Académique Documents

Professionnel Documents

Culture Documents

5.1 Power Systems Rev 01

Transféré par

Yosep SibagariangDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

5.1 Power Systems Rev 01

Transféré par

Yosep SibagariangDroits d'auteur :

Formats disponibles

5.

1 Power Systems

Tideland Signal Corp.

featuring

Aids to Navigation Products

00 00 Rev

UPDATE RELEASE Description

03.03.2008 11.19.2007 Date

CWQ CWQ By

A.

Design Considerations

The weakest link in modern Aids to Navigation Systems is the power system. In most cases, a solar system must be used in remote site locations and, naturally, on buoys. When mains power is easily available, this is often the preferred system. A mains power system is very forgiving and capacity is not normally an issue. However, it may not always be completely reliable and, on occasions, may require a battery and charger in reserve. Solar powered systems should be designed with accurate climatic data and with sufficient design margins. Opting to save a few dollars in capital expenditure is false economy, risking disproportionate expense on failed equipment and extra maintenance visits. So when designing a system what should be taken into account? The essential consideration is the amount of energy used, which is expressed, either in amperehours per day (Ah/day) at input voltage or watt-hours per day (Wh/day). This figure tells us exactly how much energy needs to be replaced in the power system each day. What else needs to be considered? Basically nothing. Once that figure is known, the power system requirements can be calculated. Before providing some examples it is worth mentioning the operating voltage. For most AtoN companies the standard design voltage is 9V to 36V DC. The most common nominal systems are 12V or 24V. Both are equally acceptable but generally 24V is reserved for larger systems or systems with longer cable runs where power loss may be an issue. All AtoN suppliers are capable of providing you with sufficient information to calculate Ah/Day or Wh/day power consumption figures. Some will even provide the actual calculations. Here are some examples: Flash Character Duty Cycle To calculate Ah per day to enable solar sizing we first need to know the duty cycle of the flash character. The duty cycle is the percentage ON time for a particular flash duration. For example; 0.3 s [sec.] on, 0.7 s [sec.] off Duration of flash character or period = 1 s On time is 0.3 s Duty Cycle (%age) is on time divided by period x 100 = 0.3s/1s x 100 = 30% Thus the duty cycle is 30% 0.5 s on, 1.0 s off, 2.0 s on, 11.5s off Period = 15s Total on time = 2.5s Duty Cycle = 2.5s/15s x 100 = 16.7% In this case, the duty cycle is 16.7% Ah/day Once the flash character duty cycle is known the Ah/day can be calculated. Assume: lamp size: 12VDC 2.03A, 17% flash character duty cycle

5.1 Power Systems

Tideland Signal Corporation 2008

2 of 9

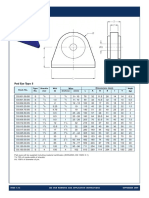

Lamp on time: 0.3 second (hence, average current is 2.76A) Fig.1). 14 hour night. Flasher quiescent power drain = 0.1 Ah/day Calculation [for Ah/day] (14 hours x 2.76A x 0.17) + 0.1Ah quiescent = 6.67Ah/day Thus the Ah/day figure is 6.67 Ah/day Two features of the calculations, above, are worthy of note: the hours of darkness and the average current As a good rule of thumb, most calculations assume a mean night of 14 hours. Nonetheless at extreme latitudes, this might be increased. The average current takes into account the surge of current that is applied to a filament lamp at contact closure. The table, below lists values of average current for sizes of lamp and contact closure times (CCT). FIGURE 1. Average Lamp Current

AVERAGE CURRENT (In amperes) LAMP SIZE (amperes) 0.25 0.55 0.58 0.77 0.833 1.00 1.15 1.35 1.67 1.9 2.03 2.92 3.00 3.05 3.33 4.17 6.25 8.33 CCT 0.2 sec 0.282 0.666 0.715 0.970 1.060 1.310 1.530 1.836 2.35 2.73 2.96 CCT 0.3 sec 0.272 0.639 0.682 0.916 1.002 1.230 1.415 1.728 2.20 2.55 2.76 4.25 4.49 CCT 0.4 sec 0.268 0.621 0.664 0.894 0.974 1.180 1.380 1.647 2.09 2.43 2.62 3.97 4.07 4.15 4.60 4.64 CCT 0.5 sec 0.262 0.605 0.647 0.870 0.945 1.150 1.334 1.592 2.02 2.32 2.50 3.73 3.84 3.91 4.30 4.56 CCT 1.0 sec 0.254 0.578 0.618 0.816 0.887 1.070 1.242 1.471 1.82 2.09 2.23 3.27 3.36 3.42 3.73 4.40 6.63 8.87

5.1 Power Systems

Tideland Signal Corporation 2008

3 of 9

With LED Technology there is no surge/inrush current to be taken into account, so calculations are simpler. Ah/day calculation for LED lights Assume: Lantern is rated at 7W, so current = 0.583A at 12V DC. lantern input power in Watts (W). Flash character duty cycle = 20% Flasher quiescent power drain = 0.1 Ah/day Most manufacturers quote LED

Most manufacturers quote LED lanterns in terms of Watts (W). If we assume a lantern is rated at 7W the current is 0.583A at 12V DC.

Assume a 20% duty cycle flash character

Calculation: (14 hours x 0.583A x 0.2) + 0.1Ah quiescent = 1.63Ah/day Thus the Ah/day figure is 1.63 Ah/day

FIGURE 2. V = Volts

Some useful conversion facts applicable to DC systems. V x A = W (watts) W A = V (volts) W V = A (amps) s = second CCT = contact closure time LED = light emitting diode

DC = Direct Current A = Amps (Current) I = Current (Amps) W = Watts Ah = Ampere hours mA = 0.000A (2mA = 0.002A) k = 1000 (2k = 2000)

5A @12V = 60W 2.5A @ 24V = 60W

5.1 Power Systems

Tideland Signal Corporation 2008

4 of 9

B.

Solar Power Systems

Solar power systems are the most commonly used by AtoN. Their charging source, the sun, is free; they can be installed in most locations, with due regard to shading, fouling of arrays, and maintenance, requirements are simple. In a solar power system, solar panels charge the battery by day and the battery operates the AtoN load as required. The battery also provides another important function, holding reserve energy (charge), thereby allowing for the lack of recharge on days when there is reduced or no solar charging. For given loads (in Ah/day or Wh/day), solar array charging power and battery capacity can be calculated. Apart from ensuring sufficient battery power there is another consideration. When a lead acid (most commonly used) battery falls below a certain capacity it is much harder to re-charge. With such batteries, it is normal practice to design a solar system that does not allow the battery to fall below a certain level of capacity 40% in temperate climes and 50% or more in locations where temperatures close to freezing may be encountered. Batteries also degrade over a period of time and it is good design practice to include an aging factor of up to 20%. Solar panels are normally selected based on their wattage. Common sizes used in the AtoN industry are 5W, 10W, 20W, 30W, 50W, 65W and 85W. Output voltages are usually 12V or 24V; 48V is rare. 6V and 18V systems - once considered popular- are now obsolete. When selecting solar modules it is of the utmost importance to select marine grade due to the very harsh environment. A solar module used on the roof of a house, for example, is probably not going to last long on a buoy in the open sea. Finally, like batteries, solar modules also de-grade over a period of time. It is, therefore, good design practice to use a de-grading margin in solar sizing calculations. calculations. With the following inputs, a calculation can be run, to size the solar array and battery bank. Ah/day or Wh/day load Battery Requirement + 20% Solar Requirement + 20%

Regulator

Solar Module

Battery

5.1 Power Systems

Tideland Signal Corporation 2008

5 of 9

In the early days, solar sizing was based upon experience in different locations and on various DOS based programs. It then moved on to more sophisticated programs and recently IALA produced their own recommended solar sizing program. All AtoN companies will have various methods and also solar panel companies will offer a design service. Many companies have now adopted the IALA solar sizing program as their standard. This program allows the designer to input equipment rating, duty cycle and various parameters to select a suitable solar and battery package. Figure 3 provides an example.

FIGURE 3.

IALA Solar Program

5.1 Power Systems

Tideland Signal Corporation 2008

6 of 9

C.

Mains Power and Battery Chargers

Sometimes it is convenient to install a lantern directly to a secure source of main power, in bridge light applications for example. In this case a lantern accepts 110V or 240V AC directly. Naturally total power requirements should be calculated but AtoN lanterns use so very little power that this is not normally a problem for mains powered systems.

Although some lanterns can accept a direct connection to main power, many cannot. In this case the AtoN supplier may install a small AC/DC converter within the lantern. A common system is to install a battery charger that may run one or several AtoNs. This is a more robust system as it operates at mains power but has the added advantage of providing a back up in the event of mains power failure.

Mains power is supplied to the battery charger and charges a 12V or 24V DC system. Chargers are rated for the applicable duty and Tideland has a marine grade, 10A, charger that is also ATEX certified for platform use. Battery capacities are usually chosen to provide a safety margin for possible power cuts. Even allowing for say 10 days reserve a 105Ah battery is often sufficient. Although a main powered system is less challenging to design, care should be taken in selection of marine grade cables, switches and junction boxes. Battery chargers come in all shapes and sizes but always remember marine grade. One other point often forgotten is ambient temperature as equipment is installed in various climates. Tideland equipment is designed to -40C to +70C.

5.1 Power Systems

Tideland Signal Corporation 2008

7 of 9

D.

Batteries

A good reliable battery is of the utmost importance. Tideland has lost count of the number of times it has been called to fix an installation only to find poor quality batteries have been used. Many buyers will look at a specification for a 12V 105Ah battery and purchase a truck battery thinking it is cost effective and will last; WRONG! A vehicle battery is designed for high ampere starting and a strong charge. It is also designed for a less arduous environment. A battery designed for a solar powered AtoN environment is designed for a slow solar charge and a slow power discharge. It is also designed for rough abuse, a buoy rolling for example. Marine quality batteries are more expensive but how much does it cost to go out to an AtoN to replace a defective battery? The most common battery used is a sealed lead acid battery. Lead acid batteries have been workhorses for AtoN applications for many years and continue to be the most reliable power source. Typical application lifetime of the lead acid battery is about 5 to 8 years with excellent cost efficiency and decent energy density (14 Watt*hour/lb). Its low self-discharge rate of 1 to 3% per month is the best among batteries of different technologies. The other advantage of the lead acid battery is the charge efficiency over the temperature range, which is excellent, compared with other types of batteries. Lead acid batteries are manufactured based on different technologies such as: Pure lead (Plante) Lead Antimony Antimony alloy additive to the lead. Lead Calcium Calcium alloy additive to the lead. Hybrid Employing a mixture of alloys such as tin, aluminum etc., added to the pure lead.

Other types of battery are available such as Nickel Cadmium (NiCad). These are sometimes used in colder climates, as they are better suited to recovery from deep discharges. Tideland supplies various marine grade batteries, which have been proven in the field with life cycles from 3 to 5 years and higher. They include: P/N 182.1078-00 - V12MF : lead calcium type, sealed. 12V/105AH. P/N 182.1062-00 - V6MF : pure lead. 6V/100AH P/N 182.1083-00 - Energy Cell : Gel type, VRLA, 12V/105AH P/N 182.1073-00 2G-12 : primary cell, gelified, air polarized, 2.7V/1200AH P/N 182.1074-00 3G-12: primary cell, gelified, air polarized, 4.05V/1200AH P/N 182.1101-00 sealed lead, 12V/38AH P/N 182.1104-00 - sealed lead, 2V/12AH P/N 182.1105-00 NICAD battery system 12V/105AH.

5.1 Power Systems

Tideland Signal Corporation 2008

8 of 9

E.

Battery Boxes

A battery box protects a power system and promotes longer battery life. Poorly designed boxes will lead to premature failure by allowing batteries to suffer environmental and physical damage. Battery boxes should be designed to hold the batteries securely, to protect them from the environment and allow batteries to breath. Common materials include polyethylene for smaller boxes, GRP and sometimes galvanized or stainless steel. For most applications GRP is suitable as it is strong and lightweight.

The FG-2 holds one or two , 105Ah batteries rated at 12V and is a commonly used on small solar systems.

An FG-8 is a common site on offshore platforms and will hold up to six 105Ah batteries rated at 12V.

For special applications ATEX certified battery boxes are required. These are suitable for installation in explosive environments.

5.1 Power Systems

Tideland Signal Corporation 2008

9 of 9

Vous aimerez peut-être aussi

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryD'EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryPas encore d'évaluation

- gp860101 ComDocument38 pagesgp860101 Comfahimidrus1Pas encore d'évaluation

- Maxlumina® Marine Signal Lantern: FeaturesDocument2 pagesMaxlumina® Marine Signal Lantern: FeaturesMichael Cordero100% (1)

- 16625195-FDDRev02 (MANUAL)Document649 pages16625195-FDDRev02 (MANUAL)Lakshmi KishorePas encore d'évaluation

- Crouse Hint PDFDocument180 pagesCrouse Hint PDFJEFFERSON ALEJANDRO MURILLO CAPERAPas encore d'évaluation

- 2 Gear DriveDocument4 pages2 Gear DrivebanerjeeamlanPas encore d'évaluation

- Calibration, Traceability & Least Count - TrainingDocument44 pagesCalibration, Traceability & Least Count - TrainingCaspian DattaPas encore d'évaluation

- Modular I/O System Profibus Dpv1 750-333 / 750-833: Technical Description, Installation and ConfigurationDocument154 pagesModular I/O System Profibus Dpv1 750-333 / 750-833: Technical Description, Installation and Configurationtester11100% (1)

- Safe HydraulicsDocument76 pagesSafe Hydraulicsrobertofca2266Pas encore d'évaluation

- 39GC C12 1PD 1 - CarrierDocument27 pages39GC C12 1PD 1 - Carrierks aksPas encore d'évaluation

- Mil-Dtl-27422d Tank, Fuel, Crash-Resistant, Ballistic Tollerant, AircraftDocument47 pagesMil-Dtl-27422d Tank, Fuel, Crash-Resistant, Ballistic Tollerant, AircraftfogdartPas encore d'évaluation

- Bonstrand #2412 Keylock System PDFDocument28 pagesBonstrand #2412 Keylock System PDFKamatchi NathanPas encore d'évaluation

- ELTEK For Sale From Powerstorm 19nov14Document6 pagesELTEK For Sale From Powerstorm 19nov14MorroJopalPas encore d'évaluation

- Accesorios Media Tension ElastimoldDocument88 pagesAccesorios Media Tension ElastimoldFrancisco CanPas encore d'évaluation

- Spare Part List-M3019Document30 pagesSpare Part List-M3019Saket SamratPas encore d'évaluation

- Encoder: Technical Manual 222115-001 40223723-SeriesDocument34 pagesEncoder: Technical Manual 222115-001 40223723-SeriesAndres NavarroPas encore d'évaluation

- Sock SurfDocument60 pagesSock SurfClintonDestinyPas encore d'évaluation

- Flygt IOM 3153-095Document72 pagesFlygt IOM 3153-095jose03Pas encore d'évaluation

- Section 5 - Supplier Quality Surveillance: 1.0 GeneralDocument3 pagesSection 5 - Supplier Quality Surveillance: 1.0 Generalanishgirme100% (1)

- Makita Grinder CatalogDocument19 pagesMakita Grinder CatalogSuryana Maman100% (1)

- 884 and 885 Hydraulic Benders: Instruction ManualDocument40 pages884 and 885 Hydraulic Benders: Instruction ManualAnonymous wKvJXBJ2iPas encore d'évaluation

- Hobart CatalogDocument138 pagesHobart CatalogHuỳnh TrươngPas encore d'évaluation

- 1.8.1.1.11.2.3 Titan C Service Manual (NEW)Document70 pages1.8.1.1.11.2.3 Titan C Service Manual (NEW)WaynePas encore d'évaluation

- Qdoc - Tips Ul 508aDocument56 pagesQdoc - Tips Ul 508aAlexPas encore d'évaluation

- Howco Global BrochureDocument17 pagesHowco Global BrochureGuido FloresPas encore d'évaluation

- Advantage & Disadv of Bellow & Slip JointDocument2 pagesAdvantage & Disadv of Bellow & Slip JointSharun Suresh0% (1)

- E175e PDFDocument88 pagesE175e PDFgoomiPas encore d'évaluation

- 08 MIR CentrifugeDocument1 242 pages08 MIR Centrifugeanse1Pas encore d'évaluation

- Cembre Lugs Crimps TerminalsDocument168 pagesCembre Lugs Crimps TerminalsJeffrey ArandiaPas encore d'évaluation

- Anchor Chain PDFDocument10 pagesAnchor Chain PDFchristianvanPas encore d'évaluation

- 2008 Nec Code Review AppletonDocument24 pages2008 Nec Code Review AppletonMarcos GonzalesPas encore d'évaluation

- Hardwood GradingDocument24 pagesHardwood Gradinga1tiplanoPas encore d'évaluation

- Pomtava S.A. 1611-4-2 Ch-2732 ReconvilierDocument3 pagesPomtava S.A. 1611-4-2 Ch-2732 ReconvilierDolores FuertesPas encore d'évaluation

- Air Flex - ClutchDocument34 pagesAir Flex - ClutchJuan Gustavo GuillermoPas encore d'évaluation

- As 3791-1991 Hydraulic HoseDocument7 pagesAs 3791-1991 Hydraulic HoseSAI Global - APAC0% (1)

- Lovol 1004Document2 pagesLovol 1004Dhee DoodzPas encore d'évaluation

- Tanktrader BV: Technical Specification For 20' X 8' X 8'6" Iso Icc Type Tank Container For Bulk Bitumen (Un T3 Code)Document9 pagesTanktrader BV: Technical Specification For 20' X 8' X 8'6" Iso Icc Type Tank Container For Bulk Bitumen (Un T3 Code)Nauman AliPas encore d'évaluation

- Cat Walk InfoDocument428 pagesCat Walk InfoEmmanuel Soberano Hernandez100% (1)

- PSC Ergodyne Range 2021Document45 pagesPSC Ergodyne Range 2021Project Sales CorpPas encore d'évaluation

- Price List November 2016: Miniature Circuit Breaker - MCB Miniature Circuit Breaker - MCBDocument4 pagesPrice List November 2016: Miniature Circuit Breaker - MCB Miniature Circuit Breaker - MCBsandeepsmartPas encore d'évaluation

- Silicone Chemical Compatibility Chart PDFDocument7 pagesSilicone Chemical Compatibility Chart PDFTiago SucupiraPas encore d'évaluation

- Pneumatic Slide GateDocument7 pagesPneumatic Slide Gateemad sabriPas encore d'évaluation

- Instructions For Use: Rotors and TubesDocument158 pagesInstructions For Use: Rotors and TubesShan AhmadPas encore d'évaluation

- Pad EyesDocument2 pagesPad Eyesberry habPas encore d'évaluation

- d500 750 1000 O1 01 1up PDFDocument192 pagesd500 750 1000 O1 01 1up PDFLOMBARDO LOPEZPas encore d'évaluation

- 4.84kWh - Standard - Product Specification - R0.2 - 20190319Document48 pages4.84kWh - Standard - Product Specification - R0.2 - 20190319danilo reyesPas encore d'évaluation

- AC Motor (Chinese Produce)Document5 pagesAC Motor (Chinese Produce)Ali Alakari100% (1)

- BOP Chamber Volume & Dimensions: No Equipment Size & Rating Manufacture TypeDocument14 pagesBOP Chamber Volume & Dimensions: No Equipment Size & Rating Manufacture TypeBoedi SyafiqPas encore d'évaluation

- Installing and Maintaining Drill LinesDocument1 pageInstalling and Maintaining Drill LineslacariaPas encore d'évaluation

- SA 02 TDS 11 Carriage InterferenceDocument4 pagesSA 02 TDS 11 Carriage InterferenceHayLenLeePas encore d'évaluation

- Kirloskar Valves Technical Specification CatalogueDocument24 pagesKirloskar Valves Technical Specification CatalogueAbhinay SuratkarPas encore d'évaluation

- EHP Series Piston Accumulators: 0.1 To 1000 Litres, Up To 350 BarDocument32 pagesEHP Series Piston Accumulators: 0.1 To 1000 Litres, Up To 350 BarMichael Akhramovich100% (1)

- Manual MPC Manual MPCH Master BushingH Master BushingDocument28 pagesManual MPC Manual MPCH Master BushingH Master BushingLeonardo Rachen RodriguezPas encore d'évaluation

- 02-A Kinetico Owners Manual - Commercial Plus Softener SeriesDocument32 pages02-A Kinetico Owners Manual - Commercial Plus Softener SeriesCastoriadisPas encore d'évaluation

- 130 Kit Deadline Anchor (En)Document19 pages130 Kit Deadline Anchor (En)c.valderrabano81Pas encore d'évaluation

- Manual 752 RB3 PartDocument10 pagesManual 752 RB3 PartLee NaidooPas encore d'évaluation

- Safety & Operating Manual: Power Crimp 707 CrimperDocument20 pagesSafety & Operating Manual: Power Crimp 707 CrimpervankarpPas encore d'évaluation

- Astm A435 2012Document2 pagesAstm A435 2012FernandoiPas encore d'évaluation

- Gexol PDFDocument36 pagesGexol PDFJPas encore d'évaluation

- 8 OffGrid DesignGuidelinesDocument20 pages8 OffGrid DesignGuidelinesMarkos AntoniosPas encore d'évaluation

- ABB - Busduct Brochure - 12pp - WEB PDFDocument12 pagesABB - Busduct Brochure - 12pp - WEB PDFAnonymous CLJyqZPas encore d'évaluation

- Ac DistributionDocument19 pagesAc Distributionsrinimeha@gmail.comPas encore d'évaluation

- EasergyP5 NRJED313567EN 270519 PDFDocument94 pagesEasergyP5 NRJED313567EN 270519 PDFrizki bunaiPas encore d'évaluation

- No Description Size QTY Unit Price Cables: NYY 0.6/1 KVDocument1 pageNo Description Size QTY Unit Price Cables: NYY 0.6/1 KVtees220510Pas encore d'évaluation

- The Path of The Smart GridDocument11 pagesThe Path of The Smart Gridmmorsy1981Pas encore d'évaluation

- Extra High Voltage (Ehv) Ac TransmissionDocument15 pagesExtra High Voltage (Ehv) Ac TransmissionManmohan MeenaPas encore d'évaluation

- For ELECTRICAL TESTING LABORATORIES - The NABL (PDFDrive)Document122 pagesFor ELECTRICAL TESTING LABORATORIES - The NABL (PDFDrive)Mani Dhamodharan100% (1)

- Cod.380S.A: Instruction ManualDocument24 pagesCod.380S.A: Instruction ManualstopnaggingmePas encore d'évaluation

- General Description Features: EzbuckDocument9 pagesGeneral Description Features: EzbuckCristina NistorPas encore d'évaluation

- Power Systems: Power Systems Undervoltage and Overvoltage Time Lag RelaysDocument4 pagesPower Systems: Power Systems Undervoltage and Overvoltage Time Lag RelaysHarkishen SinghPas encore d'évaluation

- KNK1053 Kondezatorske BaterijeDocument4 pagesKNK1053 Kondezatorske BaterijeCybossPas encore d'évaluation

- Report On The Logic GatesDocument33 pagesReport On The Logic GatesSamyak Sau63% (27)

- Fairchild Power Producs Selection GuideDocument74 pagesFairchild Power Producs Selection GuidevasilmanolovPas encore d'évaluation

- Unit 3 Power Electronics For Renewable Energy SystemsDocument88 pagesUnit 3 Power Electronics For Renewable Energy SystemsTamil SelvanPas encore d'évaluation

- DC-DC Converters - MINI-PS - 12 - 24DC-24DC-1 - 2866284Document7 pagesDC-DC Converters - MINI-PS - 12 - 24DC-24DC-1 - 2866284Antonio SerranoPas encore d'évaluation

- MCB Trip CurvesDocument3 pagesMCB Trip CurvesKirran Kumar SeelammPas encore d'évaluation

- Present NoeraDocument12 pagesPresent NoeraOtuagaPas encore d'évaluation

- Brochurer ESBDocument4 pagesBrochurer ESBcikgusuriyatiPas encore d'évaluation

- HSPE-144M M6 HC Bifacial 450W Rev.00Document2 pagesHSPE-144M M6 HC Bifacial 450W Rev.00Alejandro Holguin QuinteroPas encore d'évaluation

- PSS1 0109Document4 pagesPSS1 0109Joanna BaileyPas encore d'évaluation

- Earthing Design SOFTWARE - REV01Document10 pagesEarthing Design SOFTWARE - REV01Rahul SrivastavaPas encore d'évaluation

- Service Manual: 1/2-Din Graphic Equalizer/CrossoverDocument10 pagesService Manual: 1/2-Din Graphic Equalizer/CrossovertecnitelPas encore d'évaluation

- OptiX RTN PI-DC B21 Product Overview and Installation Guide 01 PDFDocument8 pagesOptiX RTN PI-DC B21 Product Overview and Installation Guide 01 PDFSaeed Ashraf KhanPas encore d'évaluation

- Integration Relay: On-Vehicle InspectionDocument1 pageIntegration Relay: On-Vehicle InspectiondennoPas encore d'évaluation

- Ethicon Harmonic 300 Generator - Service ManualDocument80 pagesEthicon Harmonic 300 Generator - Service ManualMetrologia BiomedicaPas encore d'évaluation

- SHELL100 12pDocument2 pagesSHELL100 12pLuizABastosPas encore d'évaluation

- slvt145r PDFDocument93 pagesslvt145r PDFJuan AntonioPas encore d'évaluation

- Sliver3000 Panel SpecificationsDocument5 pagesSliver3000 Panel SpecificationsembokoPas encore d'évaluation

- Monoi: Heat-Shrinkable MV Indoor TerminationDocument1 pageMonoi: Heat-Shrinkable MV Indoor Terminationkushwah9kpriyaPas encore d'évaluation

- Automatic Synchronisation of AlternatorDocument2 pagesAutomatic Synchronisation of AlternatorInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation