Académique Documents

Professionnel Documents

Culture Documents

Valvestar 7.1 Manual

Transféré par

rramones6574Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Valvestar 7.1 Manual

Transféré par

rramones6574Droits d'auteur :

Formats disponibles

LESER WORKS STANDARD Manual VALVESTAR 7.

1

Table of contents

LWN 703-19-EN page 1

1 Preface ............................................................................................................................... 2 1.1 System Requirements .................................................................................................. 2 2 Whats new ......................................................................................................................... 3 - Reaction force according to AD2000 A2, API 521, DIN ISO 4126........................................ 3 3 Installations......................................................................................................................... 3 3.1 Installation from CD ROM ............................................................................................ 3 3.2 Installation from Network.............................................................................................. 3 3.3 Installed programs........................................................................................................ 3 4 Updates and Uninstall ......................................................................................................... 4 5 Terms ................................................................................................................................. 4 5.1 Projects........................................................................................................................ 4 5.2 Sizings ......................................................................................................................... 4 5.3 Valves .......................................................................................................................... 4 5.4 Wizard.......................................................................................................................... 4 6 Quick start........................................................................................................................... 5 6.1 Create project .............................................................................................................. 5 7 The user interface ............................................................................................................. 12 7.1 Profiles....................................................................................................................... 12 User Information....................................................................................................... 13 Configuration............................................................................................................ 13 Unit Settings............................................................................................................. 13 Valves types............................................................................................................. 14 Volume flow standards ............................................................................................. 14 7.2 Languages ................................................................................................................. 14 7.3 Helpful hints ............................................................................................................... 14 7.4 Loading and saving projects....................................................................................... 14 7.5 Manual valve configuration......................................................................................... 14 7.5.1 Wizard................................................................................................................. 14 7.5.2 How to change manually valve data .................................................................... 14 7.6 Reports ...................................................................................................................... 14 7.6.1 Report ................................................................................................................. 14 7.6.2 One Page Report ................................................................................................ 14 7.6.3 Project Report ..................................................................................................... 14 7.6.4 Drawings ............................................................................................................. 14 7.7 Master Data ............................................................................................................... 14 8 Menu................................................................................................................................. 14 9 The Toolbar ...................................................................................................................... 14

continues on page 2

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

1 Preface

LWN 703-19-EN page 2

LESER is proud to present the new VALVESTAR 7.1 the new standard tool to size safety valves. We developed a totally new sizing program with a lot of new features and benefits for you. The main goals for the development of VALVESTAR 7.1 were: Easy to use a simple and common user interface. A wizard will guide you to each sizing and help you. Technical Leadership We implemented API 520, ASME VIII, AD 2000:A2, DIN EN ISO 4126 as sizing standards. More than 1500 articles from LESER are stored in the database of VALVESTAR. Various options are available for each valve. The link www.valvestar.com leads you to the online version of VALVESTAR. You may use it if you dont want to install VALVESTAR on your computer. Complete Set of Technical Documentation Drawings, sectional drawings, product photos and focus drawings for accessories are part of this new Version. Several new reports are available that may be exported to different formats (rtf, pdf, xls,). Internationalization VALVESTAR may be translated in any language your operation system (OS) supports. We appreciate your help in translating this version to your language. We took great care to fix all errors in VALVESTAR. Unfortunately it is impossible to simulate all combinations of Hard- and Software in all languages. If you face any problems with VALVESTAR, please inform us. Please mail errors and suggestions to valvestar@leser.com. 1.1 System Requirements

Please find listed below the requirements: Operation-System: WINDOWS 98 WINDOWS ME WINDOWS NT with Servicepack 6 WINDOWS 2000 WINDOWS XP WINDOWS 2003 Hardware: Pentium III 200 MB free space on your hard disc

continues on page 3

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

2 Whats new

LWN 703-19-EN page 3

This new VALVESTAR version 7.1 is completely built from scratch. It is developed in Microsoft .net technology. Several calculations have been added to valve star, e.g. - DIN ISO 4126 - API 520 Appendix D two face flow - Reaction force according to AD2000 A2, API 521, DIN ISO 4126 New reports have been introduced: - Complete standard report with Service data Valve data Sectional drawings and focus drawings Complete part lists New protect report with convenient export function to Microsoft Excel - One page report with main valve data (horizontal and vertical layouts) The design for the inlet and outlet calculation is completely new VALVESTAR is now Unicode ready and foreign languages like Chinese and Japanese can be implemented. 3 3.1 Installations Installation from CD ROM Insert CD ROM in your disc drive and run setup.exe Just follow the instructions during the setup. 3.2 Installation from Network

After downloading the VALVESTAR ZIP file you need to copy the extracted files on your local hard disc. A Network installation from a remote drive is not possible. Run set up and follow the instructions. 3.3 Installed programs

The setup will install the following in your computer: MS .net frame work MS DAC Version 2.8 VALVESTAR version 7.1

continues on page 4

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

4 Updates and Uninstall

LWN 703-19-EN page 4

If you are connected to Internet, VALVESTAR will automatically recognise whether new versions are available. If you want to uninstall VALVESTAR please follow the instruction below: Select in Settings Control Panel Add / Remove Programs and select VALVESTAR Then click Uninstall to remove it. Just follow the Wizard.

Terms

This chapter shall introduce you with the main terms which are used in VALVESTAR. 5.1 Projects

Several projects can be active and loaded at the same time. Projects are the folders containing the sizings and all projects-depending information. 5.2 Sizings

Sizings are depending on codes/standards and consisting of service conditions, medium-data and valves. 5.3 Valves

A valve consists of approval data, connections, part lists, drawings etc. A valve can be configurated according to the customer requirements. One or more valves may be added to one sizing. On the one hand they have the characteristics for the calculation (depending from the code). On the other hand valves may include technical information concerning the design. E.g. you can choose a steel-bellow or an O-ring-disc. These configurations may influence the calculation (e.g. liftrestriction). Wizard Whenever you create a new sizing or project, a wizard will guide you to proceed the task.

continues on page 5

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

6 Quick start

LWN 703-19-EN page 5

This chapter will introduce you the main features of VALVESTAR. We will create a new project and a sizing for saturated steam according to AD 2000: A2. We will select a safety valve and configure the inlet and outlet connections. Finally we will create the documentation in pdf-format. 6.1 Create project

You can create a project from the Welcome dialog by selecting Create new sizing or from menu by selecting Sizing -> Add Sizing. A new screen appears (Figure 2, wizard is guiding you)

Figure 1 Welcome dialog

Figure 2 Create new sizing wizard

continues on page 6

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 6

Click next button to proceed. In the next screen you can specify the tag number, the medium the available sizing standards for the medium and use standardized units. There are also additional calculations available (e.g. reaction force, .) which may by chosen to each standard.

After clicking the next you can type in the service condition. Those fields, which require input data are marked red. When you move the mouse into those red fields a balloon control pops up and informs you about restrictions.

We choose the following service condition: Set pressure Constant back pressure Overpressure Required massflow 10 bar-g 0 bar-g 10 % 10.000 kg/h

continues on page 7

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

We select steam data according to DIN EN ISO 4126-1.

LWN 703-19-EN page 7

VALVESTAR calculates the saturation temperature: 188 the isentropic exponent k=1,14 and C, the specific volume v=0,163m3/kg.

The next task is to find an appropriate valve. Therefore you can specify valve parameters in the Valve finder

continues on page 8

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 8

The more selective your parameters are, the faster will be the calculation of VALVESTAR in the next screen. In the Valve selection screen are all safety valves shown, which meet the requirements from the Valve finder. In the left upper screen you can select the type, in the right upper screen the body material and the lifting device. VALVESTAR pre selects the appropriate safety valves based on the capacity exceed. You can choose a different valve by clicking on the row and pressing the select button. VALVESTAR then loads the complete valve data from the data base depending on your computer this may take up to 5 seconds.

After you have selected a valve you may configure it according your requirements. First you can change the inlet and outlet connections. Whenever additional input data are available they are stored in list controls e.g. pressure rating e.g. PR are available #150 and #300.

continues on page 9

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 9

The section valve accessories allows you the selection of several option codes and you can also specify required inspections.

As a result you find a part list according to your specification. If you select the check box certificate the option code for the corresponding part list position is chosen.

continues on page 10

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 10

Finally valvestar informs you about dimensional data of the safety valve.

Click Finish button to finish your sizing. After finishing your sizing you get back to the valve explorer. The left part of the screen shows you all projects and sizing of the tree structure. When you double click an option in the tree structure the right part of the screen shows a content of the object.

continues on page 11

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 11

Finally we want to store project dependent data in our project. We double click on the root of the tree (new project). You can choose a project name and add descriptive data for internal use in the description section. Several additional input fields are available, which can be customized and renamed by you. We choose a suitable name for our project, add a comment in the internal description and select in the menu Documentation -> Report. VALVESTAR allows you a customization of the reports. You can select the language, unit system (differ from the sizing units) and select only those sections, which you need for your internal reporting. You can output the printout to your printer to pdf or to a preview on the screen. We select preview and a new screen appears. From the preview you can print the document or export it to several different file formats. You will find an example of the printout in the appendix 1.

continues on page 12

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 12

Congratulations! You have finished your first sizing with VALVESTAR. You will find out that all sizings follow this scheme. The wizard will always support you. For further information about codes and standards please refer to chapter XXXX. In the next chapter you learn more about the user interface and additional functionality of VALVESTAR. 7 7.1 The user interface Profiles

All initial settings are stored in profiles. It is possible to store several settings in different profiles. The following data is stored in the profiles: general data (company and contact data)

You may change or create a profile by clicking Profiles -> Default -> Edit.

continues on page 13

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 13

User Information This section contains information about the user (the person who created or changes the sizing). The data is used for history and the short name will be printed on the data sheet. Configuration The configuration section allows you to customize the initial settings of sizings. You can set up an Environmental pressure select country dependent decimal and group separator. Further it is possible to choose the source for steam data. Also you may predefine your default sizing/standard code. At least you can choose between several application modes. We suggest you to choose the standard mode, which will able you to use all calculation features. The professional mode allows you to overwrite standard settings for valves. Deep knowledge of safety valves is needed to use this mode. The super user mode is reserved for LESER and its partners.

Unit Settings For each code/standard unit presetting is possible. First select the code/standard in the top list box then change the position and unit according your needs.

continues on page 14

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 14

Valves types It may be useful to preselect the body material and the lifting device for each LESER type. This filter will be applied if you leave all fields in the valve finder blanc.

Volume flow standards Several volume flow standards are already implemented in the VALVESTAR. Three user defined volume flows are free for your own use. Languages

7.2

VALVESTAR is delivered with several languages for user interface and data sheets. You can select a different language from the user face menu Tools -> Language -> select a language.

continues on page 15

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 15

You can select the language for the report from the report options window, which pops up when you select from the menu Documentation -> Report

7.3

Helpful hints

We recommend you to frequently store your work. Please note that you can specify a default folder to store your data. You can use the default cut and paste functionality as you know from other software. You can copy either the project sizing from the valve by marking it with the mouse and click in the menu Edit Copy and then Paste it in a new structure. VALVESTAR checks whether it is possible to copy an object. It is impossible to copy a valve AD A2000-sizing into ASME sizing because of the different structure of the sizing. 7.4 Loading and saving projects

You can load a project from a file system. Select from a menu File -> Load Project

You can store projects in the same way. It is also possible to use the short keys (Control+O = open project, Control+S = save project). You can also unload and save all active project from the menu. 7.5 7.5.1 Manual valve configuration Wizard

You can select several accessories and configure the inlet and outlet of the safety valve. This feature is available from the wizard when you create a sizing and from the pop up menu when you right click on the safety valve and select Valve construction. Clicking Valve construction leads you to the wizard. You can go back to the valve selection and exchange the valve (The other way to

continues on page 16

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 16

exchange the valve would be deleting it with cut-functionality and then right click the sizing and select Add Valve.

Valve connections In the first step you select your inlet and outlet connection. See page 9 valve connections. First select a flange in the upper part of the screen. Then push the select button to accept the chosen connection. In some cases you may need a connection which is not listed in the possible inlet connections. In this case you can overwrite in the bottom section the selected values. Please take care that this connection is available for you valve. Valve accessories The valve accessories window shows all available accessories according to the current price list. You can select accessories in the check boxes in the list control. The part list of the safety valve will be changed according your specification. VALVESTAR checks whether combinations of accessories are possible or not. VALVESTAR is not an ERP System. Because of the complexity of the product, it may be possible that you select with VALVESTAR a combination of the accessories, which is not valid. You may also select one or more inspections. Not all options are listed in our price list. You may add additional options codes with an edit custom button. Some codes allow lift restrictions. You can choose between standard lift, a calculated lift according your required mass/volume flow or choose manually a lift restriction. Part Lists The part list is a result of your configuration. If a certificate is required you may select a check box in the column certificate. The check box is only available for those parts for which a certificate is available.

continues on page 17

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 17

Please note that Valvestar offers only material part lists without part number. Please contact LESER if you need spare part numbers. Valve dimensions The valve dimensions screen shows all dimensions of the safety valve. 7.5.2 How to change manually valve data

Sometimes it is necessary to change valve data manually (e.g. special contructions). You may use this feature also, if new articles are invented but not yet available in VALVESTAR. Right click on the safety valve and select from the popup menu valve information. Please note that this feature is only available if you work in professional or super user mode. Now you can overwrite nearly every value (even the article number itself). If you change parameters like discharge diameter depending calculation data will be changed too and applied in the calculation. As a result it is possible to size any valve with VALVESTAR. 7.6 7.6.1 Reports Report

The standard report includes all data for the valves and the sizing. You can select the items by checking the boxes with a mouse click. You may also change the units for the report. As output destination are preview, pdf and printer available. From the preview are export functionalities for several file formats available.

continues on page 18

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 18

7.6.2

One Page Report

The One Page Report is a condensed report which fits always on one page. You can select a horicontal or vertical design 7.6.3 Project Report

The Project Report is feature which creates a singe excel file with all nessecary information to place an order by LESER. It contains the option code and several valve data. This file is useful for big projects. 7.6.4 Drawings

Valvestar is delivered with a huge number of drawings enabling you to create sophisticated documentation. Please take care that you do not use the drawings to the center to face dimensions. These dimensions should be taken from the report. 7.7 Master Data

The database contains master data from LESER valves, flanges, medium data etc. LESER took great care to ensure the correctness of these data. Please handle all displayed data with care. VALVESTAR allows you to change several data manually which influence data like center to face dimensions (e.g. manually changed connections), discharge coefficients

continues on page 19

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

8 Menu

LWN 703-19-EN page 19

The menu is context sensitive. It appears different depending from the chosen icon in the valve explorer. A project report is only available if a sizing or a project is selected. The One Page report is only available if a valve is selected. Other items are always displayed like Medium, File 9 The Toolbar

The following icons are useful short cuts to advanced functionality: Create a new Project - Open an existing Project

- Save Project - Cut selected item - Copy selected item - Delete selected item - Insert item - Create Sizing - Display Inspections and Certificates - Add valve - Valve Info - Steam Properties

continues on page 20

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

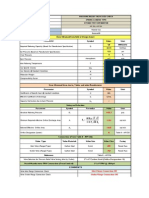

10 Inlet- and Outlet Calculations 10.1 Inlet Calculation The inlet calculation is available in the wizard as shown below:

LWN 703-19-EN page 20

After you selected the valve (like in standard sizing) you are asked to specify the pipe. You may select optionally components and define the straight pipe.

continues on page 21

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

LWN 703-19-EN page 21

The next screen is a combination of maximum length and minimum diameter calculation.Valvestar calculates for several diameters (dependent from the inlet of the valve) the maximum length of the given diameter.

When you select a pipe it is possible to specify the length of the pipe. Valvestar will then calculate the pressure drop for the selected pipe.

continues on page 22

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

10.2 Outlet Calculation

LWN 703-19-EN page 22

The outlet calculation is similar to the inlet calculation. A new feature enables you to calculate different pipes with diameters.

The Effective pipe resistance is calculated according to german standard AD 2000 A1. You may add a pressure drop from a silencer (which is added to the built up back pressure). It is possible to add components for each diameter by clicking the Edit Button. A new Window appears.

You can select several components. The -value for the pipe bends are calculated according a Formula from W. Witte. You may overwrite the values if you want to use other values.

continues on page 23

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

LESER WORKS STANDARD Manual VALVESTAR 7.1

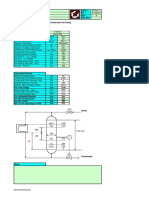

10.3 Fire Case

LWN 703-19-EN page 23

The Fire Case is available only for gas calculations. It is assumed that either a gas is stored in vessel or a liquid with a liquid height below the height of the vessel. The flow is assumed as gaseous (one phase) flow. Select gas as medium when you begin with a sizing. Select Fire Case in the checkbox.

Select as usual the medium and click next. Now you are asked to select the wetted or unwetted surface calculation.

The two methods will be represented in single chapters.

10.3.1 Wetted Surface 10.3.2 Unwetted Surface

End of LWN

LESER

GmbH & Co. KG

processed: Cal approved: refer to M 086300

edition: 27.02.07 replaces edition: 00.00.00

Vous aimerez peut-être aussi

- Normal Design: Depressurize From Design Pressure To 50% in 15 MinutesDocument2 pagesNormal Design: Depressurize From Design Pressure To 50% in 15 Minutesmatteo2009Pas encore d'évaluation

- Pressure Relief Valve Sizing and Selection CheckDocument2 pagesPressure Relief Valve Sizing and Selection CheckGiftObionochiePas encore d'évaluation

- Instrucalc IIDocument27 pagesInstrucalc IINorberto Soto100% (1)

- Blowdown Valves and Safety Valves ExplainedDocument4 pagesBlowdown Valves and Safety Valves ExplainedAmanda MartinezPas encore d'évaluation

- Pressure Drop of Full Bore Vs Reduced Bore Ball ValvesDocument1 pagePressure Drop of Full Bore Vs Reduced Bore Ball ValvesArt G. EnziPas encore d'évaluation

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluPas encore d'évaluation

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariPas encore d'évaluation

- Float Board Level GaugeDocument6 pagesFloat Board Level GaugeanaismariaPas encore d'évaluation

- PRESSURE SAFETY VALVE DATA SHEETDocument1 pagePRESSURE SAFETY VALVE DATA SHEETBABILIN VPas encore d'évaluation

- Small Bore Orifice For Gas Flow PDFDocument4 pagesSmall Bore Orifice For Gas Flow PDFManufacturer VerifyPas encore d'évaluation

- 00000-Jds-003 (Level Trans DS) Rev 0Document4 pages00000-Jds-003 (Level Trans DS) Rev 0sithulibraPas encore d'évaluation

- Valvula de Presion y Vacio GROTHDocument16 pagesValvula de Presion y Vacio GROTHSantiago CastañoPas encore d'évaluation

- Orifice Calc Gas Rev 0Document1 pageOrifice Calc Gas Rev 0edufragaPas encore d'évaluation

- Heat Tracing DatasheetDocument6 pagesHeat Tracing DatasheetEmamokePas encore d'évaluation

- Rosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionDocument24 pagesRosemount 1495 Orifice Plate, 1496 Flange Union, 1497 Meter SectionJames ThomasPas encore d'évaluation

- Calculate The Wetted Surface Area of Pressure VesselsDocument7 pagesCalculate The Wetted Surface Area of Pressure VesselsHsein WangPas encore d'évaluation

- Design Practices - SVsDocument12 pagesDesign Practices - SVsagarwalashwin32Pas encore d'évaluation

- 48" X 15' Three Phase Test SeparatorDocument2 pages48" X 15' Three Phase Test Separatorpraash bhattPas encore d'évaluation

- Pump CalcDocument1 pagePump CalcMoch WildanPas encore d'évaluation

- Steam Condensate Pot Sizing PDFDocument1 pageSteam Condensate Pot Sizing PDFjittshong8072Pas encore d'évaluation

- PSV Sizing - Two Phase (Two-Points)Document2 pagesPSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradPas encore d'évaluation

- Orbit ValveDocument12 pagesOrbit ValveanildhakePas encore d'évaluation

- EHB en 7.5 Sizing According To ISO 4126 1Document10 pagesEHB en 7.5 Sizing According To ISO 4126 1XpizmonPas encore d'évaluation

- Hydrate Formation in ValvesDocument6 pagesHydrate Formation in ValvesChem.EnggPas encore d'évaluation

- Valve Sizing Application NotesDocument12 pagesValve Sizing Application Notestxagus100% (1)

- Dresser-Rand GFC Databook - Gas Field Policies-4Document4 pagesDresser-Rand GFC Databook - Gas Field Policies-4kistaiPas encore d'évaluation

- User's GuideDocument30 pagesUser's GuideAnonymous Wd2KONPas encore d'évaluation

- A106-B Pipe Temperature CalculatorDocument8 pagesA106-B Pipe Temperature CalculatorAksheyPas encore d'évaluation

- The Weby's: PSV Selection For BeginnerDocument15 pagesThe Weby's: PSV Selection For BeginnerShanmuga MuthukumarPas encore d'évaluation

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocument3 pagesSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Load Capacity Limits For Flanged NozzleDocument6 pagesLoad Capacity Limits For Flanged Nozzlektjayakumar3878100% (1)

- Air Cooler Design and Principle EIEPD 1696073698Document58 pagesAir Cooler Design and Principle EIEPD 1696073698Evandro Silva100% (1)

- Condensate Tank - For 250Document3 pagesCondensate Tank - For 250Sakthi VelPas encore d'évaluation

- PSV Sizing OrificeDocument4 pagesPSV Sizing OrificeRupak PatilPas encore d'évaluation

- Flow Meter Sizing MOSDocument11 pagesFlow Meter Sizing MOSra9622Pas encore d'évaluation

- Tutorial Pressure Relief Valve AnalysisDocument1 pageTutorial Pressure Relief Valve Analysissanthosh_yash1Pas encore d'évaluation

- Application of UG-140 For Overpressure Protection: FeaturesDocument4 pagesApplication of UG-140 For Overpressure Protection: FeaturesB rg100% (1)

- Fisherr D4 Control Valve AssemblyDocument12 pagesFisherr D4 Control Valve AssemblyMixmikmic' KrittananPas encore d'évaluation

- Gas Blowby CaseDocument2 pagesGas Blowby Casejainrakeshj4987Pas encore d'évaluation

- HSV86 PDFDocument48 pagesHSV86 PDFMohamed El MaadawyPas encore d'évaluation

- CFD predictions on Liquid Pressure Recovery Factor (FL) for control valvesDocument9 pagesCFD predictions on Liquid Pressure Recovery Factor (FL) for control valvesAshok SureshPas encore d'évaluation

- Compact Prover Datasheet PDFDocument12 pagesCompact Prover Datasheet PDFMary Soledad Huarcaya EspinoPas encore d'évaluation

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHIPas encore d'évaluation

- Relief 5Document5 pagesRelief 5Mo ZeroPas encore d'évaluation

- CaesarDocument1 pageCaesarRizky PratamaPas encore d'évaluation

- PSV SizingDocument8 pagesPSV SizingMinh DoPas encore d'évaluation

- Ejercicio 246 PSV438 RESUELTODocument2 pagesEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaPas encore d'évaluation

- DRESSER Regulators FlowgridDocument12 pagesDRESSER Regulators Flowgridzalziza100% (1)

- PSV SIZING CALCULATIONSDocument3 pagesPSV SIZING CALCULATIONSAthiphap SrisupareerathPas encore d'évaluation

- Restrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazineDocument1 pageRestrictive Orifice - Method 1: Rough Method Provided Originally in An Article in Chemical Engineering MagazinealvinchuanPas encore d'évaluation

- Coriolis Mass Flow MeterDocument2 pagesCoriolis Mass Flow MeterSreejesh SundaresanPas encore d'évaluation

- Chien1995 PDFDocument6 pagesChien1995 PDFFelipeMorenoPas encore d'évaluation

- Mechanical RegulatorDocument12 pagesMechanical Regulatorshashi chaugulePas encore d'évaluation

- Relief Valve CalculationsDocument9 pagesRelief Valve CalculationssegunoyesPas encore d'évaluation

- Fluid Flow Basics OF Throttling ValvesDocument43 pagesFluid Flow Basics OF Throttling ValvesSandro AraújoPas encore d'évaluation

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudylguardiaPas encore d'évaluation

- Practica # 2 PRV2SIZE PDFDocument4 pagesPractica # 2 PRV2SIZE PDFCarmen Zurita VeizagaPas encore d'évaluation

- b0860rw ADocument22 pagesb0860rw Aabdel taibPas encore d'évaluation

- Cadread UkDocument52 pagesCadread UkdarenedPas encore d'évaluation

- Iec 62623-2012Document98 pagesIec 62623-2012dinkohePas encore d'évaluation

- CMP 101 Set 12 Algorithm and FlowchartsDocument23 pagesCMP 101 Set 12 Algorithm and FlowchartsNitin GroverPas encore d'évaluation

- Courier Service System PROJECTDocument28 pagesCourier Service System PROJECTPriyanshu RanjanPas encore d'évaluation

- Automation Framework - Evaluation CriteriaDocument5 pagesAutomation Framework - Evaluation CriteriaShinu AroraPas encore d'évaluation

- Sensus Ultra: Developer's GuideDocument16 pagesSensus Ultra: Developer's GuideAngel David PinedaPas encore d'évaluation

- Rs 2332Document10 pagesRs 2332SaitejaTallapelly100% (1)

- Use Oracle Visual Builder Add-In For Excel To Create Purchase RequisitionsDocument40 pagesUse Oracle Visual Builder Add-In For Excel To Create Purchase RequisitionsMohmed BadawyPas encore d'évaluation

- HiAlgo ReadMeDocument3 pagesHiAlgo ReadMeraymond_db_elvizzzPas encore d'évaluation

- Android ScainDocument28 pagesAndroid ScainSaprinus SapPas encore d'évaluation

- Combinational Logic Decoder and Encoder Circuit DesignDocument26 pagesCombinational Logic Decoder and Encoder Circuit Designeng zamPas encore d'évaluation

- Tactical PAW Configuration Guide Alpha-EmeraldDocument22 pagesTactical PAW Configuration Guide Alpha-EmeraldMiguel Angel Castillo OrellanaPas encore d'évaluation

- CT097 3 3 CSVC NP000384 NP000391 NP000477Document9 pagesCT097 3 3 CSVC NP000384 NP000391 NP000477Dinanath DahalPas encore d'évaluation

- Design of A Lightweight TCPIP Protocol StackDocument13 pagesDesign of A Lightweight TCPIP Protocol StackKhalid SalehPas encore d'évaluation

- Attend Connectors Main Catalogue PDFDocument12 pagesAttend Connectors Main Catalogue PDFpritpal singhPas encore d'évaluation

- Apple Product Catalog Fall 1993Document68 pagesApple Product Catalog Fall 1993cinemafia100% (5)

- FW Upgrade Guide ENGDocument6 pagesFW Upgrade Guide ENGStamatis SarlisPas encore d'évaluation

- Annex 4 - CSSDocument28 pagesAnnex 4 - CSSZINA ARRDEE ALCANTARAPas encore d'évaluation

- COMP1117 Computer ProgrammingDocument22 pagesCOMP1117 Computer ProgrammingDONGHWEE CHOIPas encore d'évaluation

- Ec6301 Oop&Ds NotesDocument107 pagesEc6301 Oop&Ds Notesprabhuabi143Pas encore d'évaluation

- Solaris OBP Reference GuideDocument125 pagesSolaris OBP Reference GuidechafuPas encore d'évaluation

- Lt225 DatasheetDocument3 pagesLt225 DatasheetIsrael Zamarripa RamírezPas encore d'évaluation

- UML TutorialDocument9 pagesUML TutorialKadeKapoerPas encore d'évaluation

- Design and Implementation of a Relational Database Management SystemDocument19 pagesDesign and Implementation of a Relational Database Management SystemAbhishek SalunkePas encore d'évaluation

- Sgi O2 Sales FlyerDocument4 pagesSgi O2 Sales Flyeruzmzb95tPas encore d'évaluation

- Data Structures NotesDocument97 pagesData Structures NotesKibru AberaPas encore d'évaluation

- 001-Storage Basics and Application Environments V1.01Document56 pages001-Storage Basics and Application Environments V1.01Phan AnPas encore d'évaluation

- Lenovo Thinkcentre M71e Lenovo Ih61m Msi MS-7687 Rev 1.0 PDFDocument33 pagesLenovo Thinkcentre M71e Lenovo Ih61m Msi MS-7687 Rev 1.0 PDFYetawa GuaviarePas encore d'évaluation

- TURCK As Interface Masters GatewaysDocument30 pagesTURCK As Interface Masters GatewaysBaneMarkovicPas encore d'évaluation

- 10 Total Mark: 10 X 1 10: NPTEL Online Certification Courses Indian Institute of Technology KharagpurDocument7 pages10 Total Mark: 10 X 1 10: NPTEL Online Certification Courses Indian Institute of Technology KharagpurvitPas encore d'évaluation

- Kit For The 12F675 Book PDFDocument29 pagesKit For The 12F675 Book PDFCelso Silva SivaPas encore d'évaluation