Académique Documents

Professionnel Documents

Culture Documents

Lead Engineer

Transféré par

api-121412605Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lead Engineer

Transféré par

api-121412605Droits d'auteur :

Formats disponibles

KARL BREITER 2919 E. Kentucky Ave., Holladay, Utah 84117 kb12f45dc@westpost.

net (801) 278-5416

CHIEF ENGINEER Design & Development / Manufacturing - Engineering Liaison / Operations / Vendor Coordination Program-Project-Product Management / TQM / Cost Control / Design & Process Impro vement As an experienced engineer who uniquely combines design, fabrication, and operat ions expertise with business acumen, I have developed and implemented creative s olutions to seemingly intractable engineering problems. My experience encompasse s creation and manufacturing of large and small products from conception through build. I have developed and put in place strategies to cut costs, streamline operations , preserve lucrative contracts and enhance the bottom line. Employing next-gener ation technologies, I build and lead cross-functional teams for consistently suc cessful large government contract design and fabrication programs. Developing and implementing resourceful engineering solutions Leading programs/projects to on-target completion Creating testing procedures to ensure functionality Improving operational and manufacturing processes With a proven record of success, I have won numerous awards including 12 Team Re cognition awards, three Creating Value cost-savings awards, three Saving Achieve ment awards, and a Superior Contributor award. My BS degree in Aerospace Enginee ring is from Pennsylvania State University. SELECTED ACCOMPLISHMENTS Slashed parts rejection rate. Problems with the forging/heat treatment process o f large steel parts was negatively impacting ATKs ability to meet performance an d safety standards. Developed and implemented testing processes that identified problem areas. Initiated cost-effective solution that saved $600K per year. Created new design for key next-generation Space Shuttle part. The ability to me et the re-use requirement for metal parts in the new shuttle was in doubt. The p arts could be easily assembled, but not disassembled. Proposed change to interna l joints allowing disassembly as needed. New design was adopted, preserving $2M contract. Redesigned shuttle booster component. ATK took over a contract for small rocket booster motors. Previous vendors case design was overly complex and prevented re pair if necessary. Evaluated problem and redesigned machining processes allowing for parts interchangeability and repair. Reduced scrap rate and saved $1.5M per . Identified and solved manufacturing problem. ATK discovered manufacturing vendor had mis-machined 18 large shuttle booster parts resulting in an inability to re -use the parts (a contract requirement). Led investigation team and identified r oot-cause of problem. Designed and implemented $450 solution that saved $1.9M. Developed tool recycle plan. ATK kept old obsolete tooling at various vendors, c osting thousand of dollars to store and maintain. Key member of team to identify

what could be reused or modified and what was junk. Developed and implemented t ool reuse plan, saving company $500K and winning major cost-saving award. Redesigned O-rings for next generation space shuttle. ATKs contract for O-rings required that they perform at low temperatures. Led team to develop test on full -scale booster demonstration to prove ability to meet reliability requirements. Product successful passed, ensuring timely shuttle launches, avoiding $1M per la unch delay loss. CAREER HISTORY ATK Launch Systems, $1B aerospace and defense manufacturer. Chief Engineer, Ares Project Engineering, 2007 to 2010. Directed metal components and sealing for next generation Space Shuttle. for design team. Built and led cross functional teams of made up nalysts, production, quality, and management. Managed budgets up engineering for Set priorities of engineers, a to $3M.

Senior Engineering/Scientist, Design Engineering, 1991 to 2007. Responsible for design and testing of new and future metal hardware for various technical progra ms. Design/fabrication and re-use engineering requirements development and imple mentation. Managed team of three engineers. Earlier: Started as Lead/Principal Engineer, R&D, Design Engineering for Hercule s Aerospace. Responsible for design, fabrication, and monitoring of graphite/met al sub-assemblies. Outside Interests: In my free time I enjoy golf, hiking, camping, skiing, music, and sports.

Vous aimerez peut-être aussi

- Well Testing Project Management: Onshore and Offshore OperationsD'EverandWell Testing Project Management: Onshore and Offshore OperationsPas encore d'évaluation

- For For More Sample Engineering Resumes Go To - : Customer #2, PH.D., PEDocument3 pagesFor For More Sample Engineering Resumes Go To - : Customer #2, PH.D., PEDeepak krishnanPas encore d'évaluation

- Senior Mechanical Manufacturing Engineer in Lebanon Hanover NH Resume Donald AveryDocument2 pagesSenior Mechanical Manufacturing Engineer in Lebanon Hanover NH Resume Donald AveryDonald AveryPas encore d'évaluation

- Steel Structures Design Based on Eurocode 3D'EverandSteel Structures Design Based on Eurocode 3Évaluation : 3 sur 5 étoiles3/5 (1)

- Mechanical Engineer Resume Sample PDFDocument0 pageMechanical Engineer Resume Sample PDFMajestic MahiPas encore d'évaluation

- Adrian's ResumeDocument4 pagesAdrian's ResumestarusaPas encore d'évaluation

- Design & Construction of the Contract Package ConceptD'EverandDesign & Construction of the Contract Package ConceptPas encore d'évaluation

- Mechanical Engineer Sample ResumeDocument3 pagesMechanical Engineer Sample ResumePawan Kumar YadavPas encore d'évaluation

- Piping EngineerDocument4 pagesPiping EngineerdennykvgPas encore d'évaluation

- Michael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Document3 pagesMichael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Jeremy WilliamsPas encore d'évaluation

- Patel - ResumeDocument2 pagesPatel - ResumeAnkit PatelPas encore d'évaluation

- CMH Resume Project 2021R2 CMH PDFDocument4 pagesCMH Resume Project 2021R2 CMH PDFAli AyubPas encore d'évaluation

- Product Design EngineerDocument3 pagesProduct Design Engineerapi-121412254Pas encore d'évaluation

- Monster Resume FormatDocument3 pagesMonster Resume FormatMSKumarPas encore d'évaluation

- Project Manager Detailed Resume SoDocument4 pagesProject Manager Detailed Resume SomarkmeshPas encore d'évaluation

- Engineering and DesignDocument52 pagesEngineering and DesignsaiPas encore d'évaluation

- CV-Harsha D (Structural Engg - CEng)Document6 pagesCV-Harsha D (Structural Engg - CEng)Samantha HartPas encore d'évaluation

- Design For CastingDocument6 pagesDesign For CastingJosue Cruz NavarroPas encore d'évaluation

- Director Engineering in Detroit MI Resume Shashank KarnikDocument3 pagesDirector Engineering in Detroit MI Resume Shashank Karnikshashankkarnik100% (1)

- Engineer Materials Research Design in Greater Chicago IL Resume Christopher WhiteDocument3 pagesEngineer Materials Research Design in Greater Chicago IL Resume Christopher WhiteChristopher WhitePas encore d'évaluation

- Manufacturing Process Improvement EngineerDocument4 pagesManufacturing Process Improvement Engineerapi-77387206Pas encore d'évaluation

- Construction Manager or Project Manager or Electrical EngineerinDocument7 pagesConstruction Manager or Project Manager or Electrical Engineerinapi-121297457Pas encore d'évaluation

- Abdul GaffarDocument2 pagesAbdul GaffarVivek ThakurPas encore d'évaluation

- Jeffrey E. Valleroy 8-17-18Document4 pagesJeffrey E. Valleroy 8-17-18Jeff ValleroyPas encore d'évaluation

- Venkadachalapathy Thangavel: LinkedinDocument4 pagesVenkadachalapathy Thangavel: Linkedinvenkatachalapathy.thPas encore d'évaluation

- Design For Manufacture and Design For 'X': Concepts, Applications, and PerspectivesDocument21 pagesDesign For Manufacture and Design For 'X': Concepts, Applications, and Perspectiveshunt191Pas encore d'évaluation

- Resume - Mukul BokilDocument2 pagesResume - Mukul BokilMukul BokilPas encore d'évaluation

- 01 VKT - 2012 JanDocument6 pages01 VKT - 2012 JanVinod Kumar TurkiPas encore d'évaluation

- Prashanth Vavilala MGRDocument2 pagesPrashanth Vavilala MGRsharma301Pas encore d'évaluation

- Ample Esume: BjectiveDocument1 pageAmple Esume: BjectiveJoy JohnPas encore d'évaluation

- IDIBrochure 2008 ADocument18 pagesIDIBrochure 2008 AsutarniPas encore d'évaluation

- Senthil Kumar.R: Career ProfileDocument5 pagesSenthil Kumar.R: Career ProfileGurmeet SinghPas encore d'évaluation

- Joel Destefano: BE AEROSPACE, Tucson, ArizonaDocument5 pagesJoel Destefano: BE AEROSPACE, Tucson, ArizonaShannon EstradaPas encore d'évaluation

- Director VP Aerospace Operations Engineering in Los Angeles CA Resume Kenneth BennerDocument3 pagesDirector VP Aerospace Operations Engineering in Los Angeles CA Resume Kenneth BennerKennethBennerPas encore d'évaluation

- Thomas Pulliam 20230112Document4 pagesThomas Pulliam 20230112Arth PatelPas encore d'évaluation

- Amp 16606 P 31 CastDocument3 pagesAmp 16606 P 31 Castعلی ایروانیPas encore d'évaluation

- CEng Competence ExemplarsDocument6 pagesCEng Competence ExemplarsMajeed Rumani86% (7)

- Mechanical Design EngineerDocument4 pagesMechanical Design Engineerapi-79066865Pas encore d'évaluation

- Navas Onthath CV 11.12.2018Document8 pagesNavas Onthath CV 11.12.2018NavasOT100% (1)

- Pete Skill Resume 09Document2 pagesPete Skill Resume 09greengoatPas encore d'évaluation

- Robert Dellaguardia, CWI: Senior Project ManagerDocument3 pagesRobert Dellaguardia, CWI: Senior Project ManagerJesse JohnsonPas encore d'évaluation

- Structural Engineering Dissertation IdeasDocument7 pagesStructural Engineering Dissertation IdeasPayForAPaperKansasCity100% (1)

- M Tech Production Engineering Thesis TopicsDocument4 pagesM Tech Production Engineering Thesis TopicsDoMyPaperSingapore100% (2)

- Senior Project Manager PMP in Southwest USA UT Resume Glenn WrightDocument2 pagesSenior Project Manager PMP in Southwest USA UT Resume Glenn WrightGlennWright2Pas encore d'évaluation

- Director Research Development Engineering in Denver CO Resume Daniel Leif SkaarDocument4 pagesDirector Research Development Engineering in Denver CO Resume Daniel Leif SkaarDanielLeifSkaarPas encore d'évaluation

- Vigneshwaran.S: Areas of ExposureDocument2 pagesVigneshwaran.S: Areas of Exposuremamillapalli sri harshaPas encore d'évaluation

- Reverse Engineering NotesDocument4 pagesReverse Engineering Notesapi-379303652100% (2)

- Career Episode SampleDocument8 pagesCareer Episode SampleSashi Kumar100% (2)

- Senior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerDocument2 pagesSenior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerSteven FischerPas encore d'évaluation

- Global VP Engineering Electronics in USA Resume Thirukumar VethanayagamDocument3 pagesGlobal VP Engineering Electronics in USA Resume Thirukumar VethanayagamThirukumarVPas encore d'évaluation

- Tech ProposalDocument44 pagesTech ProposalnickcruzltdPas encore d'évaluation

- Manufacturing Supplier Quality Engineer in Nashua NH Resume Daniel DudkaDocument2 pagesManufacturing Supplier Quality Engineer in Nashua NH Resume Daniel DudkaDaniel DudkaPas encore d'évaluation

- Project Manager or Construction Project ManagerDocument3 pagesProject Manager or Construction Project Managerapi-77654706Pas encore d'évaluation

- Mechanical Engineer Project Manager in Houston TX Resume Patrick OjoDocument5 pagesMechanical Engineer Project Manager in Houston TX Resume Patrick OjoPatrickOjoPas encore d'évaluation

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarPas encore d'évaluation

- 15 Design For Manifacture PDFDocument21 pages15 Design For Manifacture PDFBoris NguetaPas encore d'évaluation

- Imothy Ensen Project Management / Construction Management: ContinuedDocument3 pagesImothy Ensen Project Management / Construction Management: Continuedtimhunts4funPas encore d'évaluation

- Machine Design Lec - 1Document22 pagesMachine Design Lec - 1Sasthi HensPas encore d'évaluation

- Gas Turbine Power Plant PDFDocument28 pagesGas Turbine Power Plant PDFPao CastillonPas encore d'évaluation

- Implementing TQ in The Construction Industry - A Practical GuideDocument279 pagesImplementing TQ in The Construction Industry - A Practical Guidechrispittman100% (1)

- Domino PizzasDocument2 pagesDomino PizzasJefferson Medinaceli MalayaoPas encore d'évaluation

- SUMUDocument23 pagesSUMUHumberto DávalosPas encore d'évaluation

- VOLTE For DummiesDocument52 pagesVOLTE For Dummiespmo79Pas encore d'évaluation

- Chandrasekhar BADocument6 pagesChandrasekhar BAChandrasekhar TadikamallaPas encore d'évaluation

- What Is Waterfall Quiz ExplanationsDocument4 pagesWhat Is Waterfall Quiz ExplanationsInteract peoplePas encore d'évaluation

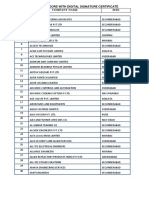

- List of Vendors With Digital Signature Certificate Sl. No. Company Name SiteDocument18 pagesList of Vendors With Digital Signature Certificate Sl. No. Company Name SiterajavinugmailcomPas encore d'évaluation

- Data Ware HousingDocument12 pagesData Ware HousingakyddudePas encore d'évaluation

- 2946 1223 00 - Overhaul Inter Cooler - After CoolerDocument12 pages2946 1223 00 - Overhaul Inter Cooler - After CoolerMax JohnPas encore d'évaluation

- Amine Modeling For CO2 Capture: Internals SelectionDocument7 pagesAmine Modeling For CO2 Capture: Internals SelectionGopi Kiran NPas encore d'évaluation

- Mba Aviation Management Dissertation TopicsDocument6 pagesMba Aviation Management Dissertation TopicsHelpWithPaperWritingAlbuquerque100% (1)

- Northwell Inc SWOTDocument2 pagesNorthwell Inc SWOTPaul ACrackerPas encore d'évaluation

- Case StudiesDocument8 pagesCase StudiesTrung VõPas encore d'évaluation

- Spacecraft Dynamics - Final ProjectDocument11 pagesSpacecraft Dynamics - Final ProjectJames Carrillo100% (1)

- 01 DOC-00-236 Live Working Manual IndexDocument4 pages01 DOC-00-236 Live Working Manual IndexIbnu Shina Aria BentarPas encore d'évaluation

- 5b83dd5bb402392891138b3b - Datasheet - Adv Kick Over Tool - US - 1017Document2 pages5b83dd5bb402392891138b3b - Datasheet - Adv Kick Over Tool - US - 1017felipePas encore d'évaluation

- Explo - Lirika OTC PDFDocument6 pagesExplo - Lirika OTC PDFMariusz PawlasPas encore d'évaluation

- Vmeca, Generador de Vacio Serie VQDocument6 pagesVmeca, Generador de Vacio Serie VQjoselin salasPas encore d'évaluation

- Role of Software Agents in E-CommerceDocument15 pagesRole of Software Agents in E-CommerceRishabhPas encore d'évaluation

- 6 SAP PP Level I TrainingDocument45 pages6 SAP PP Level I TrainingsowjanyaPas encore d'évaluation

- TOYOTA SR 09 - EngagingEmployees PDFDocument11 pagesTOYOTA SR 09 - EngagingEmployees PDFurooj salmanPas encore d'évaluation

- SOF Support Ship ConeptDocument229 pagesSOF Support Ship Coneptfoxbat05Pas encore d'évaluation

- PTS 20160HDocument57 pagesPTS 20160HronelbarafaeldiegoPas encore d'évaluation

- Examination Report FCLDocument1 pageExamination Report FCLpatilbhushan854Pas encore d'évaluation

- Itp For Equipment Erection - StaticDocument5 pagesItp For Equipment Erection - StaticSuraj ShettyPas encore d'évaluation

- Mid RevisionDocument6 pagesMid RevisionAhmed BeheryPas encore d'évaluation

- Electronic Hotel Locking Solutions Brochure-VingcardDocument40 pagesElectronic Hotel Locking Solutions Brochure-VingcardfaeqsaPas encore d'évaluation

- Advanced AMS Machinery ManagerDocument21 pagesAdvanced AMS Machinery Managersatya_chaganti100% (2)

- WMM SheetDocument6 pagesWMM SheetManiteja Reddy TatipallyPas encore d'évaluation

- 101 Great Answers to the Toughest Interview QuestionsD'Everand101 Great Answers to the Toughest Interview QuestionsÉvaluation : 3.5 sur 5 étoiles3.5/5 (29)

- Consulting Interview: How to Respond to TOP 28 Personal Experience Interview QuestionsD'EverandConsulting Interview: How to Respond to TOP 28 Personal Experience Interview QuestionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Job Interview: How to Talk about Weaknesses, Yourself, and Other Questions and AnswersD'EverandJob Interview: How to Talk about Weaknesses, Yourself, and Other Questions and AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- Job Interview: The Complete Job Interview Preparation and 70 Tough Job Interview Questions with Winning AnswersD'EverandJob Interview: The Complete Job Interview Preparation and 70 Tough Job Interview Questions with Winning AnswersÉvaluation : 4 sur 5 étoiles4/5 (7)

- A Joosr Guide to... What Color is Your Parachute? 2016 by Richard Bolles: A Practical Manual for Job-Hunters and Career-ChangersD'EverandA Joosr Guide to... What Color is Your Parachute? 2016 by Richard Bolles: A Practical Manual for Job-Hunters and Career-ChangersÉvaluation : 4 sur 5 étoiles4/5 (1)

- Fire Protection Engineering in Building DesignD'EverandFire Protection Engineering in Building DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Job Interview: Outfits, Questions and Answers You Should Know aboutD'EverandJob Interview: Outfits, Questions and Answers You Should Know aboutÉvaluation : 5 sur 5 étoiles5/5 (4)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemD'EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemPas encore d'évaluation

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ED'EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EÉvaluation : 3 sur 5 étoiles3/5 (6)

- Amazon Interview Secrets: How to Respond to 101 Popular Amazon Leadership Principles Interview QuestionsD'EverandAmazon Interview Secrets: How to Respond to 101 Popular Amazon Leadership Principles Interview QuestionsÉvaluation : 5 sur 5 étoiles5/5 (4)

- Unbeatable Resumes: America's Top Recruiter Reveals What REALLY Gets You HiredD'EverandUnbeatable Resumes: America's Top Recruiter Reveals What REALLY Gets You HiredÉvaluation : 5 sur 5 étoiles5/5 (2)

- The 250 Job Interview Questions: You'll Most Likely Be Asked...and the Answers That Will Get You Hired!D'EverandThe 250 Job Interview Questions: You'll Most Likely Be Asked...and the Answers That Will Get You Hired!Évaluation : 4 sur 5 étoiles4/5 (5)

- Incidents That Define Process SafetyD'EverandIncidents That Define Process SafetyPas encore d'évaluation

- Workbook to Accompany Maintenance & Reliability Best PracticesD'EverandWorkbook to Accompany Maintenance & Reliability Best PracticesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- How to Be Everything: A Guide for Those Who (Still) Don't Know What They Want to Be When They Grow UpD'EverandHow to Be Everything: A Guide for Those Who (Still) Don't Know What They Want to Be When They Grow UpÉvaluation : 4 sur 5 étoiles4/5 (74)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsD'EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsÉvaluation : 4 sur 5 étoiles4/5 (11)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisD'EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Switchers: How Smart Professionals Change Careers - and Seize SuccessD'EverandSwitchers: How Smart Professionals Change Careers - and Seize SuccessÉvaluation : 5 sur 5 étoiles5/5 (2)

- The Science of Rapid Skill Acquisition: Advanced Methods to Learn, Remember, and Master New Skills and Information [Second Edition]D'EverandThe Science of Rapid Skill Acquisition: Advanced Methods to Learn, Remember, and Master New Skills and Information [Second Edition]Évaluation : 4.5 sur 5 étoiles4.5/5 (23)

- Finding Your Passion: 33 Strategies for Finding, Growing and Keeping Your Dream Job While Avoiding Stress BurnoutD'EverandFinding Your Passion: 33 Strategies for Finding, Growing and Keeping Your Dream Job While Avoiding Stress BurnoutÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Cyber Security for Beginners: How to Become a Cybersecurity Professional Without a Technical Background (2022 Guide for Newbies)D'EverandCyber Security for Beginners: How to Become a Cybersecurity Professional Without a Technical Background (2022 Guide for Newbies)Pas encore d'évaluation

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesD'EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesPas encore d'évaluation

- Online Personal Brand: Skill Set, Aura, and IdentityD'EverandOnline Personal Brand: Skill Set, Aura, and IdentityÉvaluation : 3 sur 5 étoiles3/5 (1)

- Developing Soft Skills: An On-the-Go WorkshopD'EverandDeveloping Soft Skills: An On-the-Go WorkshopÉvaluation : 4 sur 5 étoiles4/5 (7)

- Culture, Health and Illness: An Introduction for Health ProfessionalsD'EverandCulture, Health and Illness: An Introduction for Health ProfessionalsPas encore d'évaluation

- Introduction to Petroleum Process SafetyD'EverandIntroduction to Petroleum Process SafetyÉvaluation : 3 sur 5 étoiles3/5 (2)

![The Science of Rapid Skill Acquisition: Advanced Methods to Learn, Remember, and Master New Skills and Information [Second Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/419715394/149x198/b9c2899614/1683669291?v=1)