Académique Documents

Professionnel Documents

Culture Documents

Cotton Spi̇nni̇nng Tam Hali̇ Tümü

Transféré par

Manolya ŞakarDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cotton Spi̇nni̇nng Tam Hali̇ Tümü

Transféré par

Manolya ŞakarDroits d'auteur :

Formats disponibles

COMPARISON OF RING, OPEN-END, ROTOR, HOLLOW, VORTEX AND FRICTION YARNS A.

INTRODUCTION Within the last two decades, number of new yarns spinning techniques were developed to increase the yarn productivity and quality other than they found in conventional ring spun yarns. Modern techniques, open-end, rotor, hollow, vortex and friction spinning systems have supply much more caution from engineers and technologists due to their high productivity. These technologies separate from ring spinning not only in the design of the spinning units, but also in the physical properties of the yarns, which may be identified by the configuration of the fibres. Many researchers have analyzed the structure of ring spun yarns and structural differences in staple yarns lead to different yarn properties. Today, yarn production is highly advanced technology that opportunities the engineering of different yarn structure having specific properties for particular application. Because yarn structure depend on processing conditions and spinning technologies. The physical properties of yarn can be supposed to be influenced by process variables. According to research: To describe the structures of ring, rotor, and friction spun yarns and to set up the relationships between the properties and the structures of the three different yarn types. The physical properties are breaking tenacity, elongation, yarn evenness, and hairiness. B.COMPARATION OF STRUCTURES OF RING, ROTOR, AND FRICTION SPUN YARNS Many researchers have analyzed the structure of ring spun yarns since the early 1950s, focusing on fiber migration. Morton found that the intervals of helix profiles decreased as the twist increased. Hearle and Gupta showed that with increased twist, there was a marginal decrease in mean fibre position and magnitude of migration, whereas the migration intensity increased considerably. As for rotor spun yarn, Hearle and his associates concluded that the low strength of rotor spun yarns could be attributed to poor fibre alignment and inferior fibre migration within the yarn body. Lord pointed out that the low tenacity of the rotor spun yam was due to relatively shallower fibre migration, a fairly large number of folded fibres, poor distribution of load over them fibres, high twist multiple, different twist structure, and spinning tension. Luenenschloss and Brockmanns used stereo-scanned pictures and cross

sections of yams interspersed with tracer fibres to determine the structure of friction spun yarns. They concluded that friction spun yarns had a strongger migration than ring spun yarns, and the migration moved from the sheath to the core almost without reversal of direction. Rust Lord found that the migration theory for ring spun yarns was in adequate for friction spun yarns due to the conical disposition of fibres. From a comparison study of the migration characteristics of staple yarns, Alagha and associates concluded that the differences in migration characteristics of yarns on different spinning systems were due to different twisting methods and tension levels present during yarn formation. In general, structural differences in staple yarns lead to different yarn properties. Because yarn structure depends on processing conditions and spinning technologies, the physical properties of yarn can be supposed to be influenced by process variables. Thus, it is very important to understand yarn structure and its effects on physical properties for various spinning systems, because each kind of yarn manufactured by a specific spinning method has unique properties. While there have been efforts to determine yarn properties for various spinning systems in terms of yarn structure, most of these were handled qualitatively. Our objectives in this work are to characterize the structures of ring, rotor, and friction spun yarns to establish the relationships between the properties and the structures of the three different yarn types. For this purpose, we conduct experimental studies on yarn structure to quantify it in terms of fiber migration, packing density, spatial orientation angle and helix angle (twist angle). The physical properties we examine are breaking tenacity, elongation, yarn evenness, and hairiness. 1. Experimental Specimens for ring, rotor, and friction spun yarns were prepared from cotton slivers and rovings containing 1 % black dyed (tracer) fibers. The linear density of the slivers and the rovings were 4250 Tex (Ne 0.14) and 580 Tex (Ne 1.0), respectively. The mean fiber length was 28.6 mm (1 /s inches) and the micronaire value was 4.2. The spinning conditions for sample preparation are summarized in Table I. Yam properties such as yarn tenacity, breaking elongation, hairiness, evenness, and imperfections were investigated. The test methods and experimental conditions are shown in Table I. All the tests were performed under a standard atmosphere of 20 2C and 65 2% RH.

Table1: Test Conditions For Yarn Properties Property Test method Testing machine Sample length /test Tenacity an elongation ASTM D2256 USTER 250 300mm/min 100 Pre-tensional force, 0.5 g/tex Testing speed No, of Other conditions

testing

Tensorapid mm(gauge length)

hairiness

ASTM D 5647

Zweigle G565 hairiness tester

500 mm

50 mm/min

Tension applied during test, 10 g hair length measured over 1 mm and 3 mm

U%, IPI

Uster method

Uster Tester 3

1000 mm

400mm/min 5

Setting imperfection indicator(IPI)

of

Thin places (50%) Thick (+50%) Neps (+200%) places

2. Comparisons of Three Types of Yarn (Friction, Rotor, Ring) The yarn properties are tenacity, breaking elongation, thickness variation, and hairiness. Ring spun yarn has the highest tenacity and the friction yarn a considerably lower one. Thickness variations show that the ring spun yarn has the best yarn evenness with 7.8% (U %) and the least imperfections. The evenness values of the rotor and friction spun yarns are

almost at the same level,

whereas the friction spun yarn exhibits more imperfections than the rotor

spun yarn. This may be accounted for by the folded and entangled fibers in the friction spun yarn. Yarn evenness and fewer imperfections of the ring spun yarn seem to contribute to better yarn tenacity. Another factor in yarn tenacity is fiber migration. The higher the fiber migration, the greater the resistance of fibers to slippage under loading. According to the experimental results for the relation between yam tenacity and the migration factor, fiber migration indeed contributes positively to yarn tenacity, this positive contribution can be described by the increased self-locking structure of yarn, which increases the resistance to slippage between fibers and better utilization of fiber strength for yarn tenacity. One of the important mechanical properties distinct differences for various kinds of yarn is breaking elongation. The processing conditions for many successive processes where ring spun yarns are used are not available for rotor or friction spun yarns, mainly due to the difference in breaking elongation. Friction spun yarns can be more extensible despite its low tenacity and weak migration. According to experimental results, the friction spun yam has the highest breaking elongation. Rotor spun yarn is known to have better breaking elongation than ring spun yarn.

3. Yarn Hairiness of Three Type of Yarn

Yam hairiness plays an important role in fabric roughness, luster, and shade, etc. To investigate the relation between hairiness and the structural parameters, detested hairiness. The rotor spun yarn obviously shows less hairiness than the others, independent of hair length. The friction spun yarn exhibits almost the same hairiness as the ring spun yarn. Yam hairiness can be influenced by fiber distribution across the yam cross section or the mean fiber position. In according to research, the rotor spun yarn shows the lowest mean fiber position of 0.40, and the friction spun yam has the highest value of 0.60. The major findings of researches, the ring spun yarn exhibits the highest fiber migration, and the friction spun yarn shows the lowest. The friction spun yarn is most compact near the yarn surface, while the rotor spun yarn is most dense around the yarn axis. The fibers in a ring spun yarn are moderately spread across the yarn cross section.

C.COMPARATION OF OPEN END YARN AND RNG YARN 1. Quality Characteristics Of OE Yarn As Compared To Ring Yarn

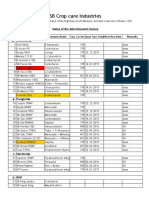

Production Package Size Tex RangeTwistAverage StrengthVariation In Strength ExtensibilityWork Of RuptureRegularityCount Variation AppearanceMore Bulkiness HairinessCleanliness NeppinessYarn FaultsResistance To Abrasion Handle Structure Fiber BlendingTake Up Of Size Take Up Of Dyes End Breaks In Spinning Fly Liberation

Increased 3-3.5 Times Increased 20 Times 20-30 10-15% Higher 15-20% Weaker Less 10% Higher Same

10-20% Better Better Uniform Spinning Volume Increased By 10% 20-40% Less Better Fewer Neps Decreased By 80% 20-30% Better Harsher Different Much Better Better ( Less Size Required)

Better ( Vivid Colors) Reduced 75% Less

2.Characteristics Of OE Yarn In Use And Of Fabric Made From Them- Comparison With Ring Spinning End Breaks Knots (After Winding) Warp Breaks In Weaving Weft Breaks In Weaving Tensile Strength Tearing Strength Bursting Strength Appearance Barring Cover Cleanliness Neppiness Resistance To Abrasion Handle Thermal Insulation Air Permeability Take Up Of Dyes Absorption Of Water Shrinkage Reduced By 50% Decreased By 15-17/Kg Decreased By 70% Decreased By 25% Reduced Reduced Reduced More Uniform More Better 10% Better Better Fewer Neps 5-7% Better Harsher 10-15% Better 15-25% Better Better ( Vivid Colors, Clear Definitions) Much Better Same

D. COMPARATION OF MURATA VORTEX SPUN YARNS WTH RING AND OPEN-END ROTOR SPUN YARNS The structure and properties of Murata vortex spun yarns are investigated and compared with ring and open-end rotor spun yarns. According to research, Matsuo show that cotton yarns are spun from the same lot of Australian raw cotton fibers using the Murata vortex, ring, and open-end rotor spinning methods. Yarn structures are observed with an optical microscope equipped with a digital camera. The differences in measured yarn properties such as evenness, hairiness, bulkiness. Tenacity, compression properties, and bending properties can be explained by the observe differences in the yarn structure (2004, ss.819-816). Ring spinning has a low production rate; the ring spun yarn structure is generally accepted as the fundamental or basic structure in spun yarn technology Recently, Murata vortex spinning (MVS), based on the air jet spinning technology by the Murata Machinery Company in Japan, has been commercialized. With the MVS system, it becomes possible to use a wider fiber length range for 100% cotton yarn, allowing spinning of a wider yarn size production range.

One of the great advantages of MVS is that it can deliver yarn at up to 400 m/min. Although the number of MVS frames operating in mills is still much lower than the number of Ring spinning (RS) and Open End Rotor Spinning (OERS) frames, MVS installations are growing rapidly because of high production rates compared with Ring Spinning (RS) and Open End Rotor Spinning (OERS).However, there has been no research in which the structure and yarn properties of MVS are systematically compared with number of Ring spinning (RS) Open End Rotor Spinning (OERS). According to research; MATSUO used the same Australian cotton fibers arranged by CSIRO, Australia, was used to produce 100% cotton yarn on the RS, OERS, and MVS systems in research(2004, s 820) . and

MVS yarns possess higher core fiber parallelization than OERS and RS yarns. Wrapper fiber parallelization in MVS yarns is closer to the core fiber parallelization of RS yarns. In the MVS yarn structure, core fibers are considered to have zero twist, which differs from RS and OERS yarn structures. MVS yarn structure, it is also clear that the core fiber strand is enveloped by a thin layer of wrapper fibers with good parallelization

1. Yarn Properties A) Yarn Evenness the physical properties of yarns.

Researcher used the same lot of cotton fibers for all the spinning methods, which was a great advantage when comparing them evenness results for all yarns. Researcher found no significant evenness differences in the three kinds of yarns, except for a higher frequency of thick places and neps in the MVS yarn. The hairiness length (1 mm) for the MVS yarn was similar to the OERS yarns and lower than the RS yarns. For the hairiness length (3 mm), MVS yarn hairiness is much lower than the other two kinds of yarns. B) Yarn Tenacity The yarn tenacity value of RS yarn is higher than tenacity of OERS and MVS yarns. The reason for the lower tensile values in the OERS yarn structure is the lack of fiber parallelization, which causes a non-uniform load distribution. With regard to Mvs yarns, the twisted fiber core of RS yarn as opposed to the nontwisted core of the MVS yarn creates a stronger bond between the fibers. While these fundamental structural effects cause the higher tenacity value of RS yarn compared with MVS yarn, it is important to note that there is no optimal selection of twist factor for this MVS yarn production from the view point of tenacity. C) Yarn Mechanical Properties MVS yarn had the highest compression energy value (WC of these three kinds of yarn, which can be partly explained by its bulkiness. Another factor for the higher WC may be the higher resistance to compression pressure found in Mvs yarn particularly in the displacement range from 0.02 to 0.055 cm. The bending rigidity of MVS yarn is higher than OERS and RS yarns. At the end of research, many properties of MVS, RS and OERS yarns are found in the tables.

2. Conclusion As modified fiber classification scheme to analyze fiber arrangements in ring spun yarn, open-end rotor spun yarn, and Murata vortex spun yarn. Researcher investigated the yarn properties and yarn formation mechanism for a better understanding of the basic differences

in these yarns. This research has shown that ring and OERS yarns are mainly composed of core fibers, which are generally highly parallel, although the core fiber parallelization of open end rotor spun yarn is much less uniform than that of ring yarn. In this research, MVS wrapper fiber parallelization is regarded as the same as the arrangement of core fibers in a ring yarn. MVS core fibers, which are also highly oriented in parallel, have almost no twist. More than half of the surface area of MVS yarns is covered and packed by the layer of wrapper fibers. The uniformity arrangement of these wrapper fibers makes the Murata vortex spun yarn the least hairy of the three yarn types. The structural differences can be reasonably explained by the yarn-forming mechanism of each spinning method. The structural differences of each yarn type confer different tensile, compression, and bending rigidity values. According to research; in this regard, Murata vortex yarns are stiffer than ring and open-end rotor spun yarns, while ring yarns have the highest tenacity values. Klein show that Murata vortex spinning are compared by Ring Yarn (1993, Sections 1.6.1 & 1.6.2) A) Murata vortex systems Yarn Properties (compared with Ring Yarn) B) C) 15% lower strength Less extensible Stiffer and harder Rougher & duller Less untwisting tendency Less pilling More even Main Advantages Of Murata Vortex Spinning According To Ring Spinning High speed (to 300 m/min) Short process Main Disadvantages Of Murata Vortex Spinning According To Ring Spinning Limited fiber range Limited yarn count Lower yarn strength/elongation Harsher handle

E. COMPARATION OF RNG YARN WTH AIR JET/ ROTOR or FRICTION

Single yarn strength of air jet/ rotor or friction yarn is less than that of ring yarn. So fabrics made from ring yarn will be stronger than those made from air jet/rotor or friction yarn. The fabric made from ring yarn will be weaker than those made from the other yarns. The presence of wrapper fibers inside the rotor, air jet and friction yarns increase the frictional force inside the fabric and therefore resist rupture, among other factors such as the rupture of wrapper fibers inside the fabric for these yarns are more than ring yarn, which enhance further frictional force.

F. COMPARATION OF MURATA VORTEX SPUN YARNS WTH AR JET SPUN YARNS In order to have a general knowledge about this yarn spinning systems, we need to compare the properties of air-jet and vortex yarns. Also, no work to date has been reported regarding the difference between these yarns. A study was conducted to reveal the difference between the properties and structure of the vortex and air-jet spun yarns. A) Comparison of Yarn Structures of Vortex and Airjet Yarns. Yarn structure is one of the most important factors that have an effect on the properties of spun yarns and Vortex-spun yarn has a two-part structure. In the first part of this study, the properties of vortex and air-jet spun yarns made from various PES/cotton blends were compared and a piece of vortex yarn was untwisted and viewed under the Scanning Electron Microscope and SEM images confirmed that vortex yarns consist of two distinctive parts: the core and the sheath. (Basal, Oxenham ,n.d.) The examination of these yarns under the microscope showed that Air Jet fibers are consisting from approximately %95 untwisted and parallel core fibers and %5 wrapper fibers. On the other hand, Vortex fibers are nearly consisting from % 90 untwisted and parallel core fibers and %10 wrapper fibers. This indicates that Vortex yarns have more Ring like appearance and

a higher number of wrapper fibers compared to air jet yarns. B) Comparison of the Mechanical Properties of yarns

The researches that made with the blended yarns were produced from three different blends of black polyester (1.7 den, 1.5 in) and cotton fibres (4.1 mic., 0.91 in) (blend ratios: 33/67, 50/50, 67/33), is revealed that

yarns made by Vortex had a higher evenness, less numbers of thick

places and lower hairiness values compared by Air Jet systems. Vortex yarns also has a higher tenacity value for every blend ratio except the 100% polyester case, and as the cotton content increased in the blend, the difference enlarged. For 100% polyester yarn, on the contrary, the tenacity values of Vortex and Air jet yarns did not differ so much. Vortex yarns show lower elongation values compared to Air jet yarns. (Basal, Oxenham ,n.d.)

The higher tenacity values of vortex yarns are because of the higher number of wrapper fibers in these yarns. Also, the number of wrapper fibers is attributed to yarn strength. In air jet spinning edge fibers ultimately produce wrapper fibers, and the number of edge fibers depends on the fibers at the outside. One possible explanation for the reduction in elongation is the decrease in fiber slippage due to better grip by wrapper fibers. Possibly the drop in hairiness values is another result of better wrapping.

G. COMPARATION OF STRUCTURES OF RING AND HOLLOW SPNDLE SPUN YARNS A hollow spindle wrapped yarn is a new yarn consisting of a core yarn and a wrapping yarn. The structure of a hollow spindle wrap spun yarn depends greatly on the steadiness of binder tension and of balloon rotation. The two commonly used binder bobbin forms, the cop type and the flanged type, both as sources of spinning condition fluctuation, are examined in order to reveal their effects on the wrap spun yarn structure. False twist is introduced on hollow spindle spinning machines in order to avoid strand breaks before it is tightly wrapped up. However, an investigation of the false twist g-wrapping process shows that this inevitably causes irregular yarn tortuosity. The hollow spindle is designed as a false twisting assembly. The fibre strand does not pass directly after entering the vertical spindle instead, shortly after entering the spindle; this strand is led out again and back around the spindle with wrap about one- quarter of the spindle periphery. In this way, as the spindle rotates, the strand is provided with the twist between the drafting arrangement and head of the hollow spindle. These turns of twist are cancelled out again in the spindle head in accordance with the false twist principle. This twist prevents the strand from falling apart in the length prior to filament staple fibres wrappings with filament. A wrap spun yarn consists of non-twisted parallel bundle of staple fibres held together by helically wrapped filament. The proportion of the filament in the yarn is about 2-5 %. Due to helical wrapping of the filament and by radial pressure, necessary cohesion between the individual staple fibers is improved. This imparts desired strength to the yarn. The number of wraps per unit length in a standard PL yarn is approximately the same as the amount of twist in a comparable ring spun yarn. As the turns of twist increase, it causes more energy consumption and it is necessary to use bobbin for the smaller filament yarns. However, the production in hollow spindle systems is much higher than conventional ring spinning systems and such quality parameters like evenness, neps, and strength are better than ring systems. Also, the fabrics that are produced with hollow spindle systems, the resistance to friction and strength is higher.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Company Registration Procedure Handbook in Cambodia, EnglishDocument124 pagesCompany Registration Procedure Handbook in Cambodia, EnglishThea100% (16)

- April 8/91: All GroupsDocument33 pagesApril 8/91: All Groupsreza mirzakhaniPas encore d'évaluation

- FM Testbank-Ch18Document9 pagesFM Testbank-Ch18David LarryPas encore d'évaluation

- Assignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Document8 pagesAssignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Ren ZkPas encore d'évaluation

- Matrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014Document19 pagesMatrices and Vectors. - . in A Nutshell: AT Patera, M Yano October 9, 2014navigareePas encore d'évaluation

- Small Business and Entrepreneurship ProjectDocument38 pagesSmall Business and Entrepreneurship ProjectMădălina Elena FotachePas encore d'évaluation

- Performance Evaluation of The KVM Hypervisor Running On Arm-Based Single-Board ComputersDocument18 pagesPerformance Evaluation of The KVM Hypervisor Running On Arm-Based Single-Board ComputersAIRCC - IJCNCPas encore d'évaluation

- Verilog A Model To CadenceDocument56 pagesVerilog A Model To CadenceJamesPas encore d'évaluation

- Schermer 1984Document25 pagesSchermer 1984Pedro VeraPas encore d'évaluation

- Wood ReportDocument36 pagesWood Reportメルヴリッ クズルエタPas encore d'évaluation

- Newcastle University Dissertation FormatDocument6 pagesNewcastle University Dissertation FormatWriteMyEnglishPaperForMeSterlingHeights100% (1)

- Multi-Media Approach To Teaching-LearningDocument8 pagesMulti-Media Approach To Teaching-LearningswethashakiPas encore d'évaluation

- Diazonium Salts Azo DyesDocument8 pagesDiazonium Salts Azo DyesAnthony Basanta100% (1)

- ACTIX Basic (Sample CDMA)Document73 pagesACTIX Basic (Sample CDMA)radhiwibowoPas encore d'évaluation

- Most Probable Number (MPN) Test: Principle, Procedure, ResultsDocument4 pagesMost Probable Number (MPN) Test: Principle, Procedure, ResultsHammad KingPas encore d'évaluation

- Annex A - Scope of WorkDocument4 pagesAnnex A - Scope of Workمهيب سعيد الشميريPas encore d'évaluation

- Products ListDocument11 pagesProducts ListPorag AhmedPas encore d'évaluation

- Presentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadDocument14 pagesPresentación de Power Point Sobre Aspectos de La Cultura Inglesa Que Han Influido en El Desarrollo de La HumanidadAndres EduardoPas encore d'évaluation

- OracleCarrierManifestingPartnerIntegration PDFDocument40 pagesOracleCarrierManifestingPartnerIntegration PDFvishal_vishnu11Pas encore d'évaluation

- Chemistry II EM Basic Learning MaterialDocument40 pagesChemistry II EM Basic Learning MaterialMAHINDRA BALLAPas encore d'évaluation

- DR Afwan Fajri - Trauma - Juli 2023Document82 pagesDR Afwan Fajri - Trauma - Juli 2023afwan fajriPas encore d'évaluation

- 16-ELS-Final-Module 16-08082020Document18 pages16-ELS-Final-Module 16-08082020jeseca cincoPas encore d'évaluation

- SAP HCM Case StudyDocument17 pagesSAP HCM Case StudyRafidaFatimatuzzahraPas encore d'évaluation

- Rolling TechnologyDocument4 pagesRolling TechnologyFrancis Erwin Bernard100% (1)

- MMB & DFT 2012 Workshop ProceedingsDocument44 pagesMMB & DFT 2012 Workshop ProceedingsFelipe ToroPas encore d'évaluation

- Service Letter Service Letter Service Letter Service Letter: Commercial Aviation ServicesDocument3 pagesService Letter Service Letter Service Letter Service Letter: Commercial Aviation ServicesSamarPas encore d'évaluation

- Chapter 10 Translation ExposureDocument14 pagesChapter 10 Translation ExposurehazelPas encore d'évaluation

- Medical Equipment Quality Assurance For Healthcare FacilitiesDocument5 pagesMedical Equipment Quality Assurance For Healthcare FacilitiesJorge LopezPas encore d'évaluation

- Adding and Subtracting FractionsDocument4 pagesAdding and Subtracting Fractionsapi-508898016Pas encore d'évaluation

- E-Waste: Name: Nishant.V.Naik Class: F.Y.Btech (Civil) Div: VII SR - No: 18 Roll No: A050136Document11 pagesE-Waste: Name: Nishant.V.Naik Class: F.Y.Btech (Civil) Div: VII SR - No: 18 Roll No: A050136Nishant NaikPas encore d'évaluation