Académique Documents

Professionnel Documents

Culture Documents

A A 59326B

Transféré par

cvz240159Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A A 59326B

Transféré par

cvz240159Droits d'auteur :

Formats disponibles

INCH-POUND A-A-59326B September 12, 2005 SUPERSEDING A-A-59326A May 1, 2003

COMMERCIAL ITEM DESCRIPTION COUPLING HALVES, QUICK-DISCONNECT, CAM-LOCKING TYPE The General Services Administration has authorized the use of this commercial item description, by all federal agencies. 1. SCOPE. 1.1 This commercial item description (CID) covers 21 types of quick-disconnect, cam-locking, coupling halves and their fittings used in fuel and water handling equipment. 2. CLASSIFICATION. 2.1 The couplings will conform to the following types, classes, sizes and styles. 2.2 Types. The following are types of quick-disconnect, cam-locking, coupling halves and adapters. Type I Coupling Half, Male by Internal Pipe Thread A-A-59326/1 Type II Coupling Half, Male by Hose Shank A-A-59326/2 Type III Coupling Half, Male by External Pipe Thread A-A-59326/3 Type IV Coupling Half, Male by Flange, TTMA (Truck A-A-59326/4 Trailer Manufacturers Association) Type V Coupling Half, Female by Internal Pipe Thread A-A-59326/5 Type VI Coupling Half, Female by Hose Shank A-A-59326/6 Type VII Coupling Half, Female by External Pipe Thread A-A-59326/7 Type VIII Coupling Half, Female by Flange, TTMA A-A-59326/8 Type VIII A Coupling Half, Female by Flange, Hexagon A-A-59326/9 Beneficial comments, recommendations, additions, deletions, clarifications, etc., and any data which may improve this document should be sent by letter to: US Army Tank-automotive and Armaments Command, ATTN: AMSRD-TAR-D, 6501 East 11 Mile Road, Warren, MI 483975000. AMSC N/A DISTRIBUTION STATEMENT . Draft only, not to be used for acquisition Purposes FSC 4730

A-A-59326B Type IX Type X Type XI Type XII Type XIII Type XV Type XVI Type XVII Type XVIII Type XIX Type XX Type XXI Type XXII Coupling Half, Cap, Dust Coupling Half, Plug, Dust Reducer, Male by Female and Female by Male Reducer, Male by External Pipe Thread Reducer, External Pipe Thread by Female Adapter, 45, Female Thread Swivel Collar by Male Coupling Half, Female by External Straight Threads Coupling Half, Male by Internal Straight Threads Coupling Half, Female Reducer by Internal Pipe Thread Nipple Adapter, Male by External Grooved Pipe Y Connection, Flanged, TTMA Adapter, Male by Male Adapter, Female by Female, Cam Locking Type A-A-59326/10 A-A-59326/11 A-A-59326/12 A-A-59326/13 A-A-59326/14 A-A-59326/15 A-A-59326/16 A-A-59326/17 A-A-59326/18 A-A-59326/19 A-A-59326/20 A-A-59326/21 A-A-59326/22

2.3 Classes. Coupling halves and adapters will be of the following classes, based on the material of construction. Class A - Aluminum Alloy with anodized coating Class B - Copper Alloy (Brass or Bronze). Class BA - Aluminum Bronze Class SS - Stainless Steel 2.4 Sizes. The coupling halves and adapters will conform to the sizes specified in the applicable table of the federal specification sheet, for the configuration shown on the accompanying figure and will be designated by a dash number. 2.5 Style. The coupling halves shall have the following styles: Style 1 Style 1 couplings do not require the incorporation of a positive locking mechanism to lock the cam arms in the closed position but the cam arms shall stay in the closed position when the coupling halves are assembled. Style 2- Style 2 couplings shall incorporate a positive self locking mechanism to lock the cam arms in the closed position when the coupling halves are assembled. The locking mechanism shall be manually released (the release doesnt have to stay in the released position) before the cam arms can be moved to the open position.

A-A-59326B 3.0 SALIENT CHARACTERISTICS. 3.1 Description. These coupling halves and adapters are suitable for use with suction hoses, discharge hoses, nozzles, and for various fittings and manifolds. Requirements shall be as defined herein and on the individual specification sheets. In the event that there is a conflict between the two documents, the specification sheet shall govern. 3.2 Materials. Materials shall be of sufficient durability to meet all performance requirements, in any of the environments, specified herein. Couplings and accessories shall not be made from hazardous materials (HazMats), ozone depleting substances (ODCs) or leach or otherwise develop toxins. 3.2.1 Fuel distribution service. Couplings and accessories shall be manufactured from any materials suitable for use with gasoline and the following diesel fuels and kerosene-based petroleum fuels. Copper or copper alloys shall not be used where it could come into direct contact with the fuel. a. MIL-DTL-83133 (JP-8)(NATO F-34). b. MIL-DTL-5624 (JP-5)(NATO F-44). c. ASTM-D-975, Diesel Fuel d. A-A-52557 Diesel-military, including NATO F-54). e. ASTM-D-1655 (Jet A-1) (NATO F-35) 3.2.2 Drinking water service. Couplings and accessories shall be manufactured from any materials suitable for potable water service. Lead shall not be used. The components shall contain no materials or substances that could leak or disintegrate and cause the water to become non-potable. All surfaces that contact the water shall conform to the applicable Federal regulations for use with potable water. 3.2.3 Recovered materials. Recovered materials, collected from solid waste and reprocessed to become a source of raw material, may be used in the manufacture of the couplings (see 4.0). However, used, rebuilt, or re-manufactured components and parts shall not be incorporated 3.2.4 Dissimilar metals. The couplings and accessories shall be fabricated from compatible materials, inherently corrosion resistant or treated to provide protection against the various forms of corrosion and deterioration to which they are susceptible. Dissimilar metals except for stainless steel pins and key rings shall not be used in intimate contact with each other unless protected against galvanic corrosion. 3.3 Configuration. The coupling halves and fittings shall conform to these interface requirements. 3.3.1 Assemblies. The coupling half assembly shall conform to figure 1 and table 1. 3.3.2 Male coupling half. Male coupling halves shall conform to figure 2 and table 2. 3

A-A-59326B 3.3.2.1 Wrenching surfaces. The flats or lugs on the coupling half shall be of sufficient size to permit a positive grip by standard tools for manipulation of the coupling half. A boss, or other means, to accept the s-hook or ring of a retaining chain shall be incorporated on or adjacent to one of the flats or lugs. The ring attaching feature shall be of sufficient strength to withstand the repeated free fall of a dust cap in accordance with A-A-59326/10. It shall be of sufficient durability to withstand repeated use, without deformation, and shall not bind or abrade the ring or s-hook. 3.3.3 Female coupling half. Female coupling halves shall conform to figure 3 and table 3. For 6-inch coupling halves, more than two cam arms shall be provided for the 150 psi rated coupling halves. 3.3.3.1 Pull rings. The cam arms shall incorporate assembled pull rings, of sufficient strength and durability to withstand repeated openings of the arms using the rings. The pull rings shall be made of corrosion resistant materials or stainless steel. Neither the rings nor arms shall be abraded or deformed, and the ring shall not bind, for the life of the coupling half. 3.3.4 Gaskets. Female coupling halves shall contain gaskets conforming to figure 4 and table 4. A G designation shall be used in Lieu of Type and Class designations for A PIN for a separate procurement (see7.5). Gaskets will be designated by A-A-59326-G-XX 3.3.5 Flanges. Flanges for types IV, VIII, and XX shall conform to figure 5 and table 5. A chamfer is acceptable on the inside opening of all flanges. Threads shall be tapered NPT threads. See specification sheets for thread sizes. 3.4 Performance. The coupling assembly shall not leak or distort when subjected to the required hydrostatic pressure for 5 minutes. 3.4.1 Hydrostatic test pressure. Unless otherwise indicated on the specification sheet, through 4-inch couplings shall withstand hydrostatic pressure of not less than 300 pounds per square inch gage (psig). 6-inch, 75 psi rated, female cam-locking type coupling halves shall withstand a hydrostatic pressure of not less than 150 psig. 6-inch, 150 psi rated female camlocking type coupling halves shall withstand a hydrostatic pressure of not less than 225 psig. 3.4.2 Working pressure. Unless otherwise indicated on the specification sheet, - through 4inch couplings shall be rated for a minimum of 150 pounds per square inch (psi) and 6-inch couplings shall be rated for a minimum of 75 psi or a minimum 150 psi. The female 6-inch 150 psi rated coupling shall use more than two cam arms. Acquisition documents shall specify either 75 psi or 150 psi working pressure for 6-inch coupling halves. (See 7.3) 3.4.3 Torque. The torque required to completely close each cam arm shall be as specified in table 3, and the amount of gasket compression shall be as specified in table 4. 3.4.4 Interchangeability. All parts having the same type and size, irrespective of manufacturer, shall be capable of being interchanged, without modification, with no impairment of functional or physical characteristics. 4

A-A-59326B 3.5 Identification marking. 2-inch and larger couplings shall be legibly and permanently marked in characters that are a minimum of .25 inch high. Couplings less than 2-inches shall be marked in characters that are a minimum of .120 inch high or the couplings may be identified on a securely attached tag or marked on the packaging medium. The markings shall include, as a minimum, the manufacturers identification and a part number. 4.0 REGULATORY REQUIREMENTS. The offerer/contractor is encouraged to use recovered material to the maximum extent practicable, in accordance with paragraph 23.403 of the Federal Acquisition Regulation (FAR). 4.1 Regulations. The coupling halves shall comply with all applicable Federal and State mandatory requirements and regulations relative to the manufacture, packaging and labeling. 5.0 PRODUCT CONFORMANCE PROVISIONS. The products provided shall meet the salient characteristics of this commercial item description, conform to the producers own drawings, specifications, standards, and quality assurance practices, and be the same product offered for sale in the commercial market. The Government reserves the right to require proof of such conformance. 5.1 Market acceptability. The item offered shall be of the latest model of the standard product of the supplier that shall have been used in the field for at least one year by commercial organizations. 5.2 Examination. Each coupling assembly shall be examined for compliance with requirements specified in 3.2 through 3.5. Any modification necessary following failure to meet the specified requirements shall receive particular attention for adequacy and suitability. This element of inspection shall encompass all examinations of performance and dimensional requirements. Non-compliance with any specified requirement, or the presence of one or more defects lessening required efficiency shall constitute cause for rejection. 6.0 PACKAGING. Preservation, packaging, packing, labeling, and marking shall be as specified in the contract or purchase order. 7.0 NOTES(This section contains information of an explanatory nature that may be helpful but is not mandatory.) 7.1 Intended Use. The quick disconnect couplings and accessories covered by this CID are primarily to be used in suction hose, discharge hose, and nozzles for various fittings and manifolds for the handling of liquid products, such as fuel, potable water, or waste water. 7.2 Conformance data requirements. When this CID is used for procurement, the product conformance clause should appear in the solicitation. 7.3 Acquisition requirements. Acquisition documents must specify the following: a. Title, number, and date of this CID and the related federal specification sheet(s). b. Type, Size, Class, style and the quantity required. 5

A-A-59326B c. Component material designations (see 3.2). d. When other than stainless steel pull rings are required (see 7.4.5). e. For 6-inch coupling halves, the working pressure shall be specified as either 75 psi or 150 psi (see 3.4.2). f. Packaging requirements (see 6.0). 7.4 Material specification. The contracting officer will select from the following options for materials and finishes. 7.4.1 Housings. Unless otherwise indicated on the specification sheet, materials used in the manufacture of the coupling assembly housings will be as follows: Class A - Aluminum alloy - UNS A03560, A07120, or A07130 per ASTM B26 Aluminum Alloy UNS A03560 in T6 Temper, A07120, or A07130 per ASTM B26 for castings and 2011, or 6061 per ASTM B211 for bar stock. Class B Copper alloy UNS C83600, C83800, C84400, C90500, or C92200 per ASTM B61, B62, or B584, or copper alloy C37700 per ASTM B283. Copper Alloy UNS 37700, C83600, C83800, C84400, C90500, or C92200per ASTM B584 for castings or C36000 per ASTM B16 for bar stock, or copper alloy C37700 per ASTM B283. Class BA - Aluminum Bronze - UNS C60600, C61300, C61400, C62400, C63000, C64200 or C64210 per ASTM B150, or per ASTM B148 for castings. Class SS - Stainless steel - UNS S30400 or S31600 per ASTM A276 or A582 for bar stock or per ASTM A314 for forgings. Stainless steel - UNS S30400 or S31600 per ASTM A276 or A582/479 for bar stock or per ASTM A314 for forgings and CF-8 or CF-8M per ASTM A743 / A743M for castings.

7.4.1.1 Finish. Unless otherwise indicated on the specification sheet, coupling assembly housings will be finished as follows: Class A - Aluminum alloy - Anodic coating, non-dyed, 0.0004 inch minimum thickness. Class B - Copper alloy - Plain (no finish) Class BA - Aluminum Bronze - Plain (no finish) Class SS - Stainless steel - Plain (no finish) or per ASTM A351 for castings. 7.4.2 Gaskets. Gaskets shall be of nitrile material for use in temperatures above -20 F. Nitrile gaskets shall conform to ASTM D 2000, Grade M2BG610 B14EA14EF21F17Z1Z2. Z1: The compression set after 22 hours @ 70 C will not exceed 60 percent when tested in accordance with ANSI/ASTM D 395. 6

A-A-59326B When polyurethane is selected, use the following water resistance test: Z2: After 14 days in distilled water @ 70 C the maximum change in strength will be 40 percent when tested in accordance with ANSI/ASTM D 471. 7.4.2.1 Temperatures for gaskets. For temperatures below - 20 F gaskets shall be of elastomers suitable for use up to -70 F. 7.4.3 Cam arm materials. Unless otherwise indicated on the specification sheet, materials used in the manufacture of the cam arms will be Copper Alloy UNS C36500, C37700, C46400, C48200, or C48500 per ASTM B124 for forgings, or Stainless Steel UNS S30400, or S31600 per B325 or grades CF-8, or CF-8M per ASTM A743, or suitable powdered metal per MPIF STD 35, or suitable investment cast metal to ASTM A351 or A743. 7.4.4 Cam pins. Unless otherwise indicated on the specification sheet, materials used in the manufacture of the cam pins will be CRES Alloy UNS S30323, S30300 per ASTM A582, or Class S30430 or S31600, condition A, per ASTM A276. 7.4.5 Pull rings. Unless otherwise indicated (see 7.3), materials used in the manufacture of the pull rings will be CRES Alloy UNS S30400 or S30200 per ASTM A313.

7.5 Part Identification Number (PIN). The following part identification numbering procedure is for government purposes and does not constitute a requirement for the contractor. Identification by cross-referenced numbering systems (see 7.6) will be acceptable. The PIN to be used for a coupling half acquired using this CID, and associated federal specification sheets will be indicated in each federal specification sheet. The PIN used for a gasket only using this CID is generated as follows: Gaskets conforming to this CID are interchangeable with gaskets conforming to MS 27030. AA59326-G - X Dash Number (see Table 4) Indicate G for Gasket CID Number Example: AA59326G6 = A 2 Nominal size coupling gasket

A-A-59326B

7.6

Cross reference data. Coupling assemblies conforming to this CID are interchangeable with coupling assemblies conforming to MIL-C-27487. The following listing provides cross-references to the equivalent Military Standards. Mil-Standard sheet MS27020 MS27021 MS27022 MS27023 MS27024 MS27025 MS27026 MS27027 MS70091 MS27028 MS27029 CID Spec sheet A-A-59326/12 A-A-59326/13 A-A-59326/14 A-A-59326/15 A-A-59326/16 A-A-59326/17 A-A-59326/18 A-A-59326/19 A-A-59326/20 A-A-59326/21 Mil-Standard sheet MS49000 MS49001 MS49002 MS70088 MS70096 MS70095 MS70097 MS70100 MS39336 MS39352

CID Spec sheet A-A-59326/1 A-A-59326/2 A-A-59326/3 A-A-59326/4 A-A-59326/5 A-A-59326/6 A-A-59326/7 A-A-59326/8 A-A-59326/9 A-A-59326/10 A-A-59326/11

7.7 International Standardization. Certain provisions of this specification (dimensions) are the subject of international standardization agreements (STANAG No. 2761 and QSTAG 240). When amendment, revision, or cancellation of this specification is proposed, that will modify the international agreement concerned, the preparing activity will take appropriate action through international standardization channels, including departmental standardization offices, to change the agreement or make other accommodations (see specification sheets 1, 2, 4, 5, 7 14, and 1621). 7.8 Subject term (key word) listing. Cam lock Fitting Hose coupling Qdisc Kamlok 7.9 Sources of documents. 7.9.1 Copies of ASTM standards are available from the American Society for Testing and Materials, 1916 Racine Street, Philadelphia, PA 19103. 7.9.2 Copies of ANSI/ASME standards are available from the American National Standard Institute, 11 W. 42nd Street, New York, NY 10036. 8

A-A-59326B 7.9.3 Copies of The Metals & Alloys in the Unified Numbering System (UNS) are available from the Society of Automotive Engineers, Inc., 400 Commonwealth Drive, Warrendale, PA 15096-0001. 7.9.4 Copies of MPIF Standard 35 are available from the Metal Powder Industries Federation, 105 College Road East, Princeton, NJ 08540-6692. 7.9.5 The Code of Federal Regulations (CFR) may be obtained from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

B MAX

COUPLING HALF, MALE

RING, PULL

CHAIN

PIN, CAM

ARM, CAM

GASKET, SEE FIGURE 4

A MAX

COUPLING HALF, FEMALE

E .015 REF

RING, PULL

1.4 0.2 REF

D REF NUMBER OF TURNS

.106 W IRE REF

PULL RING DETAIL

FIGURE 1. Coupling assembly, quick-disconnect, cam-locking type.

A-A-59326B

TABLE 1. Coupling assembly, quick-disconnect, cam-locking type. A B (Max) B (Max) D E (Max) (Style 1) (Style 2) 1.50 2.88 3.10 2 0.156 1.50 2.88 3.10 2 0.156 1 1.75 3.00 3.50 2 0.156 1 3.00 3.69 4.30 2 0.156 1 3.00 3.94 4.50 2 0.156 2 3.00 4.38 4.90 2 0.156 2 3.00 4.88 5.40 2 0.156 3 3.25 5.75 6.40 2 0.250 4 3.25 6.88 7.50 2 0.250 6 4.25 10.10 10.60 3 0.250 Note: Dimensions are in inches, tolerances for dimension E shall be .02 for two place, .005 for three place decimals, unless otherwise specified hereon. Nominal Size Dimensions

10

A-A-59326B

R .19 MIN REF 7.75 MAX .19 .01 REF 6 THRU 12 EVEN NUMBER OF SIDES OPTIONAL FOR SIZES 1/2 THRU 4 ONLY

H MIN

FOR SIZE 6 ONLY (2 LUGS)

K MIN REF RADIUS C F MIN 125 E 63 0.20 .05 REF RADIUS G .02 2 PLACES J MIN WALL THICKNESS

+.09 -.02

A B

125 15

FIGURE 2. Coupling half, male.

11

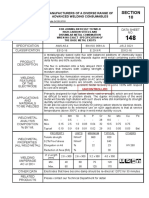

TABLE 2. Coupling half, male. Nominal Size A B C D E Dimensions F G H J (Min ) .09 .09 .09 .12 .12 .12 .15 .15 .20 .20 J SS (Min) .06 .06 .09 .09 .09 .09 .13 .13 .15 .15 K (Min) .37 .37 .37 .50 .50 .50 .63 .63 .87 .87 K SS (Min) .37 .37 .37 .50 .50 .50 .63 .75 .75 .75

1 1 1 2 2 3 4 6 75 psi

0.737 0.732 1.035 1.030 1.144 1.139 1.388 1.383 1.690 1.685 2.065 2.060 2.545 2.540 3.202 3.197 4.307 4.302 6.362 6.357

0.959 0.954 1.264 1.259 1.446 1.441 1.792 1.787 2.105 2.100 2.484 2.479 2.985 2.980 3.604 3.599 4.708 4.703 6.929 6.924

.378 .372 .378 .372 .378 .372 .441 .435 .441 .435 .441 .435 .441 .435 .503 .497 .503 .497 .659 .653

0.07 0.09 0.13 0.13 0.13 0.13 0.19 0.19 0.22 0.22

.471 .465 .471 .465 .565 .559 .690 .684 .690 .684 .848 .842 .848 .842 .895 .889 .895 .889 .963 .957

1.06 1.00 1.32 1.56 1.62 1.87 1.94 2.00 2.07 2.25

0.03 0.06 0.09 0.12 0.12 0.12 0.12 0.12 0.12 0.12

.959 1.264 1.259 1.446 1.441 1.792 1.787 2.105 2.100 2.484 2.479 2.985 2.980 3.604 3.599 4.708 4.703 6.929 6.924

6 6.362 6.929 .659 0.22 .963 2.25 0.12 6.929 .25 .15 .87 .75 150 psi 6.357 6.924 .653 .957 6.924 Note: Dimensions are in inches. Tolerance shall be .02 for two place, .005 for three place decimals; angles 2, unless otherwise specified hereon. Tolerances dont apply to J and K minimum dimensions.

12

A-A-59326B

B

SEE VIEW

125

D MIN

C

A

A

A

125

.09

VIEW

A-A

VIEW

ITEMS NOT SHOWN OMITTED FOR CLARITY

Note: For Reference Only

FIGURE 3. Coupling half, female.

13

A-A-59326B

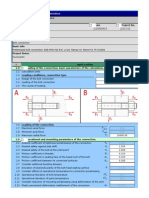

TABLE 3. Coupling half, female. Nominal Size A B Dimensions C D (Min) D Stainl ess Steel (Min) .06 .06 .09 .09 .09 .09 .13 .13 .15 E* Gasket (see figure 4) Torque to close cam arms

NA -1 60 inch lbs., max NA -2 60 inch lbs., max NA -3 70 inch lbs., max NA -4 100 inch lbs., max NA -5 100 inch lbs., max NA -6 100 inch lbs., max NA -7 100 inch lbs., max NA -8 140 inch lbs., max 3.90 -9 150 inch lbs., max 6 6 (75 6.950 7.14 .28 .20 .15 5.90 -10 200 inch lbs., max psi) 6 6 (150 6.950 7.14 .28 .25 .15 5.90 -10 200 inch lbs., max psi) 6 Note: Dimensions are in inches. Tolerance for dimension A, B, and C shall be .02 for two place, .005 for three place decimals; angles 1 unless otherwise specified hereon. * Dimension E is for reference purposes only and is not required.

1 1 1 2 2 3 4

.967 1.276 1.466 1.812 2.125 2.510 3.011 3.630 4.734

1.06 1.42 1.59 2.00 2.25 2.69 3.19 3.78 4.94

.19 .25 .28 .28 .28 .28 .28 .28 .28

.09 .09 .09 .12 .12 .12 .15 .15 .20

14

A-A-59326B

A

B C

FIGURE 4. Coupling Half Gasket.

TABLE 4. Gasket dimensions and specifications. Dash Coupling Dimension Min. gasket Number Nominal Size A B C compression -1 .967 1.06 0.19 0.025 Ref -2 1.375 .875 .218 0.025 Ref -3 1 1.563 1.063 .250 0.025 Ref -4 1 1.938 1.359 .250 0.025 Ref -5 1 2.188 1.625 .250 0.025 Ref -6 2 2.625 2.000 .250 0.025 Ref -7 2 3.125 2.375 .250 0.025 Ref -8 3 3.719 3.000 .250 0.025 Ref -9 4 4.875 4.000 .250 0.025 Ref -10 6 7.063 6.000 .250 0.025 Ref Note: Dimensions are in inches; tolerance shall be .010 for three place decimals, unless otherwise specified hereon.

15

A-A-59326B

NX

.438 .006

.030 M A

M

Nx

360 N

-A-

D

-B-

+.04 -.02

NOTE: For interpretation of geometric tolerancing symbology, see ASME Y14.5M. FIGURE 5. TTMA Flange drilling template.

16

A-A-59326B TABLE 5. TTM Flange dimensions. Nominal Dimension N size A B C D (No. of holes) 2 2.00 4.500 3.750 .375 6 2 2.50 5.000 4.250 .375 6 3 3.00 5.625 4.875 .375 8 4 4.00 6.625 5.875 .375 8 6 6.00 8.875 8.125 .500 12 1X2 1.00 4.500 3.750 .375 6 2X3 2.00 5.625 4.875 .375 8 2X4 2.00 6.625 5.875 .375 8 3X4 3.00 8.625 5.875 .375 8 Note: Dimensions are in inches, tolerance shall be .02 for two place, .005 for three place decimals, unless otherwise specified hereon.

MILITARY INTERESTS: Custodians: Army - AT Navy - YD Air Force 99 Review Activities: Army - AV, GL Navy - MC, SH Air Force - 71 DLA - CC

CIVIL AGENCY COORDINATING ACTIVITY: Preparing Activity: Army - AT (Project 4730-2005-071)

17

Vous aimerez peut-être aussi

- A-A-59326a (1) AcoplamentoDocument15 pagesA-A-59326a (1) AcoplamentogilsonPas encore d'évaluation

- Commercial Pipe Thread Couplings SpecifiedDocument3 pagesCommercial Pipe Thread Couplings Specifiedcvz240159Pas encore d'évaluation

- Mil C 27487FDocument18 pagesMil C 27487FT Mathew TholoorPas encore d'évaluation

- Astm A179 PDFDocument2 pagesAstm A179 PDFHimanshu GaurPas encore d'évaluation

- Astm A134Document4 pagesAstm A134Francisco HernandezPas encore d'évaluation

- SAE J518-1993 液压分体法兰 PDFDocument13 pagesSAE J518-1993 液压分体法兰 PDFliu zhao liu zhaoPas encore d'évaluation

- Retentor Din 3760Document13 pagesRetentor Din 3760Marcelo Godinho BatistaPas encore d'évaluation

- Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesDocument5 pagesContact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) FlangesJosé Luis Sierra100% (1)

- Astm A216 PDFDocument4 pagesAstm A216 PDFilliasuddinPas encore d'évaluation

- DIN 128 en PDFDocument3 pagesDIN 128 en PDFDaniel PuiaPas encore d'évaluation

- Bleed or Drip RingDocument2 pagesBleed or Drip RingAnonymous 6ZWS6IG2J9Pas encore d'évaluation

- 5p0102ab - KSB Megachem - O&m Manual PDFDocument12 pages5p0102ab - KSB Megachem - O&m Manual PDFRishabh VermaPas encore d'évaluation

- BS 3799Document28 pagesBS 3799Nigel FiresPas encore d'évaluation

- API 600 Vs API 603Document9 pagesAPI 600 Vs API 603Farid A Ghani100% (1)

- Sae J518 1993 PDFDocument14 pagesSae J518 1993 PDFdinesh panchal67% (3)

- DIN Superseded StandardsDocument32 pagesDIN Superseded StandardsGurdeep Singh100% (2)

- MSS SP 80 PDFDocument35 pagesMSS SP 80 PDFMuhamed AneeshPas encore d'évaluation

- A 285 - A 285M - 12 PDFDocument3 pagesA 285 - A 285M - 12 PDFأسامة وحيد الدين رمضان100% (1)

- Catalogo - TechlokDocument30 pagesCatalogo - Techlokorea1Pas encore d'évaluation

- Asme BPVC 2021 Section Viii Div. 1-2 - Ug-32Document2 pagesAsme BPVC 2021 Section Viii Div. 1-2 - Ug-32canizales70Pas encore d'évaluation

- Astm F 468Document11 pagesAstm F 468Ivan AlanizPas encore d'évaluation

- Iso 5211Document2 pagesIso 5211fabiosouza2010100% (4)

- DIN125ADocument1 pageDIN125AManoj PatilPas encore d'évaluation

- Castings, Austenitic, For Pressure-Containing PartsDocument7 pagesCastings, Austenitic, For Pressure-Containing Partsist93993100% (1)

- Astm B 505 PDFDocument8 pagesAstm B 505 PDFprodn123Pas encore d'évaluation

- Din 444Document1 pageDin 444joseocsilvaPas encore d'évaluation

- Sae 516 2005Document28 pagesSae 516 2005khhose67% (3)

- Standards Book 2002Document129 pagesStandards Book 2002oliveiralauroPas encore d'évaluation

- Din 939Document5 pagesDin 939rafael_engineer100% (3)

- Din 3357-1Document7 pagesDin 3357-1gm_revankar39420% (1)

- BS 3799 (74) Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum Industry PDFDocument32 pagesBS 3799 (74) Specification For Steel Pipe Fittings, Screwed and Socket-Welding For The Petroleum Industry PDFjodasi300% (1)

- PASCAL Check Valves CatalogueDocument19 pagesPASCAL Check Valves Cataloguecrys100% (1)

- Pressure-Reducing Valves For Water Systems, ShipboardDocument10 pagesPressure-Reducing Valves For Water Systems, Shipboardreza amiriniaPas encore d'évaluation

- +GF+ BS en 10242Document45 pages+GF+ BS en 10242stignz100% (2)

- b16 21 PDFDocument21 pagesb16 21 PDFavinash_k007Pas encore d'évaluation

- Din 2440-1978 EngDocument2 pagesDin 2440-1978 EngalsonccyPas encore d'évaluation

- Pressure Vessel Plate Specification RequirementsDocument34 pagesPressure Vessel Plate Specification Requirementsedisson_barreraPas encore d'évaluation

- ANSI B18.22 WashersDocument5 pagesANSI B18.22 WashersMario SuyamaPas encore d'évaluation

- DIN 7060 Curcular Sight Glass PDFDocument14 pagesDIN 7060 Curcular Sight Glass PDFalathekoala100% (2)

- Grayloc Product Catalog Woodco Usa PDFDocument7 pagesGrayloc Product Catalog Woodco Usa PDFDesign2 Department0% (1)

- Sae J417 1983 (En)Document11 pagesSae J417 1983 (En)Oh No Potato100% (1)

- BS en 558-2008Document30 pagesBS en 558-2008Fabio Peres de LimaPas encore d'évaluation

- ANSI B1.20.1 - NPT - American National Standard Taper Pipe ThreadsDocument2 pagesANSI B1.20.1 - NPT - American National Standard Taper Pipe Threadsdaf dafPas encore d'évaluation

- Astm A193 B7Document1 pageAstm A193 B7Wan Mohd Thariq100% (1)

- Sae J 343Document10 pagesSae J 343hartala_2000Pas encore d'évaluation

- Api 618 PDFDocument20 pagesApi 618 PDFHenry Jose Espinoza BejaranoPas encore d'évaluation

- Asme B16.10 - 2009 PDFDocument50 pagesAsme B16.10 - 2009 PDFTECNICOPas encore d'évaluation

- MSS SP-127-2001Document28 pagesMSS SP-127-2001Isabella MencacciPas encore d'évaluation

- Hydrodynamic Calculation Butterfly Valve (Lattice Disc)Document18 pagesHydrodynamic Calculation Butterfly Valve (Lattice Disc)met-calcPas encore d'évaluation

- BF-PPS As Dismantling Joints - EngDocument3 pagesBF-PPS As Dismantling Joints - EngbikarexpansionjointsPas encore d'évaluation

- Iso 4411Document18 pagesIso 4411Fabio StuiPas encore d'évaluation

- Astm A351 16Document7 pagesAstm A351 16Nguyen JohnPas encore d'évaluation

- MSS SP 6 (Flanges) PDFDocument6 pagesMSS SP 6 (Flanges) PDFtoys_chile0% (2)

- TypesDocument14 pagesTypesJoice BeserraPas encore d'évaluation

- DTL 18182 FDocument10 pagesDTL 18182 FHutauruk Edward V RogatePas encore d'évaluation

- JHDocument14 pagesJHghome123Pas encore d'évaluation

- A 928 - A 928M - 04 Qtkyoc9boti4tqDocument6 pagesA 928 - A 928M - 04 Qtkyoc9boti4tqsachinguptachdPas encore d'évaluation

- General Series Overhead Crane: User ManualDocument27 pagesGeneral Series Overhead Crane: User ManualjokoPas encore d'évaluation

- 12TMSS02R0, Saudi Electriicity Company StandardsDocument0 page12TMSS02R0, Saudi Electriicity Company StandardsMohammed NazeeruddinPas encore d'évaluation

- Grounding Rods Technical SpecificationDocument12 pagesGrounding Rods Technical SpecificationAnthony DavisPas encore d'évaluation

- Dust Plug Coupling Spec Details Sizes Chain AccessoriesDocument3 pagesDust Plug Coupling Spec Details Sizes Chain Accessoriescvz240159Pas encore d'évaluation

- 1.3.3 Electricity and magnetism Name Symbol SI unit Notes Q ρ ρ = Q/V σ Σ = Q/A C V, φ V = dW/dQ U, U = V E E = Ψ Ψ = ∫D⋅ dA C C = Q/U ε ε ε ε εDocument2 pages1.3.3 Electricity and magnetism Name Symbol SI unit Notes Q ρ ρ = Q/V σ Σ = Q/A C V, φ V = dW/dQ U, U = V E E = Ψ Ψ = ∫D⋅ dA C C = Q/U ε ε ε ε εcvz240159Pas encore d'évaluation

- Suction Line DPDocument4 pagesSuction Line DPudokasPas encore d'évaluation

- A A 59326 - 2BDocument5 pagesA A 59326 - 2Bcvz240159Pas encore d'évaluation

- A A 59326BDocument17 pagesA A 59326Bcvz240159Pas encore d'évaluation

- Dust Plug Coupling Spec Details Sizes Chain AccessoriesDocument3 pagesDust Plug Coupling Spec Details Sizes Chain Accessoriescvz240159Pas encore d'évaluation

- A A 59326BDocument17 pagesA A 59326Bcvz240159Pas encore d'évaluation

- Model 2100bDocument4 pagesModel 2100bkeyur1109Pas encore d'évaluation

- Amua Water Sysems ProductsDocument2 pagesAmua Water Sysems Productsevelyne_kiambatiPas encore d'évaluation

- Lab Report Experiment 1Document7 pagesLab Report Experiment 1Mohommad YawariPas encore d'évaluation

- MD Preboard 2011Document8 pagesMD Preboard 2011Francis Almia100% (1)

- Soldering, Brazing and Welding BasicsDocument7 pagesSoldering, Brazing and Welding BasicsJerin CyriacPas encore d'évaluation

- Kitz Butterfly Valve CatalogDocument28 pagesKitz Butterfly Valve CatalogAngel DavidPas encore d'évaluation

- SCAFCO Heavy Duty Steel Framing Product Manual Technical Notes B27532Document28 pagesSCAFCO Heavy Duty Steel Framing Product Manual Technical Notes B27532Mưa Vô HìnhPas encore d'évaluation

- 20160323010442-C50E (Ck50)Document2 pages20160323010442-C50E (Ck50)novkovic1984Pas encore d'évaluation

- Recycling Companies in LebanonDocument3 pagesRecycling Companies in LebanonVonder100% (1)

- Machining ProcessDocument51 pagesMachining ProcessSudeepPas encore d'évaluation

- Series 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Document12 pagesSeries 5000 Globe Valve: Pressure Class ASME 150 - 2500 / DIN PN 10 - 400Gopinath GunasekaranPas encore d'évaluation

- Torsion LabDocument22 pagesTorsion LabNeoXana01Pas encore d'évaluation

- 3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMDocument1 page3.28 & 3.29 Kawat Las Nikko Steel 312 2,6 X 350 MM & 3,2 X 350 MMumarPas encore d'évaluation

- Bainite Obtaining CIDocument6 pagesBainite Obtaining CIashokjkhannaPas encore d'évaluation

- Navedtra 14310 PDFDocument346 pagesNavedtra 14310 PDFskylancer-3441Pas encore d'évaluation

- Norsk Staal 2009 Engels K 141209Document54 pagesNorsk Staal 2009 Engels K 141209rejestrownikkPas encore d'évaluation

- Wirelock General InfoDocument7 pagesWirelock General InfoSteve MorrisonPas encore d'évaluation

- 12 Tig WeldingDocument8 pages12 Tig WeldingSampath KumarPas encore d'évaluation

- 25 Frame Plunger Pump: Standard Brass Model Stainless Steel Model Nickel Aluminum Bronze ModelDocument4 pages25 Frame Plunger Pump: Standard Brass Model Stainless Steel Model Nickel Aluminum Bronze ModelAnonymous IN80L4rRPas encore d'évaluation

- Chromecore 434N-S: Technical Data SheetDocument1 pageChromecore 434N-S: Technical Data Sheetdneprmt1Pas encore d'évaluation

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83Pas encore d'évaluation

- Physical and Chemical Changes WorksheetDocument4 pagesPhysical and Chemical Changes Worksheetapi-307565882100% (1)

- API 570 Open Book (26-02-18)Document5 pagesAPI 570 Open Book (26-02-18)Mahmoud Alwasif100% (1)

- ADI - A Perfect Engineering MaterialDocument12 pagesADI - A Perfect Engineering MaterialVS SaravananPas encore d'évaluation

- CBG7370 en Service MaterialDocument8 pagesCBG7370 en Service Materialluis martinezPas encore d'évaluation

- AISI 1045 Carbon Steel G10450 Din CK45 W-Nr. 1.1191 JIS S45C Sheet PlateDocument3 pagesAISI 1045 Carbon Steel G10450 Din CK45 W-Nr. 1.1191 JIS S45C Sheet Platenhirpara1Pas encore d'évaluation

- BoltCon - 02Document105 pagesBoltCon - 02Marinel1955100% (1)

- Essential Guide to Solid Wire and Rod ElectrodesDocument128 pagesEssential Guide to Solid Wire and Rod ElectrodesRaron1Pas encore d'évaluation

- Literature - 220 Ancra CatalogDocument116 pagesLiterature - 220 Ancra Catalogvinurules20Pas encore d'évaluation