Académique Documents

Professionnel Documents

Culture Documents

Eci Offset 2009 en

Transféré par

icsoicsoDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Eci Offset 2009 en

Transféré par

icsoicsoDroits d'auteur :

Formats disponibles

Offset 2009

ECI offset profiles 2009

June 2009

2009, European Color Initiative, www.eci.org

Offset 2009

New characterization data and ICC profiles for standard printing conditions

As of June 2009, new Fogra characterization data sets, as well as ECI offset profiles are available, which replace existing versions. The characterization data sets FOGRA45 for heatset web offset printing on improved LWC paper (light weight coating), and FOGRA46 for heatset web offset printing on standard LWC paper, are based on print runs conducted by the ECI web offset working group. For offset printing on uncoated white paper a new profile based on FOGRA47 has been introduced.

Specific characteristic of Uncoated why characterization data and ICC profile with CIELAB values different from common measurements

Ideally process control and quality assurance for proofing and production printing use identical CIELAB coordinates. As helpful mean to implement the international printing standard, the characterization data should contain the aim values of the international standard ISO 12647-2. As a prerequisite the CIELAB values of the paper tone and the printing inks, measured on typical paper, comply with the aim values of the standard ISO 12647-2 (print process control) and the respective Fogra characterization data set (proofing). For the paper types 1+2 for offset printing on gloss and matt coated paper, the CIELAB values measured in daily production comply with the aim values (FOGRA39, ISO Coated v2). If these aim values are matched in a metered evaluation by proof and production print, the two match visually as well. Due to a significantly higher degree of optical brighteners, this does not apply to offset printing on uncoated white paper (paper type 4). The paper shade of typical uncoated white paper shows a b* value of -6 and more if measured under standard compliant conditions (without UV or polarized filter). This corresponds to a blueish colour with the consequence of unfeasible proofing results with regard to the paper shade simulation and pastel colours. In order to facilitate proof prints properly matching the production printing, the CIELAB values of the new characterization data set for offset printing on uncoated white paper (FOGRA47) deviate from the blueish colour measurement of typical uncoated white paper.

Why two characterization data sets and ICC profiles for web offset printing on LWC paper?

Due to the yellowish paper shade, the characterization data set FOGRA28 and the ICC profile ISO Web Coated do not reflect the paper tone and colour appearance of heat set web offset printing on todays most commonly used LWC papers. In order to create a successor for ISO Web Coated, four European web offset printers conducted a test print series on a selection of typical LWC papers. Based on a comparison of the printed results it was obvious that a single ICC profile is not sufficient to represent the colour appearance of all LWC papers. Todays most commonly used LWC papers can be devided in the two groups standard and the more frequently used improved papers. For that reason the ECI, bvdm and Fogra recommend to generally use the new profile PSO LWC Improved (ECI) for colour conversion and proofing as successor for ISO Web Coated. The intended use of the second new profile PSO LWC Standard (ECI) is proofing for heatset web offset printing on slightly yellowish LWC paper only.

2009, European Color Initiative, www.eci.org

Offset 2009

Recommendations for Uncoated proofs

Another specific characteristic applies to proofing for offset printing on uncoated stock: Using a semi-matt proofing substrate, commonly used for coated proofs, will yield a poor visual proof to print match even in the case of an excellent metered proof evaluation. The use of uncoated proofing stock results in the best possible metered match with the aim values of the characterization data set and the best possible visual proof to print match.

Where can the profiles be obtained? From which date are they valid?

The new ECI offset profiles can be freely downloaded from the ECI website (www.eci. org). The characterization data sets FOGRA45 through FOGRA47 can be downloaded also free of charge from the Fogra website (www. fogra.org). The ECI, bvdm and Fogra recommend the immediate use of the new characterization data sets and profiles.

Which profile should I use?

In general, the ECI, bvdm, and Fogra recommend using the ICC profile which matches the intended printing condition, for colour conversion as well as for proofing. You will find an overview of all ECI offset profiles for standard printing conditions on page 4. Some paper manufacturers and suppliers provide information regarding recommended characterization data sets (Fogra number) and ECI offset profiles according to the paper stock. The ECI offset profile ISO Coated v2 300% (ECI) is a good choice in cases where the intended printing condition is not yet known. The advantage of the version of the coated profile with a maximum total ink coverage of 300% is its higher flexibility regarding the use for sheetfed and web offset printing. Prepress data prepared with this profile can be converted to many other printing conditions with good results, however, the best possible results will be achieved with cmyk prepress data prepared with the profile that matches thatprinting condition exactly.

2009, European Color Initiative, www.eci.org

Offset 2009

Offset package 2009 Overview

Profiles for sheetfed and heatset web offset printing according to ISO 12647-2:2004 and ISO 12647-2:2004/Amd 1:2007

Profile file name ISOcoated_v2_eci.icc Profile name ISO Coated v2 (ECI) Printing condition Paper types 1 and 2, gloss and matte coated Tone value increase curves A (CMY) and B (K) as defined in ISO 12647-2:2004 Paper types 1 and 2, gloss and matte coated Tone value increase curves A (CMY) and B (K) as defined in ISO 12647-2:2004 Paper type 3, improved gloss coated (LWC) Tone value increase curves B (CMY) and C (K) as defined in ISO 126472:2004 Paper type 3, standard gloss coated (LWC) Tone value increase curves B (CMY) and C (K) as defined in ISO 126472:2004 Paper type 4, uncoated white offset Tone value increase curves C (CMY) and D (K) as defined in ISO 126472:2004 Paper type 5, uncoated yellowish offset Tone value increase curves C (CMY) and D (K) as defined in ISO 126472:2004 Paper type SC, Super calandered Tone value increase curves B (CMY) and C (K) as defined in ISO 126472:2004 Characterization data FOGRA39L

ISOcoated_v2_300eci.icc

ISO Coated v2 300% (ECI)

FOGRA39L

PSO_LWC_Improved_eci. icc New 2009

PSO LWC Improved (ECI)

FOGRA45L

PSO_LWC_Standard_eci.icc PSO LWC Standard (ECI) New 2009

FOGRA46L

PSO_Uncoated_ISO12647_ eci.icc New 2009

PSO Uncoated ISO12647 (ECI)

FOGRA47L

ISOuncoatedyellowish.icc

ISO Uncoated Yellowish

FOGRA30L

SC_paper_eci.icc

SC Paper (ECI)

FOGRA40L

Tone value increase for the 40% control patch: Curve A: 13% Curve B: 16% Curve C: 19% Curve D: 22% Curve F: 28% The bvdm Media Standard Print (free of charge download from www.bvdm.org) provides aim values for the whole range from 0 up to 100 percent in 5% steps. 4 2009, European Color Initiative, www.eci.org

Offset 2009

Profile file name PSO_MFC_paper_eci.icc

Profile name PSO MFC Paper (ECI)

Printing condition Paper type MFC, Machine finished coating Tone value increase curves B (CMY) and C (K) as defined in ISO 126472:2004 Paper type SNP, Standard newsprint, heatset web offset printing Tone value increase curves C (CMY) and D (K) as defined in ISO 12647-2:2004

Characterization data FOGRA41L

PSO_SNP_paper_eci.icc

PSO SNP Paper (ECI)

FOGRA42L

PSO_Coated_NPscreen_ ISO12647_eci.icc

PSO Coated NPscreen ISO12647 (ECI)

Paper type 1 and 2, gloss and matFOGRA43L te coated non-periodic screening (NPscreen), 20 m Tone value increase curve F (CMYK) as defined in ISO 12647-2:2004 Paper type 1 and 2, gloss and matFOGRA43L te coated non-periodic screening (NPscreen), 20 m Tone value increase curve F (CMYK) as defined in ISO 12647-2:2004 Paper type 4, FOGRA44L uncoated white offset non-periodic screening (NPscreen), 30 m Tone value increase curve F (CMYK) as defined in ISO 12647-2:2004

PSO_Coated_300_ NPscreen_ISO12647_eci.icc

PSO Coated 300% NPscreen ISO12647 (ECI)

PSO_Uncoated_NPscreen_ ISO12647_eci.icc

PSO Uncoated NPscreen ISO12647 (ECI)

Tone value increase for the 40% control patch: Curve A: 13% Curve B: 16% Curve C: 19% Curve D: 22% Curve F: 28% The bvdm Media Standard Print (free of charge download from www.bvdm.org) provides aim values for the whole range; from 0 up to 100 percent in 5% steps.

2009, European Color Initiative, www.eci.org

Vous aimerez peut-être aussi

- E0499 Fogra Softproof HandbookDocument43 pagesE0499 Fogra Softproof HandbookMarcus FX100% (1)

- Color Expert Compering TVI Vs G7Document12 pagesColor Expert Compering TVI Vs G7BiswajitMaityPas encore d'évaluation

- FIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesD'EverandFIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesPas encore d'évaluation

- Fogra Specification - System and Process Check For Large Format Printing Application V1.0Document26 pagesFogra Specification - System and Process Check For Large Format Printing Application V1.0Carnot Junior100% (1)

- The CIP3 Output Plugin EnablesDocument2 pagesThe CIP3 Output Plugin EnablesEric DucheminPas encore d'évaluation

- 6.density & Colour MeasurementDocument3 pages6.density & Colour MeasurementShraddha GhagPas encore d'évaluation

- Understanding Paper Whiteness PDFDocument2 pagesUnderstanding Paper Whiteness PDFSappiETCPas encore d'évaluation

- Selecting A Paper For G7 Calibration PDFDocument3 pagesSelecting A Paper For G7 Calibration PDFSappiETCPas encore d'évaluation

- G7 How To 2009Document68 pagesG7 How To 2009Peibol SotoPas encore d'évaluation

- EFI Vs GMG Vs CGS Is There A Clear WinnerDocument18 pagesEFI Vs GMG Vs CGS Is There A Clear WinnersmkazmiPas encore d'évaluation

- PC CatalogDocument28 pagesPC CatalogSeenivasagam SeenuPas encore d'évaluation

- BESTColor Manual EN4-1Document110 pagesBESTColor Manual EN4-1vitprint22Pas encore d'évaluation

- OnPress 63Document22 pagesOnPress 63Carlos GrajalesPas encore d'évaluation

- The Ink Room of TomorrowDocument4 pagesThe Ink Room of TomorrowQuý Đình Mai MaiPas encore d'évaluation

- UserGuide GreyBalance2 enDocument50 pagesUserGuide GreyBalance2 enpnpha02123Pas encore d'évaluation

- G7 Pre Qualification Checklist Sheetfed v1.3Document6 pagesG7 Pre Qualification Checklist Sheetfed v1.3Ganjar RukmaPas encore d'évaluation

- Fogra Softproof Handbook PDFDocument43 pagesFogra Softproof Handbook PDFLalo GutierrezPas encore d'évaluation

- Introduction To The G7 Proofing and Printing System Calibration MethodologyDocument6 pagesIntroduction To The G7 Proofing and Printing System Calibration MethodologySappiETCPas encore d'évaluation

- Devicelink Profiles Fundamentals and Applications 2nd Edition PDFDocument38 pagesDevicelink Profiles Fundamentals and Applications 2nd Edition PDFomar tlebPas encore d'évaluation

- Offset PrintingDocument5 pagesOffset PrintingajiitrPas encore d'évaluation

- 00 MediaStandard - Print - 2018Document78 pages00 MediaStandard - Print - 2018Lý Phương NamPas encore d'évaluation

- Expert Guide Screening TechDocument81 pagesExpert Guide Screening TechJason TiuPas encore d'évaluation

- Press: Flexible. Easy. Intelligent. Accurate Color On All Printing DevicesDocument4 pagesPress: Flexible. Easy. Intelligent. Accurate Color On All Printing DevicesmigueldemacrolabPas encore d'évaluation

- Achieve G7 Master Printer Status: Improve Gray Balance and Color ConsistencyDocument2 pagesAchieve G7 Master Printer Status: Improve Gray Balance and Color ConsistencyChenna VijayPas encore d'évaluation

- Inkformation 4 en 02Document28 pagesInkformation 4 en 02MohammadAlAmeenPas encore d'évaluation

- Snap Gracol Swap IsoDocument15 pagesSnap Gracol Swap IsoKalvoPas encore d'évaluation

- Eagle RipDocument4 pagesEagle RippedroaraoztPas encore d'évaluation

- Lombardi Company PresentationDocument35 pagesLombardi Company PresentationPam Landi0% (1)

- Reference Manual Printing and Converting PerformanceDocument74 pagesReference Manual Printing and Converting PerformanceAli HussnainPas encore d'évaluation

- G7 How-ToDocument56 pagesG7 How-Tomythchenling100% (2)

- 201 - 200landa NanographyDocument12 pages201 - 200landa NanographykjkrishnanPas encore d'évaluation

- Flexo Vs OffsetDocument18 pagesFlexo Vs OffsetJavier Martinez CañalPas encore d'évaluation

- Understanding Working Principles Laser Printer: Click To Edit Master Subtitle StyleDocument13 pagesUnderstanding Working Principles Laser Printer: Click To Edit Master Subtitle StyleJucia ChawPas encore d'évaluation

- Pigments Training - Printing - Doman-ShotwellDocument18 pagesPigments Training - Printing - Doman-ShotwellHerbert AguilargonzalezPas encore d'évaluation

- E - Plate II Print HDDocument2 pagesE - Plate II Print HDmigueldemacrolabPas encore d'évaluation

- Problem Cases in The PressroomDocument45 pagesProblem Cases in The PressroomHeidelberg IndiaPas encore d'évaluation

- Harper Anilox RollDocument88 pagesHarper Anilox Rollsuracheted0% (1)

- Prinect StandardizationDocument36 pagesPrinect StandardizationVesna DjurovicPas encore d'évaluation

- Faq From IccDocument27 pagesFaq From IccAnonymous FGY7goPas encore d'évaluation

- Print Color Management ISO 12647-2: SystemserviceDocument1 pagePrint Color Management ISO 12647-2: SystemserviceAngel de LuzPas encore d'évaluation

- Guidelines For Using Print Production Standards v1.0 2019Document20 pagesGuidelines For Using Print Production Standards v1.0 2019Javier Martinez CañalPas encore d'évaluation

- Gatf Test Form / Analysis User GuideDocument68 pagesGatf Test Form / Analysis User GuideStephi Otterburg ClavelPas encore d'évaluation

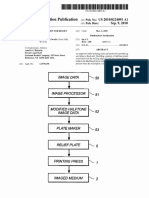

- Us 20100224091Document12 pagesUs 20100224091Cikumunya ArsPas encore d'évaluation

- Frequently Asked Questions (FAQ's) Pertaining To GRACoL, G7, and ISO 12647-2Document6 pagesFrequently Asked Questions (FAQ's) Pertaining To GRACoL, G7, and ISO 12647-2SappiETCPas encore d'évaluation

- Device Link ProfileDocument28 pagesDevice Link ProfileMarcos Flint0% (1)

- Dot GainDocument5 pagesDot GainKrissada Anuchon100% (1)

- Ffta First 5.0 Design GuideDocument87 pagesFfta First 5.0 Design GuideSharlowPas encore d'évaluation

- Paper Standards Measurements Final Version EngDocument22 pagesPaper Standards Measurements Final Version Eng0913313502367% (3)

- Dot Spread-Dot GainDocument3 pagesDot Spread-Dot GainMansour SolimanPas encore d'évaluation

- 2 - Phu Luc 2 - Print - Control - SystemDocument1 page2 - Phu Luc 2 - Print - Control - SystemLý Phương NamPas encore d'évaluation

- Anilox Rolls Selection GuideDocument4 pagesAnilox Rolls Selection GuideMismail EgypacPas encore d'évaluation

- Workflow - PDF OTIMODocument56 pagesWorkflow - PDF OTIMOrafael_faria_4Pas encore d'évaluation

- ICC Minor Revision For WebDocument102 pagesICC Minor Revision For WebRolo Calfio AcostaPas encore d'évaluation

- X Rite GregtagmacbethDocument21 pagesX Rite GregtagmacbethdeepanairbalachandraPas encore d'évaluation

- Offset TrialDocument64 pagesOffset TrialOgi Permana PutraPas encore d'évaluation

- Measuring CMYK Halftones: The Case For Spot Color Tone Value (SCTV) FormulaDocument24 pagesMeasuring CMYK Halftones: The Case For Spot Color Tone Value (SCTV) FormulaLong HộiPas encore d'évaluation

- Eagle RIP OperatorGuide - ENGDocument151 pagesEagle RIP OperatorGuide - ENGKingsley Gomes100% (1)

- Notes On Michelangelo's Sistine Chapel Fresco PaintingsDocument3 pagesNotes On Michelangelo's Sistine Chapel Fresco PaintingsGreg O'DeaPas encore d'évaluation

- Classical Oil Painting TechniqueDocument124 pagesClassical Oil Painting Techniquefakamada6044100% (15)

- Sculpture: 3 Dimensional Shapes and ArtworkDocument2 pagesSculpture: 3 Dimensional Shapes and ArtworkAlfonso RomaPas encore d'évaluation

- Marine Colour Card PDFDocument2 pagesMarine Colour Card PDFrajeshPas encore d'évaluation

- Suffolk House RestorationDocument4 pagesSuffolk House RestorationJoshua Mathew de SouzaPas encore d'évaluation

- Drowing 2Document163 pagesDrowing 2alebeley21Pas encore d'évaluation

- MNA S-Me: (Artista) (Imera)Document2 pagesMNA S-Me: (Artista) (Imera)razvicosteaPas encore d'évaluation

- Plaster Textures & Acrylic FinishesDocument24 pagesPlaster Textures & Acrylic FinishesVirgil SteleaPas encore d'évaluation

- Toyota BrandStdsGdDocument15 pagesToyota BrandStdsGdsrsthilaire0% (1)

- Handwriting Collection GuideDocument96 pagesHandwriting Collection Guidemagno86Pas encore d'évaluation

- Alvar AltoDocument81 pagesAlvar Altoa4104165100% (1)

- AfricaDocument61 pagesAfricaGerome Bautista VInluanPas encore d'évaluation

- Veer200507 Activity PDFDocument100 pagesVeer200507 Activity PDFOmar Abdallah Najar MedinaPas encore d'évaluation

- Unit 1 Arts HandoutDocument4 pagesUnit 1 Arts HandoutKylle De GuzmanPas encore d'évaluation

- Picture Books Plus - 100 Extension Activities in Art, Drama, Music, Math, and Science PDFDocument149 pagesPicture Books Plus - 100 Extension Activities in Art, Drama, Music, Math, and Science PDFClóvis Batista Dos SantosPas encore d'évaluation

- How To Hold A Watercolor BrushDocument12 pagesHow To Hold A Watercolor BrushFarah Fauzi100% (2)

- Salvador Dali BiographyDocument1 pageSalvador Dali BiographyDavid DebruynePas encore d'évaluation

- Airbrush The Magazine - Issue 1 - March-April 2019 PDFDocument46 pagesAirbrush The Magazine - Issue 1 - March-April 2019 PDFtae talPas encore d'évaluation

- Annie Leibovitz Favorite BooksDocument5 pagesAnnie Leibovitz Favorite BooksDonovan AlexPas encore d'évaluation

- Contemporary Philippine Arts From The Regions First Grading ExamDocument3 pagesContemporary Philippine Arts From The Regions First Grading Examjcb bnhs100% (1)

- Lodi Gardens: Saumya Wadhwa B.ARCH 3 (B) Vastukala AcademyDocument12 pagesLodi Gardens: Saumya Wadhwa B.ARCH 3 (B) Vastukala AcademyAbhishek RawatPas encore d'évaluation

- Jewelry 2011cat-Vol87 9957Document274 pagesJewelry 2011cat-Vol87 9957Tomy Daniel Ramirez AlvarezPas encore d'évaluation

- Butterfly Lighting Assignment RubricDocument1 pageButterfly Lighting Assignment Rubricapi-235556762Pas encore d'évaluation

- A969248439 - 23974 - 11 - 2018 - Art Deco ExpressionismDocument19 pagesA969248439 - 23974 - 11 - 2018 - Art Deco ExpressionismNazimPas encore d'évaluation

- Internship at Simplex Infrastructure LTDDocument46 pagesInternship at Simplex Infrastructure LTDSanthosh HMPas encore d'évaluation

- World Class References B - P PDFDocument106 pagesWorld Class References B - P PDFMujahidin AhmadPas encore d'évaluation

- The Layers of Portrait Painting With Joshua LaRock - Supplemental PDFDocument5 pagesThe Layers of Portrait Painting With Joshua LaRock - Supplemental PDFAlison De Sando ManzoniPas encore d'évaluation

- Ak ProductsDocument1 pageAk ProductsLea LeaPas encore d'évaluation

- ART145 Tut 1Document4 pagesART145 Tut 1Letz GoPas encore d'évaluation

- Unit 4 VA - SOUTH INDIADocument113 pagesUnit 4 VA - SOUTH INDIAShaik Humer Sadikh100% (1)

- Advancing Your Photography: Secrets to Making Photographs that You and Others Will LoveD'EverandAdvancing Your Photography: Secrets to Making Photographs that You and Others Will LoveÉvaluation : 5 sur 5 étoiles5/5 (3)

- Edward's Menagerie: Dogs: 50 canine crochet patternsD'EverandEdward's Menagerie: Dogs: 50 canine crochet patternsÉvaluation : 3 sur 5 étoiles3/5 (5)

- Dark Data: Why What You Don’t Know MattersD'EverandDark Data: Why What You Don’t Know MattersÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The World Beneath: The Life and Times of Unknown Sea Creatures and Coral ReefsD'EverandThe World Beneath: The Life and Times of Unknown Sea Creatures and Coral ReefsÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Grokking Algorithms: An illustrated guide for programmers and other curious peopleD'EverandGrokking Algorithms: An illustrated guide for programmers and other curious peopleÉvaluation : 4 sur 5 étoiles4/5 (16)

- Blockchain Basics: A Non-Technical Introduction in 25 StepsD'EverandBlockchain Basics: A Non-Technical Introduction in 25 StepsÉvaluation : 4.5 sur 5 étoiles4.5/5 (24)

- The Food Stylist's Handbook: Hundreds of Media Styling Tips, Tricks, and Secrets for Chefs, Artists, Bloggers, and Food LoversD'EverandThe Food Stylist's Handbook: Hundreds of Media Styling Tips, Tricks, and Secrets for Chefs, Artists, Bloggers, and Food LoversÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Planets: Photographs from the Archives of NASAD'EverandThe Planets: Photographs from the Archives of NASAÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The Art of Photography: A Personal Approach to Artistic ExpressionD'EverandThe Art of Photography: A Personal Approach to Artistic ExpressionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Boudoir Photography: Tips for Presenting Today’s Stunning Women, aged 21 to 81D'EverandBoudoir Photography: Tips for Presenting Today’s Stunning Women, aged 21 to 81Évaluation : 3 sur 5 étoiles3/5 (2)

- Photographing Women: Posing, Lighting, and Shooting Techniques for Portrait and Fashion PhotographyD'EverandPhotographing Women: Posing, Lighting, and Shooting Techniques for Portrait and Fashion PhotographyÉvaluation : 4.5 sur 5 étoiles4.5/5 (7)

- Fusion Strategy: How Real-Time Data and AI Will Power the Industrial FutureD'EverandFusion Strategy: How Real-Time Data and AI Will Power the Industrial FuturePas encore d'évaluation

- The Photography Exercise Book: Training Your Eye to Shoot Like a Pro (250+ color photographs make it come to life)D'EverandThe Photography Exercise Book: Training Your Eye to Shoot Like a Pro (250+ color photographs make it come to life)Pas encore d'évaluation

- Dinosaurs: 101 Super Fun Facts And Amazing Pictures (Featuring The World's Top 16 Dinosaurs)D'EverandDinosaurs: 101 Super Fun Facts And Amazing Pictures (Featuring The World's Top 16 Dinosaurs)Évaluation : 4 sur 5 étoiles4/5 (6)

- Tough Enough: Arbus, Arendt, Didion, McCarthy, Sontag, WeilD'EverandTough Enough: Arbus, Arendt, Didion, McCarthy, Sontag, WeilPas encore d'évaluation

- Be Useful: Seven Tools for Life by Arnold Schwarzenegger: Key Takeaways, Summary & AnalysisD'EverandBe Useful: Seven Tools for Life by Arnold Schwarzenegger: Key Takeaways, Summary & AnalysisPas encore d'évaluation

- Vivian Maier Developed: The Untold Story of the Photographer NannyD'EverandVivian Maier Developed: The Untold Story of the Photographer NannyÉvaluation : 4.5 sur 5 étoiles4.5/5 (9)

- Starting Database Administration: Oracle DBAD'EverandStarting Database Administration: Oracle DBAÉvaluation : 3 sur 5 étoiles3/5 (2)

- Get Started in Digital Glamour Photography (Lingerie Edition)D'EverandGet Started in Digital Glamour Photography (Lingerie Edition)Évaluation : 2.5 sur 5 étoiles2.5/5 (5)

- Optimizing DAX: Improving DAX performance in Microsoft Power BI and Analysis ServicesD'EverandOptimizing DAX: Improving DAX performance in Microsoft Power BI and Analysis ServicesPas encore d'évaluation