Académique Documents

Professionnel Documents

Culture Documents

Power Screws Fasteners and Rivted Joints Mech 2011

Transféré par

Eslam Mohamed SayedDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Power Screws Fasteners and Rivted Joints Mech 2011

Transféré par

Eslam Mohamed SayedDroits d'auteur :

Formats disponibles

1

Dr. Mostafa Shazly

Faculty of Engineering, Room 211

Email: mostafa.shazly@bue.edu.eg

Design of Riveted

and Bolted Joints

Figure 16.1 Parameters used in

defining terminology of thread profile.

Thread Geometry

Figure 16.2 (a) Single-, (b) double-, and

(c) triple-threaded screws.

Pitch p : the distance from a point on one thread to the same point to the adjacent

thread.

|: The thread angle

h

t

: The largest possible thread height.

Number of threads per inch n = 1/p

Lead l : the distance that a screw would advance relative to the nut in 1 revolution

l = m*p, m: number of starts

Helix angle o=tan

-1

(l/td

p

)

2

Acme, UN, and M Threads

Thread profiles. (a) Acme; (b) UN.

Details of M and UN thread profiles.

The ACME threads are used for power screws and machine

tool threads. Its thread angle is 29

o

The unified UN thread (US system) and the M thread

(Metric system) are used extensively and have thread angle

of 60

o

. By defining the pitch (p), all other thread

parameters can be defined

Please refer to page 709 from textbook for more details

0.5

0.866

tan30

t o

p

h p = =

What is meant by UNF x 16

and M16x1.5?

Dimensions and tensile stress areas for UN coarse and fine threads. Root

diameter is calculated from Eq. (16.2) and Fig. 16.4.

UN Coarse and Fine Threads

3

Dimensions and tensile stress areas for M coarse and fine threads. Root

diameter is calculated from Eq. (16.2) and Fig. 16.4.

M Coarse and Fine Threads

Power Screws

Power Screws are used for:

To obtain mechanical advantage in order to lift weight, as

in a screw type of jack for cars.

To exert large forces, as in home compactor or press.

To obtain precise positioning of an axial movement, as in

a micrometer screw or the lead screw of a lathe

Details of Acme thread profile.

(All dimensions are in inches.)

| |

|

\ .

2

r p

t

p c

p c

The Tensile stress area

d +d

A =

4 2

The pitch diameter of an ACME

power thread is

d = d - 0.5p- 0.01 (in)

d = d - 0.5p- 0.254 (mm)

4

Crest diameters, threads

per inch, and stress areas

for Acme threads.

The shear area is given

for 1 long of thread

engagement

Acme Threads

Power Screws

Power Screws

Forces and Torque

5

Forces on Power Screw

Raising the Load

0

sin , cos

0 0

0 tan 2

sin cos cos

0

0

cos

n n

n n n

CD C

D D

CD A

A

C

u u

|

u u u

o

= =

= =

Forces on Power

Screw

forces acting on

tangential plane.

Raising the Load

The torque required to raise the load and overcome

the collar friction force is obtained by multiplying

the horizontal forces by appropriate radii.

forces acting on

axial section

Substitute for P

n

6

Forces on Power Screw

(c) forces acting on

tangential plane.

Lowering the Load

The torque required to lower the load and overcome

the collar friction force is obtained by multiplying the

horizontal forces by appropriate radii.

Power Screws

Power and Efficiency

The power, in horse power, can be given by

The power, in watts, can be given by

Torque applied when friction is zero

Effieciency=

Actual Torque Applied

7

Power Screws

Self Locking Screws

If the collar friction is eliminated by using rolling elements, then

to prevent the load from sliding down

If the screw thread has large lead angle, the friction force may

not be able to stop the tendency of the load to slide down, and

gravity will cause the load to fall.

Power Screws

Summary

8

Example

15

A single-threaded M323.5 power screw is used to raise a 12-kN

load at a speed of 25 mm/s. The coefficients of friction are 0.08 for

the thread and 0.12 for the collar. The collar mean diameter is 55

mm. Determine the power required. Also determine how much

power is needed for lowering the load at 40 mm/s.

Example

16

Since the lead is L = 3.5 mm, and the load is raised at 25 mm/s, the screw must be

rotating at a speed of e = 25/3.5 = 7.14 rev/s = 44.88 rad/s. Therefore the power is

the product of torque and angular velocity, or

The torque to lower the load is given by

9

Three types of threaded fastener. (a) Bolt and nut;

(b) cap screw; (c) stud.

Types of Threaded Fasteners

Strength of Steel Bolts

The terms proof load and proof strength are used in defining the bolt strength

The proof load of a bolt is the maximum load that a bolt can withstand without

acquiring a permanent deformation

Proof strength (S

p

) ~ 0.8 * Yield strength

Tensile stress area

Where n is the number of threads per inch

10

Tensile stress area

Strength of Steel Bolts

Failure Modes for Fasteners in Shear

Failure modes due to shear loading

of riveted fasteners. (a) Bending of

member; (b) shear of rivet

Bending of Members

( )

( )

( )

1 2

2

2

0.6

: section moment of area

j

y

j

t t

P t

S

I

I

o

+ | |

|

\ .

= s

Shear of Rivets

(Single or Double)

2

4

sy

P

S

d

t

t

= s

11

Failure Modes for Fasteners in Shear

Failure modes due to shear loading

of riveted fasteners. (c) tensile

failure of member; (d) bearing of

member on rivet.

Tensile Failure of Members

( )

min

min

. .

y

P

S

A

e g A b d t

o = s

=

Compressive Bearing Failure of

Members

. .

y

bearing

bearing

P

S

A

e g A dt

o = s

=

Eccentric loading of group of riveted fasteners (a)

Assembly of rivet group; (b) radii from centroid to

center of rivets; (c) resulting triangles; (d) direct

and torsional shear acting on each rivet; (e) side

view of member.

Eccentric Loading of Bolted Joints

(Shear Loading)

The eccentric loading will cause two

types of shear stresses; primary shear

and secondary shear

Set arbitrary axes and locate the

centroid of the group of bolts

Determine the distance from the

centroid to each bolt, r

j

Calculate the primary (direct) shear on

each bolt, direction same as external

load

Calculate the rotation torque

T=P e

e: distance from loading point to

bolt group centroid

, , bolt area

i i i i

i

i i

A y Ax

y x A

A A

= = =

d

i

P

A

t =

12

Eccentric loading of group of riveted fasteners (a)

Assembly of rivet group; (b) radii from centroid to

center of rivets; (c) resulting triangles; (d) direct

and torsional shear acting on each rivet; (e) side

view of member.

Eccentric Loading of Bolts

(Shear Loading)

Calculate the secondary shear on each

bolt, direction perpendicular to the

radius from the centroid to the bolt

under consideration and in the same

sense as the rotation torque

Add both the primary and secondary

shears (vectors addition)

(you may use graphical methods)

!!! Remember that the

member is under bending

loading

2

j

sj

j j

Tr

r A

t =

Example

24

Vous aimerez peut-être aussi

- Blake Mouton Managerial GridDocument3 pagesBlake Mouton Managerial GridRashwanth Tc100% (1)

- The Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Document6 pagesThe Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Dilshan0% (1)

- Screw Jack DesignDocument13 pagesScrew Jack DesignIbrahimovic Elsaied78% (9)

- Chapter 3 Strength Calculation of JointsDocument76 pagesChapter 3 Strength Calculation of Jointsrobel metiku100% (1)

- BPS C1: Compact All-Rounder in Banknote ProcessingDocument2 pagesBPS C1: Compact All-Rounder in Banknote ProcessingMalik of ChakwalPas encore d'évaluation

- Bring Your Gear 2010: Safely, Easily and in StyleDocument76 pagesBring Your Gear 2010: Safely, Easily and in StyleAkoumpakoula TampaoulatoumpaPas encore d'évaluation

- MD VI Shaft DesignDocument11 pagesMD VI Shaft DesignShatendra SahuPas encore d'évaluation

- Power Screw & GearsDocument91 pagesPower Screw & Gearssam0415100% (1)

- Eccentric ConnecctionsDocument41 pagesEccentric ConnecctionsShyam Suryawanshi100% (1)

- 1 Screw Rivet WeldDocument26 pages1 Screw Rivet WeldWajih RaziUddin100% (1)

- Me331-Design of Machine Elements Unit Iii Design of Fasteners and JointsDocument21 pagesMe331-Design of Machine Elements Unit Iii Design of Fasteners and JointsMuthuvel MPas encore d'évaluation

- Contact Stress Analysis of Barrel CouplingDocument8 pagesContact Stress Analysis of Barrel CouplingBruno SantosPas encore d'évaluation

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshPas encore d'évaluation

- Design and Fabrication of Motorized Screw JackDocument8 pagesDesign and Fabrication of Motorized Screw Jackvarma100% (1)

- Mdid Lab ManualDocument48 pagesMdid Lab Manualjaimin777Pas encore d'évaluation

- Chapter Two: 2.coupling, Clutch & BrakeDocument79 pagesChapter Two: 2.coupling, Clutch & BrakeEskinder Markos Official ChannelPas encore d'évaluation

- TE - 2019 - Design of Machine Elements PDFDocument4 pagesTE - 2019 - Design of Machine Elements PDFonkar nikamPas encore d'évaluation

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- Design1 SheetsDocument9 pagesDesign1 SheetsYou channelPas encore d'évaluation

- 6 Shafts PDFDocument23 pages6 Shafts PDFViven SharmaPas encore d'évaluation

- GATE - IES QuestionsDocument4 pagesGATE - IES QuestionsMahesh Chandrabhan ShindePas encore d'évaluation

- 07 Power Screws and Threaded Fasteners (Handout)Document16 pages07 Power Screws and Threaded Fasteners (Handout)tnvsaikiran3100% (3)

- Design of GearsDocument62 pagesDesign of Gearsصبا رياض فتاح الرفاعيPas encore d'évaluation

- Me6503 Dme023Document4 pagesMe6503 Dme023Bakkiya RajPas encore d'évaluation

- Question Chapter 8Document5 pagesQuestion Chapter 8Mohamed AshrafPas encore d'évaluation

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyPas encore d'évaluation

- 02-Chapter 08-Fasteners (A)Document21 pages02-Chapter 08-Fasteners (A)Muhammad UmarPas encore d'évaluation

- Session 11.Document12 pagesSession 11.vijayakumarPas encore d'évaluation

- Design of ShaftsDocument26 pagesDesign of ShaftsKrishna VamsiPas encore d'évaluation

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliPas encore d'évaluation

- Chapter 1 Shaft (Cont'd)Document47 pagesChapter 1 Shaft (Cont'd)Rayuth KEATPas encore d'évaluation

- Lecture Slides: Screws, Fasteners, and The Design of Nonpermanent JointsDocument45 pagesLecture Slides: Screws, Fasteners, and The Design of Nonpermanent JointsAbdulPas encore d'évaluation

- LabManual MDID2016 2016 02 24 16 29 36Document23 pagesLabManual MDID2016 2016 02 24 16 29 36Rajat MehtaPas encore d'évaluation

- Unit 3 Design of ShaftsDocument14 pagesUnit 3 Design of Shaftsaditya.1540011Pas encore d'évaluation

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- Me-331 Design of Machine Elements Unit Iv Design of Basic ElementsDocument25 pagesMe-331 Design of Machine Elements Unit Iv Design of Basic ElementsMuthuvel MPas encore d'évaluation

- Dr. Suvandan Saraswat: Machine Design I (EME-501)Document67 pagesDr. Suvandan Saraswat: Machine Design I (EME-501)Suvandan SaraswatPas encore d'évaluation

- 4363 111 Machine Design IDocument6 pages4363 111 Machine Design Iyogesh_b_k100% (2)

- 1 ShaftDocument20 pages1 ShaftAJ BantayPas encore d'évaluation

- Important Questions Unit 1,2Document7 pagesImportant Questions Unit 1,2rajeswariPas encore d'évaluation

- CH 8Document16 pagesCH 8Omar AbdullahPas encore d'évaluation

- MD 08 Ch8 FasternersDocument45 pagesMD 08 Ch8 FasternersAbdulPas encore d'évaluation

- Design of MachinesDocument12 pagesDesign of MachinesRenold ElsenPas encore d'évaluation

- Knuckle JointDocument21 pagesKnuckle JointNelly Ad-apPas encore d'évaluation

- Chapter III - TorsionDocument19 pagesChapter III - TorsionMostafa Essam Ezzat MahmoudPas encore d'évaluation

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalPas encore d'évaluation

- BFC 20903 (Mechanics of Materials) Chapter 6: TorsionDocument26 pagesBFC 20903 (Mechanics of Materials) Chapter 6: TorsionHamierul MohamadPas encore d'évaluation

- Experimental Investigation On Torsional Rigidity of Power ScrewsDocument4 pagesExperimental Investigation On Torsional Rigidity of Power ScrewsIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalPas encore d'évaluation

- MDDocument5 pagesMDYogesh DanekarPas encore d'évaluation

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanPas encore d'évaluation

- Copy Slides Test 2Document60 pagesCopy Slides Test 2fatin_musaPas encore d'évaluation

- 08 r05310305 Design of Machine Members IDocument9 pages08 r05310305 Design of Machine Members IKrupanandareddyYarragudiPas encore d'évaluation

- DME Question Bank Unit (3-4-5)Document7 pagesDME Question Bank Unit (3-4-5)PrathamPas encore d'évaluation

- Chapter One Shaft DesignDocument71 pagesChapter One Shaft DesignhaymanotPas encore d'évaluation

- Design and Development of An Octagonal Strain Ring Based Load Cell - 2Document16 pagesDesign and Development of An Octagonal Strain Ring Based Load Cell - 2Arunava ChoudhuryPas encore d'évaluation

- QB Unit-3,4,5Document7 pagesQB Unit-3,4,5Agranshu BhardwajPas encore d'évaluation

- Termpaper-Strength Analysis of Screw Jack-Mechanics of SolidsDocument21 pagesTermpaper-Strength Analysis of Screw Jack-Mechanics of SolidsOmkar Kumar JhaPas encore d'évaluation

- LM2 2Document67 pagesLM2 2MADHESWARAN SPas encore d'évaluation

- Time Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Document3 pagesTime Allowed: 1.5 Hours Full Marks: 70: 604 (S) August 2021Sourav BhowmikPas encore d'évaluation

- MACHINE DESIGN Part4Document32 pagesMACHINE DESIGN Part4MADHESWARAN SPas encore d'évaluation

- Differential Forms on Electromagnetic NetworksD'EverandDifferential Forms on Electromagnetic NetworksÉvaluation : 4 sur 5 étoiles4/5 (1)

- Spanish Greeting Card Lesson PlanDocument5 pagesSpanish Greeting Card Lesson Planrobert_gentil4528Pas encore d'évaluation

- 1188 2665 1 SMDocument12 pages1188 2665 1 SMRita BangunPas encore d'évaluation

- Installing Surge Protective Devices With NEC Article 240 and Feeder Tap RuleDocument2 pagesInstalling Surge Protective Devices With NEC Article 240 and Feeder Tap RuleJonathan Valverde RojasPas encore d'évaluation

- Community Profile and Baseline DataDocument7 pagesCommunity Profile and Baseline DataEJ RaveloPas encore d'évaluation

- Load Chart Crane LiftingDocument25 pagesLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- Supply List & Resource Sheet: Granulation Techniques DemystifiedDocument6 pagesSupply List & Resource Sheet: Granulation Techniques DemystifiedknhartPas encore d'évaluation

- Swelab Alfa Plus User Manual V12Document100 pagesSwelab Alfa Plus User Manual V12ERICKPas encore d'évaluation

- L GSR ChartsDocument16 pagesL GSR ChartsEmerald GrPas encore d'évaluation

- The Pneumatics of Hero of AlexandriaDocument5 pagesThe Pneumatics of Hero of Alexandriaapi-302781094Pas encore d'évaluation

- Internal Resistance To Corrosion in SHS - To Go On WebsiteDocument48 pagesInternal Resistance To Corrosion in SHS - To Go On WebsitetheodorebayuPas encore d'évaluation

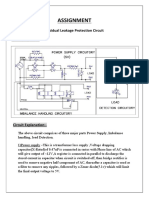

- Assignment: Residual Leakage Protection Circuit Circuit DiagramDocument2 pagesAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaPas encore d'évaluation

- Ficha Tecnica Bomba Inyeccion MiniFlex EDocument1 pageFicha Tecnica Bomba Inyeccion MiniFlex Ejohn frader arrubla50% (2)

- Dec 2-7 Week 4 Physics DLLDocument3 pagesDec 2-7 Week 4 Physics DLLRicardo Acosta Subad100% (1)

- Entrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanDocument3 pagesEntrepreneurial Capacity Building: A Study of Small and Medium Family-Owned Enterprisesin PakistanMamoonaMeralAysunPas encore d'évaluation

- "Organized Crime" and "Organized Crime": Indeterminate Problems of Definition. Hagan Frank E.Document12 pages"Organized Crime" and "Organized Crime": Indeterminate Problems of Definition. Hagan Frank E.Gaston AvilaPas encore d'évaluation

- Nominal GroupDocument3 pagesNominal GroupSrourPas encore d'évaluation

- 5steps To Finding Your Workflow: by Nathan LozeronDocument35 pages5steps To Finding Your Workflow: by Nathan Lozeronrehabbed100% (2)

- Pam8610 PDFDocument15 pagesPam8610 PDFRaka Satria PradanaPas encore d'évaluation

- MLX90614Document44 pagesMLX90614ehsan1985Pas encore d'évaluation

- ISO Position ToleranceDocument15 pagesISO Position ToleranceНиколай КалугинPas encore d'évaluation

- Ilovepdf MergedDocument503 pagesIlovepdf MergedHemantPas encore d'évaluation

- Halloween EssayDocument2 pagesHalloween EssayJonathan LamPas encore d'évaluation

- CL Honours Report NamanDocument11 pagesCL Honours Report NamanNaman VermaPas encore d'évaluation

- OTP User Manual For English) v1,0Document15 pagesOTP User Manual For English) v1,0auyinPas encore d'évaluation

- SDS ERSA Rev 0Document156 pagesSDS ERSA Rev 0EdgarVelosoCastroPas encore d'évaluation

- Atomberg Gorilla FanDocument12 pagesAtomberg Gorilla FanjothamPas encore d'évaluation

- TIA Guidelines SingaporeDocument24 pagesTIA Guidelines SingaporeTahmidSaanidPas encore d'évaluation