Académique Documents

Professionnel Documents

Culture Documents

1

Transféré par

VaradarajDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1

Transféré par

VaradarajDroits d'auteur :

Formats disponibles

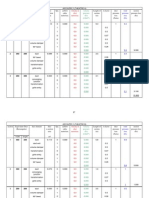

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 1 1.1 DESCRIPTION GENERAL REQUIREMENTS * AS- BUILT DRAWING * Contractor has to submit final detailed AS- built drawings of all external works such as fence ,entrance gate, guard house, guard room, electrical room and all other items in the general site plan including final design pattern of interlock tiles of walkways and drive ways to the Consultant. Also, submit all the electro-mechanical * works underneath or upon the ground level in the general site plan. (All these drawings shall be in one electronic CD plus one original copy on special mylar paper and two blue print copies).This Item (1.1) shall be a condition to pay the Final Invoice. * SHOP DRAWINGS * Contractor has to submit detailed Shop drawings of all external works such as fence, gates, guard house, guard room, electrical room and all others in the general site plan including design pattern of interlock tiles of walkways and drive ways to the * Consultant for final approval prior to start its related activity. Contractor has to submit all the electro-mechanical works underneath or upon the ground level in the general site plan before starting work in the site. 2 Site visitation and soil test * * L.S. 1 included LOCATION Inoice ref no UNIT REVISED QTY. REMARKS Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion

Total Value Qty Value Qty

Balance Value

#DIV/0!

0.00

0.00

0.00

UNIT

included

0%

0%

0.00

0.00

0.00

1.00

1.2

#DIV/0!

0.00

0.00

0.00

0%

0.00

0.00

1.00

The Contractor shall visit the site and inspect it. He shall check the soil type, the level of under groundwater table and bearing capacity and compare it with the * mentioned in the designed structural drawings.This shall be made by making soil laboratory test in any approved soil testing facility. 3 3.1 3.1.1 EXTERIOR WORKS FLOORING SITE WORKS * * * *

#DIV/0!

0.00

0.00

0.00

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

0.00 0.00 0.00 0.00

0.00 0.00 0.00 0.00

0.00 0.00 0.00 0.00

Supply and install 120mm thick asphalt paving in two layers (50mm + 70mm) layers for all driveways and parking areas ( which has no interlock ). All asphalt mixture shall be supplied from AL-OSAIS or from ARAMCO according to the American * specification for asphalt works and tests. Also,supply & install the base course and sub-base course ( All works according to ASTM and AASHTO Tests and Specifications ) on the following: Subgrade preparation: Removing all the undersize materials from site, leveling, sloping, spray water and make compaction by rollers; it's weight not less than 25 tons with vibrator and make * compaction with a percentage of maximum density not less than 95% of Proctor Test .

#DIV/0!

0.00

0.00

0.00

3.1.1.1

#DIV/0!

0.00

0.00

0.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 1/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # DESCRIPTION Supply and install 300mm sub-base course as layer according to AASHTO Tests. Laying shall be made in required and approved levels. Submerge with water and * use roller compactor with complete density not less than 95% of Proctor Test. Supply and install 200mm base course per layer according to AASHTO Tests. Laying shall be made in required and approved levels. Submerge with water and * use roller compactor with a percentage of maximum density 100% of ProctorTest. Supply and spread hot liquid bitumen MCO (MC1). Shall be made in two perpendicular direction layers and equal to one and half kilogram per square meter * (According to Asphalt Institute, Inc. Specifications). Supply and install 7cm asphaltic bender course layer with it's aggregate graded size 3/4 inch according to ASTM Specifications and Tests using all the special * mechanical equipments. Supply and spread hot liquid bitumen tack coat (MC2) with a shall be made in one * layer 0.75 kilogram per square meter (According to ASTM Specifications and Tests). Supply and install 5cm asphaltic wearing course mixture layer with it's aggregate graded size 1/2 inch according to ASTM Specifications and Tests using all the * special mechanical equipments. Supply and install ceramic eye cat supplied from Saudi Ceramic or alternate and phosphoric yellow colour paint (AASHTO M 248 Specifications) supplied from Al * Jazeera Company for parking tracks and distribute marking with mechanical equipments. The item include all the necessary accessories. All approved heavy and light equipments, workers, technical tests and all the necessary works to complete the * job. Total price for one square meter including all last described items(3.1.1.3 - 3.1.1.7). * 3.1.2 Side walk and Car parking. * M2 2,213 This area is for asphalt 59 130,567.0 LOCATION Inoice ref no UNIT REVISED QTY. 0 REMARKS Whole Site Works Existing on Site is Marl Whole Site Works Existing on Site is Marl Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion #DIV/0!

Total Value Qty Value Qty

Balance Value

3.1.1.2

M2

0.00

0.00

0.00

3.1.1.3

M2

#DIV/0!

0.00

0.00

0.00

3.1.1.4

#DIV/0!

0.00

0.00

0.00

3.1.1.5

#DIV/0!

0.00

0.00

0.00

3.1.1.6

#DIV/0!

0.00

0.00

0.00

3.1.1.7

#DIV/0!

0.00

0.00

0.00

3.1.1.8

#DIV/0!

0.00

0.00

0.00

#DIV/0!

0.00

0.00

0.00

0%

0% #DIV/0!

0.00

0.00

0.00

2,213.00

130,567.00

0.00

0.00

0.00

Supply and install concrete interlock paving for side walks and car parking including interlock, plain concrete, selected fill layer, compaction, concrete curbstone, bituminous layer, cement mortar (350 kg ordinary portland cement per one cubic red sand clean from organic or clay particles, sweet water for mix according to Saudi * Specifications), expansion joints from flexible material Fosam production and all the necessary materials or items to complete the job according to the plan drawing and the Consultant's approval on the following: Concrete red and grey interlock blocks (7 x 10 x 20cm). For walkway supplied from Almedeafer or Bin Dayel or AL MOJIL companies or alternate approved supplier (Compressive strength 90 N/mm2 according to German Specifications BS 6717) * rested on 7cm red sand. Interlock blocks are rested on 20cm thick of compacted sub-base layer (ASTM Specifications). Concrete red and grey interlock blocks (10 x 12 x 20cm). For walk car parking supplied from (Almedeafer or Bin Dayel or AL MOJIL) companies or alternate approved supplier (Compressive strength 90 N/mm2 according to German Specifications BS 6717) rested on 7cm red sand upon bituminous 2 cold coats supplied from Bitumat (AASHTO Specifications), underneath the last layers 10 cm * thick. Reinforced concrete (3000psi. ordinary portland cement type I) reinforced with wire mesh #8mm @20cm. Pavement layer from the interlock and the plain concrete rested on polyethylene sheets (200 micron) thick and 20cm thick of compacted sub-base layer (ASTM Specifications).

#DIV/0!

0.00

0.00

0.00

3.1.2.1

M2

#DIV/0!

0.00

0.00

0.00

3.1.2.2

M2

#DIV/0!

0.00

0.00

0.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 2/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # DESCRIPTION Concrete red and grey interlock blocks (10x12x20cm). For Building Perimeter parking supplied from (Almedeafer or Bin Dayel or AL MOJIL) companies or * alternate approved supplier (Compressive strength 90 N/mm2 according to German Specifications BS 6717) rested on 7cm red sand. Supply and install 50 x 30 x 15 cm concrete curbstone supplied from Al Kifah or Almedeafer or alternate companies, this size of curbstone to define the edges of all * walk way interlock all around main building ( see it's location in Arch. Plan Drawing).The concrete curbstone block shall be installed on 10cm plain concrete( 2500 psi ordinary portland cement) with width 25cm . Supply and install 50 x 20 x 15 cm concrete curbstonesupplied from Al Kifah or Almedeafer or alternate companies, this size of curb- stone to define the edges of all interlock parking places and to define the edges of green areas ( see it's location * in Arch. Plan Drawing). The concrete curbstone block shall be installed on 10cm plain concrete( 2500 psi ordinary portland cement) with width 25cm . Concrete red and grey interlock blocks (7x10x20cm). For external sidewalk way outside fences(1% slope for out direction) Supplied from Almedeafer or Bin Dayel or AL MOJIL companies or alternate approved supplier rested on 7cm clean red sand. * Interlock blocks are rested on 20cm thick of compacted sub-base layer ( ASTM Specifications) and confined with concrete curbstone 40 x 30 x 15 cm as explained in Item No. 3.1.2.3. Supply and installl green area landscaping same as distributed in drawings complete with item with all required grass, soil, trees and fertilizers complete item. This green area contains the following plants: grass,Washingtonia,Dodongaviscosa,Ficusni Tipa (Tree),Chloredendum Enerme. * LOCATION Inoice ref no UNIT REVISED QTY. 1,284 REMARKS Unit price 85 Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion 0%

Value

Invoice - 5 % Qty completion 0%

Total Value Qty Value Qty

Balance Value

3.1.2.3

M2

Building Perimeter

109,140.0

0.00

0.00

0.00

1,284.00

109,140.00

3.1.2.4

LM

320

47

15,040.0

0%

0%

0.00

0.00

0.00

320.00

15,040.00

3.1.2.5

LM

450

47

21,150.0

0%

0%

0.00

0.00

0.00

450.00

21,150.00

3.1.2.6

M2

NIL

0.0

#VALUE!

0.00

0.00

0.00

#VALUE!

0.00

3.1.2.7

M2

1,100

32

35,200.0

0%

0%

0.00

0.00

0.00

1,100.00

35,200.00

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

0.00 0.00 0.00 0.00 0.00

0.00 0.00 0.00 0.00 0.00

0.00 0.00 0.00 0.00 0.00

4 4.1

All plants and green area shall be distributed according to the defined places in drawings and the approved submitted landscaping shop drawing design to the * Consultant and the Owner. * FENCE WORKS: * Excavation * Excavate for all footings and grade beams. Foundation level for footings must be not less than (-1.2m) below natural grade level and as shown in structural drawings. * The foundation level must be cleaned from any strange materials and shall be compacted to 95% of maximum dry density as per Saudi Specifications.

1a

M3

972

11

10,692.0

70%

680.4

7,484.4

30%

291.6

3,207.6

0.0

0%

0.0

0.0

0%

0.00

972.00

10,692.00

0.00

0.00

4.2

Backfill

#DIV/0!

0.00

0.00

0.00

Above and around foundations to leveled ground surface of the site and to bottom of (grade slab or asphalt base course) using clean granulated sand and the last 20 cm from selected fill A-1-A according to American Specifications( AASHTO). Rate shall * include submerging with raw water and the compaction 75% for clean sand and 95% for selected fill from the maximum dry density.

1b

M3

742

17

12,614.0

70%

519.4

8,829.8

0%

0.0

0.0

0.0

0%

0.0

0%

0.00

519.40

8,829.80

222.60

3,784.20

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 3/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 4.3 Masonry and Fence Steel Works DESCRIPTION * LOCATION Inoice ref no UNIT REVISED QTY. REMARKS Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion #DIV/0!

Total Value 0.00 Qty 0.00 Value 0.00 Qty

Balance Value

Rates shall be fully inclusive for a complete job including , concrete to block ties, wall ties and types of joints reinforcement. Mortar, grouting of cavities and joints including fillers where required.*The contractor will take approval from the * Consultant about any materials before supplying. *Block with it's sizes and types shall be supplied from Almedeafer or Bin Dayel or AL MOJIL companies or alternate approved supplier. Supply and install concrete hollow block with size 20x20x40cm with dry density 1.8 t/m3. The blocks shall be built by using mortar (350kg ordinary portland cement and one cubic graded clean sand).Sweet water shall be used for this mix.The rate * include all the necessary accesories,handling,wetting block. Treat the masonry with water for 4 days. Note. No need for block work for our Fence according to the Architectural * Drawings. Supply and install steel fence with height equal to 2.80ms consists of square steel columns 80mm x 80mm x 4mm thick every 5m,vertical steel rectangular secs. 70mm x 20mm x 2.80m height every 23cm. All vertical members shall be electrical mechanical welding 6mm thick with one rectangular steel sec. 80mm x 20mm at the bottom level of the 2.8m height and another one at the level of 2.47m of the height. All steel is black steel protected with 2 primer coats and painted with 2 coat spray coloured painting. Paints shall be supplied from Al Jazeera or other alternate supplier with the Consultant's approval. The work shall be completed with all the accessories and any missed items. Supply and install one leaf steel door size 1.00m wide x 2.10m height consists of steel frame tube sec. (60mm x 50 mm x 4mm thick), rectangular steel tube sections for horizontal and vertical girders ( 20mm x 20mm x 1.5mm @ 50cm ) , covering with steel sheets for both sides with thickness 1.5mm and all steel sections shall be painted with primer and the steel sheets and frames shall be painted with coloured paint bullet ( All paints shall be supplied from Al Jazeera).The work shall be completed with all necessary accessories as the submitted shop drawing and samples to the Consultant . Supply and install sliding steel door 6.00m wide x 2.5m height consists of steel tube frame sec.(80mm x 60mm x 5mm thick), rectangular steel sections for vertical girders ( 30mm x 30mm x 3mm thick. @ 23 cm) and two horizontal girders withe same section in the top and bottom of the gate.All the secs. shall be steel welded 6mm thick and paint bullet painted. The work shall be completed with all accessories, bottom steel wheels and the steel railway. Supplier shall be Randa or Almasmak or alternate supplier. Supply and install sliding double leaf steel door 12.00m wide x 2.5m height consists of steel tube frame sec.(100mm x 80mm x 5mm thick), rectangular steel sections for vertical girders ( 30mm x 30mm x 3mm thick @ 23 cm) and three horizontal girders with same section in the top, middle and bottom of the gate . All the secs. shall be steel welded 6mm thick. and paint bullet painted. ( Al Jazeera Paints supplier ...etc.). The work shall be completed with all accessories; bottom steel wheels and the steel railway. Supplier shall be Randa or Almasmak or alternate supplier.

#DIV/0!

0.00

0.00

0.00

4.3.1

M2

NIL

#VALUE!

0.00

0.00

0.00

#DIV/0!

0.00

0.00

0.00

4.3.2

LM

872

445

388,040.0

20%

174.4

77,608.0

0%

0.0

30%

261.60 116,412.00 436.00 194,020.00

436.00

194,020.00

4.3.3

Nos.

2200

2,200.0

0%

0%

0.00

0.00

0.00

1.00

2,200.00

4.3.4

Nos.

10000

10,000.0

0%

0%

0.00

0.00

0.00

1.00

10,000.00

4.3.5

Nos.

20000

20,000.0

0%

0%

0.00

0.00

0.00

1.00

20,000.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 4/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 4.4 Water Proofing Supply and install cold water proofing for all concrete surfaces attach with soil like [ Footings, neck columns, grade beams, reinforced concrete walls]. The work shall be completed with all accessories and according to ( ASTM , Saudi Kingdom) Specifications. The materials shall be supplied from Dermabit or Bitumat or alternate suppliers. Supply and install 2 coats of cold bituminous paint for all R.C. surfaces attached with soil after cleaning it's surfaces and repairing all voids by cemented mortar and chemical additive ADI-BOND. Supply and install 2cm expansion joints in longitudinal reinforced concrete members every 12 linear meter which consists of 2cm filler board, filler rod and flexible joining sealant material ( Fosam supplier). Plain Concrete Supply and install 2000psi plain concrete ( ordinary portland cement type I ) with 10cm thick under R.C. foundation and grade beams. The bottom of excavated soil must be cleaned from any strange materials and compact it as mentioned in ( 4.1). Spray clean water and use good wooden forms. The work shall be completed and includes all the necessary accessories. The work shall be according to ( ASTM , Saudi Kingdom) Specifications. Reinforced Concrete Supply and install reinforced concrete according to ASTM and Saudi kingdom specifications. Contractor must review all the drawings and check the design carefully and follow all the general and special notes mentioned in drawings. Rate shall include all formwork & rebars. Treat with clean sweet water and all the neccessary items to complete the work. Supply and install 3500 psi reinforced concrete for foundation using sulphate resistant portland cement type V , steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 4000 psi reinforced concrete for column neck using sulphate resistant portland cement type V , steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 3500 psi reinforced concrete for grade beams using sulphate resistant portland cement type V , steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 3500 psi reinforced concrete for retaining wall using sulphate resistant Portland cement type V , steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Paints and Plaster works for concrete and walls DESCRIPTION * * LOCATION Inoice ref no UNIT REVISED QTY. REMARKS Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion

Total Value 0.00 0.00 Qty 0.00 0.00 Value 0.00 0.00 Qty

Balance Value

#DIV/0!

0.00

0.00

0.00

4.4.1

2d

M2

2,039

18,351.0

70%

1,427.3 12,845.7

15%

305.9

2,752.7

0%

0.0

0%

0.0

0%

0.00

1,733.15 15,598.35

305.85

2,752.65

4.4.2 4.5

* *

2c

L.S.

11000

11,000.0

70%

0.7

7,700.0

15%

0.2

1,650.0

0%

0.0

0%

0.0

0% #DIV/0!

0.00 0.00

0.85 0.00

9,350.00 0.00

0.15

1,650.00

2a

M3

35

370

12,950.0

70%

24.5

9,065.0

25%

8.8

3,237.5

0%

0.0

0%

0.0

0%

0.00

33.25

12,302.50

1.75

647.50

4.6

#DIV/0!

0.00

0.00

0.00

#DIV/0!

0.00

0.00

0.00

4.6.1

2b

M3

106

860

91,160.0

70%

74.2

63,812.0

25%

26.5

22,790.0

0%

0.0

0%

0.0

0%

0.00

100.70

86,602.00

5.30

4,558.00

4.6.2

M3

970

0.0

#DIV/0!

0.00

0.00

0.00

0.00

0.00

4.6.3

M3

900

0.0

#DIV/0!

0.00

0.00

0.00

0.00

0.00

4.6.4 4.7

* *

M3

234

990

231,660.0

95%

222.3

220,077.0

0%

0.0

0%

0.0

0% #DIV/0!

0.00

222.30 220,077.00

11.70

11,583.00

0.00

0.00

0.00

4.7.1

Supply and install painting & plaster works on fence concrete, wall parts and all tooled jointed finish surfaces considering the following: *Damaged areas must be repaired with the approved patching material. Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove loose concrete particles, loose mortar, fins, projection and surface contaminants (hand tools can be used). Vacuum or blow down to remove dust and * loose particles from surface. *After all preparing as above, the paint coats shall be: One coat primer, 2 coat filling and 2 coat approved paint .All used materials shall be supplied from Al Jazeera or any alternate approved samples. Any coat shall start after drying of the last one before. Supply and install 15mm plaster layer on the following: a) First coat ( scratch coat ) the mortar consist from 450 kg cement / m3 special sand for plastering. Put this coat by pressure on the wall or concrete surface. Keep it wet 7 days before the second coat. b) Second coat 15 mm thick, the mortar consist from 300 kg cement / m3 special * sand for plaster.Keep it wet 7 days. c) Wiremesh for all jointing between concrete and block and all opening of pipes of electrical, plumbing and water before scratch coat. d) Cement used at all works is sea water resistance cement. All materials according to the ASTM and Saudi Kingdom Specifications.

#DIV/0!

0.00

0.00

0.00

M2

800

22

17,600.0

0%

0%

0.00

0.00

0.00

800.00

17,600.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 5/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 4.7.2 DESCRIPTION * Supply and install paints for concrete or wall parts on the following: a) Plaster must be allowed to dry thoroughly at least 30 days before painting. b) Damaged areas must be repaired with the approved patching material. c) Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove concrete, loose mortar, fins, projection and surface contaminants ( Hand tools can be used). * d) Vacuum or blow down to remove dust and loose particles from surface. e) After all preparing as above the paint coats will be : 2 coat primer, 2 coat texture paint. All materials used will be (Al Jazeera) or as approval from the Owner. f) Any coat start after the drying of the last one before. GUARD HOUSE AND GUARD ROOM: Excavation * * * LOCATION Inoice ref no UNIT M2 REVISED QTY. 800 REMARKS Unit price 22 Total 17,600.0

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion 0%

Value

Invoice - 5 % Qty completion 0%

Total Value 0.00 Qty 0.00 Value 0.00 Qty

Balance Value 17,600.00

800.00

#DIV/0!

0.00

0.00

0.00

5 5.1

#DIV/0! #DIV/0! #DIV/0!

0.00 0.00 0.00

0.00 0.00 0.00

0.00 0.00 0.00

Excavate for all footings and grade beams. Foundation level for footings must be not less than (-1.5m) below natural grade level and as shown in structural drawings. * The foundation level must be cleaned from any strange materials and shall be compacted to 95% of maximum dry density as per Saudi specifications. 5.2 Backfill Above and around foundations to leveled ground surface of the site and to bottom of (grade slab or asphalt base course) using clean granulated sand and the last 20cm from selected fill A-1-A according to American Specifications( AASHTO). Rate shall include submerging with raw water and the compaction 75% for clean sand and 95% for selected fill from the maximum dry density. . Masonry Rates shall be fully inclusive for a complete job including R.C. lintels over doors and windows, . Mortar, grouting of cavities and joints including fillers where required. *The contractor will take approval from the Consultant about any materials before supplying. *Block with it's sizes and types shall be supplied from Almedeafer or Bin Dayel or AL MOJIL Companies or alternate approved supplier. Supply and install thermal isulated concrete hollow block with size 20x20x40cm with dry density 1.8 t/m3,the blocks shall be built by using mortar ( 350kg ordinary portland cement and one cubic graded clean sand. Sweet water shall be used for this mix. The rate include all the necessary accesories,handling,wetting block. Treat the masonry with water for 4 days. Supply and install concrete hollow block with size 20 x 20 x 40cm with dry density 1.8 t/m3. The blocks shall be built by using mortar (350kg ordinary portland cement and one cubic graded clean sand). Sweet water shall be used for this mix. The rate include all the necessary accesories,handling,wetting block. Treat the masonry with water for 4 days. Water Proofing Supply and install cold water proofing for all concrete surfaces attach with soil like [ Footings, neck columns, grade beams,reinforced concrete walls]. The work shall be completed with all accessories and according to ( ASTM, Saudi Kingdom) Specifications. The materials shall be supplied from Dermabit or Bitumat or alternate suppliers. Supply and install 2 coats of cold bituminous paint for all R.C. surfaces attached with soil after cleaning it's surfaces and repairing all voids by cemented mortar and chemical additive ADI-BOND. Supply and install water proofing for roof as follows: 1- Light weight concrete 2500 psi 7cm thick for 1% slope to rain drainage pipe. 2-One layer of membrane 4mm ( Bitumat supplier) with its corners.(Roof must be checked by with water for 24 hours) 3-Auluminium flashing 30cm width with all accessories and sealant. 4-Extruded 50mm thick insulation board 30 kg/m3 over membrane with 200 micron polyethelene sheets. 5-Protection layer of 50mm aggregate layer. *

1a

M3

25

11

278.3

99%

25.0

275.0

0%

0.0

0.0

0%

0.0

0%

0.0

0%

0.00

25.00

275.00

0.30

3.30

#DIV/0!

0.00

0.00

0.00

1b

M3

10

17

170.0

100%

10.0

170.0

0%

0.0

0.0

0%

0.0

0%

0.0

0%

0.00

10.00

170.00

0.00

0.00

5.3

#DIV/0!

0.00

0.00

0.00

#DIV/0!

0.00

0.00

0.00

5.3.1

M2

80

85

6,800.0

0%

0%

0.00

0.00

0.00

80.00

6,800.00

5.3.2

M2

80

65

5,200.0

100%

80.0

5,200.0

0%

0.0

0%

0.0

0%

0.00

80.00

5,200.00

0.00

0.00

5.4

#DIV/0!

0.00

0.00

0.00

#DIV/0!

0.00

0.00

0.00

5.4.1

M2

70

630.0

100%

70.0

630.0

0%

0.0

0.0

0%

0.0

0%

0.0

0%

0.00

70.00

630.00

0.00

0.00

5.4.2

M2

70

70

4,900.0

0%

0%

0.00

0.00

0.00

70.00

4,900.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 6/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 5.5 DESCRIPTION Plain Concrete Supply and install 2000psi plain concrete (ordinary portland cement type 1) with 10cm thick under R.C. foundation and grade beams. The work includes 300 micron polyethylene sheets underneath plain concrete. The bottom of excavated soil must be cleaned from any strange materials and compact it as mentioned in (Item 4.1). Spray clean water and use good wooden forms. The work shall be completed and includes all the necessary accessories. The work shall be according to ( ASTM, Saudi Kingdom) Specifications. Supply and install anti-termite protection under P.C. & grade slab. Reinforced Concrete Supply and install reinforced concrete according to ASTM and Saudi Kingdom Specifications. Contractor must review all the drawings and check the design carefully and follow all the general and special notes mentioned in drawings. Rate shall include all formwork & rebars. Treat with clean sweet water and all the neccessary items to complete the work. Supply and install 3500 psi reinforced concrete for foundation using sulphate resistant portland cement type 5, steel yield strength 60,000 psi including underneath 250 micron polyethylene vapour barrier. All dimensions shall be as mentioned in structural drawings. Supply and install 4000 psi reinforced concrete for column neck using sulphate resistant portland cement type 5, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 3500 psi reinforced concrete for grade beams using sulphate resistant portland cement type 5, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 4000 psi reinforced concrete for drop beams using ordinary portland cement type 1, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 4500 psi reinforced concrete for columns using ordinary portland cement type I, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. * LOCATION Inoice ref no UNIT REVISED QTY. REMARKS Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion #DIV/0!

Total Value 0.00 Qty 0.00 Value 0.00 Qty

Balance Value

2a

M3

2.1

370

777.0

100%

2.1

777.0

0%

0.0

0.0

0%

0.0

0%

0.0

0%

0.00

2.10

777.00

0.00

0.00

5.5.1 5.6

* *

L.S.

500

500.0

100%

1.0

500.0

0%

0.0

0.0

0%

0.0

0%

0.0

0% #DIV/0!

0.00 0.00

1.00 0.00

500.00 0.00

0.00

0.00

M3

NIL

#VALUE!

0.00

0.00

0.00

5.6.1

2b

M3

4.4

860

3,784.0

100%

4.4

3,784.0

0%

0.0

0.0

0%

0.0

0%

0.0

0%

0.00

4.40

3,784.00

0.00

0.00

5.6.2

M3

NIL

#VALUE!

0.00

0.00

0.00

5.6.3

M3

960

3,840.0

100%

4.0

3,840.0

0%

0.0

0%

0.0

0%

0.00

4.00

3,840.00

0.00

0.00

5.6.4

M3

960

3,840.0

100%

4.0

3,840.0

0%

0.0

0%

0.0

0%

0.00

4.00

3,840.00

0.00

0.00

5.6.5

M3

1000

4,000.0

100%

4.0

4,000.0

0%

0.0

0%

0.0

0%

0.00

4.00

4,000.00

0.00

0.00

5.6.6

5.6.7

Supply and install 3500 psi reinforced concrete15cm thick with 5 # 8mm steel wire mesh for slab on grade using sulphate resistant portland cement type 5 including * underneath 200 micron polythylene vapour barrier. All dimensions and places shall be as mentioned in structural drawings. Supply and install 4500 psi reinforced concrete for solid slab 30cm thick using ordinary portland cement type 1, steel yield strength 60,000 psi. All dimensions shall * be as mentioned in structural drawings.

M3

670

2,680.0

80%

3.2

2,144.0

20%

0.8

536.0

0%

0.00

4.00

2,680.00

0.00

0.00

M3

8.40

900

7,560.0

100%

8.4

7,560.0

0%

0.0

0%

0.0

0%

0.00

8.40

7,560.00

0.00

0.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 7/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 5.7 INTERNAL WALL FINISHING. DESCRIPTION * LOCATION Inoice ref no UNIT REVISED QTY. REMARKS Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion #DIV/0!

Total Value 0.00 Qty 0.00 Value 0.00 Qty

Balance Value

Supply and install painting & plaster works on concrete parts, ceiling, wall parts and all tooled jointed finish surfaces considering the following: Damaged areas must be repaired with the approved patching material. Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove loose concrete particles, loose mortar, fins, projection and surface contaminants(Hand tools can be * used). Vacuum or blow down to remove dust and loose particles from surface. *After all preparing as above the paint coats shall be : two coat primer, 2 coat putty, 2 coat filling and 2 coat approved paint. All used materials shall be supplied from Al Jazeera or any alternate approved samples. Any coat shall start after drying of the last one before. Supply and install 15mm plaster layer on the following: a) First coat (scratch coa ) the mortar consist from 450 kg cement / m3 special sand for plastering. Put this coat by pressure on the wall or concrete surface. Keep it wet 7 days before the second coat. b) Second coat 15 mm thick , the mortar consist from 300 kg cement / m3 special * sand for plaster. Keep it wet 7 days. c) Wiremesh for all joining between concrete and block and all opening of pipes of electrical, plumbing and water before scratch coat. d) Cement used at all works is ordinary portland cement. All materials according to the ASTM and Saudi Kingdom Specifications. Supply and install internal paints for concrete or wall parts on the following: * * * * * a) Plaster must be allowed to dry thoroughly at least 30 days before painting. * b) Damaged areas must be repaired with the approved patching material. c) Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove concrete, loose mortar, fins, projection and surface * contaminants (Hand tools can be used). * d) Vacuum or blow down to remove dust and loose particles from surface. e) After all preparing as above the paint coats will be : 2 coat primer, 2 coat putty, 2 coat texture paint. All materials used will be (Al Jazeera) or as approval from the * Owner. f) Any coat start after the drying of the last one before. * Refer to architectural dwg. There is a change in dimension for the architectural

#DIV/0!

0.00

0.00

0.00

5.7.1

M2

85

Refer to architectural dwg. There is a change in dimension for the architectural

44

3,740.0

50%

42.5

1,870.0

44%

37.5

1,650.0

0%

0.00

80.00

3,520.00

5.00

220.00

5.7.2

M2

85

Refer to architectural dwg. There is a change in dimension for the architectural

22

1,870.0

0%

100%

85.00

1,870.00

85.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

1,870.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

0.00

0.00

#DIV/0! #DIV/0! #DIV/0! #DIV/0!

0.00 0.00 0.00

0.00

0.00

0.00

5.8

Supply and install glazed 20cm x 20cm x 6mm Saudi ceramic tiles. Fixing shall be made by using 3cm thick Ventonite mix or 6mm thick bond coat (Saudi Kingdom * Specifications) on plastered walls. Cross plastic spacer shall be used complete with all necessary accessories.

M2

85

115

9,775.0

0%

0%

0.00

0.00

0.00

85.00

9,775.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 8/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 5.8.1 DESCRIPTION INTERNAL FLOOR FINISH FOR GUARD HOUSE : * Supply and install unglazed 20cm x 20cm x 9mm Saudi ceramic tiles. Fixing shall be made by using 3cm thick mortar mix (350kg portlant cement type 1 for one cubic meter graded clean sand) . (Saudi Kingdom Specification shall be respected) on * 7cm clean sand mixed with portland cement ( 1 cement to 6 sand ratio ) and all shall be wetted with clean water. Cross plastic spacer shall be used complete with all necessary accessories. CEILING FINISHES * Supply and install 15mm plaster layer on the following: a) First coat (scratch coat) the mortar consist from 450 kg cement / m3 special sand for plastering. Put this coat by pressure on the ceiling concrete surface. Keep it wet 7 days before the second coat. b) Second coat 15 mm thick , the mortar consist from 300 kg cement / m3 special * sand for plaster. Keep it wet 7 days. c) Wiremesh for all joining between concrete and block and all opening of pipes of electrical, plumbing and water before scratch coat. d) Cement used at all works is ordinary portland cement. All materials according to the ASTM and Saudi Kingdom Specifications. Supply and install paints for concrete ceiling parts on the following: * LOCATION Inoice ref no UNIT REVISED QTY. REMARKS Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion #DIV/0!

Total Value 0.00 Qty 0.00 Value 0.00 Qty

Balance Value

M2

27

115

3,105.0

0%

0%

0.00

0.00

0.00

27.00

3,105.00

5.9

#DIV/0!

0.00

0.00

0.00

5.9.1

M2

27

Refer to architectural dwg. There is a change in dimension for the architectural

22

594.0

0%

0%

0.00

0.00

0.00

27.00

594.00

5.9.2

#DIV/0!

0.00

0.00

0.00

a) Plaster must be allowed to dry thoroughly at least 30 days before painting. b) Damaged areas must be repaired with the approved patching material c) Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove concrete, loose mortar, fins, projection and surface contaminants (Hand * tools can be used). d) Vacuum or blow down to remove dust and loose particles from surface. e) After all preparing as above the paint coats will be : 2 coat primer , 2 coat putty , 2 coat texture paint. All materials used will be Al Jazeera) or as approval from the Owner. f) Any coat start after the drying of the last one before. 5.10 EXTERNAL WALL FINISHING *

M2

27

Refer to architectural dwg. There is a change in dimension for the architectural

22

594.0

0%

0%

0.00

0.00

0.00

27.00

594.00

#DIV/0!

0.00

0.00

0.00

Supply and install painting & plaster works on concrete parts, wall parts and all tooled jointed finish surfaces considering the following: Damaged areas must be repaired with the approved patching material. Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove loose concrete particles, loose mortar, fins, projection and surface * contaminants (Hand tools can be used). Vacuum or blow down to remove dust and loose particles from surface. *After all preparing as above the paint coats shall be : One coat primer, 2 coat filling, liquid coat polyurethane and 2 coat approved paint and one. All used materials shall be supplied from Al Jazeera or any alternate approved samples. Any coat shall start after drying of the last one before. Supply and install 15mm external plaster layer on the following: a) First coat (scratch coat) the mortar consist from 450 kg cement / m3 special sand for plastering. Put this coat by pressure on the ceiling concrete surface. Keep it wet 7 days before the second coat. b) Second coat 15 mm thick , the mortar consist from 300 kg cement / m3 special * sand for plaster. Keep it wet 7 days. c) Wiremesh for all joining between concrete and block and all opening of pipes of electrical , plumbing and water before scratch coat. d) Cement used at all works is ordinary portland cement. All materials according to the ASTM and Saudi Kingdom Specifications. Supply and install external paints for concrete or wall parts on the following: *

#DIV/0!

0.00

0.00

0.00

5.10.1

M2

127

Refer to architectural dwg. There is a change in dimension for the architectural

22

2,794.0

0%

0%

0.00

0.00

0.00

127.00

2,794.00

5.10.2

M2

127

Refer to architectural dwg. There is a change in dimension for the architectural

22

2,794.0

0%

0%

0.00

0.00

0.00

127.00

2,794.00

a) Plaster must be allowed to dry thoroughly at least 30 days before painting. b) Damaged areas must be repaired with the approved patching material. c) Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove concrete, loose mortar , fins, projection and surface contaminants (Hand tools can be used). d) Vacuum or blow down to remove dust and loose particles from surface. e) After all preparing as above the paint coats will be : 2 coat primer ,2 coat texture paint , one liquid coat polyurethane. All materials used will be (Al Jazeera) or as approval from the Owner. F) Any coat start after the drying of the last one before.

* * * * * *

#DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

0.00 0.00 0.00 0.00 0.00 0.00

0.00 0.00 0.00 0.00 0.00 0.00

0.00 0.00 0.00 0.00 0.00 0.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 9/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 5.11 DOORS AND WINDOWS DOORS: DESCRIPTION * * Nos. 2 2200 4,400.0 LOCATION Inoice ref no UNIT REVISED QTY. REMARKS Unit price Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion

Value

Invoice - 5 % Qty completion #DIV/0! #DIV/0! 0%

Total Value 0.00 0.00 0.00 Qty 0.00 0.00 1.00 Value 0.00 0.00 2,200.00 1.00 Qty

Balance Value

5.11.1

Supply and install including all accessories (hinges, lock, closuresetc). Main entrance, Guard room and house doors (1 x 2.10 ) solid wooden door , Maranti * wood. Bathroom door (0.70 x 2.10) water flush auluminium door with louver as shown ( leaf bottom shall be elevated 10 cm up ground). Aluminium sec. alobco type for frame * with water proof cladding. All accessories ( hinges, lock,closures,...etc) WINDOWS For Guard Room and House: *

50%

1.0

2,200.0

2,200.00

5.11.2

Nos.

NIL

#VALUE! #DIV/0!

0.00 0.00

0.00 0.00

0.00 0.00

Supply and install aluminium windows . Glass window shall be 18mm thick (6mm inner clear tempered glass, 6mm air and external 6mm obscured glass). Windows shall be provided with additional insect proof screen shutters and all hardware * accessories shall be Italy manufactured ( hinges,lock, weather proofing, fittings and sealant..etc) complete with all requirements to complete the work. 5.11.3 W2 ( 0.70 x 0.70 ) Aluminium awning type window (aluminium sec. olobco or altharaia 1.8mm) as specified above and in drawings. * Nos. NIL

#DIV/0!

0.00

0.00

0.00

#VALUE!

0.00

0.00

0.00

0.00

5.11.4

W3 (1.20 x 1.00 ) SLIDING WINDOW IN ALUMINUM FRAME ( 18mm thick clear tempered double glass) sliding in aluminium frame 2mm sec. olobco or altharaia as * specified above and in drawings. W4 ( 1.20 x 1.00 ) FIXED 18 mm thick clear tempered double glass with (aluminium * frame 2mm aluminium sec. olobco or altharaia) as specified above and in drawings. Guard House and room kitchens: Supply and install counter top kitchen consists of aluminium sections 2.5mm thick and granite top 3cm thick including german stainless-steel with two pool, flexible waist and all the accessories like hinges , lock,etc. to complete the work. * *

Nos.

800

2,400.0

100%

3.0

2,400.0

0%

0.00

3.00

2,400.00

0.00

0.00

5.11.5 5.12

Nos.

700

2,100.0

0%

0% #DIV/0!

0.00 0.00 0.00

0.00 0.00 0.00

0.00 0.00 0.00

3.00

2,100.00

L.S.

NIL

#VALUE!

6 6.1.0

UNDERGROUND (WATER TANK, PUMP ROOM, UNDERGROUND FIRE TANK * ,SEPTIC TANK) , SCECO Room, Electrical Room: SCECO ROOM AND ELECTRICAL ROOM: * Supply and install SCECO room ( 25.25m x 4.2 m ) and electrical room ( 5.31m x 4.2m )according to the mentioned dimensions in the Architectural Drawings includes * steel doors and conduits and all the necessary items to complete the work on the following: Excavate for all footings and grade beams. Foundation level for footings must be not less than (-1.5m) below natural grade level and as shown in structural drawings. * The foundation level must be cleaned from any strange materials and shall be compacted to 95% of maximum dry density as per Saudi Specifications. Back fill around foundations to leveled ground surface of the site and to bottom of (Finishing or Asphalt base course) using clean granulated sand according to American Specifications(AASHTO). Rate shall include submerging with raw water * and the compaction 75% from the maximum dry density. All the space to the foundation depth in-between R.C. transformer foundations shall be empty and 15cm of graduated gravel shall be put to permit cable installation and inspection. Supply and install concrete hollow block with size 20 x 20 x 40cm with dry density 1.8 t/m3. The blocks shall be built by using mortar (350kg ordinary portland cement and one cubic graded clean sand). Sweet water shall be used for this mix. The rate * include all the necessary accessories,handling,wetting block. Treat the masonry with water for 4 days. Supply and install 2 coats of cold bituminous paint for all R.C. surfaces attached with soil after cleaning it's surfaces and repairing all voids by cemented mortar and * chemical additive ADI-BOND. Supply and install water proofing for electrical room and SCECO roof as follows: 1- Light weight concrete 2500 psi 7cm thick for 1% slope to rain drainage pipe. 2-One layer of membrane 4mm (Bitumat supplier) with its corners. (Roof must be checked by with water for 24 hours). 3-Aluminium flashing 30cm width with all accessories and sealant. 4-Extruded 50mm thick insulation board 30 kg/m3 over membrane with 200 micron polyethylene sheets. 5-Protection layer of 50mm aggregate layer. Supply and install 2000psi plain concrete (ordinary portland cement type 1) with 10cm thick under R.C. foundation and grade beams. The bottom of excavated soil must be cleaned from any strange materials and compact it as mentioned in (Item 4.1). Spray clean water and use good wooden forms.The work shall be completed and includes all the necessary accessories.The work shall be according to ( ASTM, Saudi Kingdom) Specifications. Reinforced Concrete Supply and install reinforced concrete according to ASTM and Saudi kingdom Specifications. Contractor must review all the drawings and check the design carefully and follow all the general and special notes mentioned in drawings. Rate shall include all formwork & rebars. Treat with clean sweet water and all the neccessary items to complete the work. Supply and install 3500 psi reinforced concrete for foundation using sulphate resistant portland cement type 5, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 4000 psi reinforced concrete for column neck using sulphate resistant portland cement type 5, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 3500 psi reinforced concrete for grade beams using sulphate resistant portland cement type 5, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 4000 psi reinforced concrete for drop beams using ordinary portland cement type 1, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. Supply and install 4000 psi reinforced concrete for columns using ordinary portland cement type 1, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings.

#DIV/0! #DIV/0! Dimension Change #DIV/0!

0.00 0.00 0.00

0.00 0.00 0.00

0.00 0.00 0.00

6.1.1

M3

45

Refer to structural dwg.

11

495.0

100%

45.0

495.0

0%

0.0

0%

0.0

0%

0.00

45.00

495.00

0.00

0.00

6.1.2

M3

20

17

340.0

100%

20.0

340.0

0%

0.0

0%

0.0

0%

0.00

20.00

340.00

0.00

0.00

6.1.3

M2

NIL

#VALUE!

0.00

0.00

0.00

6.1.4

M2

90

810.0

100%

90.0

810.0

0%

0.0

0%

0.0

0%

0.00

90.00

810.00

0.00

0.00

6.1.5

M2

65

70

4,550.0

0%

0%

0.00

0.00

0.00

65.00

4,550.00

6.1.6

M2

370

1,480.0

100%

4.0

1,480.0

0%

0.0

0%

0.0

0%

0.00

4.00

1,480.00

0.00

0.00

7.00

#DIV/0!

0.00

0.00

0.00

#DIV/0!

0.00

0.00

0.00

7.10

M3

NIL

#VALUE!

0.00

0.00

0.00

7.20

M3

NIL

#VALUE!

0.00

0.00

0.00

7.30

M3

900

5,400.0

100%

6.0

5,400.0

0%

0.0

0%

0.0

0%

0.00

6.00

5,400.00

0.00

0.00

7.40

M3

900

5,400.0

70%

4.2

3,780.0

30%

1.8

1,620.0

0%

0.0

0%

0.00

6.00

5,400.00

0.00

0.00

7.50

M3

970

4,850.0

100%

5.0

4,850.0

0%

0.0

0%

0.0

0%

0.00

5.00

4,850.00

0.00

0.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 10/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # DESCRIPTION Supply and install 3500 psi reinforced concrete 20cm thick with 5 # 8mm steel wire mesh for electrical room AND SCECO slab on grade using sulphate resistant * portland cement type 5 . All dimensions and places shall be as mentioned in structural drawings. Supply and install 4000 psi reinforced concrete for electrical room and SCECO solid slab 15cm thick using ordinary portland cement type I, steel yield strength 60,000 psi. All dimensions shall be as mentioned in structural drawings. * LOCATION Inoice ref no UNIT REVISED QTY. 13 REMARKS Unit price 640 Total

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion 100% 13.0

Value

Invoice - 4 % Qty completion 0%

Value

Invoice - 5 % Qty completion 0%

Total Value Qty Value Qty

Balance Value

7.60

M3

8,320.0

8,320.0

0.0

0.00

13.00

8,320.00

0.00

0.00

7.70

M3

900

8,100.0

100%

9.0

8,100.0

0%

0.0

0%

0.00

9.00

8,100.00

0.00

0.00

8.00

8.10

Supply and install 15mm internal plaster layer on the following: a) First coat (scratch coat) the mortar consist from 450 kg cement / m3 special sand for plastering. Put this coat by pressure on the wall or concrete surface. Keep it wet 7 days before the second coat. b) Second coat 15 mm thick , the mortar consist from 300 kg cement / m3 special * sand for plaster. Keep it wet 7 days. c) Wiremesh for all joining between concrete and block and all opening of pipes of electrical, plumbing and water before scratch coat. d) Cement used at all works is ordinary portland cement. All materials according to the ASTM and Saudi Kingdom Specifications. Supply and install external plaster layer 15mm thick specified as mentioned in Item * No. 6.1.14

M2

150

22

3,300.0

70%

105.0

2,310.0

0%

0.0

30%

45.0

990.0

0%

0.00

150.00

3,300.00

0.00

0.00

M2

165

22

3,630.0

70%

115.5

2,541.0

0%

0.0

30%

49.5

1,089.0

0%

0.00

165.00

3,630.00

0.00

0.00

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 11/12

Date :- 15 March 2011

Project Title: Location: Owner: Date:

Proposed Pipe Insulation and Jacketing Factory 2nd Industrial Dammam Perma-Pipe Saudi Arabia March 14, 2011 B.O.Q

Reference Number :SA-FED-OTH-001-001-11-REV0 SITE - CIVIL & ARCHITECTURAL # 9.00 DESCRIPTION Supply and install internal paints for concrete or wall parts on the following: a) Plaster must be allowed to dry thoroughly at least 30 days before painting. b) Damaged areas must be repaired with the approved patching material. c) Use power grinder equipped with a suitable grinding stone of appropriate size and hardness to remove concrete, loose mortar , fins, projection and surface contaminants (Hand tools can be used). d) Vacuum or blow down to remove dust and loose particles from surface. * * * * * LOCATION Inoice ref no UNIT M2 REVISED QTY. 150 REMARKS Unit price 22 Total 3,300.0

Invoice - 1 % Qty completion

Value

Invoice - 2 % Qty completion

Value

Invoice - 3 % Qty completion

Value

Invoice - 4 % Qty completion 100% 150.0

Value 3,300.0

Invoice - 5 % Qty completion 0% #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! 0% #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0! #DIV/0!

Total Value 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Qty 150.00 0.00 0.00 0.00 0.00 0.00 0.00 165.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Value 3,300.00 0.00 0.00 0.00 0.00 0.00 0.00 3,630.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 Qty 0.00

Balance Value 0.00

e) After all preparing as above the paint coats will be : 2 coat primer ,2 coat texture * paint. All materials used will be (Al Jazeera) or as approval from the Owner. 9.10 F) Any coat start after the drying of the last one before. Supply and install external paints for concrete or wall parts as the following: a) Plaster must be allowed to dry thoroughly at least 30 days before painting. b) Damaged areas must be repaired with the approved patching material c) Use power grinder equipped with a suitable grinding stone of approriate size and hardness to remove concrete, loose mortar, fins, projection and surface contaminants (Hand tools can be used). d) Vacuum or blow down to remove dust and loose particles from surface. e) After all preparing as above the paint coats will be : 2 coat primer, 2 coat texture paint, one liquid coat polyurethane. All materials used will be (Al Jazeera) or as approval from the Owner. f) Any coat start after the drying of the last one before. Supply and install SCECO door. Contractor shall return to SCECO and take the approved section which shall submitted to the Consultant for approval. The gate rate shall be loaded on the construction room rate. UNDERGROUND (FIRE WATER TANK, PUMP Tank, SEPTIC TANK). Supply and install lump sum R.C. underground fire water tank and septic tank complete (excavation,earth work, plain concrete 2500psi upon polyethylene sheets 300 micron, formwork, reinforced concrete 4000psi, water stop, moisture insulation 4mm thick bituminous layers, surrounding it 20 x 20 x 40cm concrete hollow block works, steel ladder, heavy duty iron covers and all according to ASTM and Saudi Kingdom Specifications. The work shall be complete with all accessories and sleeves. Supply and install lump sum R.C. underground (pump tank and fire water tank (22*4.5*1.20 m) complete as explained . Supply and install lump sum R.C. septic tank ( 6*4.5*1.5 m) with block work and open from down (without flooring )complete with all accessories complete as explained Block . * * * * * * * * * * INCLUDED M2 165 22 3,630.0 100% 165.0 3,630.0

0.00

0.00

10 11

#DIV/0! #DIV/0!

#DIV/0!

0.00

0.00

0.00

11.1 11.2 11.3 11.4

* * *

L.S. L.S. L.S. L.S.

1 1 0 1

165000 32000 0 65000

165,000.0 32,000.0 0.0

25%

0.3

41,250.0

50%

0.5

82,500.0

0% 0%

0.0

15% 90% #DIV/0!

0.15 0.90

24,750.00 28,800.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 171,832.0

0.90 0.90 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

148,500.00 28,800.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 827,072.7

0.10 0.10 0.00

16,500.00 3,200.00 0.00

11.5

Supply and install compressor room (10.80m x 4.70m) with louvers on three sides and concrete on the rear portion. The work implementation include all necessary items to complete the work as per ASTM and Saudi Kingdom Specifications. Supply and install R.C. open water tanks (under the Cooling Tower). The said open water tanks has a dimension of 5.15m x 2.60m x1.50m and 2.60m x 1.20m x 1.50m. The thickness for the tank is 0.20m and 0.15m thick for the partition wall between the two tanks. Work implementation shall include all necessary items to complete the work as per ASTM and Saudi Kingdom Specs. Supply and install concrete mechanical trench with steel cover . Supply and install chiller plat form ( plain concrete ) Supply and install steel structure for AHU Total of SITE - CIVIL & ARCHITECTURAL

* * * * * * * * * * * *

0% 65,000.0

L.S.

70000

70,000.0

0%

0% #DIV/0! #DIV/0! #DIV/0! #DIV/0! 0% #DIV/0! #DIV/0! 0% 0% 15,795.0

0.00

65,000.00

1.00

70,000.00

11.6 11.7 11.8

M L.S No.

70 1 2

new item new item new item

1100 3800 3200

77,000.0 3,800.0 6,400.0 1,706,894.3 115,872.9 341,410.8 182,162.0

0% 0%

70.00 1.00 2.00

77,000.00 3,800.00 6,400.00 879,821.7

Gulf Builder For Contracting - B.O. Rev.10

1- SITE - CIVIL ARCHITECTURAL 12/12

Date :- 15 March 2011

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- NSCPDocument3 pagesNSCPJulius Christian PerezPas encore d'évaluation

- 10 Cold Form SteelDocument24 pages10 Cold Form Steelbernaduscatur100% (1)

- Sor 5-08 Dcsem RDocument97 pagesSor 5-08 Dcsem RPremkumar Gopalan GPas encore d'évaluation

- Building ConstructionDocument42 pagesBuilding ConstructionHeng Yee Tan100% (1)

- Calculation SheetDocument4 pagesCalculation SheetAhmed KhattabPas encore d'évaluation

- 11.1 SOR Building Tradesmen - FinalDocument131 pages11.1 SOR Building Tradesmen - FinalDharma RamalingamPas encore d'évaluation

- Masonry Works Billing No. 10Document12 pagesMasonry Works Billing No. 10Lilvic Galera-SabladPas encore d'évaluation

- Model File: Rumah Tinggal 2 Lantai Ma Vita, Revision 0Document27 pagesModel File: Rumah Tinggal 2 Lantai Ma Vita, Revision 0Fris BauPas encore d'évaluation

- R8 Spyder V10 - Side Radiator InstallationDocument5 pagesR8 Spyder V10 - Side Radiator InstallationohshafiPas encore d'évaluation

- Roofing Handbook 2nd EdDocument552 pagesRoofing Handbook 2nd Edlwin_oo2435100% (7)

- Lab 1St FloorDocument5 pagesLab 1St FloorAditya PranotoPas encore d'évaluation

- Report of 10 of Khadapkar 02.12Document15 pagesReport of 10 of Khadapkar 02.12Mahi DabhiPas encore d'évaluation

- DS Gypframe ProfilesDocument12 pagesDS Gypframe ProfilesAleem UllahPas encore d'évaluation

- Kharkopar STN Concept, Material, ServicesDocument6 pagesKharkopar STN Concept, Material, Serviceskomal100% (1)

- Bur 3 - Concrete WorksDocument26 pagesBur 3 - Concrete WorkszulfaisalPas encore d'évaluation

- HF PDFDocument1 pageHF PDFTroi LauraPas encore d'évaluation

- MosquejDocument12 pagesMosquejdr.afroza1875Pas encore d'évaluation

- WindowsDocument36 pagesWindowsVenu GopalPas encore d'évaluation

- Specs DIVISION 1 Day2Document29 pagesSpecs DIVISION 1 Day2Nerinel CoronadoPas encore d'évaluation

- Water ChillerDocument32 pagesWater ChillerPaing Phyo Ko78% (9)

- Polyiso InsulationDocument2 pagesPolyiso Insulationarbor02Pas encore d'évaluation

- Factors Affecting Selection of Foundation For BuildingsDocument4 pagesFactors Affecting Selection of Foundation For BuildingskamalPas encore d'évaluation

- Wfcm2001workbookandappendix PDFDocument150 pagesWfcm2001workbookandappendix PDFMiguelCasillaSolizPas encore d'évaluation

- Dsi - Eds Solar Thermal - Did1050enDocument2 pagesDsi - Eds Solar Thermal - Did1050eningrcPas encore d'évaluation

- DuraGal DCM Lintels Sep01Document30 pagesDuraGal DCM Lintels Sep01Denise2512Pas encore d'évaluation

- Duct Design Calculation Pressure DropsDocument6 pagesDuct Design Calculation Pressure DropsngarinyagaPas encore d'évaluation

- Frame Structures 2Document39 pagesFrame Structures 2Hamza Siddiqi100% (1)

- CRSI Technical Note - Stainless Steel RebarDocument8 pagesCRSI Technical Note - Stainless Steel Rebaralum_91Pas encore d'évaluation

- Car Parking ReportDocument202 pagesCar Parking ReportIlmtalabPas encore d'évaluation