Académique Documents

Professionnel Documents

Culture Documents

Gad b402 10301860

Transféré par

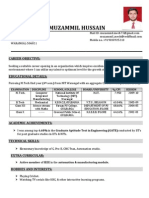

Muzammil HussainDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Gad b402 10301860

Transféré par

Muzammil HussainDroits d'auteur :

Formats disponibles

GAD BRIEF

No. 402 INDUSTRIAL

Using Accumulators for Shock Suppression

Many mobile and industrial applications experience severe shock when a moving part such as a bucket or boom stops suddenly. Quick closing valves or pump start/stop cycles can trigger water hammer-type ripples that travel through the system and that can build to peak pressures well in excess of the normal operating pressure. These shock waves can produce harsh noises or worse, damage upstream components, leading to system failure. Piping can also excite a natural harmonic that resonates throughout the system, again causing damage. a properly designed accumulator can reduce (and in many cases eliminate) the undesired results of the shock. While piston accumulators can be implemented in these systems, more commonly a bladder accumulator is chosen for its quick response. Another method for absorbing shock is to force the oil path through the accumulator. Schematic 2 is representative of Parkers Greer PulseTone that has a baffle in the hydraulic port; the baffle directs the oil into the shell of the bladder accumulator, thereby providing the best protection against shock.

Common Orientations The following three schematics demonstrate the most common orientations of plumbing an accumulator into the system. In Schematic 1, a T-union is installed in the hydraulic line. The accumulator should be installed as close as reasonably possible on the perpendicular branch of the T. Absorbing Shock A wide port on the fluid end of the The incorporation of an accumulator into such systems enables these surges accumulator will provide the best opportunity for the shock to be to be absorbed by the entrapped gas, absorbed by the accumulator. thereby reducing their harmful effects. Application symptoms: 1. Valves closing quickly 2. Cylinder bottoming out and relief, vent or compensator valves not responding quickly enough Regardless of the source of the shock and whether you are designing for it, or it arrives as an unexpected visitor

Schematic 1

Schematic 2

Though the Pulse-Tone has superior shock suppression characteristics, what should you do if your budget does not allow for this component? Schematic 3 shows a third option for plumbing the accumulator into the system. It is a general rule of thumb that this type of installation will take an additional 5% of the shock out of the system.

However, when insufficient data is available to properly size an accumulator for shock, then the following are good guidelines: 1. Use the largest port available. 2. Use a port that matches your line size. 3. Use 60% of the maximum operating pressure for the pre-charge pressure as a starting point.

this will help you understand how your accumulator size will grow with an increase in shock pressure. Varying your pre-charge pressure will alter this calculation, too. 5. The compression ratio should not exceed 4:1 (shock pressure: pre-charge pressure).

Schematic 3

Proper Sizing When sizing for shock, the key factors are the mass and velocity of the fluid in the hydraulic line and the pressure of the shock waves, as demonstrated in the equation and Table of Variables below:

Using these guidelines, you should be able to adequately size an accumulator for shock. And remember to always 4. Make an educated guess as to what call a Parker Global Accumulator your shock pressure is, then plug it Division Application Engineer for into the equation. Repeat with expert guidance, to double-check double your initial shock pressure; your calculations or to ask questions.

Shock Variables

Symbol P2 Pm P1 n g w A L V V1

3

V1 =

P2 (12wAL )( V 2)( n1) P 1 2(g)( P2)

( )

1

1/ n

System Pressure (psi) Shock Pressure (psi) Pre-charge (psi) Discharge Coefficient Acceleration due to Gravity (ft/sec2) Specific Weight of Fluid (lbs/ft ) Effective Flow Area of Pipe (ft ) Length of Pipe (ft) Fluid Velocity (ft/sec) Accumulator Volume (in3)

2

[(

Pm P2

(n-1)/ n

Equation and Table of Variables

See also:

2010 Parker Hannifin Corporation

9/2010

Parker Hannifin Corporation Global Accumulator Division 10711 N Second Street Machesney Park, IL 61115 USA phone 815 636 4100 fax 815 636 4111 www.parker.com/accumulator

Vous aimerez peut-être aussi

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Selection of PumpsDocument8 pagesSelection of Pumpssmohsinshah9492100% (9)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Engineer's Resume SummaryDocument2 pagesEngineer's Resume SummaryMuzammil HussainPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- 005 Women in FisheriesDocument2 pages005 Women in FisheriesMuzammil HussainPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Smart Valve Flow ConditionersDocument4 pagesSmart Valve Flow ConditionersMuzammil HussainPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Carrier Infinity Control Owners ManualDocument35 pagesCarrier Infinity Control Owners ManualsunshineorthodocPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A I R P O R T S Construction Program Management 56Document56 pagesA I R P O R T S Construction Program Management 56Carl WilliamsPas encore d'évaluation

- VBR 50-30-2 Water Heating BattDocument4 pagesVBR 50-30-2 Water Heating BattCsiszer RobertPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Part5 CONCRETE, STEEL AND STRUCTURES PDFDocument284 pagesPart5 CONCRETE, STEEL AND STRUCTURES PDFyassir dafallaPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- QFD ThesisDocument90 pagesQFD ThesisIrshad AliPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- ABIR ProfileDocument30 pagesABIR ProfileMohamad NasserPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Civil Engineering Industrial Training Presentation (Piling Site)Document25 pagesCivil Engineering Industrial Training Presentation (Piling Site)Bshfirnaudz50% (2)

- Ied Product Disassembly Chart 1Document8 pagesIed Product Disassembly Chart 1api-668364903Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Schedule Q (Quality Requirements)Document86 pagesSchedule Q (Quality Requirements)jeswinPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- 8015-0151-SC03-00-000-Cl-RP-00050 - A - Geotechnical Report Template - Pipeline From CPF To WP 11-WQ (II)Document79 pages8015-0151-SC03-00-000-Cl-RP-00050 - A - Geotechnical Report Template - Pipeline From CPF To WP 11-WQ (II)Fabrizio MansuetoPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Ritter Solar GMBH & Co. KGDocument30 pagesRitter Solar GMBH & Co. KGMagdyPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Weld Fit-Up Verification: Employee TrainingDocument10 pagesWeld Fit-Up Verification: Employee TrainingMohammad RizwanPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Polished Concrete Flooring - Metro Mix ConcreteDocument9 pagesPolished Concrete Flooring - Metro Mix ConcreteMetroMix ConcretePas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- 000 - Proj Description - ISSUE - SHEETDocument3 pages000 - Proj Description - ISSUE - SHEETbra9tee9tiniPas encore d'évaluation

- MB4 (Rafter To Corner Column)Document63 pagesMB4 (Rafter To Corner Column)Crystal JanePas encore d'évaluation

- QuizDocument7 pagesQuizVirgilio VelascoPas encore d'évaluation

- PMBI WorkflowDocument3 pagesPMBI WorkflowBrian MiguePas encore d'évaluation

- Chemrite - 540Document2 pagesChemrite - 540ghazanfarPas encore d'évaluation

- Polycarbonate Glazing SystemDocument16 pagesPolycarbonate Glazing SystemGirish DhawanPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- (Asce) Co 1943-7862 0000567Document6 pages(Asce) Co 1943-7862 0000567ilhamPas encore d'évaluation

- Rainwater Tank SolutionsDocument8 pagesRainwater Tank SolutionsGreen Action Sustainable Technology GroupPas encore d'évaluation

- NSW - Design of Reinforced Soil WallsDocument60 pagesNSW - Design of Reinforced Soil WallsJordana FurmanPas encore d'évaluation

- Scrutiny Report of Building PlanDocument7 pagesScrutiny Report of Building PlanSubirBhowmikPas encore d'évaluation

- Strutfast Cable Trays - LRDocument11 pagesStrutfast Cable Trays - LRzimtonyPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Alternator (Bus) Mercedes OM 926 LA: (Europa) (Engine)Document12 pagesAlternator (Bus) Mercedes OM 926 LA: (Europa) (Engine)Karthii AjuPas encore d'évaluation

- IIT Fracture and Fatigue Short CourseDocument248 pagesIIT Fracture and Fatigue Short CourseSumit BasuPas encore d'évaluation

- Design and Construction Specifications 218ppDocument218 pagesDesign and Construction Specifications 218ppGeoff LeachPas encore d'évaluation

- QSB3.3 Parts Catalog 68331277Document91 pagesQSB3.3 Parts Catalog 68331277Галина КарташоваPas encore d'évaluation

- Stress and Strain - Axial Loading2Document33 pagesStress and Strain - Axial Loading2Clackfuik12Pas encore d'évaluation

- 7B AnswerDocument6 pages7B AnswertarasasankaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)