Académique Documents

Professionnel Documents

Culture Documents

DP LT Calibration

Transféré par

kvsangeethDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DP LT Calibration

Transféré par

kvsangeethDroits d'auteur :

Formats disponibles

Section

3

APPLICATION CONSIDERATIONS Zero suppression

Calibration

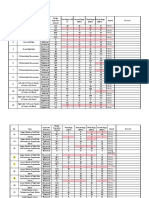

Diaphragm seal installations frequently require transmitters to be calibrated with suppressed or elevated zeroes. For more extensive calibration information see the applicable transmitter manual. A suppressed zero is needed when a gage or absolute pressure transmitter is mounted below the high side tap (the bottom process connection). When the transmitter is mounted below the high side tap, the fill fluid in the capillary puts pressure on the transmitter sensor causing it to give a positive pressure reading even when the tank is empty. Conversely, an elevated zero is needed for a gage or absolute transmitter mounted above the high side tap (the bottom process connection) or for a two seal differential pressure application. In these cases, the transmitter reads a negative pressure when the tank is empty, due to the head pressure effect of the capillary fill fluid. Example 1 calculates the maximum amount of zero elevation or suppression for a transmitter of a specific range. The results of the calculation will help in determining the mounting location for the transmitter. Example 1

Mounting Considerations for a Model 3051 Range 2 Transmitter/Seal System.

Zero elevation

Maximum Span Calculation

Maximum height of process fluid (H) = 65 inches (165 cm) Specific gravity of the process fluid (sp) = 1.0 inH2O/inch, (p) = (1 000 kg/cm3) Transmitter Lower Range Limit (LRL) = -250 inH2O (- 620 mbar) Transmitter Upper Range Limit (URL) = 250 inH2O (620mbar) Specific gravity of the (Inert) capillary fill fluid (s f) = 1.85 inH2O/inch 3 f = (1 850 kg/m ) Gravity Constant (g) for SI Units: 9,81 m/s2 American Units Step 1 Step 2 Step 3 Step 4 URL > (h) (sf) + (H) (sp) > LRL 250 inH2O > (h) (1.85 inH2O/inch) + (65 inches) (1.0 inH20/inch) > -250 185 inH2O > (h) (1.85 inH2O/inch) > -315 inH2O 100 inches > (h) > -170 inches

3-1

Model 1199 Diaphragm Seal Systems Manual SI Units Step 1 Step 2

URL > f g h + p g H > LRL 1850 mbar 1000 mbar 620 ( mbar ) > h 9, 81 ------------ ---------------- + ( 1, 5m ) 9, 81 ------------ ---------------- > 620 ( mbar ) 100 m 100 m mbar mbar 620 ( mbar ) > h 9, 81 18, 5 ---------------- + ( 1, 5m ) 9, 81 10 ---------------- > 620 ( mbar ) m m

Step 3

( 620 147 ) ( mbar ) ( 620 147 ) ( mbar ) ----------------------------------------------------- > h > --------------------------------------------------------mbar --------------- mbar 182 182 --------------- m m = 2,6 meters > h > 4,2 meters

Step 4

NOTE

3 2 2 1 mbar ---------------------- = ( 1 kg m ) ( 1 m s ) ( 1 m ) = 1 N m 100

where: (h) is the distance between the transmitter and the high pressure tap. (h) is positive if the transmitter is mounted below the high pressure tap and is negative if it is mounted above the tap. In this case for a: One Seal System Suppressed Zero (transmitter mounted below the high pressure tap) Do not mount the transmitter below the seal more than 100 inches (2,6 meters) below the seal. One Seal System Elevated Zero (transmitter mounted above the high pressure tap) Do not mount the transmitter more than 170 inches (4,2 meters) above the seal. Two Seal System Elevated Zero (independent of transmitter location) If it is necessary to measure an empty tank condition, the distance between the seal taps should not exceed 170 inches (4,2 meters).

Electronics Considerations

Zero elevation and suppression must be such that the lower range value does not exceed the transmitter lower range limit (LRL), and the upper range value is less than or equal to the transmitter upper range limit (URL). The calibrated span must be greater than or equal to the minimum span. For applications in which the transmitter is mounted above or below the high pressure tap, be sure the calibrated span does not exceed the transmitter minimum and maximum span limits. NOTE For the Model 3051 and 1151 Smart Transmitters, the maximum span equals the difference between the upper and lower range limits. For example, a Model 3051CD2 (Range Code 2) transmitter that has an upper range limit of 250 inH2O (620 mbar) and a lower range limit of 250 inH2O (- 620 mbar) has a maximum span capability of 500 inH2O (1,24 bar).

Maximum Span

3-2

Calibration

Calibrating a One Seal System With Suppressed Zero (Transmitter Mounted Below the High Side Tap)

Given: DC 200 fill fluid (sf) = 0.93 in H2O/inch (h) = 40 inches (sp) = 1.2 in H2O/inch (H) = 120 inches Given: Fill fluid ( f) = 930 kg/m3 (h) = 1 meter ( p) = 1 200 kg/m3 (H) = 3 meters (g) = 9,81 m/s2 20mA

4mA h

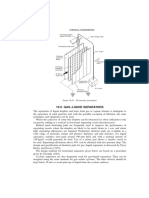

FIGURE 3-1. Transmitter Mounted Below the High Side Tap.

1. Calculate the amount of zero suppression by multiplying the distance between the process connection and the transmitter (h) by the fill fluid specific gravity (sf). American Units Step 1 Zero Suppression= (h)(sf) = (40 inches) (0.93 inH2O/inch) = 37.2 inH2O 2. Calculate the span by multiplying the maximum process fluid height (H) by the specific gravity of the process liquid (sp). Step 2 Span = (H)(sp) = (120 inches) (1.2 inH2O/inch) = 144 inH2O 3. Calibrate the transmitter using the following equation: Step 3 Calibration = Zero Suppression to (Zero Suppression + Span) = 37.2 to (37.2 + 144 inH2O) Step 4 SI Units Step 1 Step 2 Step 3 = 37.2 to 181.2 inH2O 1 Zero Suppression = f g h = 930 9, 81 -------- mbar = 91, 2 mbar 100 3 Span = H p g = -------- 1200 9, 81 mbar = 353 mbar 100 Calibration 4mA = Zero Suppression = 91, 2 mbar 20mA = Zero Suppression + Span = 91, 2 mbar + 353 mbar = 444, 2 mbar Therefore, in this example, a Model 3051C Range 2, URL = 250 inH2O (620 mbar), Model 1151Range 5, URL = 750 inH2O (1,9 mbar), or Model 2088 Range 0, URL = 220 inH2O (550 mbar) transmitter is required. NOTE 1 mbar = ( 1 kg m 3 ) ( 1 m s 2 ) ( 1 m ) = 1 N m 2 ---------------------100

Summary

3-3

1199-0160J

Model 1199 Diaphragm Seal Systems Manual

Calibrating a One-Seal System With Elevated Zero (Transmitter Mounted Above the High Side Tap)

Given: Inert fill fluid (sf) = 1.9 in H2O/inch (-h) = -30 inches (sp) = 1.1 in H2O/inch (H) = 120 inches Given: Inert fill fluid ( f) = 1850 kg/m3 (-h) = 0,75 m ( p) = 1 100 k/m3 (H) = 3 m (g) = 9,81 m/s2 Transmitter 20 mA H -h 4 mA

1199-0160k

FIGURE 3-2. Transmitter Mounted Above a Single Seal.

American Units Step 2 Step 2

1. Calculate the amount of zero elevation by multiplying the height of the transmitter above the process connection (-h) by the specific gravity of the fill fluid (sf). Zero Elevation = (-h)(sf) = (-30 inches) (1.9 inH2O/inch) = -57 inH2O 2. Calculate the transmitter span by multiplying the maximum height of the process fluid (H) by the specific gravity of the process liquid (sp). Span = (H)(sp) = (120 inches) (1.1 inH2O/inch) = 132 inH2O 3. Calibrate the transmitter using the following equation: Calibration = Zero Elevation to (Zero Elevation + Span) = -57 inH2O to (-57 + 132 inH2O)

Step 3

Step 4 SI Units Step 1

= -57 inH2O to 75 inH2O Zero Elevation = f g h 0, 75 = 1850 9, 81 ------------ mbar 100 = 136 mbar

Step 2

Span = p g H 3 = 1100 9, 81 -------- mbar 100 = 324 mbar

Step 3

Calibration: 4mA = Zero Elevation = 136 mbar 20mA = Zero Elevation + Span = 136 + 324 mbar = 188 mbar

Summary

Therefore, in this example, a Model 3051CG Range 2, URL = 250 inH2O (620 mbar), Model 1151 Range 4, URL = 150 inH2O (375 mbar), or Model 2088 Range 0, URL = 220 inH2O (550 mbar) transmitter is required. NOTE 3 2 2 1 mbar ---------------------- = ( 1 kg m ) ( 1 m s ) ( 1 m ) = 1 N m 100

3-4

Calibration

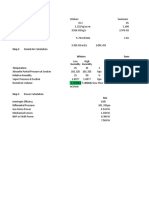

Calibrating a Two-Seal System With Elevated Zero (Transmitter Mounted Level With, Above, or Below the High Pressure Tap)

Given: DC 704 fill fluid (Sf) = 1.07 in H2O/inch (-h) = - 400 inches (Sp) = 0.9 in H2O/inch (H) = 350 inches Given: High Temperature Silicone Oil fill fluid (f) = 1 070 kg/m3 (-h) = -10 meters (p) = 900 kg/m3 (H) = 8,5 meters (g) = 9,81 m/s2 h H

Transmitter

FIGURE 3-3. Transmitter with Two-Seal System.

American Units

1. Calculate the amount of zero elevation by multiplying the distance between the process connections (h) by the specific gravity of the fill fluid (sf). Step 1 Zero Elevation = -(h)(sf) = - (400 inches) (1.07 inH2O/inch) = - 428 inH2O 2. Calculate the span by multiplying the maximum height of the process fluid (H) by the specific gravity of the process liquid (sp). Step 2 Span = (H)(sp) = (350 inches) (0.9 inH2O/inch) = 315 inH2O 3. Calibrate the transmitter using the following equation: Calibration = Zero Elevation to (Zero Elevation + Span) = - 428 inH2O to (- 428 + 315 inH2O) = - 428 inH2O to - 113 inH2O. Zero Elevation = f g h 10 = 1070 9, 81 -------- mbar 100 = 1050 mbar Step 2 Span = p g H 8, 5 = 900 9, 81 -------- mbar 100 = 750 mbar Step 3 Calibration: 4mA = Zero Elevation = 1050 mbar 20mA = Zero Elevation + Span = 1050 + 750 mbar = 300 mbar

Step 3 Step 4 SI Units Step 1

Summary

In this example a Model 3051CD Range 3, URL = 1,000 inH2O (2,5 bar) or a Model 1151DP Range 5, URL = 750 inH2O (1,9 bar) transmitter is required. NOTE 3 2 2 1 mbar ---------------------- = ( 1 kg m ) ( 1 m s ) ( 1 m ) = 1 N m 100 3-5

1199-0160L

Model 1199 Diaphragm Seal Systems Manual

FIGURE 3-4. Recommended Mounting Configuration for Vacuum Applications.

H Lmax Lmin

h Transmitter

1199-0160H

When installing diaphragm seals in vacuum applications: 1. Consult vapor pressure curves to determine that the correct fill fluid has been selected. Always compare against the minimum vacuum pressure and the maximum process temperature. 2. Always mount the transmitter below the bottom tap. 3. If in doubt, consult your local Rosemount Measurement Division representative or contact the nearest Rosemount Diaphragm Seal Support Center for guidance.

3-6

Vous aimerez peut-être aussi

- Abracadabra Viola by Peter DaveyDocument69 pagesAbracadabra Viola by Peter Daveykvsangeeth93% (15)

- Sample For Instructor Solution Manual For Matter and Interactions Vol 2 by Chabay and SherwoodDocument25 pagesSample For Instructor Solution Manual For Matter and Interactions Vol 2 by Chabay and Sherwoodomar burak100% (1)

- Air Conditioning Chapter Review QuestionsDocument53 pagesAir Conditioning Chapter Review Questionsmark410238% (8)

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and GreenDocument6 pagesNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and Greensunii19847908Pas encore d'évaluation

- Phys 211 11a.law of Heat Exchange and Change of PhaseDocument6 pagesPhys 211 11a.law of Heat Exchange and Change of PhaseRegina May Dela CruzPas encore d'évaluation

- 11.12.08 Chris Wilockx1Document56 pages11.12.08 Chris Wilockx1Raj ChavanPas encore d'évaluation

- Lecture 6 1Document24 pagesLecture 6 1Dany LoboPas encore d'évaluation

- LT Remote Seal CalibrationDocument6 pagesLT Remote Seal CalibrationmgkvprPas encore d'évaluation

- FTO Vs FTCDocument6 pagesFTO Vs FTCRizky WahyuPas encore d'évaluation

- Control of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Document2 pagesControl of Flow Rates at Startup: GAT2004-GKP-2010.009 September, 2010Enyerberht Castañeda BritoPas encore d'évaluation

- Desuperheater sizing calculation reportDocument1 pageDesuperheater sizing calculation reportErnestoPas encore d'évaluation

- Fluid Flow Basics OF Throttling ValvesDocument43 pagesFluid Flow Basics OF Throttling ValvesSandro AraújoPas encore d'évaluation

- Level Transmitter CalculationDocument15 pagesLevel Transmitter Calculationgalant_ppPas encore d'évaluation

- FV Flash Steam and Flash Vessel CalculationDocument2 pagesFV Flash Steam and Flash Vessel Calculationbeymar_5631Pas encore d'évaluation

- Rotameter Working and CalibrationDocument11 pagesRotameter Working and Calibrationsmit189Pas encore d'évaluation

- Control Valves in Split RangesDocument6 pagesControl Valves in Split RangesGaurav MishraPas encore d'évaluation

- Condensate Line SizingDocument4 pagesCondensate Line SizingMubin Ashraf SheikhPas encore d'évaluation

- Valve CV Flow Rate FormlaeDocument1 pageValve CV Flow Rate Formlaelatasharma79Pas encore d'évaluation

- Pressure Drop (Two Phases)Document38 pagesPressure Drop (Two Phases)PROCESOS PROCESOS100% (1)

- Evaporation Falling Film Forced Circulation Vapor Recompression Gea 170546Document20 pagesEvaporation Falling Film Forced Circulation Vapor Recompression Gea 170546Johan van der MenerPas encore d'évaluation

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocument9 pagesL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariPas encore d'évaluation

- The Basics of Throttling ValvesDocument56 pagesThe Basics of Throttling Valvesdanne_ePas encore d'évaluation

- Leve LDocument42 pagesLeve LSubodh SawantPas encore d'évaluation

- Air CompressorDocument51 pagesAir CompressorInaam Ur RehmanPas encore d'évaluation

- Expansion Indicator Boiler #1Document6 pagesExpansion Indicator Boiler #1Muhammad AbyPas encore d'évaluation

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 pagesPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajidePas encore d'évaluation

- Reduce TDS in Cooling Water to 390 ppmDocument6 pagesReduce TDS in Cooling Water to 390 ppmzamijakaPas encore d'évaluation

- Table Convert MMSCFD To SI SKG BetungDocument132 pagesTable Convert MMSCFD To SI SKG BetungGelorawan AditPas encore d'évaluation

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 pagesAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraPas encore d'évaluation

- 10 - Valve CV Sizing-Liquids & GasesDocument6 pages10 - Valve CV Sizing-Liquids & GasesMeliana Butar-ButarPas encore d'évaluation

- 5 Calculation Compressed Air System Principal DimensionDocument16 pages5 Calculation Compressed Air System Principal DimensionAtandho Gama MagwasyarPas encore d'évaluation

- R2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Document21 pagesR2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Diana Paula Echartea MolinaPas encore d'évaluation

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimPas encore d'évaluation

- Orifcie Sizing CalulationDocument25 pagesOrifcie Sizing CalulationmgkvprPas encore d'évaluation

- Motorised Valve: Instrument Datasheet Tag NoDocument1 pageMotorised Valve: Instrument Datasheet Tag Nokrishna kumarPas encore d'évaluation

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDocument6 pagesR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Pressure Reducing CalculatorDocument12 pagesPressure Reducing CalculatoralifbaharunPas encore d'évaluation

- SN74LVC07Document23 pagesSN74LVC07abcdPas encore d'évaluation

- Design BasisDocument1 pageDesign BasismuhdqasimPas encore d'évaluation

- Service and District Regulator ConsiderationsDocument52 pagesService and District Regulator ConsiderationsRohan Sharma100% (1)

- TRG Control ValveDocument13 pagesTRG Control Valvemilton1987Pas encore d'évaluation

- By Pass RotameterDocument6 pagesBy Pass Rotameterkrishna kumarPas encore d'évaluation

- Pneumatic Conveying Spreadsheet-ContentDocument27 pagesPneumatic Conveying Spreadsheet-Contentaladdin4dPas encore d'évaluation

- Orifice Plate Flow Calculator Pressure DropDocument6 pagesOrifice Plate Flow Calculator Pressure Droplutfi awnPas encore d'évaluation

- Evaluating Boiler Efficiencies Using Direct and Indirect MethodsDocument52 pagesEvaluating Boiler Efficiencies Using Direct and Indirect MethodsdebelaPas encore d'évaluation

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Pas encore d'évaluation

- Summer Internship Project Report MAY - JUNE 2018: "Energy Balance of Distillation Column"Document14 pagesSummer Internship Project Report MAY - JUNE 2018: "Energy Balance of Distillation Column"krishan palPas encore d'évaluation

- Tank FixturesDocument21 pagesTank FixturesASSSSSSSSSSSSPas encore d'évaluation

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pages10.9. Gas Liquid Separators: Chemical EngineeringsterlingPas encore d'évaluation

- Jet Impingement CoolingDocument9 pagesJet Impingement CoolingDanish AbbasPas encore d'évaluation

- Presure Regulator Calculate PDFDocument5 pagesPresure Regulator Calculate PDFGorast KolevPas encore d'évaluation

- Blower Power CalculationsDocument7 pagesBlower Power CalculationsMuzzamilPas encore d'évaluation

- Compact Heatless Air DryersDocument1 pageCompact Heatless Air DryersBossman Instruments TechnologyPas encore d'évaluation

- Recip Compressor Calculations For GCP-3Document4 pagesRecip Compressor Calculations For GCP-3Greg GolushkoPas encore d'évaluation

- ZM KV Idag eDocument6 pagesZM KV Idag elutfi awnPas encore d'évaluation

- Pump CalcDocument1 pagePump CalcMoch WildanPas encore d'évaluation

- 13-391 Strainers Datasheet - GrottoDocument3 pages13-391 Strainers Datasheet - GrottoAniket GaikwadPas encore d'évaluation

- Sizing CalculationDocument4 pagesSizing Calculationsachin2712Pas encore d'évaluation

- Cepde - Valve Sizing (U16ch036, U16ch037, U16ch083)Document15 pagesCepde - Valve Sizing (U16ch036, U16ch037, U16ch083)VRUSHABHPas encore d'évaluation

- Solutions 3 17Document2 pagesSolutions 3 17EDM MAGIC100% (1)

- Pump SizingDocument3 pagesPump Sizingtimayaa1000Pas encore d'évaluation

- High-pressure regulators for gas distributionDocument6 pagesHigh-pressure regulators for gas distributionManish SaraswatPas encore d'évaluation

- Statistics for Process Control Engineers: A Practical ApproachD'EverandStatistics for Process Control Engineers: A Practical ApproachPas encore d'évaluation

- Vertical KO Drum Sizing (Ver 1.0.0) : 1.0 DescriptionDocument21 pagesVertical KO Drum Sizing (Ver 1.0.0) : 1.0 Descriptionrameshkarthik810Pas encore d'évaluation

- Notification Southern Naval Command Kochi Various VacanciesDocument6 pagesNotification Southern Naval Command Kochi Various VacancieskvsangeethPas encore d'évaluation

- Kmuvkn DNT M¿ V) Ns P Ticfw:) I HCP Awn°Q¿) H¿I V HT °pwDocument15 pagesKmuvkn DNT M¿ V) Ns P Ticfw:) I HCP Awn°Q¿) H¿I V HT °pwkvsangeethPas encore d'évaluation

- Instrument Fitter Tray CalculationDocument1 pageInstrument Fitter Tray Calculationkvsangeeth100% (2)

- Conversion TableDocument3 pagesConversion TablekvsangeethPas encore d'évaluation

- Zodiac SignsDocument47 pagesZodiac Signskvsangeeth100% (1)

- Indian Railway Station Code IndexDocument3 pagesIndian Railway Station Code IndexmayurshahPas encore d'évaluation

- Violin For Dummies 2nd Edition PDFDocument39 pagesViolin For Dummies 2nd Edition PDFhydraconisPas encore d'évaluation

- Modicon ManualDocument45 pagesModicon ManualkvsangeethPas encore d'évaluation

- Vitamin BasicsDocument102 pagesVitamin Basicslouise kartikaPas encore d'évaluation

- Magnetrol Level Flow Tech HandbookDocument44 pagesMagnetrol Level Flow Tech HandbookDelfinshPas encore d'évaluation

- Pocket Safety BookDocument86 pagesPocket Safety Bookkvsangeeth100% (1)

- Petroleum RefiningDocument4 pagesPetroleum Refiningkvsangeeth100% (1)

- My Love "She Is My All"Document4 pagesMy Love "She Is My All"kvsangeethPas encore d'évaluation

- VaporpressureDocument14 pagesVaporpressureShaira TanPas encore d'évaluation

- Traversable WormholesDocument18 pagesTraversable WormholesMohaimen NirjhorPas encore d'évaluation

- Aitel Joint Mock Examinations: Uganda Certificate of EducationDocument20 pagesAitel Joint Mock Examinations: Uganda Certificate of EducationOwani JimmyPas encore d'évaluation

- Residential DaDocument14 pagesResidential DaSasquatchCornPas encore d'évaluation

- Grade 12 Physics Investigatory ProjectDocument3 pagesGrade 12 Physics Investigatory ProjectAziyaPas encore d'évaluation

- Converting Per Unit System Inertia to Engineering UnitsDocument3 pagesConverting Per Unit System Inertia to Engineering UnitsshahqazwsxPas encore d'évaluation

- Compressed Air Manual Tcm44-1249312Document8 pagesCompressed Air Manual Tcm44-1249312Osama Kamel ElghitanyPas encore d'évaluation

- Science Form 1 Chapter 1 (1.3)Document5 pagesScience Form 1 Chapter 1 (1.3)yasPas encore d'évaluation

- (LAB 9) FrictionDocument9 pages(LAB 9) FrictionMuhammad ShadzrinPas encore d'évaluation

- Full Handbook Thermodynamics11005Document169 pagesFull Handbook Thermodynamics11005Max NighswanderPas encore d'évaluation

- API MPMS Chapter 11.1 2004 Uncertainty Worksheet: +44-1397-773190 LandlineDocument3 pagesAPI MPMS Chapter 11.1 2004 Uncertainty Worksheet: +44-1397-773190 LandlineMarcos CornelioPas encore d'évaluation

- CBSE Class 11 Physics Chapter 13 - Kinetic Theory Important Questions 2023-24Document46 pagesCBSE Class 11 Physics Chapter 13 - Kinetic Theory Important Questions 2023-24Buddhadev BeraPas encore d'évaluation

- Singati Hydro Energy Ltd.Document47 pagesSingati Hydro Energy Ltd.kumarPas encore d'évaluation

- 104 K5C CapacitorDocument54 pages104 K5C CapacitorsotaquitoPas encore d'évaluation

- 1 - Physical Quantities & Units PDFDocument53 pages1 - Physical Quantities & Units PDFMazinPas encore d'évaluation

- D176Document10 pagesD176Diego Castillo JaramilloPas encore d'évaluation

- Electric Potential & Relationship Between E and VDocument18 pagesElectric Potential & Relationship Between E and VHamza Salah-Ud-DinPas encore d'évaluation

- Projectile Motion Experiment ReportDocument5 pagesProjectile Motion Experiment ReportDương Quang MinhPas encore d'évaluation

- Analysis of windscreen wiper mechanism using MSC AdamsDocument15 pagesAnalysis of windscreen wiper mechanism using MSC AdamsDeepak SomanPas encore d'évaluation

- Graph Worksheet# 1Document3 pagesGraph Worksheet# 1smoabayomi3575Pas encore d'évaluation

- Kinematics in One DimensionDocument51 pagesKinematics in One DimensionDepriPas encore d'évaluation

- Science 8 Learning Activity Sheet (Week 3)Document2 pagesScience 8 Learning Activity Sheet (Week 3)Rosita CayananPas encore d'évaluation

- Mechanical Properties of FluidsDocument8 pagesMechanical Properties of FluidsMokshPas encore d'évaluation

- Static Equilibrium (Problems)Document5 pagesStatic Equilibrium (Problems)E-m FunaPas encore d'évaluation

- Cable Sizing CalculationDocument28 pagesCable Sizing CalculationEmmanuel IfedioraPas encore d'évaluation

- Verify Thevenin and Norton TheoremsDocument5 pagesVerify Thevenin and Norton Theoremskrishnareddy_chintalaPas encore d'évaluation

- Evaluation of Losses in Thyristor Valve For SVC ApplicationDocument4 pagesEvaluation of Losses in Thyristor Valve For SVC Applicationywkimc82Pas encore d'évaluation