Académique Documents

Professionnel Documents

Culture Documents

Alternate Carry Manual

Transféré par

metallicfoamCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Alternate Carry Manual

Transféré par

metallicfoamDroits d'auteur :

Formats disponibles

TABLE OF CONTENTS

[ GENERAL, SPECIAL TOOLS AND SERVICE MATERIALS

1

PERIODIC MAINTENANCE SERVICE TROUBLE SHOOTING FUEL SYSTEM

(CARBURETOR, AIR CLEAN~R, FUEL PUMP ANO FUEL FILTER)

[ ENGINE

I~CA==R==H==EA==TE==R ====================================~ IGNITION SYSTEM

~======================~==~

I~C~RA~N~KI~NG~SY~S~TE~M~~~~~~~~~~=I I CHARGING SYSTEM I==CL==UT==CH===============:::::::===========================_ ,---I G_EA_R_SH_IF_TI_NG_C_ON_T_RO_L ~ _ TRANSMISSION DIFFERENTIAL SUSPENSION STEERING SYSTEM BRAKES BODY SERVICE BODY ELECTRICAL EQUIPMENT SERVICE DATA

(SECTION 13 5SPEEO) AND (SECTION 131 4SPEED)

13 & 13-1

PROPELLER SHAFT

SECTION 0

GENERAL, SPECIAL TOOLS AND SERVICE MATER IALS

CONTENTS

0-1. 0-2. 0-3. 0-4. 0-5. LOCATIONS OF BODY NUMBER AND ENGINE NUMBER STANDARD SHOP PRACTICES SPECIAL TOOLS REQUIRED SERVICE MATERIALS METRIC INFORMATION

,

0-1 0-2

0'-5

0-9 0-12

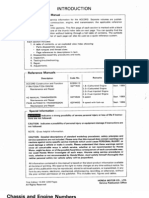

0-1. LOCATIONS OF BODY NUMBER AND ENGINE NUMBER

The body number is punched on the upper surface of the right-hand tire housing located under the seat. The engine number is punched on the righthand skirt part of the cylinder block under the carburetor.

r------,

I L I J

Fig. 0-1 Location of BOdy

!VO.

Fig. 0-2 Location of Engine No.

0-,

0-2. STANDARD SHOP PRACTICES

1. Protect painted surfaces of the body, and avoid staining or tearing seats. When working on fenders and seats, be sure to cover them up with sheets. 2. Disconnect negative terminal connection of the battery when working on any electrical part or component. This is necessary for avoiding electrical shocks and short-circuiting, and is very simple to accomplish: merely loosen wing nut on negative terminal and separate cable from terminal post. 3. In raising front or rear car end off the floor by jacking, be sure to put the jack against the center portion of the front suspension frame or rear axle housing.

4. When performing service with either front or rear carend jacked up, be sure to place safety stands under chassis frame so that body is securely supported. Refer to below figures for where to place safety stands. And then check to ensure that chassis frame does not slide on safety stands and the car is held stable for safety's sake. IMPORTANT: When placing safety stands under chassis frame, use care so that they don't contact other parts (such as bracket and pipes) installed inside (body center side) of chassis frame. Place chocks against both right and left wheels on the grou nd from both front and rear.

_-.JI__

Fig. 0-3 Front Side Fig. 0-5 Front Side

ear Side Fig. 0-6 Rear Side

5. Fig. 0-7 and 0-8 show how to lift the car by using a hoist. IMPORTANT: Before lifting up the car, check to be sure that end of hoist arm is not in contact with brake pipe, fuel pipe, bracket or any other part. When using frame contact hoist, apply hoist as shown below (right and left at the same position). Lift up the car till 4 tires are a little off the ground and make sure that the car will not fall off by trying to move car body in both ways. Work can be started only after this confirmation. Before applying hoist to underbody, always take car balance throughout service into consideration. Car balance on hoist may change depending of what part to be removed. Make absolutely sure to lock hoist after car is hoisted up. When using frame contact hoist:

6. Orderliness is a key to successful overhauling. Trays, pans and shelves are needed to set aside disassembled parts in groups or sets in order to avoid confusion and misplacement. This is particularly important for engine overhauling. 7. Have on hand liquid packing-BOND No. 1215 (99000-31110) - for ready use. This packing dope is an essential item to assure leak-free (water and oil) workmanship. 8. Each bolt must be put back t.o where it was taken from or for which it is intended. Do not depend on your hunch in tightening bolts for which tightening torque values are specified: be sure to use torque wrenches on those bolts. 9. It is advisable to discard and scrap gaskets and "a" rings removed in disassembly. Use new ones in reassembly, and try not to economize gaskets and "a" rings. 10. Use of genuine parts is imperative. Use of imitation parts is a big gamble on safety and performance. Use genuine parts and live up to the trust your customer places on you. 11. Special tools workmanship: save time and ensure good They are available from:

KENT MOORE AUSTRALIA PTY. LTD., Unit 2, 8 Gladstone Road, Castle Hill, New South Wales, Australia, 2154 Telephone: (02) 6344999 Telex: 22355

Fig. 0-7 Front Support Location

Fig. 0-8 Rear Support Location

0-3

12. Refer to the contents of this MANUAL as often as practical, and do each job properly as prescribed. NOTICE: Engine cylinders are identified by numbers. See Fig. 0-9. Counting from the front end, the cylinders are referred to as No. 1, No. 2, No. 3 and No. 4 cylinders.

Fig. 0-9 Engine Cylinder

Numbers

0-4

Vous aimerez peut-être aussi

- Daihatsu workshop manual sectionsDocument294 pagesDaihatsu workshop manual sectionsManuel Guillen100% (1)

- Workshop Manual General Section Indica Vista 1.4 Fire Euro 5 PDFDocument19 pagesWorkshop Manual General Section Indica Vista 1.4 Fire Euro 5 PDFShashikanth Nm0% (1)

- Suzuki F6a Engine ManualDocument202 pagesSuzuki F6a Engine ManualJongardsOllirum70% (20)

- Haulster Police Vehicle Service Manual with 660 Suzuki EFI EngineDocument202 pagesHaulster Police Vehicle Service Manual with 660 Suzuki EFI EngineDonald Charles FernoughtyPas encore d'évaluation

- Technical Specifications - EcoSportDocument1 pageTechnical Specifications - EcoSportBerg Auto Repairs100% (1)

- K6a WiringDocument198 pagesK6a WiringKelvin Sanchez Bastida79% (14)

- 14BBG - Sec16 - NPRHD NQR NRR Diesel Cab Chassis Electrical-0215113 FinalDocument34 pages14BBG - Sec16 - NPRHD NQR NRR Diesel Cab Chassis Electrical-0215113 FinalIgmar Franco Negrete100% (2)

- Isuzu N-Series Elf Workshop Manual - Power Take Off With Oil Pump - LGPTO-WE-0091 PDFDocument63 pagesIsuzu N-Series Elf Workshop Manual - Power Take Off With Oil Pump - LGPTO-WE-0091 PDFRicardo Cornejo LafuentePas encore d'évaluation

- Rodeo PDFDocument2 613 pagesRodeo PDFluigimasterPas encore d'évaluation

- Engine 4J Series: 4JB1/4JB1-TC/4JG2/4JH1-TC - ENGINEDocument102 pagesEngine 4J Series: 4JB1/4JB1-TC/4JG2/4JH1-TC - ENGINEImesh SachinthaPas encore d'évaluation

- Yamaha Mio Mxi 125 Service Manual PDFDocument2 pagesYamaha Mio Mxi 125 Service Manual PDFJL Acorin Inding50% (2)

- Belang R150 CatalogueDocument6 pagesBelang R150 CataloguejunidomarPas encore d'évaluation

- Mitsubishi Motor 1.5,11B 2007-2017 InglesDocument51 pagesMitsubishi Motor 1.5,11B 2007-2017 InglesmanualPas encore d'évaluation

- Engine: 1Kd-Ftv and 2Kd-Ftv EnginesDocument46 pagesEngine: 1Kd-Ftv and 2Kd-Ftv EnginesJorge Luis Garcia ArevaloPas encore d'évaluation

- Suzuki Service Manual - K15-Df100a-115a-115as-140a-99011-90j50-03benDocument131 pagesSuzuki Service Manual - K15-Df100a-115a-115as-140a-99011-90j50-03benJorge LopesPas encore d'évaluation

- Naza Ria Rover KV6 Engine Cam Marking ManualDocument7 pagesNaza Ria Rover KV6 Engine Cam Marking ManualLee Ming Fee100% (1)

- Dyna Repair Manuals Up PDR 129 eDocument242 pagesDyna Repair Manuals Up PDR 129 eRowan Cornelius100% (1)

- Jackaroo 4JX1 Engine Manual 2014 Ver 2.2Document65 pagesJackaroo 4JX1 Engine Manual 2014 Ver 2.2João Guardado100% (3)

- Navara Engine Maintenance (Yd25ddti)Document50 pagesNavara Engine Maintenance (Yd25ddti)MTK2016100% (6)

- Honda Wave18krs3e2Document122 pagesHonda Wave18krs3e2Emmanuel Maldonado100% (1)

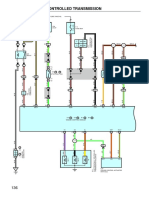

- Electronically controlled transmission system overviewDocument6 pagesElectronically controlled transmission system overviewOliver leal100% (1)

- EWD of Zace DR077W (VN)Document41 pagesEWD of Zace DR077W (VN)Binh Binh100% (1)

- Ranger Overhaul Manual SectionsDocument129 pagesRanger Overhaul Manual SectionsSumitomo Excavator100% (2)

- Engine PDFDocument254 pagesEngine PDFEder BarreirosPas encore d'évaluation

- Kawasaki Barako 175 - BC175FFFPH-2015Document74 pagesKawasaki Barako 175 - BC175FFFPH-2015Jonard Sayod100% (2)

- Suzuki Carry - AIR CLEANER, FUEL PUMP AND FILTERDocument6 pagesSuzuki Carry - AIR CLEANER, FUEL PUMP AND FILTERGersonNavarroPas encore d'évaluation

- Yamaha Jupiter MX T135 Service ManualDocument349 pagesYamaha Jupiter MX T135 Service Manualhwahyd80% (5)

- Group 37 SteeringDocument71 pagesGroup 37 SteeringNeoGaraPas encore d'évaluation

- Mitsubishi Delica User Manual Spacegear 1997 E12Document49 pagesMitsubishi Delica User Manual Spacegear 1997 E12Mel Ipona50% (4)

- Kijang Inova DieselDocument109 pagesKijang Inova Dieselbernadus ari wibowo100% (1)

- 1KDFTVL P2Document4 pages1KDFTVL P2julio797Pas encore d'évaluation

- Kelisa: PeroduaDocument64 pagesKelisa: PeroduaZamirul SyafiqPas encore d'évaluation

- Suzuki Carry Every Van Identification ChartDocument6 pagesSuzuki Carry Every Van Identification Chartteppendudes100% (1)

- Ford Everest Service ManualDocument3 pagesFord Everest Service Manualbiang_kerok150% (8)

- PDF At115 2002 NouvoDocument293 pagesPDF At115 2002 NouvoSyahrom NiezamPas encore d'évaluation

- Prado Problems 3Document23 pagesPrado Problems 3raja antony100% (1)

- Isuzu TF Series Electrical Body and ChasysDocument357 pagesIsuzu TF Series Electrical Body and ChasysAlbert Briceño88% (16)

- Power Train Components Table for FE and FG VehiclesDocument1 pagePower Train Components Table for FE and FG VehicleswilmanesPas encore d'évaluation

- 4G15M Turbo Engine ManualDocument55 pages4G15M Turbo Engine ManualPeter James Bruce ClarkPas encore d'évaluation

- NISSAN SENTRA 1993 Maintenance InfoDocument16 pagesNISSAN SENTRA 1993 Maintenance InfoAlessandro Baffa100% (1)

- Isuzu Front SuspensionDocument28 pagesIsuzu Front SuspensionHendrianto100% (2)

- PajeroDocument164 pagesPajeroAbalaru Ionut Daniel100% (1)

- Hyundai Universe PDFDocument16 pagesHyundai Universe PDFMelvin Gascon33% (3)

- JB-DET Copen Service ManualDocument1 159 pagesJB-DET Copen Service Manualnajib anuar80% (5)

- Ford Everes PDFDocument584 pagesFord Everes PDFTiến Hồ100% (6)

- IsuzuDocument5 pagesIsuzuRamon Sotta100% (1)

- 2AZ-FE FuelDocument43 pages2AZ-FE FuelAdedeji OluwatobilobaPas encore d'évaluation

- Daihatsu Type k3 Engine Service Manual No9737 No9332 No 9237 Engine MechanicalDocument71 pagesDaihatsu Type k3 Engine Service Manual No9737 No9332 No 9237 Engine MechanicalMike Nolan100% (2)

- 1991 Honda Accord Shop ManualDocument903 pages1991 Honda Accord Shop ManualMark DismorePas encore d'évaluation

- Wave110 Dash RSDocument110 pagesWave110 Dash RSAmmar Yusoff86% (7)

- Carry Section 0Document5 pagesCarry Section 0Ali CastilloPas encore d'évaluation

- ATD8696 InstructionsDocument4 pagesATD8696 Instructionsfernando chPas encore d'évaluation

- Clutch ManualDocument16 pagesClutch ManualCO BDPas encore d'évaluation

- 84-01 4.5” XJ CHEROKEE LIFT KITDocument8 pages84-01 4.5” XJ CHEROKEE LIFT KITveabreuPas encore d'évaluation

- Installation Instructions: 5568 Rear Anti-Swaybar 67-'69 Camaro & FirebirdDocument3 pagesInstallation Instructions: 5568 Rear Anti-Swaybar 67-'69 Camaro & Firebirdkkg4782Pas encore d'évaluation

- CityRover Workshop ManualDocument645 pagesCityRover Workshop ManualTheCityRover100% (17)

- Orbitrol Desarmado y ArmadoDocument9 pagesOrbitrol Desarmado y Armadojulio cesarPas encore d'évaluation

- Gts 250Document217 pagesGts 250Eduardo M. R. SousaPas encore d'évaluation

- GM 3.0 LDocument36 pagesGM 3.0 Lmeyyiti01Pas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- How to Read a LEAF CardDocument4 pagesHow to Read a LEAF CardAntonio GPas encore d'évaluation

- Basic Storage Networking Technology Certified Storage Engineer (Scse, s10-201)Document17 pagesBasic Storage Networking Technology Certified Storage Engineer (Scse, s10-201)slimanovPas encore d'évaluation

- LT 9Document2 pagesLT 9ariwibowoPas encore d'évaluation

- 4b Idb GSM Guide 11-01-12aDocument6 pages4b Idb GSM Guide 11-01-12acleonbPas encore d'évaluation

- Telecom Engineer - 263311Document3 pagesTelecom Engineer - 263311Mohamed HefnyPas encore d'évaluation

- Nokia Qatar Das Sweep Testing SowDocument12 pagesNokia Qatar Das Sweep Testing SowAsankaPas encore d'évaluation

- Eyezon Envisalink Honeywell Installation GuideDocument13 pagesEyezon Envisalink Honeywell Installation GuideJason HendersonPas encore d'évaluation

- Resolucion Jefatural #514-2003-Jef-ReniecDocument34 pagesResolucion Jefatural #514-2003-Jef-ReniecSan Ramón TarmaPas encore d'évaluation

- Sample Procedure FlowDocument3 pagesSample Procedure Flowvyly1723Pas encore d'évaluation

- Iso 22000 Documentation Kit PDFDocument9 pagesIso 22000 Documentation Kit PDFMohammad Mashatleh100% (2)

- Job NoticeDocument8 pagesJob NoticeRoni SharmaPas encore d'évaluation

- Catalog Steel ProductionDocument13 pagesCatalog Steel Productiondannyboy738Pas encore d'évaluation

- VB.Net - Variables and Data TypesDocument17 pagesVB.Net - Variables and Data TypesAnne Margaret LarcenaPas encore d'évaluation

- Solution For Structures and UnionDocument10 pagesSolution For Structures and UnionshibhiPas encore d'évaluation

- RLG PDFDocument62 pagesRLG PDFVanessa ArcePas encore d'évaluation

- ASTMD-2726 For Bituminous Core DensityDocument3 pagesASTMD-2726 For Bituminous Core Densityrajeshji_000100% (1)

- Tuberia PVC Ced40Document64 pagesTuberia PVC Ced40KoOkz GarciaPas encore d'évaluation

- Anac CF34 Engine PDFDocument10 pagesAnac CF34 Engine PDFEstevamPas encore d'évaluation

- Journey Management Plan - March 17Document3 pagesJourney Management Plan - March 17alanbozic50% (2)

- Uei Catalog v13 WebDocument48 pagesUei Catalog v13 WebrockymadhuPas encore d'évaluation

- Spicer PRO SHIFT 18 Speed Service ManualDocument48 pagesSpicer PRO SHIFT 18 Speed Service ManualAngel Frausto Beltran100% (1)

- Premium Connection SummaryOKDocument12 pagesPremium Connection SummaryOKSebas DazaPas encore d'évaluation

- Ieee C37.42Document42 pagesIeee C37.42NataGBPas encore d'évaluation

- Practical Non-Scientific Field or Bench TestDocument12 pagesPractical Non-Scientific Field or Bench TestPaulPas encore d'évaluation

- Neca 409-2009 - Installing and Maintaining Dry Type TransformersDocument42 pagesNeca 409-2009 - Installing and Maintaining Dry Type TransformersJosé Luis FalconPas encore d'évaluation

- VoLTE SIP MO-MT Call Flow PDFDocument14 pagesVoLTE SIP MO-MT Call Flow PDFRiteshPas encore d'évaluation

- Note Book Wimax: Wimax, The Worldwide Interoperability For Microwave Access, Is A Telecommunications TechnologyDocument6 pagesNote Book Wimax: Wimax, The Worldwide Interoperability For Microwave Access, Is A Telecommunications TechnologyEdwardayeniPas encore d'évaluation

- Calibrating Weighing Scales & Fuel PumpsDocument146 pagesCalibrating Weighing Scales & Fuel PumpsSelyun E OnnajPas encore d'évaluation

- GB GroutDocument4 pagesGB Groutengrrahman3135Pas encore d'évaluation

- Hi-Line Hippo ConnectorsDocument6 pagesHi-Line Hippo ConnectorsTonyPas encore d'évaluation