Académique Documents

Professionnel Documents

Culture Documents

Collapse of The NATM Tunnels at Heathrow Airport

Transféré par

Oana Mihaela BanuDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Collapse of The NATM Tunnels at Heathrow Airport

Transféré par

Oana Mihaela BanuDroits d'auteur :

Formats disponibles

SCOSS Standing Committee on Structural Safety

11 Upper Belgrave Street London SW1X 8BH

Chairman: KATE PRIESTLEY MBA CQSW HFIHEEM FRSA Secretary: JOHN CARPENTER CENG FICE FISTRUCTE FIOSH

SC/06/101 The Collapse of NATM tunnels at Heathrow Airport Reference: HSE Books 2000 (now out of print but available from libraries) In October 1994 a section of tunnel being constructed at Heathrow Airport collapsed; although there were no injuries, many people were put at risk and the consequential cost was significant. A number of the lessons arising from this collapse can be applied to engineering projects generally. The tunnel was constructed using the NATM (New Austrian Tunnelling Method) form of construction. The safety of this approach depends upon close monitoring as work progresses; it was the first time it had been used in London clay. In view of this an extensive full scale trial was undertaken at the site prior to initiating the actual works. The method involves the use of a sprayed concrete lining, applied in stages, and in such a manner that the stand-up time of exposed clay is not compromised. (A good description is given in Appendix 1 of the HSE report). The HSE report describes a number of significant decisions and actions relating to procurement and control (Paras 35-51) which impacted on risk management. These included: Differences between the trial and the main works Adoption of D&B with the construction risk taken by the contractor Adoption of self certification Use of a new contract form (the NEC) which linked payment to satisfactory completion of work Pressure on the monitoring sub-contractor to minimise their costs at tender stage

The process of monitoring and evaluation was a critical aspect and the report reviews this in detail. Significant shortfalls were evident including decisions on tunnel construction being made without correlation with current data on the settlement of the ground surface above the tunnel. The cause of failure The HSE report cites the direct cause of the tunnel collapses as a chain of events involving: Substandard construction in the initial length of the CTA concourse tunnel Grout jacking that damaged the same length of the CTA tunnel plus inadequately executed repairs Construction of a parallel tunnel in failing ground Major structural failure and progressive failure in the adjacent ground along with further badly executed repairs The HSE labelled this as having all the hallmarks of an organisational accident The HSE report states that Hazards were not identified by all the parties and risks were not controlled,

S:\Filing\G20 - G29\G28-Collapses and the like\Text reports etc\2006\December06\SC06.101 - Collapse of the NATM Tunnels at Heathrow Airport.doc

The Standing Committee on Structural Safety is an independent body supported by the Institutions of Civil and Structural Engineers and the Health & Safety Executive to maintain a continuing review of building and civil engineering matters affecting the safety of structures.

Tel.: +44 (0) 20 7235 4535 Fax: +44 (0) 20 7 235 4294/201 9165 Email: scoss@istructe.org.uk Website: www.scoss.org.uk

during construction, through the defensive systems (ie. preventative management systems) used by the parties. A full evaluation of the organisational issues and the technical details of the failure may be found in the report. Lessons from the incident Major accident potential 1 Major accident hazards are manifested in events that have a low probability of occurrence, but when they do occur they have major consequences in human and business terms. It is possible to overlook their importance because they are infrequent. Hazard and risk management 2 Such incidents must be prevented through sound risk management. 3 The lessons from past failures need to be recognised 4 The need to carefully consider new technologies, or those projects with the potential to significantly affect workers or the public is particularly important. 5 Where measurement of movements is used to monitor risk then the data must reach and be assessed by managers in an appropriate timescale. 6 Organisational and human factors, as well as technical aspects, should be considered Management systems etc 7 It is essential to reflect human and organisational factors when devising defence mechanisms 8 Defences can be affected by procurement, contract forms, and differing methodologies between companies. 9 Production pressures must be balanced by checks and balances; these must include for conflict management. 10 Remedial and maintenance activities require strong organisational procedures 11 Management systems should be led from the top, be inclusive, and promote good communication and decision making at the appropriate level. Statutory framework 12 The statutory framework provides impetus and imperative to good engineering and management. Post report note on lessons learned and the recovery solution Given the scale of the collapse and the major implications for the project, it is useful to note the impressive response by BAA which in concert with its suppliers rapidly addressed the key lessons and delivered a very effective recovery solution. This embraced a fully integrated team approach combining risk management with technical innovation and, from an initial prediction of one and a half years delay, the project was opened just six months later than the original programme. The single-team approach developed for the recovery solution is described by Powderham and Rust DEye (2003).

References 1 Powderham A. Heathrow Express Cofferdam: Innovation and delivery through the single-team approach. Part 1: Design and Construction Civil Engineering Practice Spring/Summer 2003 2 Rust DEye C. Heathrow Express Cofferdam: Innovation and delivery through the single-team approach. Part 2: Management Civil Engineering Practice Spring/Summer 2003

Rev 1

Vous aimerez peut-être aussi

- Managing Subsurface Risk For Toronto's Rapid Transit Expansion ProgramDocument10 pagesManaging Subsurface Risk For Toronto's Rapid Transit Expansion Programmorteza90Pas encore d'évaluation

- Schedule To Complete One Cycle in Class-Iii & IvDocument3 pagesSchedule To Complete One Cycle in Class-Iii & IvShivsagar yadav100% (1)

- Controlled Unclassified Information (CUI) : (When Filled IN)Document33 pagesControlled Unclassified Information (CUI) : (When Filled IN)Gerold_MPas encore d'évaluation

- Cavern and Tunnel Collapses Due To AdverDocument18 pagesCavern and Tunnel Collapses Due To AdverGelu MADEARPas encore d'évaluation

- Tunnel BlastingDocument27 pagesTunnel BlastingAiman Bashir100% (1)

- Recommendations ITA TBM 230503 133403Document120 pagesRecommendations ITA TBM 230503 133403KakaPas encore d'évaluation

- Conventional Tunneling: Drill and Blast MethodDocument6 pagesConventional Tunneling: Drill and Blast MethodGodfrey EmilioPas encore d'évaluation

- Use of Pu Grout in Himalayan Tunnel ConstructionDocument15 pagesUse of Pu Grout in Himalayan Tunnel Constructionअभितेश्वर ज्सरोटिया100% (1)

- Keller - 10 02E - Deep Vibro Techniques PDFDocument12 pagesKeller - 10 02E - Deep Vibro Techniques PDFRony AmaraPas encore d'évaluation

- Deep Vibro TechniquesDocument40 pagesDeep Vibro TechniquesChong Boon HanPas encore d'évaluation

- Roadheader6 PDFDocument6 pagesRoadheader6 PDFMika PrameswariPas encore d'évaluation

- Is.7563.1986 CUT AND COVER DESIGN PDFDocument25 pagesIs.7563.1986 CUT AND COVER DESIGN PDFParmeshwar KushwahaPas encore d'évaluation

- Flexible Shed Tunnel An Innovative SolutDocument9 pagesFlexible Shed Tunnel An Innovative SolutManojhanmawalePas encore d'évaluation

- 00 - Glendoe Tunnel Collapse in ScotlandDocument23 pages00 - Glendoe Tunnel Collapse in Scotlandmatosdirocie7101Pas encore d'évaluation

- Explosives Manufacturing and Processing Guideline To Safety TrainingDocument16 pagesExplosives Manufacturing and Processing Guideline To Safety TrainingCuesta AndresPas encore d'évaluation

- IRCON issues corrigendum for Jammu-Srinagar tunnel electromechanical workDocument41 pagesIRCON issues corrigendum for Jammu-Srinagar tunnel electromechanical workThirumalai DbkPas encore d'évaluation

- Tailings Management: Good Practice GuideDocument142 pagesTailings Management: Good Practice GuideAlibek MeirambekovPas encore d'évaluation

- Drilling and Blasting As A Tunnel Excavation Method PP TDocument29 pagesDrilling and Blasting As A Tunnel Excavation Method PP TAnonymous USbc7XzsA6Pas encore d'évaluation

- Blast Perf Small TunnelsDocument9 pagesBlast Perf Small TunnelsskarpinPas encore d'évaluation

- Meyco Hard Rock Mining enDocument12 pagesMeyco Hard Rock Mining enAlex SchoepfPas encore d'évaluation

- Hrading LectureDocument20 pagesHrading LectureMohamed Ismail ShehabPas encore d'évaluation

- ASTM For Bend TestingDocument16 pagesASTM For Bend TestingMaha LingamPas encore d'évaluation

- DBid-Build Vs DBuildDocument3 pagesDBid-Build Vs DBuildNavneet SinghPas encore d'évaluation

- Sec611 - Steel ReinforcementDocument7 pagesSec611 - Steel ReinforcementAmr Adel HameedPas encore d'évaluation

- Burnley Tunnel Fire - The Arup ViewDocument8 pagesBurnley Tunnel Fire - The Arup ViewihpakisPas encore d'évaluation

- N14673.2 - Contract Clause LogbookDocument9 pagesN14673.2 - Contract Clause Logbookjyothis_joy8315Pas encore d'évaluation

- Underground WorksDocument37 pagesUnderground WorksNilgün KayaPas encore d'évaluation

- Checklist: Environment, Health and SafetyDocument2 pagesChecklist: Environment, Health and SafetyDinesh BadhePas encore d'évaluation

- HK NotableTunnel CatDocument380 pagesHK NotableTunnel Catanar100% (1)

- Tunnel CollapseDocument6 pagesTunnel CollapseGaddam Padmaja ReddyPas encore d'évaluation

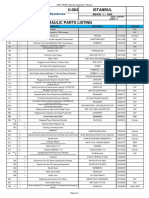

- U-064 - Hydraulic components manualDocument2 pagesU-064 - Hydraulic components manualBerat DeğirmenciPas encore d'évaluation

- Salvajina Difficult Foundation Water Power 1986 HacelasJE & Ramirez OrejuelaCADocument7 pagesSalvajina Difficult Foundation Water Power 1986 HacelasJE & Ramirez OrejuelaCAcarlos augusto ramirezPas encore d'évaluation

- Outline Report in HydrologyDocument15 pagesOutline Report in HydrologyMary Joy DelgadoPas encore d'évaluation

- Washington, D.C. To Baltimore Loop ProjectProposed by The Boring Company Environmental Assessment (Draft)Document505 pagesWashington, D.C. To Baltimore Loop ProjectProposed by The Boring Company Environmental Assessment (Draft)GMG EditorialPas encore d'évaluation

- Bauer in Africa: Work over 4 decadesDocument44 pagesBauer in Africa: Work over 4 decadesDudee Daryan100% (1)

- Krishna PanthiDocument189 pagesKrishna Panthibinod2500Pas encore d'évaluation

- References Traffic TunnellingDocument92 pagesReferences Traffic TunnellingValderi FerreiraPas encore d'évaluation

- Use of A Digger Shield For TBM Adverse Ground Conditions - Cobbles - BouldersDocument10 pagesUse of A Digger Shield For TBM Adverse Ground Conditions - Cobbles - Bouldersdafo407Pas encore d'évaluation

- Risk Factors Analyses and Preventive Measures of IDocument5 pagesRisk Factors Analyses and Preventive Measures of IGovind RaguramPas encore d'évaluation

- WTC2013 - BROX - Evaluation of Overstressing in Deep Tunnels - Feb 15 2013 PDFDocument9 pagesWTC2013 - BROX - Evaluation of Overstressing in Deep Tunnels - Feb 15 2013 PDFNicolas Cristobal Correa HernandezPas encore d'évaluation

- Tunnel-1 Support Final Design ReportDocument68 pagesTunnel-1 Support Final Design ReportAishwarya KumarPas encore d'évaluation

- Mitigation of post-blast fumeDocument8 pagesMitigation of post-blast fumealvaroaac4Pas encore d'évaluation

- Isrm2015 ProceedingsDocument131 pagesIsrm2015 ProceedingsHesbon MoriasiPas encore d'évaluation

- Rock Excavation Tests For Drill-Blast & TBM Tunnels-Predicting Cutter WearDocument41 pagesRock Excavation Tests For Drill-Blast & TBM Tunnels-Predicting Cutter WearLipsa MahapatraPas encore d'évaluation

- Fabrication and Installation of Pressure Shaft Steel LinerDocument4 pagesFabrication and Installation of Pressure Shaft Steel LinerDheeraj ThakurPas encore d'évaluation

- ICon October 2016Document60 pagesICon October 2016ogun tokucPas encore d'évaluation

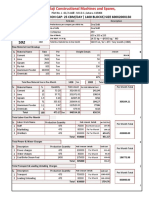

- M/s.Balaji Constructional Machines and Spares,: CLC Production Cap-25 Cbm/Day (1400 Blocks) Size 600X200X150Document2 pagesM/s.Balaji Constructional Machines and Spares,: CLC Production Cap-25 Cbm/Day (1400 Blocks) Size 600X200X150shakeebPas encore d'évaluation

- Presentación PNWS TrenchlessDocument74 pagesPresentación PNWS TrenchlessAlejandro GonzalezPas encore d'évaluation

- ShieldedTBMs RETC 1991 Walking Gripper BladeDocument20 pagesShieldedTBMs RETC 1991 Walking Gripper BladepeartmPas encore d'évaluation

- Burnley Tunnel Fire A Courts Perspective Tunneling Journal March 2013Document4 pagesBurnley Tunnel Fire A Courts Perspective Tunneling Journal March 2013ALARP (Arnold Dix)100% (1)

- TopHammers PDFDocument6 pagesTopHammers PDFStadiusPas encore d'évaluation

- Normet Rock Reinforcement Brochure 180607 ENGDocument10 pagesNormet Rock Reinforcement Brochure 180607 ENGAndrew ParhusipPas encore d'évaluation

- Float Switch: Replaces: - English Type ABZMS-41Document40 pagesFloat Switch: Replaces: - English Type ABZMS-41Renato PaivaPas encore d'évaluation

- Mining and ConstructionDocument32 pagesMining and ConstructionczoobsPas encore d'évaluation

- Istanbul Metro Cabling DiagramDocument90 pagesIstanbul Metro Cabling DiagramBerat DeğirmenciPas encore d'évaluation

- Energy Performance of Dump Trucks in Opencast Mine PDFDocument8 pagesEnergy Performance of Dump Trucks in Opencast Mine PDFIsaac VisualPas encore d'évaluation

- Non Explosive Rock Breaking TechniquesDocument7 pagesNon Explosive Rock Breaking Techniquescontenido100% (2)

- Impacts of Tunnels in The UK Arup PDFDocument9 pagesImpacts of Tunnels in The UK Arup PDFRodrigo Hernández AbarzúaPas encore d'évaluation

- Geotechnical DesignDocument35 pagesGeotechnical DesignTing Sing JuoPas encore d'évaluation

- Design Appraisal For The Construction of A Water Off-Take Channel Following Construction Design and Management RegulationsDocument4 pagesDesign Appraisal For The Construction of A Water Off-Take Channel Following Construction Design and Management RegulationsKhalid Abdel Naser Abdel RahimPas encore d'évaluation

- Microbiology Exam QuestionsDocument23 pagesMicrobiology Exam Questionswhitewave25Pas encore d'évaluation

- Analysis of Verbal Behavior Conceptualizes AphasiaDocument20 pagesAnalysis of Verbal Behavior Conceptualizes AphasiaMonalisa CostaPas encore d'évaluation

- Teaching Complementary Colors and Harmony in PaintingDocument17 pagesTeaching Complementary Colors and Harmony in PaintingMary Jean EmpengPas encore d'évaluation

- Nuclear Medicine Research Paper TopicsDocument6 pagesNuclear Medicine Research Paper Topicsxfdacdbkf100% (1)

- 3 Detailed LL Motor Sensory ExamDocument3 pages3 Detailed LL Motor Sensory Exambsm8gf6szxPas encore d'évaluation

- Roles and Function of A NurseDocument2 pagesRoles and Function of A NurseHengky HanggaraPas encore d'évaluation

- Merck Case Study AnalysisDocument42 pagesMerck Case Study Analysisswathibeliya100% (1)

- 2018 CaciDocument3 268 pages2018 CaciLiam MalonePas encore d'évaluation

- Senarai Buku Teks Kesihatan AwamDocument5 pagesSenarai Buku Teks Kesihatan AwamMOHAMAD IZAMEER ASHRAF BIN MOHD AMRAN / HPUPMPas encore d'évaluation

- Leptospirosis: An Overview of Epidemiology, Clinical Features and Diagnosis in MalaysiaDocument57 pagesLeptospirosis: An Overview of Epidemiology, Clinical Features and Diagnosis in Malaysiawoihon50% (2)

- Nursing Care for an Adolescent with DepressionDocument3 pagesNursing Care for an Adolescent with DepressionNanami MomozonoPas encore d'évaluation

- Unani Cosmeceuticals: An Overview of Formulations and Natural IngredientsDocument6 pagesUnani Cosmeceuticals: An Overview of Formulations and Natural IngredientsabdiPas encore d'évaluation

- Smart Syringe Pumps For Drug Infusion During DentalDocument9 pagesSmart Syringe Pumps For Drug Infusion During DentalAshit GandhiPas encore d'évaluation

- Asps 2013Document205 pagesAsps 2013faissal jameel100% (1)

- Endodontic InsrumentDocument52 pagesEndodontic InsrumentSawsan Z. JwaiedPas encore d'évaluation

- Grade 7 Cosme - Nail DiseasesDocument22 pagesGrade 7 Cosme - Nail DiseasesLigaya PastorPas encore d'évaluation

- Clinical Toolkit For Early Dementia Phase: 1. Standardized Mini-Mental Status Examination (MMSE)Document4 pagesClinical Toolkit For Early Dementia Phase: 1. Standardized Mini-Mental Status Examination (MMSE)Carolina MalheiroPas encore d'évaluation

- Omaha Chiefs Youth FootballDocument2 pagesOmaha Chiefs Youth FootballTony GramazioPas encore d'évaluation

- Safety Data Sheet: Classified in Accordance 29 CFR 1910.1200Document12 pagesSafety Data Sheet: Classified in Accordance 29 CFR 1910.1200Irma BermudezPas encore d'évaluation

- Vaccination ChartDocument3 pagesVaccination ChartszawPas encore d'évaluation

- Labor Cases Module 1Document337 pagesLabor Cases Module 162991Pas encore d'évaluation

- Folleto - Ing - Leoni 2Document2 pagesFolleto - Ing - Leoni 2Johnny CotzitoPas encore d'évaluation

- 1 - GL312P F1 - O&M Manual - BA246 Rev 9 (EN) PDFDocument150 pages1 - GL312P F1 - O&M Manual - BA246 Rev 9 (EN) PDFPhạm Công Khẩn63% (8)

- Adhereencia Al TX NTDocument8 pagesAdhereencia Al TX NTLibe SangPas encore d'évaluation

- Bhima Devi Poudel Adhikari 220179000 hnsn370 Assessment 1Document4 pagesBhima Devi Poudel Adhikari 220179000 hnsn370 Assessment 1api-525310113Pas encore d'évaluation

- Mmpi & EppsDocument4 pagesMmpi & Eppsshahrazia RawahaPas encore d'évaluation

- How To Read Osha StandardsDocument1 pageHow To Read Osha StandardsMaurice AnthonyPas encore d'évaluation

- Jeremy Sherr Dynamic Provings Volume 1: Reading ExcerptDocument9 pagesJeremy Sherr Dynamic Provings Volume 1: Reading ExcerptNostalgia234Pas encore d'évaluation

- Medipac (Equivalent)Document3 pagesMedipac (Equivalent)Mohamed GamalPas encore d'évaluation

- Congenital Anophthalmos in Benin CityDocument3 pagesCongenital Anophthalmos in Benin CityLjubomirErdoglijaPas encore d'évaluation