Académique Documents

Professionnel Documents

Culture Documents

DTMF Required

Transféré par

niteshaulTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DTMF Required

Transféré par

niteshaulDroits d'auteur :

Formats disponibles

1

CHAPTER-3

3.1 TRAIN TRAFFIC CONTROL

3.2 General Principles of Control Working

Introduction

This chapter gives general idea about the control working in Indian Railways. It

describes the control organization at Headquarters and then lists the general

requirements oI train control communication system. The chapter ends with the

inIormation regarding DTMF Signalling method adopted presently all over Indian

Railways Ior selective calling.

Meaning of Control

The organization set up to supervise and regulate the running oI trains and the

movement oI traIIic, in the best possible manner with the resources available is called

CONTROL.

3.3 Objects of control

Control over the movement oI trains and traIIic, over a section oI the Railway is

exercised round the clock, to achieve the Iollowing: -

(a) The cohesion in moving trains and traIIic

(b) To avoid delay to trains and traIIic

(c) To eIIect economy in working oI trains

(d) To improve the general working oI trains, and

(e) To increase the eIIiciency in working oI trains.

3.4 Elements of a Control Circuit

The basic elements oI a control circuit are

1) Control OIIice,

) Way Stations, and

3) Communication between control oIIice & way station

3

3.5 Control Offices

The control oIIices may be described as the nerve centres oI the Divisional Operating

organization. A control oIIice exists at each oI the Divisional Headquarters stations. Apart

Irom the Divisional control oIIices, at the Iollowing places that are lying within the Division

jurisdiction is also provided with control oIIices: -

Area Control:

Areas oI exceptionally industrial or commercial importance are provided with

subsidiary control oIIices called as Area Control.

Sub-control:

Where the traIIic density justiIies separate organization Ior Controlling and regulating

traIIic $:-.ontrol oIIices are provided with the same set up oI staII as provided in

Division control oIIice to control a limited portion oI the division.

Each Divisional Control OIIice is divided into one or more sections. And each

section is provided with a separate selI-contained control communication circuit with a

separate control Board. Each section or Board as it is commonly called, is manned

round the clock by the Section Controllers on shiIt duty. The work oI Section Controllers

is supervised by Deputy ChieI Controllers, who are also perIorming the shiIt duty.

The Section Controller oI each section is provided with control Board with

telecommunication Iacilities Ior contacting stations, certain important cabins, Loco

sheds, etc

Fig. Typical layout of section control in a division

Central Control office at Zonal Headquarters

(a) This is situated in the zonal Headquartered oIIice. It is connected with Division

headquarters and with important stations/yards with a view to regulating traIIic over

entire system and co-coordinating with adjoining railways.

(b) It Iunctions under the overall charge oI a ChieI controller and a Iew section

controllers in each oI the 3 shiIts and maintains detailed operating position oversees

the daily perIormance

(c) It maintains various operating records Ior reIerence and keeps the Headquarters

oIIices inIormed oI the latest position.

(d) The stock section oI the central control collects various inIormation and prepares

detailed position oI day-to-day operating perIormance.

(e) Its Mechanical and Electrical wings assist in assessing the perIormance oI their

respective departments in every day`s and in calculation oI kilometerage and

punctuality

.

3.6 The Control Organization at Divisional and Area Headquarters

The control organization generally consists oI a special oIIicer deputed Ior the purpose

with a deputy oIIicer and the Iollowing executive staII:

(a) ChieI controller.

(b) Deputy ChieI Controller.

(c) Train controller.

Chief controller is the highest executive authority in charge oI the organization and is

chieIly responsible Ior the eIIicient operation oI the system.

Deputy Chief Controller directly supervises the work oI the section controllers, assists

them during their work and also scrutinizes thoroughly the control charts.

Train controller deals with the actual movement oI the trains, does the Iollowing in the

control charts and deals with the movement oI trains as a whole.

In view oI the arduous nature oI their work, the duty hours oI train controllers are

generally restricted to 6 hours at a time. Arrangements are generally made Ior this

supervision to be exercised Ior hours so that the staII works in shiIts.

Train Control Chart

The train control is exercised adopting graphical plotting method. In the graphical

plotting method oI train control, a graphical chart is provided in which the distance is

indicated on the Y-axis and the time on X-axis. The smallest sub-division oI time axis

may be 1 or or minutes depending on the density oI traIIic. The distance axis gives

the overall length oI the section with names oI the stations and the distances between

stations.

A typical chart is shown in Iigure-1.. The oblique lines indicate the movement and

the horizontal lines the detention oI trains. The chart is provided with a border on all the

Iour sides to record particulars regarding the trains, reasons Ior undue detention etc.

Recently automatic train charting is being introduced in place oI manual charting where

Data loggers are networked.

Way Stations

The length oI the control section is determined purely on traIIic considerations, so that

Irom the transmission point oI view the best conditions are not always obtained.

Communication is normally required with:

(a) Railway station

(b) Signal Cabin

(c) Loco shed

(d) Sidings (in special cases)

(e) OIIicers` rooms

(I) OIIicers' residences

(g) Residences oI other emergency staII.

The above are generally reIerred to as way stations`. Facilities should exist Ior the way

station to be "rung" to establish communication. In cases where ringing Iacilities are not

given the way station is reIerred to as a speaking extension`. It is to be noted that there

are three possible arrangements, Ior placing the section controller in the section

(a) Tail end,

(b) Midpoint, or

(c) Remote point.

Communication Between Control Office & Way Stations

Communication plays an important role in control working. The eIIiciency oI any control

circuit mainly depends upon the perIormance oI the communication equipments

connected and communication media used.

Control communication circuits are used Ior inter-communication between each

Section Controller and all way stations under his jurisdiction with Iacility Ior selectively

calling any way side station Irom his table ( control oIIice).

On non-electriIied areas, these circuits are provided on a - wire basis on the

open lines along the route or on - wire basis through under ground communication

6

cables wires. On electriIied areas, the control communication circuits are provided only

on -wire basis through under ground communication cable wires. Four wire working

was chosen because oI the diIIiculty in maintaining the stability oI -wire ampliIier circuits

with long control sections and large number oI tapping points, practically one per

Railway station.

Provisions of the Control Communication

The control communication circuits are engineered to meet the Iollowing requirements:

(a) Speech:

( i ). Speech between the controller and the Iarthest station should be acceptable

irrespective oI the number oI wayside stations listening in.

( ii ). The controller and the wayside stations should be able to have conIerence

Iacilities.

(b) Signaling:

( i ). The controller should be able to call any station along the route or a group oI

89,9438on the section along the route or ,89,9438simultaneously.

( ii ). The controller should get an audible indication when the bell at the called

station rings.

3.7 Control Communication Equipments

The control communication circuits are omni-bus circuits when any wayside station is

talking to the controller, other stations can listen to the conversation and iI they desire

can take part in the discussion. The controller`s table is so arranged that he can carry out

his duties with minimum Iatigue and his hands are Iree to do writing work. For providing

hands Iree arrangements to the controller, a microphone and a loudspeaker are provided

in addition to normal telephone handset.

The communication equipments to be provided, Ior diIIerent signaling methods,

at controller`s place and at way stations are as tabulated below:

.

3.8 Functions of Operating Controls

The Iunctions oI the operating controls may be best described under 3 Heads:

(a) Train control

(b) TraIIic control

(c) Power control

Train control

( i ). Ensuring the punctual running oI Mail, Express & Passenger trains.

( ii ). Running Goods trains to best possible paths and with the least possible detention

enroute.

( iii ). Arranging the running oI engineering material trains to the best possible

advantage oI Engineering department.

( iv ). Arranging Engineering and/or Power blocks in such a way as to involve the

minimum disturbances to train running and best advantage oI the Engineering

Department.

( v ). Arranging relieI and regulating trains in the event oI accident

Traffic control

( i ). Allotment and distribution oI coaching and Goods stock in stations.

( ii ). Securing maximum utilization oI stock.

( iii ). Maintaining Iluidity oI Marshalling yards.

( iv ). Regulating traIIic Ior IulIilling interchange commitments.

( v ). Securing maximum workable load Ior each train compatible with the

type oI engine utilized and the special characteristics oI the

section over which the train is to be worked.

Power control

( i ). Requisitioning locomotive power i.e. Engines, direct Irom locomotive running

sheds Ior all operating requirements, viz. train working, shunting and banking.

( ii ). To ensure the most economical use oI engine power available.

( iii ). To ensure the return oI engine to Home Running sheds at regular intervals Ior

wash-outs and other maintenance requirements

.

The General Requirements of Train Control System

(a) Facilities should exist Ior the headquarters oIIice to converse with the way stations,

individually or severally.

(b) Facility should also exist Ior ringing any one or all the way station.

(c) Facility should be provided iI possible Ior signaling (or calling) Irom way station to

headquarters oIIice. This is optional and will be necessary only in cases where

traIIic is very light and the section control is not manned Ior the entire hours.

(d) The adjustment and maintenance oI the equipment should be easy. The equipment

should be rugged and rigid, the way stations equipment in particular.

(e) The equipment should be able to work within tolerable margins to avoid any critical

adjustments.

A choice has to be made Ior railway control circuit Irom the typical telephone circuits,

which may broadly be classiIied as Iollows:

(a) Point-to-Point circuit.

(b) Party line circuit.

(c) Omnibus circuit.

Point-to-Point Circuit:

Point-to-point communication circuit is generally used between two subscribers,

when secrecy is to be maintained. The number oI lines will be equivalent to the

number oI subscribers. This is not economical Ior train control working in view oI the

large number oI lines required.

Party Line Circuit :

In a party line circuit, more than two subscribers are connected to a single line and

the individual subscribers are called by a system of coded ringing. Generally magneto

ringing is used and the code consists oI combinations oI long and short rings.

Permutations and combinations by this methods are limited since a multiplicity oI

codes leads to conIusion and the required number is not always obtained due to

incorrect decoding oI the signals especially when they are combinations oI short and

long rings. Hence, the circuit is normally limited to subscribers Ior eIIicient working. In

view oI the large number oI way stations in a control circuit, this system is also not

suitable Ior train control working.

Omnibus Circuit:

In an omnibus circuit all the users or subscribers are connected to a single

telephone line or circuit. For calling any individual subscriber a unique selective

calling code is implemented. This system is just suitable Ior railway control working

because it can accommodate large number oI subscribers or way stations on a

single control circuit.

For this reason omnibus circuit is adopted Ior all railway control circuits.

On this type oI line or circuit secrecy cannot be maintained among the individual

subscribers but this is not at all a problem since railway control circuits are meant

Ior oIIicial communication related to trains working.

3.9 The Control Circuits

Control circuits in Non-RE Area

(a) Section control

(b) Deputy control

(c) Engineering control

(d) Emergency control (in under ground cables only)

Control circuits in RE Area

In ' AC electriIied areas, in addition to the control circuits mentioned Ior non-RE

Areas above, the Iollowing additional control circuits are to be provided.

(a) Traction Power Control,

(b) Traction Loco Control, and

10

(c) Remote control.

Brief Description of Control Circuits

Section Control will be provided mainly to control the movement oI train within the

control section given. Every division contain one or more than one section control

circuits. The locations connected in these section control circuits are all stations, yards,

Loco sheds, Goods sheds and oIIicials oI various departments. These control circuits are

provided both in RE and Non-RE Sections

.

Deputy control circuit is provided in each control oIIice with telecommunication

connected to important stations, yards, and loco sheds Ior collecting particulars such as

yard reports, mid-night Iigures and train ordering etc. This control circuit is generally

manned by Deputy ChieI Controller (stock), working on general shiIt. In case oI any

Iault in Section control circuits this Deputy control circuit is used as substitute to it.

The Engineering control is mainly used Ior controlling maintenance activities oI

engineering department like track maintenance, ballast movement, line blocks etc.

Emergency control is meant Ior instant communication Irom the Iield with the

headquarters in the event oI any emergency/accident. Its regular use is Ior

communication between the traction maintenance gangs and the traction power

controller. Hence the traction power controller normally operates the circuit and he can

transIer the call Irom the Iield to the section controller iI it is required. This control will be

provided in Non-RE areas also, where the control communication is provided through

under ground cable.

Traction power control is a special circuit used Ior eIIicient maintenance oI the

overhead traction equipment and its operation. A traction power controller will operate it

and it has connections with station master's oIIices, grid stations, Ieeding posts,

sectioning and sub-sectioning posts, OHE Maintenance Depots and concerned oIIicers

oI the electrical department in divisional headquarters.

Traction loco control is another special circuit operated by traction loco controller, who

is responsible Ior movement oI electrical locomotives. It has connections with electric

loco sheds, important station masters, yard masters and concerned divisional oIIicers.

Remote control is meant Ior remote operation oI the ' Traction equipments, which

works on Supervisory Control and Data Acquisition Systems (SCADA) principle.

11

3.10 Brief Description of the DTMF Signalling method adopted for Selective

Calling.

DTMF is a system oI signalling originally evolved Ior the transmission oI dialling

inIormation to automatic telephone exchanges Irom subscriber's telephones. Its

versatility has lent itselI suitable Ior the transmission oI impulses in the selective calling

system used in Railway Control Circuits as well. In this system two tones oI Irequency

within the voice band are sent out on line corresponding to a given digit. Among these

two Irequencies one is a low (row) Irequency and the other a high(column) Irequency,

both within the 'F band. The transmission oI the tones is so Iast (typically in millisecond)

that the signalling does not interIere with the speech at all.

Why two tones? Since the signalling tone is in-band( within voice band), any voice

simulation should not be recognised as a tone pulse, and that is why two tones, which

are harmonically unrelated, are used. Another reason is O/H line noise or line whistles

should not be recognised as signal.

The tones are so chosen and recommended by ITU that minimum inter

modulation occurs between each oI the 16 possible tone pairs. One tone Irom the low

Irequency group and one Irom the high Irequency group are paired to mark the keyboard

output. Since the tones are in 'F range, the signaling can be transmitted on the same

transmission medium such as the O/H lines and U/G cables.

3.11 Advantages of DTMF selective calling system

The DTMF Selective calling system is adopted Ior Rly. Control communication

because oI the Iollowing speciIic advantages:

(a) For Selective calling on O/H lines system (W) or U/G cables (W) system, the

DTMF signaling is adaptable. (Direct interIace to line).

(b) No need Ior high voltage DC or 0v / 0Hz A.C. (No need Ior SRR panels in the

RE area) Low level signalling, 00m' typically.

(c) A maximum oI Way Stations can be connected as against the stations oI in

1-impulse system.

(d) No moving parts, as the equipment is entirely solid state. A signiIicant improvement

in system reliability. Also reduction in hardware.

(e) No adjustments oI voltage/current are involved at any oI the Way stations

irrespective oI location, and hence absolutely maintenance-Iree.

(I) The system is immune to line noises and line distortion and hence poor line

conditions do not degrade the perIormance.

1

(g) Ideal Ior establishing local control Irom the accident spots.

(h) A tone generator IC generates the DTMF tones. The system is readily adaptable

Ior patching to any voice channel over UHF, 'HF, microwave or OFC networks

without any special arrangements Ior patching.

4 Wire/2 Wire Train Traffic Control Communication Equipment

General Description

The Railways train traIIic control system with DTMF voice Irequency signaling under

consideration is meant Ior use in omnibus speech circuits like section control, traction

power control, traction loco control and deputy control employing either Wire or Wire

transmission. DTMF system uses combinations oI two Irequencies in 'F band Ior

implementing selective calling oI way side stations or locations.

Control Office Equipment

Operating Requirements:

(a)The system shall permit working oI voice communication and signaling on an

omnibus circuit tapped at way stations and other places, on Wire or Wire

basis as required.

(b) It shall be possible to call maximum oI stations with -digit codes either one

at a time or a nominated group at a time or all at the same time.

(c) Audible indication to the controller that the called station has been rung shall be

provided.

(d) Every station shall be assigned a distinct calling code. In addition, a nominated

group oI stations may be assigned a group calling code. such groups should

be provided in the system. The push buttons should be designated as A, B, C &

D. The push button Ior General call shall be designated G Ior calling all stations

at the same time.

(e) The station code generation and transmission shall be accomplished by

pressing two push buttons in a sequence. The group code/ general call code

and transmission shall be accomplished by pressing relevant push button twice.

(I) The Iacility to repeat the last code transmitted by pressing one single push

button designated RT shall be provided.

13

(g) The duration oI the ringing at way station shall normally be seconds (/- 0.

second). However, Iacility shall be provided to extend this period as long as

desired by pressing a single push button designated LR by repeatedly sending

the last transmitted code aIter every . seconds.

(h) It shall be possible to send the signaling code even when two or more parties

are in conversation and also to a station engaged in conversation.

(i) The station code being transmitted shall be displayed on the console. The display

shall continue till the next code is generated. The two push buttons Ior station code

should be pressed in sequence within seconds. The Iirst digit remains displayed

Ior seconds, aIter which it gets erased automatically. It should be possible to

cancel the Iirst digit within seconds by pressing a single push button designated

DL.

(j) Facility to reset the system should be provided by pressing One single push button

designated RS.

(k) Facility to check the row /column Irequency shall be provided by pressing push

button designated RC Ior test mode.

Constituents of Control Office Equipments:

The control oIIice equipment with DTMF signaling consists oI the Iollowing:

1. DTMF Console

. DTMF code generator

3. Communication PCB consisting oI Microphone ampliIier, Head/Hand set transmitter

ampliIier & loudspeaker ampliIier.

. Hand set

. Head set

6. Microphone

. Loudspeaker

. Hybrid attachment (required Ior -Wire operation)

. Power supply unit

.

1

3.12 General Working Principle of DTMF Control office equipment:

For DTMF tones generation the control oIIice equipment contains a Microprocessor or a

Micro-controller. This Microprocessor/Micro-controller keeps scanning the keyboard (

By matrix) lines to check Ior any valid keyboard entry. As soon as a valid key closure

(corresponding to the Iirst digit oI the station code) is detected, the processor/controller

stores the inIormation and display the digit pressed. The processor/controller waits Ior

second key closure (corresponding to the second digit oI the station code). II a second

valid key is pressed within the speciIied period, the processor/controller updates the

display and activates the tone generator to transmit DTMF tones Ior the keys pressed,

in the order oI key-press sequence. These tones are connected to the line through a

combiner ampliIier, where they combine with speech signals coming Irom the

microphone/hand set.

In the receive direction the speech coming Irom the way stations will be Iiltered and

ampliIied beIore sending to the loud speaker.

DTMF CONSOLE

Front Panel: The eyboard on the Iront consists oI total 0 keys. Sixteen oI these are DTMF

1

keys arranged in by matrix. These are TEN decimal keys - 0 to used Ior entering the -

digit station codes. Then FOUR Group call keys - A, B, C, D and one general call key - G and

long ring key - LR. For group call and general call the same key is to be pressed twice. For

example AA, BB, GG etc. In addition to these 16 keys there are FOUR Iunction keys RS,

DL, RT and RC.

RS - Reset key is used to reset the control oIIice equipment, iI it is required to do so at any

time.

DL - Delete or Clear key used to cancel a wrong entry during the dialing process.

RT - Repeat key redials the last code transmitted.

RC - Row & Column Frequency Test key is used Ior outputting individual row and column

DTMF Irequencies Ior testing purpose. On pressing this key the equipment goes into test mode

and outputs 1st row Irequency (r1) on TX terminals on back panel. The display shows

indicating the output Irequency. Now iI RC key is pressed once again nd row Irequency (r) is

outputted on tx terminals. Similarly all row and column Irequencies are outputted sequentially

one aIter other with every press oI RC key. The equipment comes oII the test mode by

pressing reset key RS.

16

DTMF CONTROL ROOM EQUIPMENT

Long Ring key (marked LR) is used to generate the long ring at way stations as long as

desired.

Console Back Panel: - The back panel consists oI the Iollowing:

1

Side Panel: -

Side panel consists oI a volume control Ior loudspeaker marked as 'olume and socket Ior the

Handset

.

Description of Different Makes of Control Office Equipments

M/s AnuVidyut Make

The control oIIice equipment consists oI the Iollowing cards

(a) ey board & display card,

(b) Control card,

1

(c) AmpliIier card, and

(d) Power supply & Iilter

Circuit Description

Keyboard & Display card: It consists oI 0 keys and two-digit -Segment display.

Control card:

It consists oI microprocessor, the programmed EPROM, peripheral ICs and the DTMF

generator. The microprocessor scans the keyboard iI any key has been pressed, iI a

key press is detected a debounce routine is used to debounce the key. The number

corresponding to the key pressed is indicated on the display, and the microprocessor

then waits Ior the next key. When two digits oI the dialed number is entered, the dialing

sequence is started, the DTMF generator is instructed to output the DTMF code

corresponding to the Iirst digit Ior a Iixed ON time, a pause corresponding to the OFF

time is then generated, similarly the other digit is also transmitted.

The encoder oI this equipment uses 0 microprocessor Ior its working. This

microprocessor interIaces the keyboard, display and tone generator through two I/O

interIaces - IC 1 and IC . The selection oI one oI these two interIaces is done

through a decoder IC 16.

IC 1 interIaces the microprocessor with the keyboard and display unit through port B

and port A respectively. A driver IC 13 is used Ior display the digits. IC

interIaces the microprocessor with tone generator (IC ). This generates the DTMF

tones as per the key pressed on the keyboard. This system uses IC 6 as program

memory (6 B). Block diagram in Fig..6 shows these details.

Amplifier card:

This card consists oI Trans AmpliIier i.e., Microphone AmpliIier and Receive i.e.,

Loudspeaker AmpliIier. The Microphone AmpliIier circuit is designed to ampliIy m'

input signal or 0m' input signal Ior dynamic and carbon microphone respectively.

Speech output can be controlled by preset marked TX GAIN`. This also ampliIies the

DTMF signal. The output oI DTMF signal can be adjusted by preset marked as DTMF

GAIN`.

Loudspeaker Amplifier:

This circuit consists oI an AGC circuit and loudspeaker ampliIier and a Iilter circuit. AGC

circuit gives a stable output Ior input variation Irom 0 to 0dBm. The output oI AGC

goes to Iilter circuit. The output oI Iilter is given to loudspeaker ampliIier, which ampliIies

it and gives a maximum output oI 1 watt at ohms. The output oI loudspeaker ampliIier

is controller by 'OLUME control and is Iitted at the side panel oI console.

1

It consists oI a reverse polarity protection and the RC Iilters to smooth the power supply

Ior diIIerent cards. It provides power supply to control and Trans & Receive card. The

Filter circuit works Ior loudspeaker ampliIier and it rejects the Irequencies, which are out

oI the speech band.

SPECIFICATIONS:

Microphone Amplifier:

(a) Input impedance : Matched with the microphone used

(b) O/P variation : 'aried with preset marked as TX GAIN

(c) O/P level Ior input oI m' : -0 dBm to 0 dBm on a load oI 110

(d) Frequency response : Within/-3dBm Ior range0.3 to 3.kHz

(e) Harmonic distortion : Less than 3 at 0.3 to 3. kHz

(I) Output impedance : Selectable 110 or 600 as required

(g) Hand set : Plug in type

(h) Microphone : Model AUD 101 MS

0

Loudspeaker Amplifier:

(a) Input impedance : 110 with /- 10 at 1 kHz

(b) Input level : 0 to 30dBm AGC work Irom 0 to 0dBm

(c) Output level : 1 watt (max.) on a load oI

(d) Harmonic distortion : Less than 3 at 1 Hz, 1W, across

(e) Frequency response : Within /-3dBm(Ior range 0.3 to 3.kHz)

(I) Loud speaker : Dual tone watts,

Hybrid Attachment:

(a) Output impedance : 600 on -Wire side

(b) Leak between Trans & Rec. pairs : less than 0 dBm

Power Requirement:

(a) Power supply : 1 ' DC nominal, min 10.', max. 1.'

(b) Fuses : 1 A rating

(c) Reverse Polarity Protection : With Diode

(d) Quiescent current : less than 10 mA

(e) Max. Working current : less than 00 mA

M/s Epsilon ElectonicsEquipments Make

The control oIIice equipment with DTMF selection system consists oI the Iollowing:

(a) DTMF Generator (Encoder) PCB

(b) Communication PCB

(c) Handset

(d) Head set

1

(e) Table type Microphone

(I) Loud speaker

(g) W to W conversion unit (whenever wire operation is necessary)

The DTMF Generator is Microprocessor based with selI-check Iacility and display oI

called station`s assigned number. The DTMF Generator is designed Ior W operations.

The block diagram oI this equipment`s encoder is shown in Fig...

The DTMF Headquarters equipment is designed as table-top unit with push button

keypad and -segment LED display. The 1 'DC is connected at the rear oI unit Irom

the Battery/Power supply unit.

DTMF Way Station Equipment

General Description

The DTMF way station equipment design has to comply with the RDSO speciIication

No. IRS: TC-60/93. This equipment consists oI the Iollowing units.

(a) DTMF decoder & Speech circuits

(b) Control Telephone

(c) 1' DC Power supply & Battery unit

The equipment entire circuitry Ior DTMF decoder & speech ampliIiers is assembled on a

single PCB and then it is placed in a wall-mountable metal cabinet. The decoder part oI

the circuit perIorms the Iollowing Iunctions. Receives DTMF -digit station code and

decodes it into digit decimal code Compares it with the local code allotted to the

station Switches on a piezo buzzer, iI both codes are matched Sends a ring back

tone to the controller, when buzzer rings AmpliIies speech signals in both directions

Working Principle:

In the way station decoder unit a -digit station code is set locally, using two DIP

switches (oI 10 contacts each) which are named as FD ( First Digit) switch and SD

(Second Digit) switch respectively. Controller transmitted DTMF code is received Iirst at

way station by a DTMF tone decoder IC which converts the DTMF tones representing

the Iirst digit into a -bit binary which is applied as input to a -to-16 line binary

decoder. Depending on the -bit binary value only one oI 16 outputs becomes high. The

high signal representing the First Digit oI the way station code passes through the FD

DIP switch only iI the setting on DIP switch matches with the received digit. This

same signal aIter passing through the FD DIP switch triggers a second Mono-shot

whose output is given as input data Ior a Flip Flop. Similarly the second digit signal

passes through SD DIP switch and applied as clock pulse to the Flip Flop. The Flip Flop

output triggers another mono-shot oI 3 to seconds timing which drives a piezo buzzer

and also activates a ring back tone(RBT) circuit. The block diagram oI Way station

DTMF Decoder & Buzzer Activation Circuit is as shown in Fig. .a

Way Station Equipment (2-Wire)

-wire circuit is generally adopted in non-electriIied sections where communication is on

overhead alignment. For satisIactory working oI DTMF equipment in Wire over

headline territory, the over all loss on Wire does not exceed 1dB.

Operating Requirements

(a) It shall be possible to assign any DTMF station code between 01 to to a way

station using DIP switches. And also any group code Irom A, B, C, D can be

assigned to the way station.

(b) On receipt oI the valid code, it shall be decoded and a piezo-electric buzzer shall

be activated even iI the hand set is oII the cradle.

(c) AIter the buzzer in the telephone is actuated, a ring back tone shall be

automatically and transmitted to the control oIIice in acknowledgement oI the

receipt oI ring. The level oI the ring back tone when measured across trans

terminals oI way station equipment shall not be less than -1dBm.

(d) Along with the activation oI the buzzer, a visual indication oI LED shall be lit in the

telephone. The LED indication shall continue to be lit until the handset is liIted oII

the cradle.

(e) The-output level oI the buzzer shall be adjustable by means oI Iixed pad.

(I) The equipment shall not need manual resetting in case oI power interruption.

Protection Irom transients in power supply to be provided.

The equipment consisting oI wall-mounted cabinet containing signal reception,

recognition, ringing and ring back transmission circuit called decoder and voice

communication equipment. The block diagram showing the connections oI the various

components oI way station equipment is as in the Iigure .

Trouble Shooting of 4-wire DTMF Way station Equipment

(a) DTMF Decoder

TEST Equipment required are:

(a) 3 digit multi-meter

3

(b) Test Jig

(c) 1 '/100 mA DC power supplies with current limit.

The Iollowing step-by-step test plan is to be adopted whenever a DTMF receiver is

to be serviced.

( i ). Apply 1'/-3'DC to the battery terminals oI the equipment, marked 1' &

1' with proper polarity.

( ii ). Connect the ground lead oI the multi-meter (set to 0 'DC range) to the

ground (-1' point) oI the equipment.

( iii ). Check the DC voltage at the test points mentioned below:

( iv ). At TP1 connect the red lead oI the multi-meter and measure the voltage. It should

be greater than or equal to ', else check the power supply lead wires etc. Also

check whether equipment is drawing more than mA oI current. II so switch oII

DC power to the equipment and remove ICs marked, IC1, IC, and IC to IC 10

beIore carrying out any Iurther testing. II the standing current is less than mA

then continue testing as shown below.

( v ). TP voltage should be ' /-0.', else replace IC3 or D. Connect test jig

output to TRANS terminals oI the equipment and check whether the test point

marked3 on the equipment is going high, when a key is depressed.

( vi ). NOTE: TP3 will remain high until the key on the test jig is released.

( vii ). Press keys 1, .. ,0 successively and check whether the corresponding

point on the code setting terminal block is going to ' (logic high), else

replace IC.

( viii ). Press general call button marked G on the test jig while monitoring TP.TP

should go high momentarily and return to 0 aIter about 1 second, else replace

IC. Press Iirst digit oI the code then TP should go high momentarily, else

replace IC

( ix ). Press general call twice while monitoring TP6. TP6 goes high when the

general call button is pressed the second time, else replace IC. Press Iirst

digit and second digit keys in sequence, again TP6 should go high, else

replace IC.

( x ). Press general call twice. TP goes high, else replace IC6.

( xi ). Connect TP 10 to ground oI DC supply momentarily. Buzzer should come ON,

else replace Buzzer aIter checkingQ.

( xii ). Press general call twice and monitor TP and collector oI Q. They should be

at about 3 ' AC (change the multi-meter setting to read the AC voltage), else

replace IC or Q aIter checking Q, and Q.

( xiii ). The special codes are routed through Dipswitch marked A, B, C, and D. When

a special code button is pressed, TP 11 goes high iI the corresponding

Dipswitch is ON, else change Dipswitch.

( xiv ). In case the equipment is drawing more than m A oI standing current while

conducting test above, remove all ICs except IC3 as suggested and monitor

the current. Now the current should be less than 0m A, else replace IC3.

Switch OFF the power supply and insert one IC at a time and monitor the

current each time. II the current exceeds 0m A by inserting a particular IC,

replace it and continue testing.

Emergency Control Circuit

On non-electriIied sections provided with over head line wires Ior control working, to

contact the controller by the maintenance staII or Train Guard in emergencies, a

Wire portable telephone and a collapsible telescopic tubular pole are provided to

them. During emergencies they have to hook the portable telephone to the

overhead line wires directly using the telescopic tubular pole to establish

communication with the controller. When circuits are through underground cables,

it is not possible to connect a portable telephone to the control wires to establish

communication between control oIIice and any point on the line. To get over this

diIIiculty taps are provided Irom the underground cable at intervals oI about 1 M

and these are terminated on 6-pin socket. The control oIIice can be contacted by

plugging a portable control telephone into any oI the sockets. As the maintenance

staII oI the Electrical Department has to contact the Traction Power Controller

Irequently the taps have been taken Irom separate circuit instead oI section control

circuit so that the section control circuit is not unnecessarily disturbed. This

separate circuit is called the Emergency Control Circuit.

The emergency control circuit is a -Wire circuit and works similar to any

other control circuit on Wire. To respond to a call initiated Irom an emergency

socket, generally a microphone and a loud speaker will be provided with TPC Ior

this control working. A separate cable quad is allotted Ior the working oI this control

circuit. The line diagram showing the network details oI emergency control are as

shown in the Iigure-.13. At Traction Power Controller`s room, two sets oI wire

HQs. control oIIice equipments are provided one set Ior Traction Power Control

working, and other one Ior Emergency Control working. Facility is also provided to

the Traction Power Controller to transIer any emergency call received by him, to the

Section Controller iI needed.

3.13 TELEPHONES USED IN CONTROL WORKING

WAY STATION CONTROL TELEPHONE

Wire Way Station Control Telephone

The - wire way station control telephone will be provided at way stations Ior providing

communication Irom -wire omnibus control network. It will be oI desk type and works in

conjunction with control way station equipment on -Wire basis. The control way station

equipment will provide battery Ior the microphone. Trans and receive ampliIiers provided

in the control way station equipment will take care oI matching oI the impedance oI

microphone and receiver with that oI the line.

3.14Salient Features

1. The telephone consists oI ABS (Acrylonitrile Butadiene Styrene) body, HMT with

press to talk switch, cradle switch, coil cord oI length 1. meters, 6 way rosette box,

buzzer and LED.

. Both transmitter and receiver are electro dynamic transducer type.

3. It has a pre-ampliIier circuit in the Trans side to give an output voltage oI 0m'

across the line with 110 load impedance, Ior an input oI mv across the dynamic

type transmitter (0 load resistance).

Wire Way Station Control Telephone

-Wire way station control telephone will be provided at way stations Ior providing

communication Irom -Wire omnibus control network. It works along with -Wire DTMF

way station equipment. Whenever the way station is called the piezo-buzzer comes ON

in addition to a latched LED indication until the handset is liIted. AIter the telephone is

liIted, this LED gets oII and the communication will be made.

Salient Features (As per IRS: TC: 37-97)

1. The telephone body, HMT, and rosette are made oI ABS (Acrylonitrile Butadiene

Styrene).

. Both transmitter and receiver are electro-dynamic transducer type.

3. Hand set is provided with approved micro-switch.

6

. Working voltage is 3 'DC ( 0 or - 10).

SCOPE

This speciIication covers the requirements and provisions oI test and inspection oI

Universal Way Side DTMF Control Telephone used Ior control communication on Wire/

Wire Railway Control Circuits. The telephone will include the circuitry oI conventional

control telephone as well as way station equipment Ior both wire & wire control

communication systems.

This speciIication covers the general, constructional Ieatures, electrical characteristic and

technical requirements oI Universal Way Side DTMF Control Telephone. This telephone

shall work with control oIIice equipment oI train traIIic control system (U/G, MW & OFC).

Features

1. Both transmitter and receiver are oI electro dynamic transducer type.

. Transmitter works on 3 volts.

Vous aimerez peut-être aussi

- Radio Control for Model Ships, Boats and AircraftD'EverandRadio Control for Model Ships, Boats and AircraftÉvaluation : 5 sur 5 étoiles5/5 (1)

- Telecommunications Traffic : Technical and Business ConsiderationsD'EverandTelecommunications Traffic : Technical and Business ConsiderationsPas encore d'évaluation

- Control RailwayDocument127 pagesControl RailwayJatin Parmar100% (2)

- RailwayDocument30 pagesRailwayAntaripaBhuyanPas encore d'évaluation

- UntitledDocument136 pagesUntitledPankaj kumarPas encore d'évaluation

- Safe Train SeparationDocument4 pagesSafe Train SeparationbassamPas encore d'évaluation

- TC 6Document180 pagesTC 6Pankaj kumarPas encore d'évaluation

- Unit11 LinecapacityDocument22 pagesUnit11 Linecapacityupadhyay kulbhushanPas encore d'évaluation

- CBTC Generic SpecificationDocument33 pagesCBTC Generic Specificationalescien100% (1)

- Rail Signalling FundamentalsDocument17 pagesRail Signalling Fundamentalsupadhyay kulbhushanPas encore d'évaluation

- UpdatedDocument22 pagesUpdatedMAAZ KHANPas encore d'évaluation

- My DocDocument18 pagesMy DocJOY PhilipPas encore d'évaluation

- Operating Department ReportDocument9 pagesOperating Department ReportAnish AnandPas encore d'évaluation

- DMRCDocument15 pagesDMRCJohn HowardPas encore d'évaluation

- Railway Control Systems & Track MaintenanceDocument3 pagesRailway Control Systems & Track MaintenanceSakshi GuptaPas encore d'évaluation

- Intelligent Traffic LightDocument11 pagesIntelligent Traffic LightMona AliPas encore d'évaluation

- Moving block signalling increases rail capacity and efficiencyDocument5 pagesMoving block signalling increases rail capacity and efficiencyyadvikram7Pas encore d'évaluation

- Fundamental Requirements For Operations and Signalling (Version 4)Document3 pagesFundamental Requirements For Operations and Signalling (Version 4)antonioPas encore d'évaluation

- Network Structure: Computer NetworksDocument4 pagesNetwork Structure: Computer Networkspiyush dadheechPas encore d'évaluation

- Kisi-Kisi Mechanical System 2Document3 pagesKisi-Kisi Mechanical System 2Alif Anwar4Pas encore d'évaluation

- ERTMS Test Results ItalyDocument15 pagesERTMS Test Results ItalyangnavaPas encore d'évaluation

- IEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION, VOL. 7 , NO. 2, APRIL I991Document12 pagesIEEE TRANSACTIONS ON ROBOTICS AND AUTOMATION, VOL. 7 , NO. 2, APRIL I991maysamshPas encore d'évaluation

- Indian Railway TrainingDocument25 pagesIndian Railway TrainingJayant Soni57% (7)

- Communications Based Train Control (CBTC)Document29 pagesCommunications Based Train Control (CBTC)v2brother63% (8)

- Area Traffic Control SystemsDocument11 pagesArea Traffic Control SystemsVishal Khatri100% (1)

- TC6 HLDocument103 pagesTC6 HLashish118Pas encore d'évaluation

- Results of The Procedure For Selecting Manufacturers, Considering The Introduction of CBTC On Our Railway SystemDocument5 pagesResults of The Procedure For Selecting Manufacturers, Considering The Introduction of CBTC On Our Railway Systemmkashkooli_scribdPas encore d'évaluation

- CBTC ManualDocument9 pagesCBTC Manualaakashawasthi00gmailPas encore d'évaluation

- Automated Metro - Ensuring Safety and Reliability With Minimum Human InterventionDocument10 pagesAutomated Metro - Ensuring Safety and Reliability With Minimum Human InterventionpoketupiPas encore d'évaluation

- ATS Server and Client ModelDocument8 pagesATS Server and Client ModelAbhijitPas encore d'évaluation

- 2013 12 SD BUeSA EnglischDocument6 pages2013 12 SD BUeSA Englischwranghel_ion2436Pas encore d'évaluation

- Department of Aeronautical Engineering, Sec Perambalur - 621212Document28 pagesDepartment of Aeronautical Engineering, Sec Perambalur - 621212murjass85Pas encore d'évaluation

- Frauscher Whitepaper APR 23Document9 pagesFrauscher Whitepaper APR 23Tamer TaskinPas encore d'évaluation

- Part 4 of Tender DocumentDocument51 pagesPart 4 of Tender DocumentEr Rajesh BuraPas encore d'évaluation

- European Train Control System Speed-Distance Mode Curve Analysis and SimulationDocument4 pagesEuropean Train Control System Speed-Distance Mode Curve Analysis and SimulationnpfhPas encore d'évaluation

- A Mobile Platform For Nursing Robot 1985Document14 pagesA Mobile Platform For Nursing Robot 1985mohsindalvi87Pas encore d'évaluation

- Communications-Based Train Control (CBTC) Is ADocument18 pagesCommunications-Based Train Control (CBTC) Is AchaithanPas encore d'évaluation

- Train control systems in metro railwaysDocument43 pagesTrain control systems in metro railwaysupadhyay kulbhushanPas encore d'évaluation

- Ae64 Telecommunication Switching SystemsDocument12 pagesAe64 Telecommunication Switching SystemsjyvmanojkumarPas encore d'évaluation

- Moving Block&Traffic ManagementDocument10 pagesMoving Block&Traffic ManagementVIPIN DOBHALPas encore d'évaluation

- Ramin Com&NavDocument20 pagesRamin Com&NavRVMN 13Pas encore d'évaluation

- Summer Training Report "Signaling & Telecommunication": AcknowledgementDocument14 pagesSummer Training Report "Signaling & Telecommunication": AcknowledgementAdityaPas encore d'évaluation

- Indian RailwayDocument21 pagesIndian RailwayNaved IqbalPas encore d'évaluation

- Railway Signalling TermsDocument6 pagesRailway Signalling TermsTsegay Kidu100% (1)

- Centralized Traffic Control (CTC) Is A Form ofDocument7 pagesCentralized Traffic Control (CTC) Is A Form ofAmitJollyPas encore d'évaluation

- 9 ESSNo1Document168 pages9 ESSNo1Shavel KumarPas encore d'évaluation

- (17-34) Rly Paper Corrected 28-2-19-FormatDocument18 pages(17-34) Rly Paper Corrected 28-2-19-Format이기대LeekidaePas encore d'évaluation

- Simulation of Zigbee Based Tacs For Collision Detection and Avoidance For Railway TrafficDocument5 pagesSimulation of Zigbee Based Tacs For Collision Detection and Avoidance For Railway Trafficprinceram123Pas encore d'évaluation

- TMC1 TrafficSignalControlDocument93 pagesTMC1 TrafficSignalControlpronab kumarPas encore d'évaluation

- Vishal 123Document47 pagesVishal 123Vishal SharmaPas encore d'évaluation

- A Study in Industrial Robot ProgrammingDocument26 pagesA Study in Industrial Robot ProgrammingPatel Dhaval100% (1)

- CBTC ProjectDocument3 pagesCBTC ProjectchinglensanaPas encore d'évaluation

- Avionics NotesDocument22 pagesAvionics NotesRajeshkumar Baskaran0% (2)

- Traffic Light Priority Control For Emergency Vehicle Using RFIDDocument4 pagesTraffic Light Priority Control For Emergency Vehicle Using RFIDLuis Galindo BernalPas encore d'évaluation

- EUROPEAN RAIL RADIO SPECDocument97 pagesEUROPEAN RAIL RADIO SPEClahyouhPas encore d'évaluation

- DEVELOPMENT OF AN ADAPTIVE TRAFFIC CONTROL SYSTEMDocument7 pagesDEVELOPMENT OF AN ADAPTIVE TRAFFIC CONTROL SYSTEMChigozie UmeozuluPas encore d'évaluation

- Intelligent Multiple Sensor Early Failure Warning System For Train Rotary Door OperatorDocument9 pagesIntelligent Multiple Sensor Early Failure Warning System For Train Rotary Door OperatoramarolimaPas encore d'évaluation

- Automatic Train Supervision_LinkedinDocument7 pagesAutomatic Train Supervision_LinkedinJanardhana D S IyengarPas encore d'évaluation

- Mobile Train Radio CommunicataionDocument27 pagesMobile Train Radio CommunicataionKunal SharmaPas encore d'évaluation

- Advanced Control of Aircraft, Spacecraft and RocketsD'EverandAdvanced Control of Aircraft, Spacecraft and RocketsÉvaluation : 4 sur 5 étoiles4/5 (1)

- OfdmDocument24 pagesOfdmniteshaulPas encore d'évaluation

- Walia 2Document14 pagesWalia 2niteshaulPas encore d'évaluation

- Ofc Report Over Veiw and Some BasicDocument30 pagesOfc Report Over Veiw and Some BasicniteshaulPas encore d'évaluation

- IntroductionDocument31 pagesIntroductionniteshaulPas encore d'évaluation

- NITESHHHHHDocument24 pagesNITESHHHHHniteshaulPas encore d'évaluation

- Chapter 1111111Document6 pagesChapter 1111111niteshaulPas encore d'évaluation

- Sandeep YadavDocument2 pagesSandeep YadavniteshaulPas encore d'évaluation

- Documen 3333333 TDocument17 pagesDocumen 3333333 TniteshaulPas encore d'évaluation

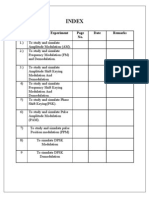

- Index: S.No. Name of The Experiment No. Date RemarksDocument1 pageIndex: S.No. Name of The Experiment No. Date RemarksniteshaulPas encore d'évaluation

- Cell Phone JammersDocument24 pagesCell Phone JammersniteshaulPas encore d'évaluation

- An UpDocument18 pagesAn UpniteshaulPas encore d'évaluation

- Comm Sim Complete FileeeeeeeeDocument23 pagesComm Sim Complete FileeeeeeeeniteshaulPas encore d'évaluation

- How To Build A Tin Can Waveguide AntennaDocument3 pagesHow To Build A Tin Can Waveguide AntennaAbid UmairPas encore d'évaluation

- ENG - 7 - Electrical Resistance Strain Gages PDFDocument16 pagesENG - 7 - Electrical Resistance Strain Gages PDFBogdan BumbaceaPas encore d'évaluation

- Uniform Plane WaveDocument63 pagesUniform Plane WavesabbithiPas encore d'évaluation

- Home Assignment Class 10 (Physics)Document5 pagesHome Assignment Class 10 (Physics)Theboss SharmaPas encore d'évaluation

- ABB molded case circuit breakers guideDocument280 pagesABB molded case circuit breakers guideMohammed AbdelsalamPas encore d'évaluation

- MVP507Document1 pageMVP507Joseph TingPas encore d'évaluation

- Contactors (18AF) : DescriptionDocument32 pagesContactors (18AF) : DescriptionRobiPas encore d'évaluation

- Bizhub Pro 920Document640 pagesBizhub Pro 920Abdul WahabPas encore d'évaluation

- Calculate Total Apparent, Average and Reactive Power in 3-Phase - Electrical Engineering Stack ExchangeDocument3 pagesCalculate Total Apparent, Average and Reactive Power in 3-Phase - Electrical Engineering Stack ExchangeNikšaPas encore d'évaluation

- 1756 Controllogix Power Supplies Specifications: Technical DataDocument24 pages1756 Controllogix Power Supplies Specifications: Technical DataNickPas encore d'évaluation

- Emic PDFDocument3 pagesEmic PDFHarinath vvPas encore d'évaluation

- Full-Scale Converter ABBDocument104 pagesFull-Scale Converter ABBismailbejPas encore d'évaluation

- Physics Project On MagnetismDocument29 pagesPhysics Project On MagnetismChandraneel SinghPas encore d'évaluation

- Appendix Bizhub Pro 920Document28 pagesAppendix Bizhub Pro 920katjho100% (1)

- WEG Automation Drives and Controls Usadrivescontrols Brochure EnglishDocument16 pagesWEG Automation Drives and Controls Usadrivescontrols Brochure EnglishAndrés NarvaezPas encore d'évaluation

- Relay and Timer Based Automatic Star-Delta StarterDocument3 pagesRelay and Timer Based Automatic Star-Delta StarterInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Debye and non-Debye relaxation mechanisms in dielectric materialsDocument8 pagesDebye and non-Debye relaxation mechanisms in dielectric materialsAP SinghPas encore d'évaluation

- 2020 - Introduction To Spintronics - L1Document55 pages2020 - Introduction To Spintronics - L1hb1323Pas encore d'évaluation

- Ic VivaDocument2 pagesIc VivaSrinivasu RajuPas encore d'évaluation

- Work Experience:: Jay-Ar Cuevas SalveDocument2 pagesWork Experience:: Jay-Ar Cuevas SalveJay-Ar Cuevas Salve100% (1)

- ESP Schedule for Shree Singaji TPP Units 3&4Document4 pagesESP Schedule for Shree Singaji TPP Units 3&4Director CommercialPas encore d'évaluation

- Quick Guide to Solar Inverter InstallationDocument15 pagesQuick Guide to Solar Inverter InstallationSalman ArainPas encore d'évaluation

- Sirius 3rb2 DatasheetDocument25 pagesSirius 3rb2 DatasheetCesar IgamiPas encore d'évaluation

- Potential TransformerDocument9 pagesPotential TransformerofjePas encore d'évaluation

- ASTM Conductor Spec SheetsDocument27 pagesASTM Conductor Spec Sheetsjavad4531Pas encore d'évaluation

- Tesla's Metaphysics and Cosmology (Velimir Abramovic)Document36 pagesTesla's Metaphysics and Cosmology (Velimir Abramovic)THE NIKOLA TESLA INSTITUTE90% (10)

- Grammaire Progressive Du Français - Niveau Intermédiaire - Livre + CorrigésDocument20 pagesGrammaire Progressive Du Français - Niveau Intermédiaire - Livre + CorrigésTiago Jeronimo Lopes0% (1)

- Perovskite BagusDocument57 pagesPerovskite BagusaditngrhPas encore d'évaluation

- Resistors in Series and in ParallelDocument4 pagesResistors in Series and in ParallelAtif MehfoozPas encore d'évaluation

- Difference Between Infrared and Ultraviolet Radiation ExplainedDocument1 pageDifference Between Infrared and Ultraviolet Radiation ExplainedKiran RajannaPas encore d'évaluation