Académique Documents

Professionnel Documents

Culture Documents

Developing Sprinkler System Design Criteria... - D.nugent Expa

Transféré par

S MujtabaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Developing Sprinkler System Design Criteria... - D.nugent Expa

Transféré par

S MujtabaDroits d'auteur :

Formats disponibles

Developing Sprinkler System Design Criteria for Flammable and Combustible Liquid Storage

David P. Nugent Aon Risk Consultants Introduction Safe handling and storage of flammable and combustible liquids requires a multi-faceted risk management strategy that includes prevention and mitigation measures. These measures should account for a potential incident to cause injuries, illness, environmental damage, property damage, and business interruption. Proper material handling is necessary to prevent or minimize unwanted liquid spills or releases. This is the most important fire safety objective during a liquid handling or storage operation. While an exposing fire involving Class A materials is always possible, a liquid spill or release is necessary for a fire to occur involving only liquids. Spills and releases are easier to manage than controlling ignition sources. A suggested list of prevention and mitigation measures follows: Material Handling Control of Ignition Sources Product Inventory Classification and Control Systems Building Construction Features (Fire Resistance, and Liquid Containment and Drainage) Spatial Separation Manual Fire Protection Administrative Controls and Emergency Planning Proper Fire Protection System Design Criteria

While all of the aforementioned needs to considered, this abstract will focus on proper fire protection system design criteria. In terms of codified criteria, the 1996 edition of NFPA 30 is the only code that lists the specific fire test basis for the sprinkler protection criteria in each of the protection tables. A companion document for NFPA 30, the Directory of Fire Tests Involving Storage of Flammable and Combustible Liquids in Containers, 3rd Edition, abstracts 155 sprinklered fire tests involving flammable and combustible liquids. This directory, which is referenced in Appendix D.2 of NFPA 30, is available from the Society of Fire Protection Engineers. Brief History of Sprinkler Protection Criteria Over the past 10 years, there have been significant changes within NFPA 30 for containerized storage. The sprinkler protection design criteria in the 1993 and earlier editions were not based upon full-scale fire tests. When polled at that time, the NFPA 30 committee membership could not state the basis for the original protection criteria. Among other important issues, the criteria that did exist was lacking in guidance on ceiling height limits and container types. Additionally, the criteria were located in the Appendix of the code, using the caveat This Appendix is not a part of the requirements of this NFPA David P. Nugent Page 1 4/27/2006

document, but is included for information purposes only. This portion of the code was not credible, was not utilized by informed professionals, and was unenforceable by authorities having jurisdiction. A watershed event occurred in 1987 involving a fire at a paint warehouse in Dayton, Ohio. This $50 million loss called attention to the inadequacies of NFPA 30. In the wake of this fire, numerous fullscale fire tests were conducted. Thereafter, individual fire test based proposals that were submitted to the NFPA 30 committee were met with mixed results. In light of this, a protection criteria task group was formed to develop fire test based sprinkler system design criteria. This task group presented to the NFPA 30 committee a proposal that included re-written protection criteria tables. After significant debate, the committee accepted this proposal for introduction into the 1996 edition of the code. Beginning with the 1996 edition of the code containerized storage of Class IB through IIIB liquids are addressed with: 6 protection tables in Section 4.8 of the 1996 edition that are based upon 85 sprinklered fire tests 10 protection tables in Section 4.8 and 1 protection table in Appendix D.4 of the 2000 edition that are based upon 136 sprinklered fire tests 11 protection tables in Section 6.8 and 1 protection table in Appendix D.4 of the 2003 edition that are based upon 155 sprinklered fire tests 11 protection tables in Section 16.5 and 1 protection table in Appendix D.4 of the 2007 (Proposed) edition that are based upon 160 sprinklered fire tests

For more information on the 2003 edition sprinkler protection tables, Appendix A contains a summary of these tables. The fire tests used for substantiation were conducted over a period of decades at FM Global Research, Underwriters Laboratories, or Southwest Research Institute and were supported by numerous financial sponsors. These tests used a variety of water miscible and immiscible liquids that were packaged in steel, plastic, or glass containers. Storage arrays consisted of palletized/solid pile, rack (with and without barriers), and shelf storage arrangements at various heights. Sprinkler systems utilized either water or foamwater with various combinations of ceiling-mounted and in-rack sprinklers. The effectiveness of different sprinkler types and discharge flows were also explored. Test results include the number of operating sprinklers and operating times, ceiling gas and ceiling steel temperatures, damage assessment, and whether or not the tests were controlled. In 1996, the concept of Protected Storage was first utilized. The 1996 and later editions of the code now make a distinction between different container types, such as metal and plastic. This was introduced along with specific criteria for relieving style and non-relieving style metal containers. Other improvements have also been made in successive editions of this code. The sprinkler protection criteria in the 2003 edition of NFPA 30: Are still based upon on sprinklered fire tests Offers more liquid, container, and protection options Are more user-friendly Has improved decision trees, drawings, and appendix materials Page 2 4/27/2006

David P. Nugent

Sprinkler Design and Storage Criteria Development The integration of new criteria for warehouse designs into NFPA 30 requires several phases before it is adopted. The generation of commodity specific sprinkler system design and storage criteria is one of the latter phases of the process. It is desirable to codify these criteria in a nationally recognized code, such as NFPA 30 (See Appendix E, NFPA 30 for more details on this process). These criteria are most reliably generated using full-scale sprinklered fire tests, which are still being conducted. They are performed in specially designed facilities under controlled conditions. Small- and intermediate-scale fire tests are useful for preliminary or interpolated results. Computer fire models cannot replicate the data from full-scale fire tests. Preference is typically given to fullscale fire tests using a credible worst-case scenario. The objective of these tests is to develop an insight into what might be expected in real life fire situations. These tests attempt to simulate actual conditions to reasonably predict fire growth rate, fire magnitude, and the effect of sprinkler operation. When utilizing criteria developed from these tests it is essential that users understand assumptions and limitations associated with this criteria. It is also important to recognize that there are no guarantees when using design criteria in these protection tables, as an out-of-control fire can still occur. Primary Fire Test Drivers The results generated during these tests are affected by the following: Material Properties (Physical and Combustion) Container Design and Size Packaging Material Ignition Scenario Storage Arrangement Mixed Storage Sprinkler System Design Parameters Burning Behavior of Flammable and Combustible Liquids The burning behavior of flammable and combustible liquids can include: Pool Fires Jetting Ruptures 2 and 3 Dimensional Spill Fires Pass/Fail Criteria A fire test is generally considered unsuccessful if any of the following conditions are met: Sustained (7 to 10 min.) Ceiling Steel Temperatures Above 1000F Excessive Number of Operating Sprinklers (sprinkler-type dependent) Fire Travel Across Open Aisle and Significant Involvement of Target Commodity Significant Fire Travel and Involvement of Test Commodity in Main Array Insufficient Fire Involvement of Test Commodity Storage Array Collapse Page 3 4/27/2006

David P. Nugent

Severe Jetting Violent Rupture of a Container Exceeding predetermined pressure and temperature limits on certain large containers

Limitations and Assumptions Based upon the current available body of knowledge, certain limitations and assumptions must be understood. These limitations and assumptions should be factored into the overall risk management strategy when utilizing the sprinkler system design criteria in NFPA 30: Flash Point - The current NFPA classification system for flammable and combustible liquids is based upon the flash point, and in some instances, the boiling point of a liquid. This ranking system only addresses the ease of ignition of a liquid and to some degree its volatility. Other important properties related to the control of fires involving these liquids, such as heat release rate, miscibility, viscosity, and reactivity, are not included. Additionally, fires involving high flash point oils (Class IIIB liquids) should not be underestimated as they can be very severe, if the fire becomes well developed. On the other end of the spectrum, Class IA liquids have not been subject to full-scale sprinklered fire tests. Tests have not been conducted as these materials have limited use in containerized products. Additionally, Class IA liquids can produce extremely severe fires. Therefore, the protection criteria tables for Class IA liquids in Appendix D.3 of NFPA 30 are not based upon full-scale sprinklered fire tests. These tables in Appendix D.3 were carried over from the Appendix D-2 in the 1993 edition of NFPA 30. Water Miscibility Diluting a water miscible flammable liquid with water may have a positive effect on fire controllability. While this is not always a practical protection strategy, a flammable or combustible liquid will not have a fire point above a certain water concentration. At that concentration which is unique to each material, while a flash may propagate across the surface of the liquid, the liquid will not undergo sustained combustion if exposed to an ignition source. During sprinklered fire testing, the effect of dilution has been most pronounced in fire tests using small plastic containers. Although not yet tested, if these small plastic containers were replaced with small metal containers, a greater improvement in controllability would be expected. Heat Release Rate The worst-case Class IB liquid of choice thus far has been heptane. While it is a worst-case Class IB hydrocarbon, other non-hydrocarbon liquids may be worstcase Class IB liquids. Fire Protection Agent When utilizing a foam-water sprinkler system, the important role foamwater plays in controlling a fire should not be minimized. Therefore, when designing a foamwater sprinkler system, adequate duration must be supplied. If the foam-water supply is depleted before control is achieved, an out of control fire may still result. Chemical Reactivity Certain reactive monomers, such as styrene and the family of acrylates, may self-react exposed to fire. Although never subjected to full-scale sprinklered fire tests, these materials will likely have a synergistic effect on fire growth and severity. It should also

David P. Nugent

Page 4

4/27/2006

be noted that Table 6.8.2(k) does contain sprinkler system design criteria for unsaturated polyester resins (with 50% by vol. IC, II, or IIIA liquid constituents). Sprinkler System Reliability System reliability should be considered when making a selection. More complicated systems, such as foam-water sprinkler systems, may provide a higher degree of fire controllability. However, more complicated systems will also be inherently less reliable. Storage Array Stability In the event of a storage array collapse during a fire, a much larger fire will likely ensue. This may result in an out of control fire. The protection criterion in NFPA 30 does not anticipate a storage array collapse. Limitations of Liquid Release Rate The protection criterion in NFPA 30 will not control fires involving large or a sudden release of heat. Violent ruptures, large pool fires, and fires with severe jetting will likely not be controlled without significant manual fire fighting as a backup. This of course presents a life-safety hazard to the fire fighters. Ignition delay An extended ignition delay during a significant flammable liquid spill may result in a deflagration-type explosion. The vapor generated, particularly if it is a 3 dimensional spill, may place the enclosure within the limits of flammability before ignition. Test Conditions with 1st Generation of Tests Some of the tests conducted in the early 1990s were conducted in ULs old test facility that had a footprint of 1,600 sq. ft. Also, some of these same tests utilized spill igniters over 2 gals and mixed commodities. Recent test results have raised issues that may question the results of these tests due to these test conditions. These concerns raise questions about the sprinkler system design and storage criteria based upon these aforementioned tests.

Challenges with Full-Scale Testing of Flammable and Combustible Liquids Reoccurring challenges with full-scale fire testing are as follows: Funding for full-scale sprinklered fire testing remains an ever present obstacle. To overcome this, consortiums are often formed to provide the necessary funding. However, success using this approach requires a consensus among a group of sponsors that may have differing objectives. Full-scale fire testing has been conducted over many years involving many disparate groups. Each of these groups has focused on objectives relevant to their group and not followed objectives outlined in a master plan. Therefore, the sprinkler system design criteria, listed in the 1996 and later editions of NFPA 30, does not address all possible scenarios found in storage facilities. Access is not always given to experimental data from previous tests. Many fire test reports are not placed within the public domain for various reasons. This includes results that may offer a competitive advantage to the sponsor or results that may shed an unfavorable light on a given product.

David P. Nugent

Page 5

4/27/2006

Fire testing with flammable and combustible liquids presents challenges not associated with ordinary commodities. Therefore, the test facility may not be able or willing to explore all of the desired unknowns given the associated risks.

Additional Testing Currently, there are 2 distinct areas where additional fire tests are warranted as follows: Developing additional sprinkler protection strategies for liquids stored in intermediate bulk containers (IBCs) Retesting with K25 EC (Extended Coverage) sprinklers and possibly other spray sprinklers with mixed storage (1st generation tests at UL)

In summary, developing effective sprinkler system design criteria for flammable and combustible liquid storage is a complicated, multi-step process. As new data is developed and released into the public domain, the NFPA 30 committee continues to challenge the original assumptions and revise the advice offered.

David P. Nugent

Page 6

4/27/2006

Appendix A NFPA 30 Protection Table Summary

Table NFPA Liquid Class

IB, IC, II, IIIA & IIIB IB, IC, II, IIIA & IIIB IB, IC, II, IIIA & IIIB IB, IC, II, & IIIA IIIB

Liquid Miscibility

(1)

Sprinkler Protection Type (2)

Water Water Foam-Water Foam-Water Water

Storage Array (3)

Single- & Double-Row Rack Palletized Single- & Double-Row Rack Palletized Single-, Double-, & Multi-Row Rack Shelf Single- & Double-Row Rack Palletized & Rack Palletized Single- & Double-Row Rack Palletized

Container Types (4)

RS-Relieving Style Non-RS Non Relieving Style

6.8.2.(a) 6.8.2.(b) 6.8.2.(c) 6.8.2.(d) 6.8.2.(e)

Miscible & Non-Miscible Miscible & Non-Miscible Miscible & Non-Miscible Miscible & Non-Miscible Miscible & Non-Miscible Miscible & Non-Miscible Miscible Miscible & Non-Miscible Miscible & Non-Miscible Miscible & Non-Miscible Non-Miscible

RS & Non-RS Metal Containers, Portable Tanks, & IBCs RS & Non-RS Metal Containers, Portable Tanks, & IBCs RS & Non-RS Metal Containers, Portable Tanks, & IBCs RS & Non-RS Metal Containers, Portable Tanks, & IBCs 5 gal. Plastic Containers

6.8.2.(f) 6.8.2.(g) 6.8.2.(h) 6.8.2.(i) 6.8.2.(j) 6.8.2.(k)

IB, IC, II, IIIA & IIIB IB, IC, II, IIIA & IIIB IB, IC, II, IIIA & IIIB II, IIIA & IIIB II, IIIA & IIIB Unsaturated Polyester Resins (with 50% by vol. IC, II, or IIIA Liquid Constituents) IIIB (450 0F)

Water Water Water Water Water Water

1 gal. Non-RS Metal Containers Plastic Containers 5 gal. or 1 gal. RS Metal Containers 793 gal. Rigid Nonmetallic IBC 793 gal. Rigid Nonmetallic IBC > 5 gal. and < 60 gal. Metal Containers

D.4(a)

Non-Miscible or Miscible Combustible Liq. w/ Conc. >50% by Vol.

Water

Single-, Double-, & Multi-Row Rack

5 gal. Plastic Containers

Notes: (1) For miscible liquids with flammable or combustible liquid concentration > 50% by vol. (2) Sprinkler protection design criteria in actual NFPA 30 tables varies (3) Storage heights in actual tables varies (4) Container sizes in actual tables varies, except as noted

David P. Nugent

Page 7

4/27/2006

References Nugent, D. P., Freeman, J. L., and Oliszewicz, M., Guidelines for Safe Warehousing of Chemicals, Center for Chemical Process Safety, American Institute of Chemical Engineers, New York, NY, 1998. National Fire Protection Association, NFPA 30, Flammable and Combustible Liquids Code, Quincy, MA, 2003. Nugent, D. P., Directory of Fire Tests Involving Storage of Flammable and Combustible Liquids in Containers, Schirmer Engineering Corporation, September, 2004 (available from the Society of Fire Protection Engineers, Bethesda, MD). Nugent, D. P., Fire Tests Involving Storage of Flammable and Combustible Liquids in Small Containers, Journal of Fire Protection Engineering, Society of Fire Protection Engineers, Boston, MA, Vol. 6, No. 1, 1994, pp. 1-9. Nugent, D. P., Full-Scale Fire Tests, Fire Protection Engineering, Society of Fire Protection Engineers, Bethesda, MD, Summer, 2002. National Fire Protection Association, Understanding Fire Protection for Flammable Liquids, Edited by Davenport, J. A., and Benedetti, R. P., Chapter 7 Container Storage, Nugent, D. P., Quincy, MA, 2003

David P. Nugent

Page 8

4/27/2006

Vous aimerez peut-être aussi

- Chemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignD'EverandChemical Engineering Design: Principles, Practice and Economics of Plant and Process DesignÉvaluation : 4 sur 5 étoiles4/5 (16)

- Industrial and Process Furnaces: Principles, Design and OperationD'EverandIndustrial and Process Furnaces: Principles, Design and OperationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- A - Sandwich Panels FinalDocument28 pagesA - Sandwich Panels Finalhschoi12Pas encore d'évaluation

- Kitchen Fire Suppression SystemsDocument47 pagesKitchen Fire Suppression Systemszhobeys100% (2)

- Nordtest Method NT Fire 049Document16 pagesNordtest Method NT Fire 049mail2021Pas encore d'évaluation

- Guidelines for Combustible Dust Hazard AnalysisD'EverandGuidelines for Combustible Dust Hazard AnalysisPas encore d'évaluation

- By Mufti Taqi UsmaniDocument4 pagesBy Mufti Taqi UsmaniS MujtabaPas encore d'évaluation

- Synthesis and Kinetic Study of Co (Salen) (Revision)Document3 pagesSynthesis and Kinetic Study of Co (Salen) (Revision)Daniel Rodman50% (2)

- Lab 12 - Bunsen Burner Flame PDDocument2 pagesLab 12 - Bunsen Burner Flame PDvictoria kairoo50% (2)

- Process STD 601Document13 pagesProcess STD 601madx44100% (1)

- Addressing The Performance of Sprinkler Systems - NFPA 25 and Other Strategies - Exec Summary - Dec 2013 NFPRF - WorkshopDocument4 pagesAddressing The Performance of Sprinkler Systems - NFPA 25 and Other Strategies - Exec Summary - Dec 2013 NFPRF - Workshopfire-1Pas encore d'évaluation

- Guideline On Smacna Through Penetration Fire StoppingDocument48 pagesGuideline On Smacna Through Penetration Fire Stoppingwguindy70Pas encore d'évaluation

- XXVIII-Paper-2018 Developments in Thinking About Emergency Liquid Containment Systems inDocument12 pagesXXVIII-Paper-2018 Developments in Thinking About Emergency Liquid Containment Systems inAbdul AwanPas encore d'évaluation

- 19-02 Revised Updated 20210526 PDFDocument30 pages19-02 Revised Updated 20210526 PDFMd Rafat ArefinPas encore d'évaluation

- Class 0 and Class 1Document7 pagesClass 0 and Class 1vinnie1973Pas encore d'évaluation

- Flare System Study EpaDocument130 pagesFlare System Study Epahk168100% (2)

- R S C S: U. S. Chemical Safety and Hazard Investigation Board Ecommendations Tatus Hange UmmaryDocument2 pagesR S C S: U. S. Chemical Safety and Hazard Investigation Board Ecommendations Tatus Hange Ummarydisconnecting nowPas encore d'évaluation

- Steel Industry Gas SafetyDocument3 pagesSteel Industry Gas SafetyJaeman ParkPas encore d'évaluation

- Proposed - TIA - 1264R - NFPA - 285Document3 pagesProposed - TIA - 1264R - NFPA - 285SANDHY PUTRA SIPAYUNGPas encore d'évaluation

- Guidelines For The Protection of Pressurised Systems Exposed To Fire PDFDocument81 pagesGuidelines For The Protection of Pressurised Systems Exposed To Fire PDFhiginio.moro6182Pas encore d'évaluation

- Fire Safety Guidance - E-July10Document108 pagesFire Safety Guidance - E-July10Moe LattPas encore d'évaluation

- Fire Extinguisher Manufacturing Project ReportDocument3 pagesFire Extinguisher Manufacturing Project ReportEMS CommercePas encore d'évaluation

- Safe Flare System Design: John Zink CompanyDocument10 pagesSafe Flare System Design: John Zink CompanyAniket S Jadhav100% (4)

- PDFDocument8 pagesPDFonizuka-t2263Pas encore d'évaluation

- RP30-7, Design Philosophy Fire & Gas CSDocument22 pagesRP30-7, Design Philosophy Fire & Gas CSyulianus_sr100% (2)

- Final Report Section 1 Summary ReportDocument8 pagesFinal Report Section 1 Summary ReportDmitryPas encore d'évaluation

- Chemcial - Design Considerations For Petrochemical Plant - ASSE ArticleDocument6 pagesChemcial - Design Considerations For Petrochemical Plant - ASSE ArticleTerry A. WaldropPas encore d'évaluation

- HLTHSS001 Assessment Requirements R1Document3 pagesHLTHSS001 Assessment Requirements R1Rohmat HidayatPas encore d'évaluation

- HSG 176Document69 pagesHSG 176rezamzaPas encore d'évaluation

- Aesolutions Codes and Standards Update Si-BmsDocument16 pagesAesolutions Codes and Standards Update Si-BmsCRAPHATPas encore d'évaluation

- FireDocument116 pagesFirejovanivanPas encore d'évaluation

- A Common Sense Approach To Hazardous Area Classification For Electronic InstrumentationDocument12 pagesA Common Sense Approach To Hazardous Area Classification For Electronic InstrumentationVanforum ForrayPas encore d'évaluation

- IEC 61511 Based Design For Gas Detection Systems Monitoring Hydrocarbon Storage Tank SystemsDocument16 pagesIEC 61511 Based Design For Gas Detection Systems Monitoring Hydrocarbon Storage Tank Systemsarsil5840Pas encore d'évaluation

- Classification of Hazardous Locations Cox Lees Ang 1691051422Document213 pagesClassification of Hazardous Locations Cox Lees Ang 1691051422tahaPas encore d'évaluation

- Demonstrate Knowledge of Gas Combustion, Burners, Control Systems, and Flame ProtectionDocument3 pagesDemonstrate Knowledge of Gas Combustion, Burners, Control Systems, and Flame ProtectionGhulam AbbasPas encore d'évaluation

- E 603 - 01 - Rtywmy0wmq - PDFDocument18 pagesE 603 - 01 - Rtywmy0wmq - PDFYogiIndraPrayogaPas encore d'évaluation

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesD'EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Industrial Fire Journal - Fire & Rescue - Hemming Group LTD - LASTFIRE Illuminates The Next StepsDocument4 pagesIndustrial Fire Journal - Fire & Rescue - Hemming Group LTD - LASTFIRE Illuminates The Next StepsIvan MarinPas encore d'évaluation

- Priest & Associates Consulting, LLC: Industry Alerts!Document7 pagesPriest & Associates Consulting, LLC: Industry Alerts!PACFIREPas encore d'évaluation

- Development of Design Fires For Performance-Based Fire Safety DesignsDocument16 pagesDevelopment of Design Fires For Performance-Based Fire Safety DesignsovunctezerPas encore d'évaluation

- Engineering Design For Process SafetyDocument6 pagesEngineering Design For Process Safetytoalok4723Pas encore d'évaluation

- Nfpa 120 - 2023Document184 pagesNfpa 120 - 2023henrique.hs18Pas encore d'évaluation

- Book Reviews/Journal of Hazardous Materials 38 (1994) 329-348 339Document6 pagesBook Reviews/Journal of Hazardous Materials 38 (1994) 329-348 339Carlos PerdomoPas encore d'évaluation

- SY09 Fire Extinguisher Provisions: Policy Status: Policy StewardDocument3 pagesSY09 Fire Extinguisher Provisions: Policy Status: Policy StewardBasil M. IkhleifPas encore d'évaluation

- Pressure Strength Test Requirements For Hermetic Refrigerant CompDocument8 pagesPressure Strength Test Requirements For Hermetic Refrigerant CompMauro GonçalvesPas encore d'évaluation

- Guide To Undertaking Assessments IloftDocument16 pagesGuide To Undertaking Assessments IloftLatanya JenkinsPas encore d'évaluation

- Firestopping - Fortifying The Front Line - Insulation Outlook MagazineDocument15 pagesFirestopping - Fortifying The Front Line - Insulation Outlook MagazineSalim BakhshPas encore d'évaluation

- Blow DownDocument108 pagesBlow DownMahesh AsapuPas encore d'évaluation

- Safe Use of Cryogenic MaterialsDocument28 pagesSafe Use of Cryogenic MaterialsJimmy Cuevas MonsalvePas encore d'évaluation

- GAPS Guidelines: Water Mist SystemsDocument4 pagesGAPS Guidelines: Water Mist SystemsGerardo D. AguilarPas encore d'évaluation

- FCRC PR 01-02 Project3p22Document402 pagesFCRC PR 01-02 Project3p221jess6Pas encore d'évaluation

- FM Global - Fire Suppression Physics For Sprinkler ProtectionDocument14 pagesFM Global - Fire Suppression Physics For Sprinkler ProtectionChidi Henry100% (1)

- Combined Cooling, Heating and Power: Decision-Making, Design and OptimizationD'EverandCombined Cooling, Heating and Power: Decision-Making, Design and OptimizationPas encore d'évaluation

- Adhesives Technology for Electronic Applications: Materials, Processing, ReliabilityD'EverandAdhesives Technology for Electronic Applications: Materials, Processing, ReliabilityPas encore d'évaluation

- Developing Cost Estimates for Environmental Remediation ProjectsD'EverandDeveloping Cost Estimates for Environmental Remediation ProjectsPas encore d'évaluation

- Advanced Distillation Technologies: Design, Control and ApplicationsD'EverandAdvanced Distillation Technologies: Design, Control and ApplicationsPas encore d'évaluation

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesD'EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesPas encore d'évaluation

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsD'EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsPas encore d'évaluation

- Post-irradiation Examination Techniques for Research Reactor FuelsD'EverandPost-irradiation Examination Techniques for Research Reactor FuelsPas encore d'évaluation

- Dimensional Analysis: Practical Guides in Chemical EngineeringD'EverandDimensional Analysis: Practical Guides in Chemical EngineeringPas encore d'évaluation

- Nozzles of Medium Velocity For Deluge SystemsDocument1 pageNozzles of Medium Velocity For Deluge SystemsS MujtabaPas encore d'évaluation

- Chemcad Examples Ccex-En20062002Document75 pagesChemcad Examples Ccex-En20062002Walter Rigamonti100% (2)

- Rabi'ul-Awwal: From Superstitions Into LightDocument6 pagesRabi'ul-Awwal: From Superstitions Into LightS MujtabaPas encore d'évaluation

- Nutrition in Plants PDFDocument2 pagesNutrition in Plants PDFgamparohit75% (4)

- C100E Resin PUROLITEDocument3 pagesC100E Resin PUROLITEmilaPas encore d'évaluation

- Distillation Column Autocad Drawing Design: July 2017Document3 pagesDistillation Column Autocad Drawing Design: July 2017Tera EducativoPas encore d'évaluation

- Mechanical Properties of MaterialsDocument3 pagesMechanical Properties of MaterialsTiras Ngugi0% (1)

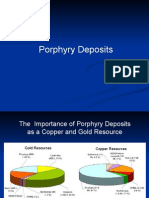

- Porphyry DepositsDocument43 pagesPorphyry DepositsVictor Valdivia100% (2)

- DehydrationDocument13 pagesDehydrationSaa D ShamimPas encore d'évaluation

- TechPlasty - PE500 - Polyethylene 500 - 2019-08-06Document2 pagesTechPlasty - PE500 - Polyethylene 500 - 2019-08-06SDKPas encore d'évaluation

- Agfa Cassettes Manual PDFDocument32 pagesAgfa Cassettes Manual PDFcarlosPas encore d'évaluation

- MSDS Songnox - 1680Document8 pagesMSDS Songnox - 1680Seshagiri KalyanasundaramPas encore d'évaluation

- Superoxide in Biology and MedicineDocument11 pagesSuperoxide in Biology and MedicineNvo SpektarPas encore d'évaluation

- PH - Wikipedia, The Free EncyclopediaDocument11 pagesPH - Wikipedia, The Free EncyclopediaShikhar MahajanPas encore d'évaluation

- Neraca MassaDocument15 pagesNeraca MassaFrengky Akmil PutraPas encore d'évaluation

- 1.TDS MIXO Plast D100Document2 pages1.TDS MIXO Plast D100mohamed ragabPas encore d'évaluation

- Material Safety Data Sheet - Calcium CarbideDocument11 pagesMaterial Safety Data Sheet - Calcium Carbidegodfrey kiyinjaPas encore d'évaluation

- XS NanoDocument24 pagesXS NanoAnonymous GgEgellVnU100% (1)

- ASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsDocument10 pagesASTM B505-B505M-12 Standard Specification For Cooper Alloy Continuous CastingsAarón Escorza MistránPas encore d'évaluation

- 025welding Engineering An Introduction - (2.5 Plasma Arc Welding)Document3 pages025welding Engineering An Introduction - (2.5 Plasma Arc Welding)Kamarul NizamPas encore d'évaluation

- SCIENCE 4 Q3 W4 Activity Sheets 2Document3 pagesSCIENCE 4 Q3 W4 Activity Sheets 2Rerai CaiellePas encore d'évaluation

- Year 9 Study Guide ChemistryDocument15 pagesYear 9 Study Guide Chemistryreem halawiPas encore d'évaluation

- State Wise Distribution of Units Registered Under Factories Act, 1948Document6 pagesState Wise Distribution of Units Registered Under Factories Act, 1948api-19850688Pas encore d'évaluation

- 2007 - Shellac in PolymerDocument43 pages2007 - Shellac in PolymerAnonymous x7VY8VF7Pas encore d'évaluation

- Enhanced Oil Recovery: SyllabusDocument24 pagesEnhanced Oil Recovery: SyllabusAkmuhammet MammetjanovPas encore d'évaluation

- Heating and Cooling CurveDocument4 pagesHeating and Cooling CurveADogThat GoesBarkPas encore d'évaluation

- Experiment 15.2 Temperature and Le Chatalier's Principle I. PurposeDocument3 pagesExperiment 15.2 Temperature and Le Chatalier's Principle I. PurposeDingPas encore d'évaluation

- The Frenkel-Kontorova Model - IntroductionDocument5 pagesThe Frenkel-Kontorova Model - Introductionreal thinkerPas encore d'évaluation

- Exp 10 - Exp 7 A Green Synthesis of Camphor UploadDocument4 pagesExp 10 - Exp 7 A Green Synthesis of Camphor UploadUyen V. NguyenPas encore d'évaluation

- Bangladesh Edible Oil Limied (Beol) : North Rupshi, Rupgonj, Narayanganj BangladeshDocument30 pagesBangladesh Edible Oil Limied (Beol) : North Rupshi, Rupgonj, Narayanganj BangladeshM. Kabbir Hossain Hero ,141437Pas encore d'évaluation

- Herbert Brown and Edward N. Peters' : Abstract: 80% or (503 000)Document5 pagesHerbert Brown and Edward N. Peters' : Abstract: 80% or (503 000)Liz HansPas encore d'évaluation