Académique Documents

Professionnel Documents

Culture Documents

Use of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete Mix

Transféré par

Mehul BarotDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Use of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete Mix

Transféré par

Mehul BarotDroits d'auteur :

Formats disponibles

Materials Letters 58 (2004) 267 271 www.elsevier.

com/locate/matlet

Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix

Sinan Hnsloglu a,*, Emine Agar b

a

Civil Engineering Department, Engineering Faculty, Ataturk University, 25240 Erzurum, Turkey b Civil Engineering Faculty, Istanbul Technical University, Maslak/Istanbul, Turkey Received 31 March 2003; accepted 28 May 2003

Abstract The purpose of this study is to investigate the possibility of using various plastic wastes containing High Density Polyethylene as polymer additives to asphalt concrete. It was investigated that the influence of HDPE-modified binder obtained by various mixing time, mixing temperature and HDPE content on the Marshall Stability, flow and Marshall Quotient (Stability to flow ratio). The binders used in Hot Mix Asphalt (HMA) were prepared by mixing the HDPE in 4 6% and 8% (by the weight of optimum bitumen content) and AC-20 at temperatures of 145 155 and 165 jC and 5 15 and 30 min of mixing time. HDPE-modified asphalt concrete results in a considerable increase in the Marshall Stability (strength) value and a Marshall Quotient value (resistance to deformation). Four percent HDPE, 165jC of mixing temperature and 30 min of mixing time were determined as optimum conditions for Marshall Stability, flow and Marshall Quotient (MQ). MQ increased 50% compared to control mix. It can be said that waste HDPE-modified bituminous binders provide better resistance against permanent deformations due to their high stability and high Marshall Quotient and it contributes to recirculation of plastic wastes as well as to protection of the environment. D 2003 Elsevier B.V. All rights reserved.

Keywords: Asphalt concrete; Waste material; Modified bitumen; Marshall stability; Marshall quotient

1. Introduction In recent years, numerous waste materials result from manufacturing operations, service industries and households in Turkey. Problems, however, are experienced due to the insufficient capacity of landfills and limited alternatives for recycling. Waste utilization is an attractive alternative to disposal in that disposal cost and potential pollution problems are reduced or even eliminated along with the achievement of resource conservation. On the other hand, recent highway construction costs have showed a rise in Turkey. It is well known that the addition of both, some waste materials and certain polymers, to asphalt binders can improve the performance of asphalt concrete [1 9]. Polyethylene has also been found to be one of the most effective polymer additives [10,11]. In Turkey, there are about million tons of materials containing HDPE. From the economic view-

* Corresponding author. Fax: +90-4422360957. E-mail address: sinanhinislioglu@yahoo.com (S. Hnsloglu). 0167-577X/$ - see front matter D 2003 Elsevier B.V. All rights reserved. doi:10.1016/S0167-577X(03)00458-0

point, it may be quite possible that waste HDPE material of may both affect the initial engineering properties of HMA pavement and increase its service life. However, since the mixing conditions for the bitumen and polymer have considerable effect on the behavior of polymermodified bitumen, it should be determined as the most suitable mixing conditions for bitumen and polymer. For this purpose, modified bitumen is obtained by mixing the bitumen and modifier at a certain temperature and time. If the consistent mixing time and mixing temperature are not provided for bitumen modifier mix, modified bitumen cannot exhibit good performance in situ, thus premature failures will occur. In addition, modifier content is also an important factor affecting the performance of the polymer-modified asphalt concretes. Therefore, there are certain recommended mixing time, mixing temperature and modifier content for all the polymers with a trademark. Stability of an HMA pavement, the most important property of the bitumen mixture in the wearing course design, is its ability to resist shoving and rutting under traffic. Therefore, stability should be high enough to handle

268

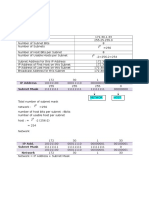

S. Hnsloglu, E. Agar / Materials Letters 58 (2004) 267271 Table 3 Gradation used in this study and gradation limits 67 1.047 215 +100 56 Sieve size (in.) 3/4 1/2 3/8 No. No. No. No. No. Gradation limits 100 77 100 66 84 46 66 30 50 12 28 7 18 4 10 Used gradation 100 87 74 54 35 14 9 6

Table 1 The results of tests performed on asphalt cement (AC-20) Penetration, 25 jC, 100 g, 5 s (1/10 mm) Specific gravity (kN/m3) Flash point (jC) Ductility, 25 jC, 5 cm/min Softening point (jC) ASTM ASTM ASTM ASTM ASTM D5 D70 D92 D113 D36

traffic adequately, but not higher than the traffic conditions required. The lack of stability in an asphalt mixture causes unraveling and flow of the road surface. Flow is the ability of an HMA pavement to adjust to gradual settlements and movements in the subgrade without cracking. The flow may be regarded as an opposite property to the stability, determining the reversible behavior of the wearing course under traffic loads and affecting plastic and elastic properties of the asphalt concrete [11]. The Marshall quotient, calculated as the ratio of stability to flow and thereby representing an approximation of the ratio of load to deformation under the particular conditions of the test, can be used as a measure of the materials resistance to permanent deformation in service [12]. The purpose of this study is to investigate the usability of the waste material containing HDPE in the HMA as a bitumen modifier. Considering their deterministic role in the performance of polymer-modified bitumen blends, the study was focused on the effects of the modifier (HDPE) content, modifier bitumen mixing time and mixing temperature on the Marshall stability, flow and Marshall Quotient.

4 10 40 80 200

2. Materials and methods The materials and experimental design procedure used in this study are following. The bitumen used was AC-20 bitumen. This asphalt was subjected to typical standard laboratory tests. The results of these tests are incorporated in Table 1. In this investigation, waste HDPE in the powdered form was used as modifier. The specific gravity of modifier was measured to be 0.935 g/cm3. The gradation of HDPE is presented in Table 2. Crushed Limestone was used as the aggregate material. A typical heavy traffic gradation for hot mix asphalts (HMA), designated as Type II in the Turkish State Highway Specifications, was selected. The selected gradation and the specification limits are shown in Table 3. Some properties of the crushed limestone

are given in Table 4 and specific gravities of aggregates are incorporated in Table 5. The Marshall Test Method was used for determining the resistance to plastic flow of bituminous mixtures prepared with or without HDPE-modified bitumen. Initially, optimum bitumen content was found to be 4.5% (by weight of total mix) for unmodified mixtures. Marshall specimens were fabricated in accordance with ASTM D 1559. A speed adjustable vertical shaft mixer with a capacity of 2 l was used to mix the HDPE and bitumen. Temperature control during mixing was achieved by using thermostat running with a thermocouple attached to the mixer. The machine was operated at 200 rpm for HDPE bitumen mixing. The utilization strategy must be coupled with environmental and energy considerations to use available materials most efficiently. Since the amount of HDPE, bitumen HDPE mixing temperature and bitumen HDPE mixing time play a crucial role in determining the performance of HDPE-modified asphalt concrete, these were considered as factors affecting the performance of asphalt concrete in the design of experiment. The binders used in HMA were prepared by mixing the HDPE in 4 6 and 8% (by the weight of optimum bitumen content) and AC-20 at mixing temperatures of

Table 4 Some physical properties of the crushed limestone aggregate Frost Los Angeles Abrasion Test Flatness Stripping (AC-5) Organic material 0<12% 22<35% cubic 60 65>50 none

Table 5 Specific gravities of aggregate (g/cm3) Table 2 The gradation of high density polyethylene Sieve size No. 10 (2 mm) No. 40 (0.42 mm) Percent passing 100 0 Size fraction Coarse aggregate Fine aggregate Filler Apparent specific gravity 2713 2729 2730 Bulk specific gravity 2682 2687

S. Hnsloglu, E. Agar / Materials Letters 58 (2004) 267271 Table 6 Specification of general directorate of Turkish highway for wearing surface course subjected to high volume of traffic Properties of Marshall specimens Stability (N) Air voids (%) Flow (mm) Voids of filled with asphalt cement (%) Specification limits min. 9 kN 35 24 75 85

269

3. Results and discussion 3.1. Stability Fig. 1 shows the variation of stability with the various bitumen and waste HDPE mixing temperature and time. It is shown that stability decreases with increasing HDPE content for all mixing temperature and mixing time. Stability of the control mixture is 14 kN. For both 4% and 6% HDPE mixes, stability is higher than the control mixture. The effect of the mixing time is more evident at 165 jC mixing temperature. The maximum stability is reached at 4% HDPE, 165 jC mixing temperature and 30-min mixing time. Marshall stability value increased by 50% when 4% HDPE was replaced with AC-20. The decreases in stability while increasing HDPE content may be attributed to the decreases in the adhesion. 3.2. Flow It is seen from Fig. 2 that flow increases with increasing the HDPE content. Flow is 3.8 mm for the control mixture. Although flow decreases with increasing the mixing temperature and mixing time, all flow values are higher than the control specimen except for the binder prepared at a mixing temperature of 165 jC, mixing time of 30 min and containing 4% HDPE. This may imply that increase in the amount of HDPE affects the interior friction of the mixture in a negative manner. The smallest flow value, 3.8 mm, is reached at 4% HDPE, mixing temperature of 165 jC and mixing time of 30 min.

145 155 and 165 jC and 5 15 and 30 min of mixing time. After obtaining the HDPE-modified bitumen, aggregate and HDPE-modified bitumen were heated separately to 165 and 155 jC, respectively, and then mixed with the aggregate in a mechanical mixer. The mixture was placed in a Marshall mold and compacted by applying 75 blows on each side of the specimen at 145 jC. It was noted that all the specimens have approximately the same air void ratio. Void ratios of the specimens were in the range of specimens 3.07 3.35%. The standard dimensions of the samples were 63.5 mm height and 101.5 mm diameter. After having cooled at room temperature for 1 day and then left in water at 60 jC for 30 min, the samples were tested with Marshall Test apparatus. All the results are obtained from compacted specimens at the optimum bitumen content of each mix type and each result is from an average of three test specimens. In order to evaluate the properties of waste HDPE-modified asphalt concrete specimen, Specification of General Directorate of Turkish Highway for Surface Coarse Subjected to High Volume of Traffic was used (Table 6).

Fig. 1. Mixing temperature/mixing time vs. stability.

270

S. Hnsloglu, E. Agar / Materials Letters 58 (2004) 267271

Fig. 2. Mixing temperature/mixing time vs. flow.

3.3. Marshall quotient Since Marshall Quotient (MQ) is an indicator of the resistance against the deformation of the asphalt concrete

[12], MQ values are calculated to evaluate the resistance of the deformation of the HDPE-modified specimens. A higher value of MQ indicates a stiffer mixture and, hence, indicates that the mixture is likely more resistant

Fig. 3. Mixing temperature/mixing time vs. Marshall Quotient.

S. Hnsloglu, E. Agar / Materials Letters 58 (2004) 267271 Table 7 Comparison of the control and waste HDPE-modified asphalt concrete mixtures Control mixture Void ratio (%) VMA (%) Voids filled with binder (%) Stability (kN) Flow (mm) Marshall Quotient (kN/mm) 3.32 12.78 75 14 3.8 3.68 Mixture with 4% HDPEa 3.07 12.57 75.55 21 3.8 5.53 Specification limits 35 min. 14 75 85 min. 9 kN 24

271

stiffness mix with a greater ability to spread the applied load. Thus, the pavements being more resistant to permanent deformation are obtained and a solid waste disposal problem is relatively solved.

Acknowledgements This study is a part of the research supported by Atatu rk University Research Fund. (Project No: 2001/130). We would like to thank to Atatu University Research Fund for rk giving us the opportunity to make this research.

a Binder was prepared by mixing the bitumen and 4% waste HDPE at the temperature of 165 jC and 30 min of mixing time.

to permanent deformation [13]. The specimen having higher MQ than that of the control mixture is prepared with 4% HDPE at 165 jC mixing temperature and 30 min mixing period (Fig. 3). The specimen under conditions above-mentioned provided all the specification limits for Marshall Design parameters. Waste HDPE content of 4% (by weight of optimum bitumen content), 165 jC of mixing temperature and mixing time of 30 min satisfy all the specification limits given in Table 6. Results of the Marshall design parameters and values of MQ for both control and waste HDPE-modified asphalt concretes mix are shown for comparison purposes in Table 7.

References

[1] R.T. Woodhams, Methods of increasing the fracture toughness of asphalt concrete, Transportation Research Board Record 843 (1982) 21. [2] G. Kraus, Modification of asphalt by block copolymers of butadiene and styrene rubber, Chemie & Techniek 55 (5) (1982) 1389. [3] J. Epps, Asphalt Pavement Modifiers, Civil Engineering/ASCE, 1986 April, p. 57. [4] R.L. Terrel, J.L. Walter, Modified asphalt pavement materials, The European Experience Proceeding Association of Asphalt Paving Technologists 55 (1986) 482. [5] S. Colagrande, Polyolefin plastics taken from solid urban waste in bituminous concrete, Proceedings of the Second European Symposium on Performance and Durability of Bituminous Materials, University of Leeds, 1997 April, p. 85. [6] D.N. Little, Enhancement of asphalt concrete mixtures to meet structural requirements through the addition of recycled polyethylene, use of waste materials in hot-mix asphalt, ASTM STP 1193 (1993) 210. [7] H. Al-Abdul-Wahhab, G. Al-Amri, Laboratory evaluation of reclaimed rubber asphaltic concrete mixes, Journal of Materials in Civil Engineering (1991 Aug.) 189. [8] S.E. Zoorob, L.B. Suparma, Laboratory design and investigation of the properties of continuously graded asphaltic concrete containing recycled plastics aggregate replacement (plastiphalt), Cement and Concrete Composites (2000 Aug.) 233. [9] P. Jew, R.T. Woodhams, Polyethylene modified bitumens for paving applications, Proceedings of the Association of Asphalt Paving Technologies 55 (1982) 541. [10] R.T. Woodhams, Bitumen-polyolefin compositions, PCT Int. Appl. (1987 Sept.) (WO 87/5313 Al). [11] N. Kuloglu, Effect of astragalus on characteristics of asphalt concrete, Journal of Materials in Civil Engineering 11 (4) (1999) 283. [12] Shell Bitumen Handbook (1991) 260. [13] Hot Mix Asphalt Materials, Mixture Design and Construction, National Center for Asphalt Technology, 1991, p. 225.

4. Conclusions From the findings of the present work, the following conclusions are drawn. It is concluded that the specimens prepared with the 165 jC mixing temperature and 30 jC mixing time for 4% HDPE have the highest stability and the smallest flow, and so the highest Marshall Quotient. A stability increase indicates that the HDPE-modified mixes are much stronger than the control mix. This mix is highly resistant to permanent deformation (rutting) in asphalt concrete. Although the flow value of HDPE-modified asphalt concrete is the same as the control mix, higher values of MQ are obtained due to higher stability values. MQ increased 50% compared to control mix. It means that asphalt concrete having higher MQ values indicates a high

Vous aimerez peut-être aussi

- Handbook of Composites from Renewable Materials, Design and ManufacturingD'EverandHandbook of Composites from Renewable Materials, Design and ManufacturingPas encore d'évaluation

- Use of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete MixDocument5 pagesUse of Waste High Density Polyethylene As Bitumen Modifier in Asphalt Concrete MixAnonymous VyjY4iPas encore d'évaluation

- Analysis of Fatigue Properties of Unmodified and Polyethylene Terephthalate Modified Asphalt Mixtures Using Response Surface MethodologyDocument11 pagesAnalysis of Fatigue Properties of Unmodified and Polyethylene Terephthalate Modified Asphalt Mixtures Using Response Surface Methodologymehrdad_so1981Pas encore d'évaluation

- Revisi 6 EnglishDocument8 pagesRevisi 6 Englishalfredokawengian1234Pas encore d'évaluation

- The Use of Polyethylene in Hot Asphalt MixturesDocument7 pagesThe Use of Polyethylene in Hot Asphalt MixturesHanafi HamidPas encore d'évaluation

- Effect of Polyester Resin Additive On The Properties of Asphalt Binders and MixturesDocument6 pagesEffect of Polyester Resin Additive On The Properties of Asphalt Binders and MixturesMael KhanPas encore d'évaluation

- Prahara 2020 IOP Conf. Ser. - Earth Environ. Sci. 426 012037Document11 pagesPrahara 2020 IOP Conf. Ser. - Earth Environ. Sci. 426 012037Sahrul MahmudPas encore d'évaluation

- Investigating The Effect of Anti Stripping Agents - For EasychairDocument30 pagesInvestigating The Effect of Anti Stripping Agents - For EasychairAmir MosaviPas encore d'évaluation

- 1 s2.0 S0950061821029020 MainDocument13 pages1 s2.0 S0950061821029020 Mainthillai malarPas encore d'évaluation

- The Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceDocument10 pagesThe Investigation of The Impact of Lucobit Polymer On Bitumen PerformanceJessica ClarkPas encore d'évaluation

- Performance Evaluation of Hot Mix Asphalt Concrete by Using Polymeric Waste PolyethyleneDocument9 pagesPerformance Evaluation of Hot Mix Asphalt Concrete by Using Polymeric Waste Polyethyleneحسين الشهريPas encore d'évaluation

- Rheological Properties of Crumb Rubber-Modified Bitumen Containing AntioxidantDocument10 pagesRheological Properties of Crumb Rubber-Modified Bitumen Containing AntioxidantAfroz Sultana ShaikPas encore d'évaluation

- Disposal of Large Consumed Plastics Cause An Environmental Pollution As They Are Considered Non-Biodegradable MaterialsDocument18 pagesDisposal of Large Consumed Plastics Cause An Environmental Pollution As They Are Considered Non-Biodegradable MaterialsKanimozhi SPas encore d'évaluation

- Rrlplastic WasteDocument7 pagesRrlplastic WasteJericko Allen ResusPas encore d'évaluation

- Matecconf Iccoee2018 05007 PDFDocument9 pagesMatecconf Iccoee2018 05007 PDFmzh887Pas encore d'évaluation

- Materials and Design: Amir Modarres, Hamidreza HamediDocument8 pagesMaterials and Design: Amir Modarres, Hamidreza Hamediaakash singhPas encore d'évaluation

- Amit MittalDocument22 pagesAmit MittalVincent VivekPas encore d'évaluation

- Dilon Dawod 1 PDFDocument8 pagesDilon Dawod 1 PDFDilon TkhomaPas encore d'évaluation

- Determination of OptimumDocument6 pagesDetermination of OptimumparambahanPas encore d'évaluation

- Evaluation The Effect of Waste Low-Density Polythlene and Crumbrubber On PH Ysical Properties of AsphaltDocument17 pagesEvaluation The Effect of Waste Low-Density Polythlene and Crumbrubber On PH Ysical Properties of AsphaltRomil SharmaPas encore d'évaluation

- Applied SciencesDocument15 pagesApplied SciencesMizanul HoquePas encore d'évaluation

- (PET) As Partial Fine Aggregate in Modified AsphaltDocument5 pages(PET) As Partial Fine Aggregate in Modified Asphaltd TjonasanPas encore d'évaluation

- National Institute of Construction Management and Research, Pune-45Document25 pagesNational Institute of Construction Management and Research, Pune-45Arnav GargPas encore d'évaluation

- Improved Asphalt Binder Using Recycle Polyethylene Polymer: TerephthalateDocument8 pagesImproved Asphalt Binder Using Recycle Polyethylene Polymer: TerephthalateOmr FwzPas encore d'évaluation

- Investigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsDocument5 pagesInvestigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsMoslem AghapourPas encore d'évaluation

- 1 s2.0 S095006182202308X MainDocument11 pages1 s2.0 S095006182202308X MainKarolinaPas encore d'évaluation

- Construction and Building Materials: Sassan A Aki, Milad MemarzadehDocument13 pagesConstruction and Building Materials: Sassan A Aki, Milad MemarzadehAndri Wahyu DinataPas encore d'évaluation

- Study The Effectiveness of The Different Pozzolanic Material On Self-Compacting ConcreteDocument7 pagesStudy The Effectiveness of The Different Pozzolanic Material On Self-Compacting ConcreteramPas encore d'évaluation

- كتاب تحسين خواص الاسفلت بالبوليمر (لغة انجليزية)Document11 pagesكتاب تحسين خواص الاسفلت بالبوليمر (لغة انجليزية)Ayoub EzubeikPas encore d'évaluation

- 2015 Utilization of Waste Plastic Water Bottle As A Modifier For Asphalt Mixture PropertiesDocument20 pages2015 Utilization of Waste Plastic Water Bottle As A Modifier For Asphalt Mixture PropertiesKhalil ZaaimiaPas encore d'évaluation

- Construction of Road Pavement Using Waste Plastic: Kavya B M, Chethan Gowda R KDocument5 pagesConstruction of Road Pavement Using Waste Plastic: Kavya B M, Chethan Gowda R KashwinmjoshiPas encore d'évaluation

- Duarte 2021Document12 pagesDuarte 2021Ali mohammadpourPas encore d'évaluation

- Bitumen Modified With PlasticsDocument7 pagesBitumen Modified With PlasticsBeatrice KunguPas encore d'évaluation

- 25 - Artigo LdpeDocument6 pages25 - Artigo LdpeCamila Dias OliveiraPas encore d'évaluation

- 1 s2.0 S0950061823033743 MainDocument10 pages1 s2.0 S0950061823033743 Mainjuan danielPas encore d'évaluation

- Construction and Building Materials: M.R.M. Aliha, H. Fazaeli, S. Aghajani, F. Moghadas NejadDocument11 pagesConstruction and Building Materials: M.R.M. Aliha, H. Fazaeli, S. Aghajani, F. Moghadas NejadMarno03Pas encore d'évaluation

- RS16Document19 pagesRS16Anurag TiwariPas encore d'évaluation

- Dynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene BlendsDocument11 pagesDynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene Blendspickpocket27Pas encore d'évaluation

- Performance Evaluation of Bituminous Concrete Incorporating Crumb Rubber and Waste Shredded ThermoplasticsDocument6 pagesPerformance Evaluation of Bituminous Concrete Incorporating Crumb Rubber and Waste Shredded ThermoplasticsInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- Marshall Mix Design of Bituminous Mix With Admixture PPTDocument15 pagesMarshall Mix Design of Bituminous Mix With Admixture PPTPrashant Kumar TPas encore d'évaluation

- Project PaperDocument7 pagesProject PaperSandeep KulharPas encore d'évaluation

- Evaluation of Reclaimed Polyethylene Modified Asphalt Concrete MixturesDocument10 pagesEvaluation of Reclaimed Polyethylene Modified Asphalt Concrete MixturesMa VeloPas encore d'évaluation

- Incorporation of Waste Plastic in Asphalt Binders To Improve TheirDocument9 pagesIncorporation of Waste Plastic in Asphalt Binders To Improve TheirSandor ManesesPas encore d'évaluation

- The Research For Crumb Rubber/waste Plastic Compound Modified AsphaltDocument13 pagesThe Research For Crumb Rubber/waste Plastic Compound Modified AsphaltCarolina Padilla GarcíaPas encore d'évaluation

- Research Institute of Industrial Technology, Gyeongsang National UniversityDocument6 pagesResearch Institute of Industrial Technology, Gyeongsang National UniversityAndrianPas encore d'évaluation

- Evaluating The Effect of Asphalt Binder Modification 2019 Case Studies in CDocument13 pagesEvaluating The Effect of Asphalt Binder Modification 2019 Case Studies in CAmin ZuraiqiPas encore d'évaluation

- Effect of Black Rice Husk Ash On The Physical and Rheological Properties of BitumenDocument9 pagesEffect of Black Rice Husk Ash On The Physical and Rheological Properties of BitumenCicy IrnaPas encore d'évaluation

- Articulo Pavimentos Flexibles Capas de RodaduraDocument9 pagesArticulo Pavimentos Flexibles Capas de RodaduraMacarena Paz Gonzalez SáezPas encore d'évaluation

- Comparison Study Between Lime Application Methods On Hma Asphalt Concrete in IraqDocument17 pagesComparison Study Between Lime Application Methods On Hma Asphalt Concrete in IraqAhmedMahirPas encore d'évaluation

- Comparative Study of Epoxy and Polyester Resin-Based Polymer ConcreteDocument7 pagesComparative Study of Epoxy and Polyester Resin-Based Polymer Concretemohamadi42Pas encore d'évaluation

- Chapter One: 1.1. Problem StatementDocument11 pagesChapter One: 1.1. Problem StatementetayhailuPas encore d'évaluation

- 1 s2.0 S0950061818329696 MainDocument8 pages1 s2.0 S0950061818329696 MainDaniel Rosas ElguetaPas encore d'évaluation

- Lime Modified Asphalt Concrete Mixes With Respective To Moisture SusceptibilityDocument9 pagesLime Modified Asphalt Concrete Mixes With Respective To Moisture SusceptibilityAhmad Mahir Al-aniPas encore d'évaluation

- Construction and Building Materials: Nicol As H Ector Carre No G Omez, Markus Oeser, Olivier FleischelDocument11 pagesConstruction and Building Materials: Nicol As H Ector Carre No G Omez, Markus Oeser, Olivier FleischelKamruzzaman ShiponPas encore d'évaluation

- Construction and Building Materials: Muhammad ArshadDocument14 pagesConstruction and Building Materials: Muhammad Arshadchristian ricaldiPas encore d'évaluation

- Study of Varying Size of Crumb Rubber in BitumenDocument6 pagesStudy of Varying Size of Crumb Rubber in Bitumendhanesh kumarPas encore d'évaluation

- Rubberized Concrete (Rubcrete) : Critic ReportsDocument4 pagesRubberized Concrete (Rubcrete) : Critic ReportsTheBeast NaralPas encore d'évaluation

- Mixture Design Consideration For Foamed Asphalt UsDocument9 pagesMixture Design Consideration For Foamed Asphalt UsBurak BulutPas encore d'évaluation

- Influence of Rice Husk Ash and Slag As Fillers in Asphalt Concrete MixesDocument9 pagesInfluence of Rice Husk Ash and Slag As Fillers in Asphalt Concrete MixesAJER JOURNALPas encore d'évaluation

- Sathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036Document11 pagesSathyan 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012036henryPas encore d'évaluation

- DWL-3200AP B1 Manual v2.40 PDFDocument83 pagesDWL-3200AP B1 Manual v2.40 PDFFrank Erick Soto HuillcaPas encore d'évaluation

- Synchro CheckDocument4 pagesSynchro CheckAdhyartha KerafPas encore d'évaluation

- Plcforum - Uz.ua: (LINK) : Eplan P8 2.0.5.4602 + CrackDocument26 pagesPlcforum - Uz.ua: (LINK) : Eplan P8 2.0.5.4602 + Crackphth411100% (1)

- 24 BitcoinDocument36 pages24 Bitcoind0c0ngthanhPas encore d'évaluation

- NTSE Stage - 1 Mock Test - 3Document16 pagesNTSE Stage - 1 Mock Test - 3Apex Institute100% (1)

- 16 Kinetics Rigid BodiesDocument30 pages16 Kinetics Rigid BodiesNkoshiEpaphrasShoopalaPas encore d'évaluation

- 2.8 Weight 2023Document13 pages2.8 Weight 2023Xinpei ShimPas encore d'évaluation

- DDP400 Open-Frame and U-Chassis :: ROAL Living EnergyDocument12 pagesDDP400 Open-Frame and U-Chassis :: ROAL Living EnergyroalscribdPas encore d'évaluation

- Math Academy AppDocument4 pagesMath Academy Appkisame1357Pas encore d'évaluation

- 1-A Survey On Mobile Edge Computing: TheCommunication Perspective PDFDocument37 pages1-A Survey On Mobile Edge Computing: TheCommunication Perspective PDFDHRAIEF AminePas encore d'évaluation

- Al-Farabi The Theory of Emanation and THDocument14 pagesAl-Farabi The Theory of Emanation and THManuel Ricardo Fernandes SoaresPas encore d'évaluation

- What Is Trim?: Changed by Moving Masses Already On Board Forward or AFTDocument2 pagesWhat Is Trim?: Changed by Moving Masses Already On Board Forward or AFTamirsyawal87Pas encore d'évaluation

- Control of Concentration in CSTR Using DMC and Conventional Pid Based On Relay Feedback MethodDocument8 pagesControl of Concentration in CSTR Using DMC and Conventional Pid Based On Relay Feedback MethodSadagopan RajaPas encore d'évaluation

- 2.lecture 1-Basics and PrecedenceDocument30 pages2.lecture 1-Basics and PrecedenceBhavesh ReddyPas encore d'évaluation

- Mariners' Polytechnic Colleges Foundation of Canaman, Camarines SurDocument4 pagesMariners' Polytechnic Colleges Foundation of Canaman, Camarines SurKristian-Emman SaratePas encore d'évaluation

- University Insitute of Engineering Electrical EngineeringDocument85 pagesUniversity Insitute of Engineering Electrical EngineeringPyrenean IbexPas encore d'évaluation

- Coding Bobol ExcelDocument4 pagesCoding Bobol ExcelMuhammad IsmunandarsyahPas encore d'évaluation

- Manual For Laying 110-500 KV XLPE Power CablesDocument84 pagesManual For Laying 110-500 KV XLPE Power CablesZoran PetrovićPas encore d'évaluation

- Assigment Sheet Tast 2 Aina MardianaDocument10 pagesAssigment Sheet Tast 2 Aina MardianaAina MardianaPas encore d'évaluation

- Physics Paper 2 Nov 2004Document16 pagesPhysics Paper 2 Nov 2004tommyliuPas encore d'évaluation

- Thermal Engineering For The Construction of Large Concrete Arch DamsDocument10 pagesThermal Engineering For The Construction of Large Concrete Arch DamsOscar LopezPas encore d'évaluation

- Microwave Mini ProjectDocument21 pagesMicrowave Mini Projectfaizan4033Pas encore d'évaluation

- Ic Assignment 2Document1 pageIc Assignment 2Nilven GastardoPas encore d'évaluation

- Combined Gas Law Lab Report HJM ResearchDocument5 pagesCombined Gas Law Lab Report HJM ResearchHelen100% (4)

- Ezy Math Tutoring - Year 5 AnswersDocument168 pagesEzy Math Tutoring - Year 5 AnswersVincents Genesius EvansPas encore d'évaluation

- Quality Control Tests For Emulsions, Syrups, Tinctures, Elixirs, Ointments and OthersDocument11 pagesQuality Control Tests For Emulsions, Syrups, Tinctures, Elixirs, Ointments and OthersMuhammad Masoom Akhtar100% (2)

- Pre - Mid Term Exam Review Class - Fa'18: Michael E. Odigie, PHD, Pe, Cmq/OeDocument89 pagesPre - Mid Term Exam Review Class - Fa'18: Michael E. Odigie, PHD, Pe, Cmq/OemichaelodigiePas encore d'évaluation

- Chapter 5 - Electric FieldDocument5 pagesChapter 5 - Electric FieldTHIÊN LÊ TRẦN THUẬNPas encore d'évaluation

- Tigear - 2 Gearing: Engineering CatalogDocument292 pagesTigear - 2 Gearing: Engineering Catalogrrobles011Pas encore d'évaluation

- Course Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Document14 pagesCourse Syllabus SHS General Physics 1 (Stem, MELC) SY 2021-2022Eushane Chiya SyPas encore d'évaluation