaff Mat EfronPas encore d'évaluation

- SpellsDocument17 pagesSpellsAnna Deniz Luna100% (2)

- Drinks Inc Issue 42 Winter 19 20Document58 pagesDrinks Inc Issue 42 Winter 19 20drinksinc100% (1)

- Issued Rations, and Foods Found or Purchased by Mess Groups: For (June 24-26 2016) "Order Out of Confusion": Marching To Monmouth CourthouseDocument6 pagesIssued Rations, and Foods Found or Purchased by Mess Groups: For (June 24-26 2016) "Order Out of Confusion": Marching To Monmouth CourthouseJohn U. Rees100% (2)

- Paraiso de Maracuja - Melati SamataajiDocument3 pagesParaiso de Maracuja - Melati SamataajiMelati Samata Aji IrawantoPas encore d'évaluation

- Sample Task 1 - 3Document32 pagesSample Task 1 - 3Saeid RajabiPas encore d'évaluation

- Red BullDocument12 pagesRed BullWang YaoPas encore d'évaluation

- Set Soal Paket 3 ADocument13 pagesSet Soal Paket 3 AAbu AbdurrahmanPas encore d'évaluation

- Worksheet EnglishDocument8 pagesWorksheet EnglishFlor MallquiPas encore d'évaluation

- ProverbsDocument97 pagesProverbshafshuPas encore d'évaluation