Académique Documents

Professionnel Documents

Culture Documents

The Basics of Electrophotography

Transféré par

Maks ProstDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Basics of Electrophotography

Transféré par

Maks ProstDroits d'auteur :

Formats disponibles

The Basics of Electrophotography

For Canon-based Systems

The accepted definition of electrophotography, as listed in the Random House Unabridged Dictionary (1993), is photography using electric rather than chemical processes to transfer an image onto paper, as in xerography. Xerography is then identified as an electrostatic printing process for copying text or graphics whereby areas on a sheet of paper corresponding to the image areas of the original are sensitized with a charge of static electricity so that, when powdered with a toner carrying an opposite charge, only the charged areas retain the toner, which is then fused to the paper to make it permanent. So how is this accomplished (in plain english)? There are basically seven (7) steps in the process, once the laser printer or copier has been turned on and gone through a short warming-up period. This allows time for the upper fuser roller to heat to the proper fusing temperature, and will vary with the type of equipment being used. The seven steps, for Canon-based systems, are as follows:

The Seven Step Imaging Process

Negative Charge PCR

1 Charging

The process begins with the charging of the organic photo conductor (OPC drum) by the primary charge roller (PCR). A constant flow of electrical current from the PCR produces an even blanket of negative charge on the surface of the rotating drum.

Drum

The laser passes through an opening in the cartridge and PCR focuses on the evenly charged drum surface. As the drum rotates the focused Drum beam of the laser scans across the drum, emitting light and discharging the drum in the pattern of the image and/or characters to be printed. This writing to the drum leaves a positively charged latent image on the drum surface (its there, but you cant see it yet).

Latent Image

Laser

2 Exposure

1999, Static Control Components, Inc. All rights reserved worldwide.

System Support Series 104 / The Fundamentals of Electrophotography

The illustration below is a schematic view of the EX/LJ4, LJ5 cartridge imaging components from the left side of the cartridge. The cartridge is oriented as it would appear installed in the printer.

Magnetic (Developer) Roller Doctor Blade Primary Charge Roller (PCR) Laser

Wiper Blade Drum Shutter (open)

Toner Hopper

Upper Fuser Roller

Waste Bin Agitator Bar Toner Paper Path Recovery Blade Transfer Zone Transfer Roller OPC Drum Development Zone (Station) Toner Low Sensor Bar Seal Channel

Paper Path

Lower Pressure Roller

Page 2

1999, Static Control Components, Inc. All rights reserved worldwide.

System Support Series 104 / The Fundamentals of Electrophotography

The Seven Step Imaging Process

Laser Doctor Blade

3 Development

Fused Toner Upper Fuser Roller

5 Fusing

The paper, along with the transferred toner image, then travels beyond the transfer roller, and outside of the cartridge. Here it Paper Lower becomes sandwiched Path Pressure between the fuser assemRoller bly, composed of an upper fuser roller and a lower pressure roller. Heat is applied by the upper roller, fusing the toner into the paper, while the lower roller applies pressure, imbedding the toner into the paper fibers. The paper cools as it exits the printer with the clean image fixed to the page. If the paper is removed before is has passed between these two rollers, as when a paper jam occurs, the image can be easily wiped or even blown off the paper.

There is a small gap between the doctor blade, or leveling blade, and Toner the magnetic developer roller (mag roller). As Mag toner is magnetically Roller Drum attracted to the mag roller it bunches up behind the doctor blade, Development Zone trying to get through this gap. The friction created by these bunched particles rubbing against one another results in a negative charge build-up on the individual toner particles. This is called the triboelectric charge. Since both the toner and mag roller are charged negatively the toner is repelled (pushed) toward the positively charged areas of the drum (the latent image). The negatively charged areas of the drum (blank areas) also repel toner, leaving only the image on the drum dusted with toner particles. This occurs in an area of the cartridge called the development zone or development station.

6 Cleaning

As the drum continues to rotate it passes under the wiper blade, which removes debris (excess Drum toner, paper fibers, etc.) from the drum. The recovery blade, located at the base of the waste bin acts Recovery Paper Blade Path as a toner dam, catching the debris as it falls from the drum and wiper blade. Also called a catcher or scavenger blade the recovery blade prevents excess toner, paper fibers, carrying agents and other foreign materials from falling out of the waste bin onto the paper.

Wiper Blade

4 Transferring

The transfer roller, which carries a positive charge, is located inside the printer Drum and is not a part of the cartridge. The paper travels on a path between the Image OPC drum and this roller. The toner-covered image Transfer Paper on the surface of the drum Roller Path is moved down toward the paper by the rotation of the drum. The positive charge of the transfer roller attracts the negatively charged toner, pulling it off the drum and down onto the paper.

Residual Charge PCR Laser Mag Roller

7 Erasure

The PCR erases any remaining positive charge from the OPC drum by applying a uniform negative surface charge to the drum. This removes the image and cleans, or blanks the drum for its next pass under the laser, where it will be written with the next image.

Page 3

Drum

1999, Static Control Components, Inc. All rights reserved worldwide.

System Support Series 104 / The Fundamentals of Electrophotography

Terms and Definitions

Agitator Bar

A thin metal bar that rotates inside the toner hopper, moving toner towards the development station.

Pull Tab (not shown)

A plastic tab attached to the seal pull strip to enable the end user to remove the seal pull strip, releasing toner into the development station.

Development Station

The area of the cartridge where toner is transferred from the toner hopper to the latent image on the OPC drum using the mag roller and doctor blade.

Recovery Blade

Acts as a dam at the base of the waste bin, preventing the toner, paper fibers and other materials from falling out of the waste bin onto the paper. Also called a catcher blade or scavenger blade.

Doctor Blade

Uniformly meters the amount of toner reaching the mag roller. Also called a metering blade or leveling blade, it is made of a precision ground metal base and a flexible blade. The doctor blade is instrumental in helping the toner particles achieve their negative charge build-up.

Seal (not shown)

A rigid gasket base with a seal attached, which acts as a toner dam to prevent leakage during shipping. The base is attached to the toner hopper sealing surface, and is removed by the user upon installation of the cartridge.

Drum Shutter

When the cartridge is not installed in the printer the shutter remains closed to protect the OPC drum from possible damage from scratches, exposure to light , etc..

Seal Channel

The area between the mag roller and hopper sections in which a seal is installed. The seal also lies in this channel, and is removed through this opening upon installation of the cartridge in the printer.

Laser

The concentrated beam of light that writes the image to the OPC drum, one line at a time.

Toner

Made up of iron oxide, silicates, coloring and iron oxide (carrying agents), this is the material that makes up the printed image.

Lower Pressure Roller

A printer component. Applies pressure to the paper as it passes through the printer to help fix the toner onto the paper.

Toner Hopper

Area of the cartridge where the unused toner is stored.

Toner Low Sensor Bar Magnetic Developer Roller (mag roller)

A coated aluminum sleeve rotating around a stationary magnet, the mag roller attracts toner, which is held onto the sleeve by the inner magnet. Together the mag roller and doctor blade charge the toner. Also called a developer roller. A metal bar which acts as an antenna to detect low toner volume in the hopper. Once a signal from the antenna reaches a specified value, the printer displays a toner low warning for the printer operator.

Transfer Roller

A printer component, pulls the toner down to the paper by way of a magnetic charge opposite to that of the OPC drum.

OPC Drum

Delivers the toner to the paper. Carries an opposite charge from that of the mag roller in order to attract the toner from the mag roller.

Upper Fuser Roller

A printer component, applies heat to the paper to fix the toner to the paper.

Paper Path

The direction in which the paper moves through the printer.

Waste Bin

Area of the cartridge where the excess toner, paper fibers and other materials are deposited by the recovery blade. Also called a waste hopper or dust bin.

Primary Charge Roller (PCR)

Uniformly charges the OPC drum., which erases the image and prepares it to be written with the next image. Also called the PCR, charge roller, roller, or the eraser.

Wiper Blade

Cleans excess materials that were not transferred to the paper from the OPC Drum , depositing them into the waste bin. Also called a cleaning blade, it is made of a metal base and polyurethane blade.

STATIC CONTROL COMPONENTS, INC.

SCC Imaging Division

3010 Lee Avenue PO Box 152 Sanford, NC 27331 US/Can 800.488.2426 US/Can Fax 800.488.2452 Intl 919.774.3808 Intl Fax 919.774.1287 www.scc-inc.com

Static Control Components (Europe) Limited

Unit 32, Suttons Business Park Suttons Park Avenue Earley Reading Berkshire RG6 1AZ United Kingdom Tel +44 (0) 118 935 1888 Fax +44 (0) 118 935 1177 www.scc-inc.com

#860 1999 Static Control Components, Inc. All rights reserved worldwide. The stylized S is a registered trademark of Static Control Components, Inc.

Vous aimerez peut-être aussi

- Boardview NM-A381 R02-SILK TOPDocument1 pageBoardview NM-A381 R02-SILK TOPMaks ProstPas encore d'évaluation

- ECOSYS M2030dn M2530dn M2035dn M2535dn SM UKDocument273 pagesECOSYS M2030dn M2530dn M2035dn M2535dn SM UKMaks Prost60% (5)

- RT8204-DS8204-06 Single Synchronous Buck With LDO ControllerDocument19 pagesRT8204-DS8204-06 Single Synchronous Buck With LDO ControllerMaks ProstPas encore d'évaluation

- IBM Thinkpad Z61 (Quanta BW2)Document80 pagesIBM Thinkpad Z61 (Quanta BW2)Maks ProstPas encore d'évaluation

- Parts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Document40 pagesParts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Maks ProstPas encore d'évaluation

- FS-1030MFP FS-1030MFP/DP FS-1130MFP FS-1035MFP/DP FS-1135MFP ECOSYS M2030dn/PN ECOSYS M2030dn ECOSYS M2530dn ECOSYS M2035dn ECOSYS M2535dnDocument46 pagesFS-1030MFP FS-1030MFP/DP FS-1130MFP FS-1035MFP/DP FS-1135MFP ECOSYS M2030dn/PN ECOSYS M2030dn ECOSYS M2530dn ECOSYS M2035dn ECOSYS M2535dnMaks ProstPas encore d'évaluation

- Parts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Document40 pagesParts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Maks ProstPas encore d'évaluation

- Parts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Document40 pagesParts Reference List: Model: DCP-8080DN / DCP-8085DN / MFC-8480DN / MFC-8680DN / MFC-80D: /MFC-888DN MFC-88 D1+ 0) &'Maks ProstPas encore d'évaluation

- Konica Minolta Bizhub 163 - 7616 Parts ManualDocument60 pagesKonica Minolta Bizhub 163 - 7616 Parts ManualgamatoysPas encore d'évaluation

- Konica Minolta Buzhup 164 184 Parts Guide ManualDocument47 pagesKonica Minolta Buzhup 164 184 Parts Guide ManualMaks ProstPas encore d'évaluation

- Technical Information On Drum Matching LG ChemDocument9 pagesTechnical Information On Drum Matching LG ChemMaks ProstPas encore d'évaluation

- Xerox Phaser 6100 Parts & ServiceDocument216 pagesXerox Phaser 6100 Parts & ServiceMaks ProstPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Canvas Integration GuideDocument27 pagesCanvas Integration GuideValerie BossPas encore d'évaluation

- MU-MIMO in LTEDocument13 pagesMU-MIMO in LTECM_123Pas encore d'évaluation

- Chapter Eighteen: Creating Competitive AdvantageDocument34 pagesChapter Eighteen: Creating Competitive AdvantageSana MehmoodPas encore d'évaluation

- Data Management: Quantifying Data & Planning Your AnalysisDocument38 pagesData Management: Quantifying Data & Planning Your AnalysisSaqlain TariqPas encore d'évaluation

- SAP OKES - Splitting StructureDocument9 pagesSAP OKES - Splitting StructureneoclessPas encore d'évaluation

- Primus Iron MachineDocument67 pagesPrimus Iron MachineKonstantinos Politis100% (1)

- What Is A BW WorkspaceDocument8 pagesWhat Is A BW Workspacetfaruq_Pas encore d'évaluation

- Types and Construction of Biogas PlantDocument36 pagesTypes and Construction of Biogas Plantadeel_jamel100% (3)

- Open Bible Stories EmdcDocument25 pagesOpen Bible Stories Emdcdebnathsuman49Pas encore d'évaluation

- Introduction To Politics SyllabusDocument10 pagesIntroduction To Politics SyllabusJoey BeetzPas encore d'évaluation

- Chapter 7 Part B Automatic Transmission: Band AdjustmentsDocument8 pagesChapter 7 Part B Automatic Transmission: Band AdjustmentsSandorPas encore d'évaluation

- Dual Prime Source Datasheet 1Document1 pageDual Prime Source Datasheet 1EstebanPas encore d'évaluation

- Module 4-STS Espinas Bsat 1-1Document2 pagesModule 4-STS Espinas Bsat 1-1Joseph Daniel EspinasPas encore d'évaluation

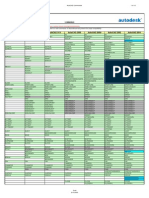

- Autocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004Document12 pagesAutocad R12 Autocad R13 Autocad R14 Autocad 2000 Autocad 2000I Autocad 2002 Autocad 2004veteranul13Pas encore d'évaluation

- YUI 2.7 Cheat Sheets ConcatenatedDocument41 pagesYUI 2.7 Cheat Sheets Concatenatedcron112Pas encore d'évaluation

- Trafo Manual ABBDocument104 pagesTrafo Manual ABBMarcos SebastianPas encore d'évaluation

- VIJAYDocument61 pagesVIJAYYOGESH CHAUHANPas encore d'évaluation

- Transmision Q7 0C8 PDFDocument139 pagesTransmision Q7 0C8 PDFAlberto Morillas PueblaPas encore d'évaluation

- Nift Panchkula Thesis Gaurav Bajaj 2009 Uar 646Document10 pagesNift Panchkula Thesis Gaurav Bajaj 2009 Uar 646vedahiPas encore d'évaluation

- Generator Hydrogen Cooling InfoDocument21 pagesGenerator Hydrogen Cooling InfovarsbsPas encore d'évaluation

- ToraycaDocument1 pageToraycaAnonymous NFsIMHyfLtPas encore d'évaluation

- Mechanics Guidelines 23 Div ST Fair ExhibitDocument8 pagesMechanics Guidelines 23 Div ST Fair ExhibitMarilyn GarciaPas encore d'évaluation

- Perdele Economic B 2VVDocument4 pagesPerdele Economic B 2VVakitainupufPas encore d'évaluation

- TDS LF-361Document2 pagesTDS LF-361ofershochetPas encore d'évaluation

- Regulation JigDocument16 pagesRegulation JigMichaelZaratePas encore d'évaluation

- 2005 TJ BodyDocument214 pages2005 TJ BodyArt Doe100% (1)

- D300D Articulated Truck Electrical System: 5MG1-UPDocument2 pagesD300D Articulated Truck Electrical System: 5MG1-UPCarlos IrabedraPas encore d'évaluation

- Requirements For Transferees FinalDocument29 pagesRequirements For Transferees FinalKaren GedalangaPas encore d'évaluation

- Compact and Reliable Switching - Smaller, More Efficient and Simpler Gas-Insulated Switchgear (GIS)Document6 pagesCompact and Reliable Switching - Smaller, More Efficient and Simpler Gas-Insulated Switchgear (GIS)qxzyPas encore d'évaluation

- Information Leaflet: 1. Introduction To PieasDocument4 pagesInformation Leaflet: 1. Introduction To Pieascensored126Pas encore d'évaluation