Académique Documents

Professionnel Documents

Culture Documents

Excavation Ragister

Transféré par

tanmayb8887Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Excavation Ragister

Transféré par

tanmayb8887Droits d'auteur :

Formats disponibles

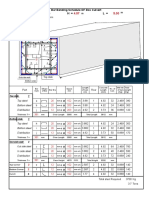

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe

Ward SECTOR NO : 8 DIA : 400 mm SANPADA NODE Description of Item LINE NO : 4A FROM : MANHOLE TO : Depth= 2.5m Width of Avg DepthTotal Qty trench (m) (m) ( m3) DATE :

S. No.

BOQ Item No.

Unit

Length (m)

SIGN GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a M a) Lift 0 to 1.5 distance of 50 M beyond area and b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than 1.50 m including trimming and levelling a) lift 0 to blasting b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

268.10 .

1.2

0.45

144.77

m3 m3 m3 m3 m3 m3

268.10

1.2

0.45

144.77

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

268.10 268.10

1.2 1.2

0.6 1

193.03 321.72

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward SECTOR NO : 10 DIA : 300 mm SANPADA NODE Description of Item LINE NO : 25 FROM : MANHOLE TO : Depth= 2.5m Width of Avg DepthTotal Qty trench (m) (m) ( m3) DATE :

S. No.

BOQ Item No.

Unit

Length (m)

SIGN GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

268.10 .

1.2

0.45

144.77

a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3 m3 m3 m3 m3 m3

268.10

1.2

0.45

144.77

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

268.10 268.10

1.2 1.2

0.6 1

193.03 321.72

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward SECTOR NO : 8 DIA : 400 mm SANPADA NODE Description of Item LINE NO : 5 MANHOLE 77 TO : Depth= 2.063m Width of Avg DepthTotal Qty trench (m) (m) ( m3) FROM : DATE : 100 SIGN GECPL PMC NMMC

S. No.

BOQ Item No.

Unit

Length (m)

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

127.00 .

1.2

0.45

68.58

m3 m3 m3 m3 m3 m3

127.00

1.2

0.45

68.58

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

127.00 127.00

1.2 1.2

0.6 0.563

91.44 85.80

SECTOR NO : 8

S. No.

BOQ Item No.

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward DIA : 400 mm LINE NO : 4 MANHOLE DATE : SANPADA NODE FROM : 69 TO : 77 Depth= 2.114m Unit Length Width of Avg DepthTotal Qty SIGN Description of Item trench (m) (m) (m) ( m3) GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

189.00 .

1.2

0.45

102.06

m3 m3 m3 m3 m3 m3

189.00

1.2

0.45

102.06

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

189.00 189.00

1.2 1.2

0.6 0.614

136.08 139.26

SECTOR NO : 9

S. No.

BOQ Item No.

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward DIA : 400 mm LINE NO : New Line Mill. End MANHOLE DATE : SANPADA NODE FROM : IX TO : 89 Depth= 2.633m Unit Length Width of Avg DepthTotal Qty SIGN Description of Item trench (m) (m) (m) ( m3) GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

321.00 .

1.2

0.45

173.34

m3 m3 m3 m3 m3 m3

321.00

1.2

0.3

115.56

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

321.00 321.00

1.2 1.2

0.75 1.133

288.90 436.43

SECTOR NO : 2

S. No.

BOQ Item No.

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward DIA : 400 mm LINE NO : 7A MANHOLE DATE : SANPADA NODE FROM : 136 TO : 141 Depth= 2.233m Unit Length Width of Avg DepthTotal Qty SIGN Description of Item trench (m) (m) (m) ( m3) GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

145.00 .

1.2

0.3

52.20

m3 m3 m3 m3 m3 m3

145.00

1.2

0.3

52.20

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

145.00 145.00

1.2 1.2

0.9 0.733

156.60 127.54

SECTOR NO : 2

S. No.

BOQ Item No.

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward DIA : 300 mm LINE NO : 7 MANHOLE DATE : SANPADA NODE FROM : 116 TO : 131 Depth= 2.018m Unit Length Width of Avg DepthTotal Qty SIGN Description of Item trench (m) (m) (m) ( m3) GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

423.00 .

0.9

0.45

171.32

m3 m3 m3 m3 m3 m3

423.00

0.9

0.45

171.32

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

423.00 423.00

0.9 0.9

0.6 0.518

228.42 197.20

SECTOR NO : 2

S. No.

BOQ Item No.

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward DIA : 400 mm LINE NO : 7 MANHOLE DATE : SANPADA NODE FROM : 131 TO : 136 Depth= 2.286m Unit Length Width of Avg DepthTotal Qty SIGN Description of Item trench (m) (m) (m) ( m3) GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

150.00 .

0.9

0.45

60.75

m3 m3 m3 m3 m3 m3

150.00

0.9

0.45

60.75

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

150.00 150.00

0.9 0.9

0.6 0.786

81.00 106.11

SECTOR NO : 2

S. No.

BOQ Item No.

Name of Work: Designing, Providing and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward DIA : 300 mm LINE NO : 8 MANHOLE DATE : SANPADA NODE FROM : 155 TO : 131 Depth= 1.825m Avg Unit Length Width of SIGN Description of Item Trench Depth Total Qty (m) (m) (m) ( m3) GECPL PMC NMMC

Item No. 1 Excavation for foundation / pipe trenches in earth, soils of all types, sand, gravel and soft murum, including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, manual dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a)Lift 0 to 1.5m a) Lift 0 to 1.5m b) Lift 1.5 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M Item No. 2 Excavation for foundation / pipe trenches in hard murum including removing the excavated material upto a distace of 50 M and lifts as below, stacking and spreading as directed by Engineer-in-charge, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 M c) Lift 3.0 to 4.50 M d) Lift 4.50 to 6.0 M e) Lift 6.0 to 7.50 M f) Lift 7.50 to 9.0 M Item No. 3 Excavation for foundation / pipe trenches in soft rock and old cement and lime masonry foundation asphalt road including removing the excavated material upto a distance of 50 M beyond area and lifts as below, stacking as directed by Engineer-incharges, normal dewatering, preparing the bed for foundation and excluding backfilling, etc. complete. a) Lift 0 to 1.5 m a) Lift 0 to 1.5 M b) Lift 1.50 to 3.0 m c) Lift 3.0 to 4.5 m d) Lift 4.50 to 6.0 m e) Lift 6.0 to 7.50 m f) lift 7.50 to 9.0 m Item No. 4 Excavation for foundation / pipe trenches in hard rock and concrete road by chiselling, wedging, line drilling, by machnial means or by any other means other than blasting including trimming and levelling the bed, removing the excavated material upto a distance of 50 metres beyond the area and lifts as below, stacking as directed by Engineer-in-charge, normal dewatering, excluding backfilling, etc. complete. a) lift 0 to 1.50 m b)lift 1.50 to 3.0 m c)lift 3.0 to 4.50m d)lift 4.50 to 6.0 m e)lift 6.0 to 7.50 m f)lift 7.50 to 9.0 m Item No. 5 Excavation for foundation /pipe trenches in Slush Muddy/ Marshy /Slushy /Soil including use of poclain, labour for dewatering during execution including removing the excavated material upto a distance of 50 metres and lifts as below, stacking and spreading as directed, preparing the bed by cleaning the mud, labour required for execution for shutterng item but excluding back filling etc. complete. Providing and fixing shuttering shall be paid separately. a) lift 0 to 1.50 m b) lift 1.50 to 3.0 m c) lift 3.0 to 4.50 m

m3

m3 m3 m3

m3 m3 m3 m3 m3 m3 m3

114.00 .

0.9

0.45

46.17

m3 m3 m3 m3 m3 m3

114.00

0.9

0.45

46.17

m3 m3 m3 m3 m3 m3 m3

m3 m3 m3

114.00 114.00

0.9 0.9

0.6 0.325

61.56 33.35

REMARK

REMARK

REMARK

viding and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward

REMARK

viding and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward

REMARK

viding and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward

REMARK

viding and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward

REMARK

viding and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward

REMARK

viding and Laying of Sewer Network and Improvement in Sewerage System at Vashi and Turbhe Ward

REMARK

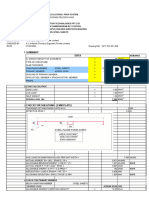

SCHEDULE B (Item rate contract) Description of Item BOQ Item No. Unit Approved Qty. Quantity executed as per Upto Date 2 Item No. 1 3 Providing, Installing, Testing, Commissioning of non clog horizontal Centrifugal Pumps including removing of existing pumping machinery and equipments, as specified below.. (Make MJP approved) Capacity - 810.00 m3/Hrs. Pump Head in mWC- 11.50 mtr. Efficiency of the pumps 81% Required Motor rating HP- 75 Speed in RPM 1000 Solid Handling size 100mm Sp Gravity 1.05 MOC Casing CF8M Impeller CF8M Wearing CF8M Shaft & Sleeve SS 316 Fastners BHT Steel Bearing Hsc. CI Mech. Seal - Gland Packing Providing, Installing, Testing, Commissioning of non clog horizontal Centrifugal Pumps including removing of existing pumping machinery and equipments, as specified below.. (Make MJP approved) Capacity - 774.00 m3/Hrs. Pump Head in mWC- 16.00 mtr. Efficiency of the pumps 81% Required Motor rating HP- 75 Speed in RPM 1000 Solid Handling size 100mm Sp Gravity 1.05 MOC Casing CF8M Impeller CF8M Wearing CF8M 4 No. 5 1 6 1081791 12 As per previous running bill 13 As per this bill 14 Amount on the basis of actual Upto Date 15

Rate in Rs.

Amount As per Previous Running Bill 16

Amount Gross payable 17

Deductions As praposed 18

Amount Net payable 19

Remarks

20

Item No. 2

No.

854524

Item No. 3

Shaft & Sleeve SS 316 Fastners BHT Steel Bearing Hsc. CI Mech. Seal - Gland Packing Providing, Installing, Testing, Commissioning of non clog Submersible Sewage Pumps including removing of existing pumping machinery and equipments, as specified below.. (Make MJP approved) Capacity - 810.00 m3/Hrs. Pump Head in mWC- 13.35 mtr. Efficiency of the pumps 78% Required Motor rating HP- 60 Speed in RPM 960 Solid Handling size 100mm Sp Gravity 1.05 MOC Casing CI IS 210 Gr. FG 220 Impeller CI IS 210 Gr. FG 220 Shoft and Sleeve SS 316 Motor Parts CI IS 210 Gr. FG 220 Fastners BHT Steel Guide Pipe Carban Steel Lifting Chain Carban Steel Mech. Seal Motor Side Carban / Crome Steel - Pump Side SiC V/s SiC Providing, Installing, Testing, Commissioning of non clog Submersible Sewage Pumps including removing of existing pumping machinery and equipments, as specified below.. (Make MJP approved) Capacity - 684.00 m3/Hrs. Pump Head in mWC- 20.00 mtr. Efficiency of the pumps 77% Required Motor rating -80 HP Speed in RPM - 1500 Solid Handling size 100mm Sp Gravity 1.05 MOC Casing CI IS 210 Gr. FG 220 Impeller CI IS 210 Gr. FG 220 Shoft and Sleeve SS 316 Motor Parts CI IS 210 Gr. FG 220 Fastners BHT Steel Guide Pipe Carban Steel Lifting Chain Carban Steel Mech. Seal Motor side Carban / Crome Steel - Pump Side SiC V/s SiC

No

854524.00

Item No. 4

No

2.00

681967.00

Item No. 5

Item No. 6

Providing, Installing, Testing, Commissioning of non clog horizontal Centrifugal Pumps including removing of existing pumping machinery and equipments, as specified below.. (Make MJP approved) Capacity - 774.00 m3/Hrs. Pump Head in mWC- 16.00 mtr. Efficiency of the pumps 81% Required Motor rating HP- 75 Speed in RPM 1000 Solid Handling size 100mm Sp Gravity 1.05 MOC Casing CF8M Impeller CF8M Wearing CF8M Shaft & Sleeve SS 410 Fastners BHT Steel Bearing Hsc. CI Mech. Seal - Gland Packing Providing, Installing, Testing, Commissioning of non clog horizontal Centrifugal Pumps including removing of existing pumping machinery and equipments, as specified below.. (Make MJP approved) Capacity - 414.00 m3/Hrs. Pump Head in mWC- 25.00 mtr. Efficiency of the pumps 70% Required Motor rating HP- 75 Speed in RPM 1500 Solid Handling size 100mm Sp Gravity 1.05 MOC Casing CF8M Impeller CF8M Wearing CF8M Shaft & Sleeve SS 316 Fasterners BHT Steel Bearing Hsc. CI Mech. Seal - Gland Packing Providing, Erecting, giving Test and trial of 75 HP foot mounted TEFC, 1000 RPM, Squirrel Cage induction Motor, conforming to IS 325 suitable for operation at 415 Volts 10 %, 3 phase, 50 Hz 3% with continuous Duty SI F class insulation , temperature rise limited to class B insulation.suitable for item no. 1 (MJP approved Make)

No

3.00

854524.00

No

3.00

659644.00

Item No. 7

No.

8.00

264125.00

Item No. 8

Supplying , erecting commissiong soft start / FCMA type starter of three wire system to operate on 380/440 volts, 3 phase, 50 HZ consisting of 1) Maint contactor AC -3 Duty and 1.5 times of full load current frating. 2) Suitable Thyristors / FCMA. 3) Ammeter with Selectors switch and CTS. 4) Motor protection relay with protection CTs for protection against a) Single phasing (Current Sensing) b) Under voltage and over voltage. c) Phase reversal. d) Over current relay having IDMT Characteristic. Suitable for 80 HP motor (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel). Supplying , erecting commissiong soft start / FCMA type starter of three wire system to operate on 380/440 volts, 3 phase, 50 HZ consisting of 1) Maint contactor AC -3 Duty and 1.5 times of full load current frating. 2) Suitable Thyristors / FCMA. 3) Ammeter with Selectors switch and CTS. 4) Motor protection relay with protection CTs for protection against a) Single phasing (Current Sensing) b) Under voltage and over voltage. c) Phase reversal. d) Over current relay having IDMT Characteristic.

No

17.00

199454.00

Item No. 9

No

7.00

140309.00

Suitable for 60 HP motor. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 10 Supplying , erecting commissiong soft start / FCMA type starter of three wire system to operate on 380/440 volts, 3 phase, 50 HZ consisting of 1) Maint contactor AC -3 Duty and 1.5 times of full load current frating. 2) Suitable Thyristors / FCMA. 3) Ammeter with Selectors switch and CTS. 4) Motor protection relay with protection CTs for protection against a) Single phasing (Current Sensing)

No

1.00

117682.00

Item No. 10

No

1.00

117682.00

b) Under voltage and over voltage. c) Phase reversal. d) Over current relay having IDMT Characteristic. 1) 40HP (200) (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel). Item No. 11 Providing, errection, testing & commissioning of PMCC powder coated made out of 14/16 SWG, CRCA sheet steel as follows: The PMCC shall be suitable for following load and incomer supply. The switchgears should be selected suitable with Type II co-ordination. Al bus bars with current density <= 1. Short ckt capacity : 40 KA. A) Incommer: Incommer 1: 400 A MCCB Incommer 2: From DG, 315A MCCB B) Out Going Feeders: 1. 40 HP Soft starter: 2No 2 .75 HP Soft starter: 1 no. 3. Lighting / Auxillary supply : 63 MCCB (TPN) 2No. MCCB with electrical interlocks. All Incommers should have apart from safety relays EF, UV, OC, energy meters which can communicate on MODBUS to the PLC to transfer minimum following Data. a. Voltage b. Current c. Active Power d. Reactive power e. Units Consumed (KWH) All outgoing feeders to be provided with 1. SFU/MCCB 2. Main Contactor 3. Soft Starter 4. Bypass Contactor 5. Overload Relay 6. Local Remote selector. 7. Start / Stop Push buttons. 8. Local indications for: ON,OFF, O/L, Seal Monitor, Phase Reversal. Soft Starting ON. 9. Potential free contacts of All as per #8 above. 10. Bus Bar type terminal for connecting Al cable of sufficient size.

No

1.00

257580.00

11. Cooling Fans of suitable capacity for all sections. 12. Panel Light 13. Heater with thermostate. 14. All spare terminals to be brought to the terminal strip. 15. All live parts to be fully shrouded with Hylam or Fiberglass sheet. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 12 Providing, errection, testing & commissioning of PMCC powder coated made out of 14/16 SWG, CRCA sheet steel as follows: The PMCC shall be suitable for following load and incomer supply. The switchgears should be selected suitable with Type II co-ordination. Al bus bars with current density <= 1. Short ckt capacity : 40 KA. A) Incommer: Incommer 1: 400 A MCCB Incommer 2: From DG, 315A MCCB B) Out Going Feeders: 1. 40 HP Soft starter: 2No 2. 75 HP Soft starter: 2 no. 3. Lighting / Auxillary supply : 63 MCCB (TPN) 2No. 4) MCCB with electrical interlocks. All Incommers should have apart from safety relays EF, UV, OC, energy meters which can communicate on MODBUS to the PLC to transfer minimum following Data. a. Voltage b. Current c. Active Power d. Reactive power e. Units Consumed (KWH) All outgoing feeders to be provided with 1. SFU/MCCB 2. Main Contactor 3. Soft Starter 4. Bypass Contactor 5. Overload Relay 6. Local Remote selector. 7. Start / Stop Push buttons. 8. Local indications for: ON,OFF, O/L, Seal Monitor, Phase Reversal. Soft Starting ON. 9. Potential free contacts of All as per #8 above.

No.

1.00

257580.00

10. Bus Bar type terminal for connecting Al cable of sufficient size. 11. Cooling Fans of suitable capacity for all sections. 12. Panel Light 13. Heater with thermostate. 14. All spare terminals to be brought to the terminal strip. 15. All live parts to be fully shrouded with Hylam or Fiberglass sheet. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 13 Providing, errection, testing & commissioning of PMCC powder coated made out of 14/16 SWG, CRCA sheet steel as follows: The PMCC shall be suitable for following load and incomer supply. The switchgears should be selected suitable with Type II co-ordination. Al bus bars with current density <= 1. Short ckt capacity : 40 KA. A) Incommer: Incommer 1: 400 A MCCB Incommer 2: From DG, 315A MCCB B) Out Going Feeders: a. 60 HP Soft starter: 3No b. 40 HP Soft starter: 1 no. c. Lighting / Auxillary supply : 63 MCCB (TPN) 2No. MCCB with electrical interlocks. All Incommers should have apart from safety relays EF, UV, OC, energy meters which can communicate on MODBUS to the PLC to transfer minimum following Data. f. Voltage g. Current h. Active Power i. Reactive power j. Units Consumed (KWH) All outgoing feeders to be provided with 1. SFU/MCCB 2. Main Contactor 3. Soft Starter 4. Bypass Contactor 5. Overload Relay 6. Local Remote selector. 7. Start / Stop Push buttons. 8. Local indications for: ON,OFF, O/L, Seal Monitor, Phase Reversal. Soft Starting ON.

NO.

1.00

257588.00

9.

Potential free contacts of All as per #8 above.

10. Bus Bar type terminal for connecting Al cable of sufficient size. 11. Cooling Fans of suitable capacity for all sections. 12. Panel Light 13. Heater with thermostate. 14. All spare terminals to be brought to the terminal strip. 15. All live parts to be fully shrouded with Hylam or Fiberglass sheet. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 14 Providing, errection, testing & commissioning of PMCC powder coated made out of 14/16 SWG, CRCA sheet steel as follows: The PMCC shall be suitable for following load and incomer supply. The switchgears should be selected suitable with Type II co-ordination. Al bus bars with current density <= 1. Short ckt capacity : 40 KA. A) Incommer: Incommer 1: 600 A MCCB Incommer 2: From DG, 315A MCCB B) Out Going Feeders: 1) 90 HP Soft starter: 1No 2) 80 HP Soft starter: 3 no. 3) Lighting / Auxillary supply : 63 4) MCCB (TPN) 5No MCCB with electrical interlocks. All Incommers should have apart from safety relays EF, UV, OC, energy meters which can communicate on MODBUS to the PLC to transfer minimum following Data. k. Voltage l. Current m. Active Power n. Reactive power o. Units Consumed (KWH) All outgoing feeders to be provided with 1. SFU/MCCB 2. Main Contactor 3. Soft Starter 4. Bypass Contactor 5. Overload Relay 6. Local Remote selector. 7. Start / Stop Push buttons.

NO.

1.00

330182.00

8. Local indications for: ON,OFF, O/L, Seal Monitor, Phase Reversal. Soft Starting ON. 9. Potential free contacts of All as per #8 above. 10. Bus Bar type terminal for connecting Al cable of sufficient size. 11. Cooling Fans of suitable capacity for all sections. 12. Panel Light 13. Heater with thermostate. 14 All spare terminals to be brought to the terminal strip. 15) All live parts to be fully shrouded with Hylam or Fiberglass sheet. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 15 Providing, errection, testing & commissioning of PMCC powder coated made out of 14/16 SWG, CRCA sheet steel as follows: The PMCC shall be suitable for following load and incomer supply. The switchgears should be selected suitable with Type II co-ordination. Al bus bars with current density <= 1. Short ckt capacity : 40 KA. A) Incommer: Incommer 1: 400 A MCCB Incommer 2: From DG, 315A MCCB B) Out Going Feeders: 1. 80 HP Soft starter: 3No 2. 80 HP Soft starter: 3No. 3. Lighting / Auxillary supply : 63 4. MCCB (TPN) 6No. MCCB with electrical interlocks. All Incommers should have apart from safety relays EF, UV, OC, energy meters which can communicate on MODBUS to the PLC to transfer minimum following Data. p. Voltage q. Current r. Active Power s. Reactive power t. Units Consumed (KWH) All outgoing feeders to be provided with 1) SFU/MCCB 2) Main Contactor 3) Soft Starter 4) Bypass Contactor 5) Overload Relay

NO.

1.00

276556.00

(R.A)

6) Local Remote selector. 7) Start / Stop Push buttons. 8) Local indications for: ON,OFF, O/L, Seal Monitor, Phase Reversal. Soft Starting ON. 9) Potential free contacts of All as per #8 above. 10) Bus Bar type terminal for connecting Al cable of sufficient size. 11) Cooling Fans of suitable capacity for all sections. 12) Panel Light 12) Heater with thermostate. 13) All spare terminals to be brought to the terminal strip. 14) All live parts to be fully shrouded with Hylam or Fiberglass sheet. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 16 Providing, errection, testing & commissioning of PMCC powder coated made out of 14/16 SWG, CRCA sheet steel as follows: The PMCC shall be suitable for following load and incomer supply. The switchgears should be selected suitable with Type II co-ordination. Al bus bars with current density <= 1. Short ckt capacity : 40 KA. A) Incommer: Incommer 1: 400 A MCCB Incommer 2: From DG, 315A MCCB B) Out Going Feeders: 1. 75 HP Soft starter: 3No 2. 60 HP Soft starter: 1 no. 3. 40 HP Soft starter: 1 no. 4. Lighting / Auxillary supply : 63 MCCB (TPN) 2No. MCCB with electrical interlocks. All Incommers should have apart from safety relays EF, UV, OC, energy meters which can communicate on MODBUS to the PLC to transfer minimum following Data. u. Voltage v. Current w. Active Power x. Reactive power y. Units Consumed (KWH)

NO.

1.00

297036.00

All outgoing feeders to be provided with 16. SFU/MCCB 17. Main Contactor 18. Soft Starter 19. Bypass Contactor 20. Overload Relay 21. Local Remote selector. 22. Start / Stop Push buttons. 23. Local indications for: ON,OFF, O/L, Seal Monitor, Phase Reversal. Soft Starting ON. 24. Potential free contacts of All as per #8 above. 25. Bus Bar type terminal for connecting Al cable of sufficient size. 26. Cooling Fans of suitable capacity for all sections. 27. Panel Light 28. Heater with thermostate. 29. All spare terminals to be brought to the terminal strip. 30. All live parts to be fully shrouded with Hylam or Fiberglass sheet. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 17 PLC Based Automation of SPH The scope consisting of supply errection, testing and commissioning of PLC : The PLC should be non redundant, modular The PLC should be capable of having following specifications: a) Digital Inputs: 32 (24 VDC) b) Digital outputs : 12 (24 VDC Transistor/ Relay) c) Analog Inputs : 2 (Min.12 Bit resoloution) Communication ports : 3. One for HMI, One for Connecting Energy Meters (MODBUS) and one for MODEM/ Router. if all the ports are not available onboard with CPU, vendor may consider communication modules. LOCAL HMI : The purpose of Local HMI is to indicate current status of the pumps, Pop up alarms, Enter time delays, and operate the pumps.

NO.

6.00

457184.00

The HMI should have facility to connect local printer on the dedicated printer port. The printer should print events, alarms, Operating hours of each pump, energy consumed and quantity of sewage pumped. The HMI should be text/ graphic preferably Touch screen with minimum screen size of 5 Diagonal. PLC Panel : The Panel should be stand alone, floor mounting type with IP 55 protection. The panel should be sized such a way that natural cooling without external fan should protect the electronics without any derating. (Recomanded Size: 1800 MM(H) x 800 MM (W) X 400 mm (D). With base frame Made out of ISMC 100.

Panel should be made out of 2 mm CRCA sheet steel duly powder coated after cleaning process through 7 tanks for surface treatment. The panel should duly wired up to ClipOn terminals and house 1. PLC 2. HMI 3. 24 VDC, 5 A, SMPS 4. Modem / Router 5. Relay boards. MCBs for Incomming Power (DP), PLC Power, I/C & O/G for 24 VDC supply, service socket, 2 additional DP MCBs for auxiliary supply. Modem/ Router : The device should act as REMOTE MANAGEMENT DEVICE . This should have facility to connect PLC with central PC at head office through either of following 1. PSTN 2. GSM/GPRS. 3. The corporation will provide any of the following connection 4. PSTN / Borad band with dynamic IP 5. SIM card with GSM/GPRS enabled with Dynamic IP. Ultra Sonic Level Transmitter : The level transmitter should be mounted from the TOP. The range should be Max 12 mtrs, but should be site settable.

Accuracy : Better than 0.5% of the range. Housing : IP 65. Supply : 230 VAC/ 24 VDC Output : 4-20 mA. (Being integrated system, Soft Starters, PMCC and PLC based automation system should be supplied as integrated combined panel) Item No. 18 Providing, double flanged short body pattern type manually operated Sluice Value having body, disc and end cover in graded cast iron to IS 210 Gr. CF 200 generally conforming in BS 5155, Synthetic rubber faced ring secured on disc by retaining ring with stainless steel screw stub shaft of stainless steel riding in Teflon bearings excluding C.C. foundation / Structural Steel support confrming to IS 13095-1991. Including lowering laying and jointing in position C.I.D./F Sluice Valve including cost of all labour jointing material, including nut bolts and giving satisfactory hydroulic testing etc. complete. P.N. 1.6 350 mm

No

1.00

95358.90

Item No. 19 Providing and supplying ISI mark CI D/F reflux valves (non-return valves ) of following dia including all taxes (Central and Local), railway freight, inspection charges unloding from railway wagon, loading into truck, transportation upto departmental stroes/ site, unloading, stacking etc. complete. Reflux valves as per I.S.5312 Part I (1984) Without by pass arrangement including lowering laying and jointing in position C.I.D./F Reflux valve (Non Return Valve) including cost of all labour jointing material, including nut bolts and giving satisfactory hydroulic testing etc. complete. PN -1.6 350 mm Item No. 20 Providing and supplying ISI mark CI D/F reflux valves (non-return valves ) of following dia including all taxes (Central and Local), railway freight, inspection charges unloding from railway wagon, loading into truck, transportation upto departmental stroes/ site, unloading, stacking etc. complete. Reflux valves as per I.S.5312 Part I (1984) Without by pass arrangement including lowering laying and jointing in position C.I.D./F Reflux valve (Non Return Valve) including cost of all labour jointing material, including nut bolts and giving satisfactory hydroulic testing etc. complete.

No.

1.00

152441.10

No

15.00

97506.15

PN -1.6 300 mm Item No. 21 Providing and supplying Air Valves double ball flanged type as per IS-10845 and MJPs standard specifications double orifice type combined with isolating sluice valve, mounted in horzontal position and operated by wheel gearing, small orifice elastic ball resting on a gun metal orifice nipple, large orifice vulcanite ball seating on moulded seat ring, inlet face and drilled, including all taxes (Central and local), insurance, third party inspection charges, loading, unloading, transportation upto departmental storer/site,etc. complete including Lowering, Laying and fixing in proper alignment and position all types of C.I. air Valves as directed by Engineer-in-Charge including cost of conveyance from stores to site of work, cost of all material and giving satisfactory hydraulic testing etc. complete. (for all class of valves) PN1.6 100 mm Providing ,erecting, connecting double flanged short body pattern type manually operated Butterfly Valve having body, disc and end cover in graded cast iron to IS 210 Gr. CF 200 generally conforming in BS 5155, Synthetic rubber faced ring secured on disc by retaining ring with stainless steel screw stub shaft of stainless steel riding in teflon bearings excluding C. C. foundation/ structural steel support confirming to IS 13095-1991, Including lowering laying and jointing in position C.I.D./F Butterfly Valve including cost of all labour jointing material, including nut bolts and giving satisfactory hydroulic testing etc. complete. PN -1.6 300 mm Item No 23 Providing, erecting pressure gauge of required range complete with syphon tube, isolating cock suitable for 12mm dia G.I. pipe. Pressure gague shall be installed as directed with tapping on rising main. Pressure gauge. (100mm dia) Providing, Erecting triple spur gear type Chain Pully Block suitable for capacity as below with 6m lift complete with load chain and hand chain sutiable for above lift, tested to 50% over load as per IS 3832 carrying ISI mark. 1) 1 Tonne Capacity No 21.00 592.00 No 19.00 18052.65

Item No 22

No.

12.00

53200.35

Item No 24

No

6.00

14338.00

Item No 25

Supplying and erecting PVC/XLPE insulated armoured cable 1100 V grade with ISI mark Three and half core, stranded aluminium conductor with 6 mm thick 25 mm width M.S. spacer with G.I. Earth wire 6 sq. mm complete erected on wall / on pole with 25 x3 mm M.S. clamps or in provided trench in an approved manner. (3.5 Core 50 Sq. mm) Supplying and erecting PVC/XLPE insulated armoured cable 1100 v grade with ISI mark Four and core soild stranded aluminium conducvtor with 6mm thick 25mm widh M.S spacer with GI earth wire 6sq mm complete erected on wall /on pole with 25 x 3 mm M.S clamps or in provided trench in an approved manner 3.5 Core 150sq mm Supplying and erecting PVC/XLPE insulated armoured cable 1100 V grade with ISI mark Three and falf core, stranded aluminium conductor with 6 mm thick 25 mm width M.S. spacer with G.I. Earth wire 6 sq. mm complete erected on wall / on pole with 25 x3 mm M.S. clamps or in provided trench in an approved manner. (3.5 Core 70 Sq. mm) Supplying and erecting flat flexible submersible cable with copper conductor, PVC insulated and PVC sheathed. 3 Core 35 Sq. mm.

Rmt

30.00

471.00

Item No 26

Rmt

50.00

1135.00

Item No 27

Rmt.

210.00

617.00

Item No 28

Rmt.

90.00

1086.00

Item No 29

Supplying and erecting PVC/XLPE insulated armoured cable 1100 V grade with ISI mark Three and falf core, stranded aluminium conductor with 6 mm thick 25 mm width M.S. spacer with G.I. Earth wire 6 sq. mm complete erected on wall / on pole with 25 x3 mm M.S. clamps or in provided trench in an approved manner. (3.5 Core 400 Sq. mm)

Rmt.

150.00

2936.00

Item No 30

Providing Lowering, Laying and Jointing with SBR rubber gaskets D.I. K-9 grade pipes of various classes with CI/MS Specials of 500 mm diameter in proper position, grade and alignment as directed by Engineer-in-charge including conveyance of material from stores to site of work, including cost of jointing materials and rubber rings labour, giving hydraulic testing etc. complete.

Rmt

4019.16

8789.55

480

480

4218984

4218984

5% 4008034.80 5

payment is Balance because of Hydraulic testing

Item No 31

Providing Lowering, Laying and Jointing with SBR rubber gaskets D.I. K-9 grade pipes of various classes with CI/MS Specials of 700 mm diameter in proper position, grade and alignment as directed by Engineer-in-charge including conveyance of material from stores to site of work, including cost of jointing materials and rubber rings labour, giving hydraulic testing etc. complete. Providing and fabricating structural steel work in rolled sections like joist, channels, angles, tees etc. as per detailed design and drawings or as directed by Engineer- In-Charge. including cutting, fabricating, hoisting, erecting, fixing in position making riveted / bolted / welded connections with connecting plates, braces etc. and including one coat of anticorrosive paint and over it two coats of painting of approved quality and shade complete. Providing and fabricating structural steel work in rolled sections like joist, channels, angles, tees etc. as per detailed design and drawings or as directed by Engineer- In-Charge. including cutting, fabricating, hoisting, erecting, fixing in position making riveted / bolted / welded connections with connecting plates, braces etc. and including one coat of anticorrosive paint and over it two coats of painting of approved quality and shade complete. Supplying and erecting pipe type earthing with 40mm dia 2.5 mtr. Long B grade G.I. pipe or 20 mm dia G.I. Rod buried in earth with necessary double G.I. earth wire No. 8 SWG Complete erected and connected to nearest switchgears /eart terminal.

Rmt.

1310.00

14599.20

648

648

9460281.6

9460282

5% 8987267.90 5

payment is Balance because of Hydraulic testing M.T. 4.50 57196.5

Item No 32

Item No 33

M.T.

4.50

68118.75

Item No 34

No

30.00

350.00

Item No 35

Supplying and erecting copper strip of different sizes used for earthing on wall and /or any purpose with necessary Copper clamps fixed on wall painted with bituminous paint in an approved manner (Joint be done as per specification) Providing and Fixing G.I. Perforated cable trays of size as below including fixing on provided angles ( 400mm x 20mm) Supplying and erecting street light 150 watts H.P.S.V. lamp fitting without lamp having deep drawn one piece aluminium body nickel chrome plated reflector with clear acrylic cover and necessary control gear and electronic ignitor etc. with necessary wiring complete with accessoriec such as copper wound choke, condenser etc. and marking Sr. No. and date of erection. (Similar to Asian / Cromtion / Bajaj / Arcade) Supplying and erecting street light 250 watts H.P.S.V. lamp fitting without lamp having deep drawn one piece aluminium body nickel chrome plated reflector with clear acrylic cover and necessary control gear and electronic ignitor etc. with necessary wiring complete with accessoriec such as copper wound choke, condenser etc. and marking Sr. No. and date of erection. (Similar to Asian / Cromtion / Bajaj / Arcade) Providing and Erecting 9m high galvanized octagonal pole with bottom of 155mm A/F, top 70mm A/F made from 3mm thick HT plate and 260x260x16 mm base plate with 1500 mm long decorative sword type double arm bracket complete erected in an approved manner on provided foundation (Similar to Bajaj make) Supplying and erecting FRP box of size 300mm x 200mm x 125mm, 2.7 mmthick permanent grey colour with 15 Amps 250 volts porecelain base kitkat fuse and top with bakelite connector strip 4 way having locking arrangement with lock and key with arrangements for incoming and outgoing cables at the bottom of the box and outgoing wire leads at the rear side provided with necessary fixing arrangements for the erection on the poles with suitable size clamps provided with nuts, bolts and washers etc. complete.

Cu M.

70.00

3969.00

Item No 36

No

343.00

325.00

Item No 37

No

19.00

3716.00

Item No 38

No

18.00

4125.00

Item No 39

No

16.00

17350.00

Item No 40

No

24.00

435.00

Item No 41

Item No 42

Reinstatment of road by excavating the potholes in rectangular shape and filling of potholes by one layers of soling 230 mm thick ,one layer of 80 mm trap metal of 200 mm thick, one layer of 40 mm trap metal of 200 mm thick including suppling and spresding of stonedust, watering compaction and 75 mm thick bituminious bound macadam with cold emulsion and bituminious macadam of 50 mm thick with bitumen of S-65 grade and 25 mm thick asphalt concrete with S-35 grade of bitumen including compaction by vibratory roller of all layers and providing and applying tack coat of 50 Kg / 100 m2 on black top surface and bitumen cantained of 250 Kg / 100 m2 for B.B.M. surface and diaposal of surplus clay / soil etc., complet. pipeline trenches of various diameter of pipes etc., complete . Disposal of excavated materials upto 3.00 Km including loading unloading etc. complee. Providing and fixing C.I. sluice gates in position as per approved drawing and specification including cost of all materials, labour, operating pedestal, connecting rod, painting with three coats of anticorrosive paint, etc. complete as directed by Engineer-in-charge. Supplying Installation ,Testing & Commissioning of power temple for 11 KV/22KV along with GOD consisting of 400 amps DO modified fiberglass cover to suit requirement of MSEDCalong with CT/PT resin cast meter G.I. structure etc including necessary earthing arrangement,30 meter 95 sq.mmH.T cable ,two indoor & two out door end termination ,RCC foundation ( 2.5 x 2.5x 1 mtr) , dismantling of exiseting pole station etc, complete (Suitable for HT supply at SPH (Make snehakit or equivalent approved by MSEDC))

4775.00

m2 Cu. M.

2900.00

882.43 89.65

Item No 43

Kg.

6000.00

77.70

Item No 44

No.

2.00

831203.00

Item No 45

Providing erecting and commissioning out door type copper wound transformer contineously rated for 3 Ph 50 HZ at full load and temp rise not exceeding 45C by therometer in oil and 50C by the resistance in winding after contineous run at full load rating the transformer should have oil immersed winding having vector group DY 11,HT side connected in Delta and LT side connection in star with neutral brought out connected to provided seperate earthing The transformer shall have power terminal arrangement bushing /cable end box on HT side and cable end box on LT side 2No channels with stopper shall provided and fixed on the provided plinth for mounting the transformer should have following standard fitting .Transformer shall be of latest manuufacturing standrad as per ammended IS specifications and the load & No load losses shall be limited to the value given below or as per IS or Norms issued by MSEDC ltdwhichever are lower 250 KVA including taking the connection from MSEDC Power transformer 11000/ 433 volt with off load trap changer Providing & laying in situ cement concrete M20 of trap/quartzite /genesis metal for foundation & bedding including bailing out water manually, formwork, compaction and curing. ( using Portland possolona cement & flyash.) Spec. IS 1489 (Part I) and BD. E-1)

No.

1.00

387375.00

Item No 46

Rmt.

213.00

3969.00

Item No 47

Supplying and erecting bank of Mixed DI Elactric condensers with the standard Capacities of 1,2,3,5,7,12,15,20 and 25 KVAR units of power factor correction for operation on 3 phase, 50 Hz, 400v +/- 10% with externally discharging resistance, earthing terminals and built on angle iron or channel iron frame work and provided with terminal cover complete erected and tested. Excavation for roadways in soft strata such as earth soil of all sorts sand, gravel or soft murum including dressing section to the required grade, camber and side slopes and conveying the excavated materials with all lifts upto a lead of 50 m and spreading for embankment or stacking, disposing as directed.

KVR

66.00

618.00

Item No 48

Cu.M.

1530.00

86.10

Item No 49

Excavation for foundation in Soft rock / old cement / lime masonry foundation including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling with available earth / murum, ramming, watering etc. complete. as directed excluding shoring and strutting .Lift upto 1.50 metres Excavation for foundation in hard rock by chiselling wedging / old cement / lime masonry foundation including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling with available earth / murum, ramming, watering etc. complete. as directed excluding shoring and strutting. Lift upto 1.50 metres Excavation for roadways in hard strata such as soft rock including dressing section to the required grade, camber and side slopes and conveying the excavated materials with all lifts upto a lead of 50 m and spreading for embankment or stacking, disposing as directed.

Cu M.

30.00

232.05

Item No 50

Cu.M.

1605.00

1188.00

Item No 51

Cu. M.

1500.00

232.05

PART B 3 Name of Work: - Designing , Constructing and Commissioning of Sewage Pumping Station for

Description of Item S. No. BOQ Item No. Unit

Approved Qty.

Rate in Rs.

2 3 Item No. 1 Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 0 to 1.5 M Item No. 2 Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 1.50 metres Item No. 2 Item No. 3 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 1.5 to 3.00 M Item No. 2 Item No. 4 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 1.50 to 3.00 metres

Sq. M.

90.16

210

Cu. M.

252.998

86.1

Sq. M.

86.98

225.75

Cu. M.

126.03

96.6

Item No. 2 Item No. 5 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 3.00 to 4.50 M Sq. M. Item No. 6 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 3.00 to 4.50 metres Cu. M. Item No. 2 Item No. 7 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 4.50 to 6.00 M. Sq. M. Item No. 2 Item No. 8 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 4.50 to 6.00 metres Cu. M. Item No. 9 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 6.00 to 7.50 M. Sq. M. 47.54 273 2.56 107.1 62.88 257.25 102.5 101.85 62.88 241.5

Item No. 2 Item No. 10 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 6.00 to 7.50 metres Cu. M. Item No. 2 Item No. 11 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 7.50 to 9.00 M. Sq. M. Item No. 12 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 7.50 to 9.00 metres Cu. M. Item No. 2 Item No. 13 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 9.00 to 10.50 M. Sq. M. 40.68 304.5 75.36 107.1 288.75 83.88 107.1

Item No. 2 Item No. 14 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 9.00 to 10.50 metres Cu. M. Item No. 15 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 10.50 to 12.00 M. Sq. M. Item No. 2 Item No. 16 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 10.50 to 12.00 metres Cu. M. Item No. 2 Item No. 17 :- Open timbering in trenches of depth more than 1.5 m for shoring and strutting including use of and waste of all necessary timber works including walling, strutts, open polling boards/ horizontal sheeting, runners, etc. as may be necessary and fixing and removal complete. (Measurements to be taken of the face/area timbered)(NBO Item No. 4-15 page No.59 ) Lift 12.00 to 13.50 M. Sq. M. 20.84 336 75.36 107.1 40.68 320.25 75.36 107.1

Item No. 18 :- Excavation for foundation in earth,soils all types, sand gravel and soft murum including removing the excavated materials upto a distance of 50 metres beyond the building area and lift as specified, stacking and spreading, necessary dewatering unless provided elsewhere, preparing the bed for the foundation and required backfilling, ramming, watering, shoring and strutting etc. complete. as directed. Lift upto 12.00 to 13.50 metres Cu. M. Item No. 2 Item No. 19 :- Dewatering on BHP basis by using water pump By using 5 to 9 Horse power pump including diversion of streams, providing earthen bunds coffer dam etc. as may be necessary for foundation and other parts of the work and bailing out and pumping out water, during and after excavation as required (The item include dewatering for excavation upto foundation level, filling foundation and sub structure masonry above water level)( Prior approval of Additional City Engineer is necessary ) Item No. 2 Item No. 20 :- Disposal off the excavated material upto 3.00 km lead etc. complete. Item No. 2 Item No. 21 :- Providing dry trap/rubble stone soling 15 cm to 20 cm thick including hand packing and compacting etc. complete. Item No. 2 Item No. 22 :- Providing and laying in situ cement concrete in proportion M-15 of trap metal for foundation and bedding, including bailing out water manually, formwork, compacting and curing. Item No. 2 Item No. 23 :- Providing and Laying Cement Plum Concrete etc. complete. Item No. 2 Item No. 24 :- Providing and casting in situ cement concrete M-30 of trap metal for R.C.C.. work like raft, grillage, strip, foundations and footing of R.C.C. Columns and steel stanchions, including bailing out water manually, centering, formwork, compacting, finishing and curing. (Excluding steel reinforcement) Item No. 2 Item No. 25 :- Providing and casting in situ cement concrete M-30 of trap metal for R.C.C. Slabs and landings of all thickness as per detailed drawings and designs, including centering, formwork, compacting, roughening the surface if special finish is to be provided and curing. (Excluding steel reinforcement) 41.69 107.1

Hour Cu. M.

360 891.3

57.75 85.39

Cu. M.

16.56

427.35

Cu. M. Cu. M.

7.24 31.82

3463.95 3167

Cu. M.

86

3979.5

Cu. M.

12

5675.25

Item No. 2 Item No. 26 :- Providing and casting in situ cement concrete M-30 of trap metal for R.C.C. pardi 75mm thick, including centering formwork, compacting, roughening the surface if special finish is to be provided and curing. (Excluding steel reinforcement) Item No. 2 Item No. 27 :- Providing and fixing in position H.Y.S.D. Steel bar reinforcement of various diameters for R.C.C. pile caps, footings, foundations, slabs, beams, columns, canopies, staircases, newels, chajjas, lintels, pardies, coping, fins, arches, etc. as per detailed designs, drawings and schedules, including cutting, bending, hooking the bars, binding with wires or tack welding and supporting as required complete. Item No. 2 Item No. 28 :- Providing internal cement plaster 20mm thick in a single coat, in cement mortar 1:3 without neeru finish to stone masonry surface in all positions including scaffolding, racking out joints, providing groove at joints of stone masonry and concrete members and curing complete. Item No. 2 Item No. 29 :- Providing sand face plaster externally in two coats using approved screened sand in all positions, including preparing the surface, providing base coat of 15 mm thick in cement mortar 1:4 mixing approved water proofing compound at the rate of 1 kilogramme / 50 kg of cement, curing the same for not less than two days, keeping the surface of base coat rough to receive the sand faced treatment 8 mm thick in cement mortar 1:4 and finishing the surface by taking out grains, curing for 14 days, scaffolding etc. complete, using Portland Pozzolana Cement & Flyash. Item No. 30 :- Providing and laying cement concrete flooring 50 mm thick with cement concrete M-25 laid to proper line, level and slope in alternate days including compaction, filling joints marking lines to give appearance of tiles 30cm x 30cm or other approved design, finishing smooth (with extra cement) in approved colour as directed and curing complete.

Cu. M.

133

5990.25

M.T.

29

58800

Sq. M.

281.17

115.5

Sq. M.

301.77

215.25

Sq. M.

43.49

224.7

Item No. 2 Item No. 31 :- Providing and fabricating structural steel work in rolled sections fixed with connecting plates or angle cleats in main and cross beams, hip and jack rafters, purlins connecting to truss members and the like, as per detailed design and drawings or as directed by Engineer- In-Charge. including cutting, fabricating, hoisting, erecting, fixing in position, making riveted/bolted/welded connections and one coat of anticorrosive paint followed by two coats of oil painting of approved quality and shade complete. Item No. 2 Item No. 32 :- Soil investigation etc. complete.

M.T.

0.38 1

56710.5 21114.3

Job Work Item No. 2 Item No :- 33 Supply & Erection testing & Commissioning of 20 HP Submerssible Pump Nos having discharge 380 m3/hr at 10 mtr head Item No. 2 Item No :- 34 Providing double Flanged short body pattern type manually operated butterfly valve having body discand cover in graded cast iron to to IS 210 Gr CF20 c generally conforming in BS 5155 Synthetic rubber faced ring secured on disc by retaining ring with stainless steel screwstub of stainless steel riding in Teflon bearing excluding C.C foundation /structural steel support confirning Nos Sluice valves PN 1.6 Item No. 2 Lowering laying & jointing in position following C.I D/F Reflux valve Butterfly valves and sluice valves including cost of all labour jointing materials including nut bolts and giving satisfactory hydraulic testing complete 200 mm dia sluice valve Item No. 2 Item No.35 :- Providing & suppling ISI mark CI/ DF reflux valve (non return valves ) of following dia including all taxes (Central & Local ) railway freight isspection charges unloading from railway wagon loading into truck transporation upto departmental stroes /site Nos unloading stacking etc complete 200 mm dia Non return valves Item No. 2 Item No. 36 :- Providing & Erecting main Nos control panal board all control unit & starter

466742

29298.15

35571.9 3 1 154761

Item No. 2 Item No. 37 :- Manufacturing providing supplying spirally welded /ERW /SAW /fabricated M.S.pipes including procurements of plates gas cutting to required size rolling tack welding assembling in suitable lengths to from pipe welding on automatic welding machine and forming V edge on both ends of pipe including all taxes ( Central & Local ) railway freight insurance unloading from railways wagon loading into truck transport to stores /situ unloading stacking etc complete Dia of Pipe 400 mm M.S ( ID) Thickness of pipe 8 mm Item No. 2 Item No. 38 :- Providing & fixing GI Pipe railing having 1.0 M height consisting 50 x 50 x 6 mm thick M.S angles as verticals at 1.5 mc/c & additional posts at every corner bends to curved shape with 3 rows of 25 mm dia G.I pipes of medium class variety as horizontal & painting 3 coats of oil paint over 1 coat of anticorrosive paint of approved colour 7 shade including cost of all labour transporting bends to curved shape etc complete Item No. 2 Item No. 39:- Providing & appling external & internal coating for steel structrures in sewages treatement plant /water treatement plant with elastomeric ( 450 5 elongation ) thermoplastic fire retardant, coating skin tensile strength 18 to 21 kg cm2 antifungal antibacterial anti corrosive graft co polymer 50 micron DFT of self bonding with steel 50 micron DFT of inner coat and Micron DFT of top coat Item No. 2 Item No. 40 :- Supplying & Erecting PVC armoured cable 1100 v grade with ISI mark three & halg coresolid /stranded aluminium conductor with G.I eath wire 6sq mm complete erected on wall /on pole with 25x 3 m MS clamps or in provided trench in an approved manner

Nos 230

6598.2

Rm

20

699.3

M2

558

590.1

Rm 31/2 core x 70 sq mm Item No. 41 :- Supplying & erecting PVC armoured cable 1100 v grade with ISI mark three core solid / stranded aluminium conductor with 6 mm thick 25 mm widh M.S spacer with GI earth wire 6 sq mm complete erected on wall /on pole with 25 x 3 mm M.S clamps or in provided trench in an approved manner Rm 3 x 10 mm 50 50

617

191