Académique Documents

Professionnel Documents

Culture Documents

COAL HANDLING Tech. Information Auto Saved)

Transféré par

R G Sanjay PrakashDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

COAL HANDLING Tech. Information Auto Saved)

Transféré par

R G Sanjay PrakashDroits d'auteur :

Formats disponibles

COAL HANDLING PLANT Introduction

Coal Handling Plant (CHP) is a plant which handles the coal from its receipt to transferring or conveying it to Boiler House and storing in Raw Coal Bunkers (R.C.Bunkers). Average size of Coal received in CHP is 300-400 mm, which is called Received off Mine (ROM) size.

Functional Work in Coal Handling Plant (CHP):

In brief it can be stated that Coal Handling Plant performs the following main functional work sequentially:

Receipt of coal in CHP from coal mines Different ways of Coal Transportation from mines Weighing of coal by Electronic Weighing Machine Unloading of coal form wagon or truck by Wagon Tipplers

Controlling coal flow on conveyor belt by Vibrating Feeder

Transferring or conveying of coal to different points by Conveyor Belts Storing & Stacking of uncrushed coal in coal yard by Stacker cum Reclaimer Coal Screening for separating sized coal and by passing the crusher by Vibrating Screen Crushing it to required size Coal Crushers Transferring & distributing the quanta of crushed coal to various coal mill bunkers by Travelling Trippers

Major Equipments of CHP:1. Wagon Tipplers 2. Vibrating Feeders 3. Conveyor Belts 4. Vibrating Screen 5. Coal Crushers 6. Travelling Trippers

Auxiliaries in Coal Handling Plant

1. Electromagnetic Separators, Cross Belt Magnetic Separator (CBMS) & Magnetic Pulley 2. Metal Detector 3. Dust extraction systems

4. Gas Extractor 5. Pull Cord

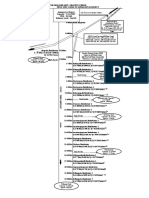

BASIC FUNCTIONAL LAYOUT OF CHP:

BASIC FUNCTIONAL LAYOUT OF CHP:

COAL HANDLING PLANT

1000 TPH Coal Handling Plant at Durgapur Projects Power Station, Extn. Unit #7 (1 x 300 MW) including Track Hopper with Paddle feeder, Crushing & Screening, Stacker cum Reclaimer and Belt Conveying System with associated Electrical, Civil & Structural and Utility work for Durgapur Projects Limited.

1 X 300 MW Durgapur Project Power Station

Wagon Tipplers:These are the giant machines having gear boxes and motor assembly and are used to unload the coal wagons into coal hoppers in very less time (e.g. 20 wagons/hr. or more).

Vibrating Feeders:These are electromagnetic vibrating feeders or sometimes in the form of dragging chains (Apron Type) Vibrating Feeder which are provided below the coal hoppers. This equipment is used for controlled removal of coal from coal hoppers.

Electromagnetic Vibrating feeding system

A vibratory feeding system includes a hopper, a tray and an electromagnetic vibrator. The hopper is disposed above the tray so that components can flow from the hopper to the tray. The vibrator is mounted to the tray. During operation, an electromagnet is rapidly energized and de-

energized causing an armature of the drive assembly to be pulled in and released up to 7,200 times per minute, in turn imparting a vertical reciprocating vibration to the support platform so that the tray can be vibrated to move components along the tray. The tray can

have a v-groove along which the plurality of components can flow.

Belt Conveyor System:Belt conveyor System is a kind of machine that to transfer the material continuously. It has the synthetic rubber belts which move on metallic rollers called idlers with the help of belt drive (pulleys). It is used in Coal Handling Plant for shifting of coal from one place to other places The belt works under the effect of frictional force. It is not only the components to transfer the material, but also the components to transfer the force.

Conveyor Belt system consists of the following components: 1. Conveyor Belt- internal Cotton canvas or Synthetic canvas or metal wire canvas impregnated with rubber covers on both face and back. 2. Pulley drive system having Drive or Head pulley with Motor, Tail Pulley, Bend Pulleys & Snub Pulley 3. Idlers 4. Gravity Take up system or Belt tensioning system 5. Belt cleaning or wiping system 6. Gear Box 7. Fluid Coupling

CONVEYOR IDLERS

TROUGHING IDLER

TROUGHING TRAINING IDLERS

IPMACT IDLER & ITS POLLAR

RETUTN IDLER

Vibrating Screen

Coal Crushers:We receive the coal in the form of odd shaped lumps. These lumps are to be crushed to required size. These lumps are crushed by coal crushers.

Trippers:These are the motorized or manually operated machines and are used for feeding the coal to different coal bunkers as per their requirement. Electromagnetic Separators:Electromagnets are used for removing of Iron and magnetic impurities from the coal. Dust Extraction System:This system is provided in CHP for suppression of coal dust in coal handling plant. Gas Extractors:Gas extractors are provided at the bunker level to remove all types of poisonous and non poisonous gases from the working area. Operational Cycles:1. Normal Bunkering cycle. 2. Stacking cycle. 3. Reclaiming Cycle. Normal Bunkering Cycle:Shifting of coal received from coal wagons directly to coal bunkers is normal bunkering cycle. Stacking Cycle:When there is no coal requirement at coal bunkers even then CHP has to unload the received coal which is stacked at open ground called yard. This is stacking cycle. Reclaiming Cycle:As and when coal wagons are not available the requirement of coal bunkers is fulfilled from the stacked coal this is reclaiming cycle. Weighing of Coal:Weighing of coal is carried out at wagon tippler. Weight of loaded wagon is taken; after unloading the coal, weight of empty wagon is taken the difference of the two will give the weight of the coal (normally 55-60 metric ton of coal come in each wagon). Payment of Coal:Payment of coal is made to the coalmines as per the weighing of coal carried out at their premises. However, if any dispute arises regarding weighing of coal same is to be settled by the committee of both the parties. Stone shells:Sometimes stone shells are received along with coal same has to be removed from the coal before bunkering and is done sometimes manually or by different type of machines. If quantum of stone shells is beyond minimum limit the cost of the coal is recovered from the coal mines against the quantity of stone shells received from them.

Chemical Analysis of Coal:Sample of coal is randomly collected from each rake by concerned MSEB staff and detailed chemical analysis, calculation of calorific value is carried out and is confirmed whether it is as per agreement with the coal mines or not.

Vous aimerez peut-être aussi

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsD'EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsPas encore d'évaluation

- Scientific American Supplement, No. 312, December 24, 1881D'EverandScientific American Supplement, No. 312, December 24, 1881Pas encore d'évaluation

- Coal Handling PLantDocument8 pagesCoal Handling PLantPrasanna kumar subudhiPas encore d'évaluation

- Coal Handling ModifiedDocument135 pagesCoal Handling ModifiedGaurav KumarPas encore d'évaluation

- CHP For EET-r2Document41 pagesCHP For EET-r2pntripathiPas encore d'évaluation

- Captive Power Plants: Boiler Feedwater PumpDocument22 pagesCaptive Power Plants: Boiler Feedwater PumpJitendra KarwePas encore d'évaluation

- Coal Handling Plant Maintenance and Operation PhilosophyDocument31 pagesCoal Handling Plant Maintenance and Operation PhilosophyJitu Jena100% (1)

- Balance of Plant DetailsDocument11 pagesBalance of Plant Detailskvrao44Pas encore d'évaluation

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocument10 pages10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulPas encore d'évaluation

- AshuDocument34 pagesAshuachint111Pas encore d'évaluation

- Thermal Power Plant ReportDocument26 pagesThermal Power Plant ReportStudent of NIT PATNAPas encore d'évaluation

- Coal Handling PlantDocument47 pagesCoal Handling PlantRajat Sharma100% (1)

- Introduction To Coal Handling PlantDocument5 pagesIntroduction To Coal Handling Plantanand ambaniPas encore d'évaluation

- Final PPT NTPC Dadri by VikasDocument50 pagesFinal PPT NTPC Dadri by VikasTushar PandeyPas encore d'évaluation

- Notes Ppe 16 17Document108 pagesNotes Ppe 16 17rudresh JmPas encore d'évaluation

- Training Report IpgclDocument50 pagesTraining Report IpgclSahil SinghalPas encore d'évaluation

- Coal Handling 1Document18 pagesCoal Handling 1pupung182Pas encore d'évaluation

- 210 MW PowerplantDocument63 pages210 MW PowerplantPratik Makwana100% (1)

- Power Plant EnggDocument23 pagesPower Plant EnggMahesh KumarPas encore d'évaluation

- Ppe Notes Viii Sem M2Document79 pagesPpe Notes Viii Sem M2anusha meesalaPas encore d'évaluation

- Coal Handling PlantDocument39 pagesCoal Handling PlantMukhtar AlamPas encore d'évaluation

- Off - Site Facilities Coal Transportation Handling: 1 June 2010 PMI Revision 00 1Document40 pagesOff - Site Facilities Coal Transportation Handling: 1 June 2010 PMI Revision 00 1Ezhil Vendhan PalanisamyPas encore d'évaluation

- A. Indira National Power Training InstituteDocument80 pagesA. Indira National Power Training InstituteAyan MajiPas encore d'évaluation

- Presentation On Coal Handling Systems: Prepared By:-Arnab Chakraborty Mba-PmDocument16 pagesPresentation On Coal Handling Systems: Prepared By:-Arnab Chakraborty Mba-PmIgnatius SamrajPas encore d'évaluation

- CEA - Standard - Design CRITERIA - CHPDocument29 pagesCEA - Standard - Design CRITERIA - CHPB DASPas encore d'évaluation

- Thermal Power Plant: M.Vijayaragavan Assistant Professor Mailam Engineering College MailamDocument44 pagesThermal Power Plant: M.Vijayaragavan Assistant Professor Mailam Engineering College MailampanthamangalamPas encore d'évaluation

- Power Plant Engineering (SMEX1016) 1Document60 pagesPower Plant Engineering (SMEX1016) 1shyam sundarPas encore d'évaluation

- 28 01 12 Eges Mini Steel PlantDocument21 pages28 01 12 Eges Mini Steel PlantElafanPas encore d'évaluation

- Index: Bandel Thermal Power Station Project Report 2009-2010Document46 pagesIndex: Bandel Thermal Power Station Project Report 2009-2010Debaditya Nath100% (1)

- Coal Handling System: Shaikh SaifDocument30 pagesCoal Handling System: Shaikh SaifKrishna SinghPas encore d'évaluation

- SMEA1403Document157 pagesSMEA1403rrpatil1221Pas encore d'évaluation

- Coal Handling PlantDocument40 pagesCoal Handling PlantAshwani Dogra80% (5)

- Coal Transportation and HandlingDocument40 pagesCoal Transportation and HandlingVinothPas encore d'évaluation

- National Thermal Power Corporation 3Document46 pagesNational Thermal Power Corporation 3Navlesh SharmaPas encore d'évaluation

- Tata Power 2Document39 pagesTata Power 2Sourav Kumar100% (1)

- CHPP FieldtripDocument33 pagesCHPP FieldtripsurajkgpPas encore d'évaluation

- Coal Handling PlantDocument38 pagesCoal Handling Plantcp6355100% (3)

- EE16104 L05 Steam Power Plant1Document42 pagesEE16104 L05 Steam Power Plant1Pratiksha AnuragiPas encore d'évaluation

- Index: History of GSECL ...................................................Document54 pagesIndex: History of GSECL ...................................................EE-02-Mosef MansuriPas encore d'évaluation

- NTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I IDocument44 pagesNTPC (National Thermal Power Corporation) Sipat Mechanical Vocational Training Report 4-Haxxo24 I Ihaxxo24Pas encore d'évaluation

- Coal r2Document9 pagesCoal r2pcpathikPas encore d'évaluation

- Basic Power Plant PDFDocument21 pagesBasic Power Plant PDFAntony ClarancePas encore d'évaluation

- 1 1general OverviewDocument30 pages1 1general OverviewpcpathikPas encore d'évaluation

- A Case Study: Sea Borne Coal Handling System For 500 MW Power PlantDocument3 pagesA Case Study: Sea Borne Coal Handling System For 500 MW Power PlantSuhasPas encore d'évaluation

- Research and Design of Coal PLC Control System in Coal-Fired Power PlantsDocument8 pagesResearch and Design of Coal PLC Control System in Coal-Fired Power PlantsĐặng Trung AnhPas encore d'évaluation

- Coal Handling Plant in A Thermal Power Generating StationDocument3 pagesCoal Handling Plant in A Thermal Power Generating StationManuel HenriquezPas encore d'évaluation

- WK 10 - Material Handling System (Conveyors) 2t 2020-2021Document65 pagesWK 10 - Material Handling System (Conveyors) 2t 2020-2021Mei Lamfao100% (1)

- Index: Bandel Thermal Power Station Project 2009-2010Document41 pagesIndex: Bandel Thermal Power Station Project 2009-2010gsrawat123Pas encore d'évaluation

- Coal Yard, CHS, AhsDocument30 pagesCoal Yard, CHS, AhsFatimah Shohina PutriPas encore d'évaluation

- Thermal Power PPT 1274193706 Phpapp02Document31 pagesThermal Power PPT 1274193706 Phpapp02bjswamyPas encore d'évaluation

- NTPCDocument17 pagesNTPCSahil AroraPas encore d'évaluation

- Coal Based Power PlantDocument41 pagesCoal Based Power Plant94gaurav100% (1)

- Rotary Discharge MachineDocument20 pagesRotary Discharge MachineMechatronics EngineeringPas encore d'évaluation

- Summer Training ReportDocument21 pagesSummer Training Reportaj_anmolPas encore d'évaluation

- Ilovepdf MergedDocument49 pagesIlovepdf MergedParmar AkshatsinhPas encore d'évaluation

- Introduction To Coal Handling PlantDocument12 pagesIntroduction To Coal Handling PlantPramod R BidvePas encore d'évaluation

- Kota Super Thermal Power PlantDocument29 pagesKota Super Thermal Power Plantatul mishra75% (4)

- Thermal Power PlantDocument73 pagesThermal Power PlantRitwik JaiswalPas encore d'évaluation

- WasheryDocument4 pagesWasherysaisssms9116Pas encore d'évaluation

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshD'EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshPas encore d'évaluation

- Refrigerator: Owner S Instructions SR-17NFB SR-19NFB SR-22NFBDocument18 pagesRefrigerator: Owner S Instructions SR-17NFB SR-19NFB SR-22NFBjchunga_lauPas encore d'évaluation

- Department of Education: Financial ReportDocument6 pagesDepartment of Education: Financial Reportchinn rabanes legaspiPas encore d'évaluation

- Original Bill Required at Destination: ShipperDocument1 pageOriginal Bill Required at Destination: ShipperEmma SinotransPas encore d'évaluation

- The Geep Is A General Purpose Vehicle!Document2 pagesThe Geep Is A General Purpose Vehicle!Marlin ZamoraPas encore d'évaluation

- Multi Wing Product Overview 2013Document12 pagesMulti Wing Product Overview 2013dharmeswarPas encore d'évaluation

- Computation of Stresses in Bridge Slabs Due To Wheel LoadsDocument43 pagesComputation of Stresses in Bridge Slabs Due To Wheel LoadsLuoYun100% (1)

- RepetMat U08 Kartk Slow Podst BDocument1 pageRepetMat U08 Kartk Slow Podst BKamila ZarzeckaPas encore d'évaluation

- Conoco Phillips - Engineering Numbering Systems (COPENS) - Document No. 2169 Rev9Document236 pagesConoco Phillips - Engineering Numbering Systems (COPENS) - Document No. 2169 Rev9Javeed A. Khan50% (2)

- Active Importers As of June 02 2015Document1 325 pagesActive Importers As of June 02 2015Melvin Banzon88% (8)

- AboutDocument3 pagesAboutTushar SharmaPas encore d'évaluation

- CHUYÊN ĐỀ 2- SUBJECT AND VERB AGREEMENTDocument5 pagesCHUYÊN ĐỀ 2- SUBJECT AND VERB AGREEMENTNguyễn Hà LinhPas encore d'évaluation

- The Merchant Shipping (Amendment) Bill 2022Document7 pagesThe Merchant Shipping (Amendment) Bill 2022Ashokk550Pas encore d'évaluation

- Lifting Handling Instructions For Horizontal TanksDocument4 pagesLifting Handling Instructions For Horizontal TanksJitendra YadavPas encore d'évaluation

- Chapter 4 - Supply Chain ManagementDocument30 pagesChapter 4 - Supply Chain ManagementAinatul Alia AlliasPas encore d'évaluation

- FR Error MercyDocument5 pagesFR Error MercyNoeRtjahya Ahmad100% (1)

- Fuel System Safety: Presented By: Tony HeatherDocument40 pagesFuel System Safety: Presented By: Tony HeatherABDELRHMAN ALIPas encore d'évaluation

- ECS-LO-4 Online-WrittenDocument11 pagesECS-LO-4 Online-WrittenM.Kishore Kumar100% (3)

- Far FA1200-5300047040 DespieceDocument6 pagesFar FA1200-5300047040 DespieceAna Guerrero LopezPas encore d'évaluation

- Earth Moving EquipmentDocument24 pagesEarth Moving EquipmentAbhishek Sinha100% (1)

- Domestic Gas PipingDocument30 pagesDomestic Gas Pipingmitasyahu50% (2)

- Ford Citroën AustinDocument2 pagesFord Citroën AustinMonsieur lapaditPas encore d'évaluation

- BMBS For Freight Stock-SKDocument25 pagesBMBS For Freight Stock-SKSoumen BhattaPas encore d'évaluation

- 3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementDocument56 pages3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementFATIN NABILA100% (1)

- Annamayya Project Capacity: 2.234 TMC FRL: 203.600 Delivery Level: 204.600Document1 pageAnnamayya Project Capacity: 2.234 TMC FRL: 203.600 Delivery Level: 204.600Guru MogaralaPas encore d'évaluation

- Caterpillar Performance Handbook 49 62020 Partie3Document4 pagesCaterpillar Performance Handbook 49 62020 Partie3ali alilouPas encore d'évaluation

- Certified True Copy: Bill of Lading For Ocean Transport or Multimodal TransportDocument4 pagesCertified True Copy: Bill of Lading For Ocean Transport or Multimodal TransportAndrea MuñozPas encore d'évaluation

- Work Mixture DistanceDocument7 pagesWork Mixture DistanceJerry LicayanPas encore d'évaluation

- Installation of Underground PipingDocument6 pagesInstallation of Underground PipingAngling DharmaPas encore d'évaluation

- Caustic Soda Feasibility StudyDocument75 pagesCaustic Soda Feasibility StudyMarcos Gonzalez50% (2)

- Haris2016 2Document5 pagesHaris2016 2VanHieu LuyenPas encore d'évaluation