Académique Documents

Professionnel Documents

Culture Documents

Section - Vii: Technical Specifications: 33 KV VCB

Transféré par

Sundaresan SabanayagamDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Section - Vii: Technical Specifications: 33 KV VCB

Transféré par

Sundaresan SabanayagamDroits d'auteur :

Formats disponibles

126

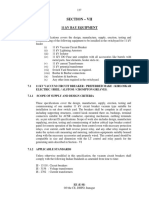

SECTION VII

TECHNICAL SPECIFICATIONS: 33 kV VCB

7.1

11 KV VACCUM CIRCUIT BREAKER : PREFERRED MAKE : KIRLOSKAR ELECTRIC / BHEL / ALSTOM / CROMPTON GREAVES / AREVA. SCOPE OF SUPPLY AND DESIGN CRITERIA These specifications cover the design, manufacture, supply, erection, testing and commissioning of one number 11 kV circuit breaker vacuum type suitable for installation in out door switch yard. The breakers shall be complete in all respect including supporting structures, control kiosk mounted there on, bushings, terminal connectors suitable for ACSR conductor, operating mechanism, earthing terminals etc. as per relevant IS specifications. Scope of work also includes design, manufacture supplying, erection, testing and commissioning of indoor cubical type breaker control panel for remote operation of the breaker from control room with necessary protection relays, over current, earth fault reverse power relay, and any other relay required to make the system safe measuring and metering, indication equipments suitably housed along with the necessary accessories and properly wired. This control panel should be compatible in size and dimension with the LT control and relay panels for the generating units described in Section - VI

7.1.1

7.1.2

APPLICABLE STANDARDS Unless otherwise modified in this specification, the vacuum circuit breakers shall comply with the following Indian Standards as amended from time to time: IS - 13118 : Circuit breakers IS - 3156 : Voltage transformers IS - 2702 : Current transformers

7.1.3 (i)

METERING AND PROTECTION Meters/instruments like KW meter, voltmeter, Ampere meter on the circuit breaker control panel shall be provided in accordance with the relevant ISI standards.

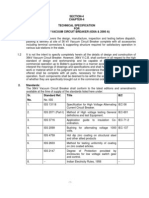

127 (ii) A triple-pole IDMTL type protection relay having two elements for over-current protection and one element for earth fault protection shall be provided on 11 kV outgoing circuit breaker control panel. The current setting range of the overcurrent elements shall be from 50% to 200% in steps of 25% and that of the earth fault element from 20% to 80% in steps of 10%. Trivector electronic energy meter (microprocessor based , digital) on control panel for metering of energy on outgoing feeder. Provision of relays shall be kept in the panel for protection of transformers from high winding temperature, high oil level temperature and low oil level. CONSTRUCTIONAL FEATURES VACCUM CIRCUIT BREAKER Out door Application: Vacuum circuit breakers for outdoor application shall be fixed type of construction and the vacuum interrupter units together with the HV connections shall be enclosed in a sealed housing (preferably of porcelain) conforming to IP65 protection (IS:2147). The operating mechanism, links, etc. shall be housed in a suitable cubicle and should be accessible for maintenance. The indicators and operating handle etc. shall be provided on the front side with a hinged door and locking device. The door shall open upwards (with hinge at the top) for protection against rain (when in open position) . No isolator shall be provided in outdoor breakers. 7.1..5 TECHNICAL PARTICULARS i. ii. iii. iv. v. vi. vii. Nominal system voltage Highest system voltage BIL Power Frequency withstand voltage Rated frequency Rated continuous current Closing mechanism with : : : : : : : 33 kV 36 kV 170 kV 70 kV 50 Hz 1250 A Electrical

(iii)

(iv)

7.1.4

spring

charging

viii. ix. x.

a. Closing coil/tripping coil (2 nos.) b. No. of Poles Symmetrical short circuit withstand capacity Temperature rise Operating duty

: : : : :

230 V AC motor and local manual closing. 48 V DC 3 750 MVA for 1 sec. Not to exceed 50oC above ambient temp. of 45oC. 0-3 min. CO-3 min.-CO.

128 xi. xii. xiii. xiv. xv. xvi. Dead time of breaker System neutral Min. creeping distance Control supply voltage Auxiliary, contacts with each circuit breaker Accessories a. b. c. d. e. ON/OFF/TRIP Emergency tripping mechanism Termination suitable with connectors Anti-pumping operation Spring charge indicator : : : : : Adjustable between 0.3 sec. to 15 sec. Solidly Earthed 900 mm 48 V DC 6NO+6NC Interchangeable at site

: : : : :

Mechanical as well as Electrical Mechanical ACSR Conductor To be provided To be provided

7.1.6 OPERATING MECHANISM i. ii. iii. Electrically / Manually operated mechanism. Breaker shall be provided with trip free mechanism. It shall be suitable for remote control from the control room. The operating mechanism shall be of spring charging type by electrical control under normal conditions. The mechanism shall be trip free electrically and mechanically. The motor for spring charging shall be suitable for operation on 230 V AC supply and shall have overload protection. A local control switch with locking arrangement shall be provided for each breaker for local operating i.e. tripping and closing during maintenance, test etc. Local/remote selector switch and Trip/Normal/Close control switch shall be provided in the mechanism cabinet. An operation counter for each breaker shall be provided. Cabinet for operating mechanism and its accessories shall be as per relevant standards with padlocking facility. Cabinet shall be simplex type, all equipment mounted on front side and wiring on back in proper wire ways. Panel illumination and anti-condensation heater shall be provided in the local and remote control panel with MCB and thermostat. Closing circuit to operate satisfactorily from 85% to 110% of the rated control voltage and tripping from 50% to 110% of the rated voltage.

iv. v. vi. vii. viii.

ix. x.

129

7.1.7

TESTS The circuit breakers, voltage transformers and current transformers shall be subjected to the following routine and type test in accordance with the details specified in the relevant Indian Standards, as amended from time to time. Circuit Breaker - IS : 13118-1991

(i)

Routine Tests ii) iii) iv) v) Power frequency voltage dry test on the main circuit Voltage test on control and auxiliary circuits. Measurement of resistance of the main circuit Mechanical operating test

(ii)

Type Tests a) b) c) d) e) f) g) h) i) j) Tests to prove mechanical performance Tests to prove mechanical operation Tests to prove that temperature rise of any part does not exceed specified limits Tests to prove that insulation complies with specified limits Tests to prove short-circuit making and breaking performance. Tests to prove sort-time current performance. Tests to prove performance when breaking line charging current Test to prove performance when breaking cable charging current Tests to prove the performance when breaking single capacitor bank currents Tests to prove the performance when breaking small inductive currents.

Vous aimerez peut-être aussi

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- 11 KV Bay EquipmentDocument22 pages11 KV Bay EquipmentSudhir ShindePas encore d'évaluation

- 33kV Breaker SpecDocument19 pages33kV Breaker SpecBala KumaranPas encore d'évaluation

- VCB PanelsDocument17 pagesVCB PanelsSenthil Prasadh100% (1)

- Acb VCBDocument4 pagesAcb VCBAbhay KumarPas encore d'évaluation

- 3 4D Recloser G2801041Document11 pages3 4D Recloser G2801041Rehan KhalilPas encore d'évaluation

- Technical Specification VCB PanelDocument14 pagesTechnical Specification VCB PanelDarshit VyasPas encore d'évaluation

- Medium Voltage Capacitor Bank SpecificationsDocument4 pagesMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaPas encore d'évaluation

- Specifications For: 11Kv Pad Mounted SwitchDocument8 pagesSpecifications For: 11Kv Pad Mounted SwitchFarhan ShahPas encore d'évaluation

- Meters & Metering Cabinet & MCCBDocument30 pagesMeters & Metering Cabinet & MCCBnatsclimbersPas encore d'évaluation

- Solar System Specs in KPDocument9 pagesSolar System Specs in KPWaseemz ShahPas encore d'évaluation

- Technical Specification of 12 KV Indoor Type Vacuum Circuit Breakers Against Tn-2593 1.0 ScopeDocument26 pagesTechnical Specification of 12 KV Indoor Type Vacuum Circuit Breakers Against Tn-2593 1.0 ScopePrintmePas encore d'évaluation

- 33kv Indoor SwitchgearDocument8 pages33kv Indoor SwitchgearpvenkyPas encore d'évaluation

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930Pas encore d'évaluation

- 11 KV, 12 Panel Board Vacuum Type Swithgear (1250) ADocument38 pages11 KV, 12 Panel Board Vacuum Type Swithgear (1250) ABoreda RahulPas encore d'évaluation

- Remarks On Diff BW TI - SPC - PSI - PROTCT - 6071 & 6072 DraftDocument6 pagesRemarks On Diff BW TI - SPC - PSI - PROTCT - 6071 & 6072 DraftRAJADEVANPas encore d'évaluation

- Chapter 3 Generator Circuit Breaker (GCB)Document15 pagesChapter 3 Generator Circuit Breaker (GCB)Anonymous nwByj9LPas encore d'évaluation

- Section 8 33KVDocument13 pagesSection 8 33KVMuna HamidPas encore d'évaluation

- Automatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksDocument13 pagesAutomatic Power Factor Correction Equipment /capacitor Banks For Low Voltage Distribution NetworksBrajan's B.Pas encore d'évaluation

- 卷二Document572 pages卷二ashraful tanvirPas encore d'évaluation

- ISF2 Catalog PDFDocument8 pagesISF2 Catalog PDFbdikicPas encore d'évaluation

- Section-7.3 Substation EquipmentDocument84 pagesSection-7.3 Substation EquipmentBRB CABLEPas encore d'évaluation

- VCB SpecificationsDocument17 pagesVCB SpecificationsHarsh GuptaPas encore d'évaluation

- Technical Specification For 150 KV Circuit BreakerDocument9 pagesTechnical Specification For 150 KV Circuit BreakerAde DwinantoPas encore d'évaluation

- 3Document33 pages3toogooodPas encore d'évaluation

- Section-4 Chapter-5 Technical Specification For 11 KV Switchgear Panels Vacuum Type (1250A)Document12 pagesSection-4 Chapter-5 Technical Specification For 11 KV Switchgear Panels Vacuum Type (1250A)PB MehtaPas encore d'évaluation

- 151919111951e37-Ts Substation Automation - 13042019Document83 pages151919111951e37-Ts Substation Automation - 13042019Manas Kumar SahooPas encore d'évaluation

- Viper - S Solid Dielectric, Three Phase Reclosers: Typical SpecificationsDocument5 pagesViper - S Solid Dielectric, Three Phase Reclosers: Typical SpecificationsErick MoraPas encore d'évaluation

- AC Circuit Breakers Routine Tests According To IEC 62271-100Document12 pagesAC Circuit Breakers Routine Tests According To IEC 62271-100sathishkannanPas encore d'évaluation

- Spec VSDDocument8 pagesSpec VSDNicodemus Ervino MandalaPas encore d'évaluation

- KUVAG Indicating System CPI VI-3P R (10-52kV)Document3 pagesKUVAG Indicating System CPI VI-3P R (10-52kV)registracijus100% (1)

- Specification 11kV VCB Panel - IndoorDocument29 pagesSpecification 11kV VCB Panel - Indoormayur100% (1)

- Specification 33KV GIS ZX0.2Document16 pagesSpecification 33KV GIS ZX0.2BADRI VENKATESHPas encore d'évaluation

- Three-Phase Overcurrent Relay Spaj 131 C: Product GuideDocument12 pagesThree-Phase Overcurrent Relay Spaj 131 C: Product GuideSharaf Ali ZyoudPas encore d'évaluation

- Tech. Spec. For 0.5s Accuracy Class LT TOD Three Phase Import-Export For 50KVA To 125 KVA Load........... Dated. 02.02.2015Document28 pagesTech. Spec. For 0.5s Accuracy Class LT TOD Three Phase Import-Export For 50KVA To 125 KVA Load........... Dated. 02.02.2015RAVIKANT SINDHEPas encore d'évaluation

- Method Statement For AC PANELDocument6 pagesMethod Statement For AC PANELkamilPas encore d'évaluation

- PG - HT Solar Bidirectional MeterDocument24 pagesPG - HT Solar Bidirectional Meterdecorindo20020% (1)

- Catalogo Wieland, Reles Medidores de CorrienteDocument78 pagesCatalogo Wieland, Reles Medidores de Corrientejose125Pas encore d'évaluation

- Protective Devices MV Panels Upto415vDocument8 pagesProtective Devices MV Panels Upto415vNATHANPas encore d'évaluation

- Technical Specification For 33 KV GisDocument20 pagesTechnical Specification For 33 KV GisAp kowshikPas encore d'évaluation

- 22kV GTPDocument41 pages22kV GTPSundaresan Sabanayagam100% (1)

- Spau140c Tob 750421encDocument12 pagesSpau140c Tob 750421encOscar Felipe C.Pas encore d'évaluation

- MSEDCL - 11KV VCB SpecsDocument37 pagesMSEDCL - 11KV VCB Specsabhi6784Pas encore d'évaluation

- Technical Specifications For Line TrapsDocument3 pagesTechnical Specifications For Line TrapshaydarPas encore d'évaluation

- 1-10-020-15 ThyristorDocument9 pages1-10-020-15 ThyristornishantpsbPas encore d'évaluation

- New Trivector Meter-3p - 3wireDocument8 pagesNew Trivector Meter-3p - 3wireVishwanath Todurkar100% (1)

- Technical Specification 2 1590816047Document35 pagesTechnical Specification 2 1590816047Mohammed wajidPas encore d'évaluation

- General: Clause No. Variable Frequency DrivesDocument15 pagesGeneral: Clause No. Variable Frequency Drivesrahul patraPas encore d'évaluation

- Pcits2000 2Document3 pagesPcits2000 2batambintanPas encore d'évaluation

- Celda Compacta de Distribucion Secundaria Ring MasterDocument160 pagesCelda Compacta de Distribucion Secundaria Ring MasterPrabhu ChandranPas encore d'évaluation

- 33 KV VCBDocument7 pages33 KV VCBMathur Dinesh0% (1)

- Manual CTI Technical Manual PDFDocument39 pagesManual CTI Technical Manual PDFaricomen43% (7)

- Spec. Hvac 2004 (CPWD)Document7 pagesSpec. Hvac 2004 (CPWD)SALIMPas encore d'évaluation

- D-07 11kv SwitchgearDocument12 pagesD-07 11kv SwitchgearShri Anvesha D100% (1)

- Hybrid SwitchgearDocument24 pagesHybrid SwitchgearbinodePas encore d'évaluation

- Workpack TEMANA ShutdownDocument23 pagesWorkpack TEMANA Shutdownhitm357Pas encore d'évaluation

- B) M V SwitchgearDocument7 pagesB) M V Switchgearnyala chisolaPas encore d'évaluation

- Technical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramDocument13 pagesTechnical Specification of LT Panel (Switchboard) : To Be Found in The One-Line DiagramSharath CherryPas encore d'évaluation

- Type VHXM: Under / Over Voltage RelayDocument6 pagesType VHXM: Under / Over Voltage RelayNikki AgarwalPas encore d'évaluation

- Difference Between Actual Versus Installed KVARDocument3 pagesDifference Between Actual Versus Installed KVARSundaresan SabanayagamPas encore d'évaluation

- The Process of Phosphating - Some FAQs - ENGINEERING REVIEW - Manufacturing - Industrial Sector Magazine & PortalDocument6 pagesThe Process of Phosphating - Some FAQs - ENGINEERING REVIEW - Manufacturing - Industrial Sector Magazine & PortalSundaresan SabanayagamPas encore d'évaluation

- 22kV GTPDocument41 pages22kV GTPSundaresan Sabanayagam100% (1)

- Specification Powder Coating Plant Document - UjjainDocument9 pagesSpecification Powder Coating Plant Document - UjjainSundaresan SabanayagamPas encore d'évaluation

- Viewtenddoc PDFDocument68 pagesViewtenddoc PDFSundaresan SabanayagamPas encore d'évaluation

- Switchgear ERADADocument4 pagesSwitchgear ERADASundaresan SabanayagamPas encore d'évaluation

- Test Distance Relay 7SA522Document55 pagesTest Distance Relay 7SA522Sundaresan SabanayagamPas encore d'évaluation

- Anord UL Product RangeDocument8 pagesAnord UL Product RangeSundaresan SabanayagamPas encore d'évaluation

- Engineering Specification For MV SwitchgearDocument21 pagesEngineering Specification For MV SwitchgearSundaresan SabanayagamPas encore d'évaluation

- ZAPI AC-1 ManualDocument62 pagesZAPI AC-1 ManualMarcos Gregorio da SilvaPas encore d'évaluation

- DS01071 XNX Universal Transmitter FLR 8-3-11Document4 pagesDS01071 XNX Universal Transmitter FLR 8-3-11itskittylimPas encore d'évaluation

- Nvidia DGX Os 4 Server: Software Release NotesDocument19 pagesNvidia DGX Os 4 Server: Software Release Notesloreto07Pas encore d'évaluation

- 6WG1 TanıtımDocument17 pages6WG1 TanıtımHalil KaraPas encore d'évaluation

- Colortrac S4e Service Manual-2Document66 pagesColortrac S4e Service Manual-2hany_elbanna2000100% (1)

- CareerCentre Resume and Cover Letter Toolkit - UofTDocument32 pagesCareerCentre Resume and Cover Letter Toolkit - UofTMallikaShakyaPas encore d'évaluation

- Manual de Reparacion MCR Serie 32-33Document34 pagesManual de Reparacion MCR Serie 32-33Fernando Tapia Gibson100% (2)

- 5th Harmonic Resonance: Power QualityDocument2 pages5th Harmonic Resonance: Power QualityLorena OrtizPas encore d'évaluation

- Bangalore It Companies Directory PDFDocument168 pagesBangalore It Companies Directory PDFdeepakraj2005Pas encore d'évaluation

- Online Mobile Phone Shop A ASP Net ProjectDocument40 pagesOnline Mobile Phone Shop A ASP Net ProjectMalathi palanisamyPas encore d'évaluation

- Key Responsibility AreasDocument6 pagesKey Responsibility AreasSubodh YadavPas encore d'évaluation

- Future MuseumDocument12 pagesFuture MuseumPatriciaPas encore d'évaluation

- Laptop Sebagai Teman Siswa: Laptop As Students' FriendDocument1 pageLaptop Sebagai Teman Siswa: Laptop As Students' Friendtigor lianda manik07Pas encore d'évaluation

- sm-g361h DsDocument44 pagessm-g361h DsTest TestPas encore d'évaluation

- Energy Management and Heat Storage For Solar Adsorption CoolingDocument11 pagesEnergy Management and Heat Storage For Solar Adsorption CoolingRendy Adhi RachmantoPas encore d'évaluation

- A Comparative Study On Mobile Platforms (Android vs. IOS) : Smt. Annapurna, K.V.S. Pavan Teja, Dr. Y. Satyanarayana MurtyDocument7 pagesA Comparative Study On Mobile Platforms (Android vs. IOS) : Smt. Annapurna, K.V.S. Pavan Teja, Dr. Y. Satyanarayana MurtyAravindhPas encore d'évaluation

- Comparison of Voltage Control Methods in Distribution Systems Using Q-V Based PI and Droop Controls of Solar InvertersDocument5 pagesComparison of Voltage Control Methods in Distribution Systems Using Q-V Based PI and Droop Controls of Solar Invertersmirko.tPas encore d'évaluation

- Library - Management - Project Report by Vaishali & Sukhwinder Kaur BCA (3rd Yr.)Document64 pagesLibrary - Management - Project Report by Vaishali & Sukhwinder Kaur BCA (3rd Yr.)Naveen SharmaPas encore d'évaluation

- 2.auto Indexing Drilling MachineDocument7 pages2.auto Indexing Drilling Machinesasitharan33Pas encore d'évaluation

- Volvo Tad 660ve SpecsDocument5 pagesVolvo Tad 660ve SpecsAhmed Mostafa YoussefPas encore d'évaluation

- Mei Cashflow SC / SC Advance Operation & Maintenance ManualDocument14 pagesMei Cashflow SC / SC Advance Operation & Maintenance ManualNoelPas encore d'évaluation

- Conveyor Safety Switches 2 5Document16 pagesConveyor Safety Switches 2 5yatinthoratscrbPas encore d'évaluation

- Lisa Kleypas Un Strain Frumos PDF 1 PDFPDF CompressDocument360 pagesLisa Kleypas Un Strain Frumos PDF 1 PDFPDF CompressIlinca100% (1)

- Mohammed M. Windows Forensics Analyst Field Guide... 2023Document318 pagesMohammed M. Windows Forensics Analyst Field Guide... 2023rick.bullard6348Pas encore d'évaluation

- Digital Front End Developement BTADocument4 pagesDigital Front End Developement BTAmannPas encore d'évaluation

- Thermal Transfer / Direct Thermal Print Engine: MH241/MH341/MH641/ MH241T/MH341T/MH641T/ MH241P/MH341P/MH641P SeriesDocument14 pagesThermal Transfer / Direct Thermal Print Engine: MH241/MH341/MH641/ MH241T/MH341T/MH641T/ MH241P/MH341P/MH641P SeriesVladimir BorkovskiyPas encore d'évaluation

- Implementing Accounting HubDocument258 pagesImplementing Accounting HubNarendra ReddyPas encore d'évaluation

- QUANTUM Q1000 Advanced ProtocolsDocument2 pagesQUANTUM Q1000 Advanced Protocolsgundala2000Pas encore d'évaluation

- ACA UNIT-5 NotesDocument15 pagesACA UNIT-5 Notespraveennegiuk07Pas encore d'évaluation

- The COBIT 5 Processes Are Split Into Governance and ManagementDocument8 pagesThe COBIT 5 Processes Are Split Into Governance and ManagementdevmasterPas encore d'évaluation