Académique Documents

Professionnel Documents

Culture Documents

Comparison of Classical and Wavelet Edge Detection For NDT Images

Transféré par

rcherrDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Comparison of Classical and Wavelet Edge Detection For NDT Images

Transféré par

rcherrDroits d'auteur :

Formats disponibles

12th A-PCNDT 2006 Asia-Pacific Conference on NDT, 5th 10th Nov 2006, Auckland, New Zealand

A COMPARATIVE STUDY ON THE PERFORMANCE OF THE CLASSICAL AND WAVELET BASED EDGE DETECTION FOR IMAGE DENOISING ON DEFECTIVE WELD THERMOGRAPHS

N.M.Nandhitha1, N.Manoharan1, B.Sheela Rani1 ,B.Venkataraman2, Baldev Raj2

1

Sathyabama Institute of Science and Technology, Deemed University, Chennai 600 119 2 Indira Gandhi Centre for Atomic Research, Kalpakkam 603 102.

Defect in welded structures is a matter of serious concern. The current practice involves interpretation by inspectors and experts, of radiographs after the weld is completed which is time consuming. With greater emphasis on automation during manufacturing process, automated NDT has gained prominence. One of the Non Destructive Evaluation (NDE) techniques that is being increasingly applied for online monitoring is thermal imaging. Thermal imaging is an advanced NDE technique based on the detection of infrared radiation. IR imaging during welding is based on the fact that a good weld would produce isothermal patterns while a weld with defects or arc misalignment, etc would produce isothermal patterns which are not symmetrical. In automated/ adaptive welding system, IR images are to be captured in real time and based on the isothermal patterns the quality of welding is to be judged. Once thermal features are detected and attributed to defects, it is necessary to quantitatively characterize them for acceptance / rejection. Quantitative characterization requires the application of advanced image processing tools for feature extraction and dimensional measurements. Edge detection is an important image processing operation which helps in detecting the Region of Interest. Traditional approaches that use classical edge detectors work fine with high quality pictures, but often are not good enough for noisy pictures because they cannot distinguish edges of different significance as they primarily focus on the coupling between image pixels on a single scale. Recent developments in Multi Scale Analysis such as Wavelet Transform help to overcome this difficulty. Analysis of the thermal image depicting lack of penetration reveals that compared to the edge detection performance of Classical Sobel & Prewitt filters wavelet based edge detectors provide better results by removing the noise. This paper compares the performance of classical edge detector with the proposed wavelet based edge detection technique that involves multiresolution analysis which significantly improves the results.

1. Introduction Welding is one of the widely used methods for joining metals. In spite of the numerous advances in the science and technology of welding, failures do occur and weld is still considered to be the weakest portion. Conventionally, the quality of the weld is ascertained only after the welding has been completed through the use of Non Destructive Testing (NDT) such as ultrasonic or radiography. Since each of these techniques is applied only after the welding is completed, a lot of time, material and manpower are wasted before one comes to know about the soundness of the weld. repaired immediately without continuing the process further. This strategy to monitor, control and maintain quality of welds is commonly known as adaptive welding or intelligent welding. Intelligent welding, as the name implies, combines welding equipment with intelligent sensing and control, knowledge of human experts, and Artificial Intelligence (AI) to improve joining efficiency and reduce the weld inhomogenities and defects. Wide variety of techniques has been reported in literature. Non-Destructive Testing sensors, which have been considered, for on-line monitoring include optical, radiography and Infrared (IR). Of the three, Infrared has the advantage that it can reveal surface and near surface perturbations. During the welding process, the position of the camera was fixed relative to the welding gun to provide measurement of temperatures in the weld pool and its vicinity. Experimental conditions were carefully maintained to minimize errors.

Inherent Limitations in conventional welding processes can be overcome if the weld is continuously monitored in real time for the assessment of defects and their automatic elimination by on-line control of the welding parameters. Moreover, the defective weld can be

12th A-PCNDT 2006 Asia-Pacific Conference on NDT, 5th 10th Nov 2006, Auckland, New Zealand However, the original image is degraded by the noise incurred due to atmospheric turbulences. Image denoising is used to remove the additive noise while retaining as much as possible the important signal features. Many classical edge detectors have been developed over time. They are based on the principle of matching local image segments with specific edge patterns. The edge detection is realized by the convolution with a set of directional derivative masks. The popular edge detection operators are Roberts, Sobel, Prewitt, FreiChen, and Laplacian operators [1-4]. They are all defined on a 3 by 3 masks, hence they are efficient and easy to apply. In situations where the edges are highly directional, classical edge detector works well because their patterns fit the edges better. But in an image corrupted with noise these edge detectors cannot distinguish actual edges from that of noise. In the recent years there has been a fair amount of research on wavelet signal de-noising [47] because wavelet provides an appropriate basis for separating noisy signal from the image signal. The paper is organized as follows. Section 2 deals with thermographs of welds. Section 3 reviews classical edge detection approaches. Section 4 discusses the multiscale wavelet model for edge detection. Section 5 deals with the performance analysis and Section 6 summarises the work. The functions are implemented in Matlab [8]. 2. Thermographs Of Welds The thermal maps produced by infrared thermal imaging instruments are called thermographs. Thermograph is defined as a 2D radiance function g(x, y), where x and y denote spatial coordinates and the value of g at any point is proportional to the radiance or energy emitted from the scene at that location. Traditionally, low intensities are represented by dark shades and high intensities by bright shades. The perturbations that arise due to variations in arc positioning, heat input and due to presence of contaminants distinctly manifest as differences in the otherwise uniform spatial and temporal surface temperature distributions of thermographs. These discontinuities of the intensity due to defects provide the locations of the object contours that are particularly meaningful for defect detection. Representation of the discontinuities or significant intensity differentials in thermographs is called edge. However due to uncontrolled illumination in and around the weld pool, thermographs have Figure 1: General Mask structure 3.1. Prewitt mask In Prewitt operator while approximating the first derivative, similar weights are assigned to all the neighbors of the candidate pixel whose edge strength is being calculated. Prewitt masks for horizontal and vertical edge detection are shown in Fig. 2 and Fig.3. intensity differential at almost every point. But not all these differentials are edges. In thermographs, weak edges correspond to weak changes in intensity values, while strong edges correspond to significant intensity gradient. Obviously stray strong edges with no spatial coherence in magnitude and orientation are noisy edges and need to be eliminated. Hence it is needed to avoid these insignificant intensity differentials which correspond to false edges in the image due to noise are to be removed. Hence edge detection with the removal of false edges is the most important step in digital image processing. 3. Classical Edge Detection Approach And Denoising In the most commonly used derivative approach, derivatives which yield high values at places where gray level changes rapidly are used to find edges of an image. Two dimensional derivatives for thermographs are computed with the help of edge masks. Computation of the gradient is based on obtaining the partial derivatives with respect to x and y. A digital image is divided into number of 3x3 sub images and 2-D convolution is performed on each of the sub image with the 3x3 edge detection masks. The general mask structure is shown in Fig. 1

W(-1,-1) W(-1,0) W(1,0) w(0,-1) W(1,-1) W(0,0) W(1,0) W(0,1) W(1,1)

-1 0 1

-1 0 1

-1 0 1

Figure 2: Prewitt mask for horizontal edge detection

12th A-PCNDT 2006 Asia-Pacific Conference on NDT, 5th 10th Nov 2006, Auckland, New Zealand

-1 -1 -1

0 0 0

1 1 1

A1(x; y) = -1 ; - 1:5 < x < 0;- 1:5 < y <1:5; +1 ; 0 < x < 1:5; -1:5 < y <1:5; (1) 0 ; otherwise A2(x; y) = -1; -1:5 < y < 0; - 1:5 < x < 1:5 +1; 0 < y < 1:5; -1:5< x <1:5 (2) 0; otherwise where A1(x; y) and A2(x; y) are the wavelet coefficients and x and y are the spatial co-ordinates. Sobel edge detector can be described as a discretized model of two orthogonal wavelets. A1(x;y) = -xei((x^2+y^2)/2) A2(x;y) = -yei((x^2+y^2)/2) (3) (4)

Figure 3: Prewitt mask for horizontal edge detection 3.2. Sobel mask In sobel operator, higher weights are assigned to the pixels close to the candidate pixels. Sobel masks for horizontal and vertical edge detection are shown in Fig. 4 and Fig. 5.

-1 0 1

-2 0 2

-1 0 1

Where A1(x; y) and A2(x; y) are the wavelet coefficients and x and y are spatial co-ordinates. Edge detection is performed by applying these masks as is done with conventional edge detection. But scale can be varied to obtain edges corresponding to different scales. As scale changes the edges due to noise are removed. Denoised thermographs are then subjected to morphological image processing for feature extraction and description. 5. Performance Analysis

Figure 4: Sobel mask for horizontal edge detection

-1 -2 -1

0 0 0

1 2 1

Figure 5: Sobel mask for vertical edge detection However the most common problems of above edge based segmentation, are edge in locations where there is no border caused by image noise or unsuitable information in thermographs 4. Multiscale Wavelet Model For Edge Detection And Denoising Noise commonly manifests itself as fine-grained structure in the thermograph, and wavelet transform provides a scale-based decomposition. Wavelet based edge detectors Edge detectors can be viewed as discretized wavelet functions. The convolution with edge detectors gives the wavelet transform of the image at a certain scale. Approximation of the continuous wavelet models will result in the classical edge detectors when discretized [9]. Once a continuous model is obtained, scales can be changed and objects are detected at different scale levels. Prewitt edge detector can be modeled as two orthogonal Haar wavelets.

The performance of Classical Edge Detectors and wavelet based Edge detectors are analyzed on a thermograph image of size 204 *188 of a defective weld with air gap due to lack of penetration. Original thermograph of the weld with air gap used for analysis is as shown in Fig.6.

Figure 6: Thermograph of weld with air gap The Original image is converted to a gray scale image to reduce computational complexity as shown in Fig.7

12th A-PCNDT 2006 Asia-Pacific Conference on NDT, 5th 10th Nov 2006, Auckland, New Zealand

Figure 7: Gray Scale Image The edges in the image are obtained by choosing Prewitt and Sobel filter as shown in Fig.8 and Fig.9 respectively.

Figure 10a: Sobel based edge detection (Scaling Factor = 15)

Figure 10b: Sobel based edge detection (Scaling Factor = 17) Figure 8: Edge detection using Sobel Mask

Figure 10c: Sobel based edge detection (Scaling Factor = 20) Figure 9: Edge detection using Prewitt mask The images in Fig. 8 and Fig. 9 include the Edge due to noise also. The sobel and Prewitt masks used could not treat the edges due to noise differently from that of the image. It is because Multiscale Edge detection is not possible with the conventional Prewitt & Sobel Masks. Wavelet based edge detectors provide a facility for varying the scaling factor, which helps in differentiating the weak edges from strong edges. The edge detected images using wavelet based Prewitt & Sobel filter are as shown in Fig. 10 and Fig. 11 respectively.

Figure 11a: Prewitt based edge detection (Scaling Factor = 15)

12th A-PCNDT 2006 Asia-Pacific Conference on NDT, 5th 10th Nov 2006, Auckland, New Zealand the multiscale edge detection property of wavelet that has helped in removing the noise. ACKNOWLEDGEMENT This project is sponsored by Indira Gandhi Centre for Atomic Research, Kalpakkam, India.

Figure 11b: Prewitt based edge detection (Scaling Factor = 17)

REFERENCES:

[1] Mero, A simplified and fast version of the Hueckel operator for finding optimal edges in pictures, Pric. IJCAI, pp. 650- 655, 1975. R.Nevatia, Evaluation of simplified Hueckel edge-line detector, Comput.,Graph., Image Process., vol. 6, no. 6, pp. 582-588, 1977. K. R. Castleman, Digital Image Processing, Englewood Cliffs, NJ: PrenticeHall, 1996. M. Hueckel, An operator which locates edges in digital pictures, J.of ACM, vol.18, no. 1, pp. 113-125, 1971. D.L. Donoho , De-Noising by Soft Thresholding, IEEE Trans. Info. Theory 43, pp. 933-936, 1993. S. Grace Chang, Bin Yu and M. Vattereli, Adaptive wavelet Thresholding for Image Denoising and Compression, IEEE Trans.Image Processing, vol. 9, pp. 1532-1546, 2000. M. Lang, H. Guo and J.E. Odegard, Noise reduction Using Undecimated Discrete wavelet transform, IEEE Signal Processing Letters, 1995 MAT LAB Image Processing Tool Box http://www.mathworks.com Jun Li, A Report on A Wavelet Approach to Edge Detection, 2003

[2]

[3] [4]

Figure 11c: Prewitt based edge detection (Scaling Factor = 20) It is evident from the Fig.10 and Fig.11, which as the scaling factor varies the noise, is removed. 6. Summary The edge detection performance of Classical Sobel and Prewitt filters are compared with the developed Wavelet based Sobel and Prewitt edge detectors. It is found that wavelet based edge detectors provide better results by removing the noise and the results are analyzed subjectively. It is

[5] [6]

[7]

[8] [9]

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Hydraulic Calculation Report - PSDocument289 pagesHydraulic Calculation Report - PSAob AprilPas encore d'évaluation

- Defects and Discontinuities GuideDocument68 pagesDefects and Discontinuities GuideRahulKumarPas encore d'évaluation

- Subcooling Superheating and Liquid Suction Heat ExchangerDocument4 pagesSubcooling Superheating and Liquid Suction Heat ExchangerDeniell Joyce MarquezPas encore d'évaluation

- Che 3G04 Winter 2004 Mcmaster UniversityDocument33 pagesChe 3G04 Winter 2004 Mcmaster UniversityAris Koreya100% (2)

- 50 CR Mo 4Document4 pages50 CR Mo 4Diogo NascimentoPas encore d'évaluation

- NDT HandBookDocument297 pagesNDT HandBookasimovvPas encore d'évaluation

- QuimicaDocument422 pagesQuimicaVernon SandovalPas encore d'évaluation

- MTech Seminar II and Project SyllabusDocument3 pagesMTech Seminar II and Project SyllabusrcherrPas encore d'évaluation

- Course Overview 2. Course Objectives: 06ec6351: Spread Spectrum and CdmaDocument9 pagesCourse Overview 2. Course Objectives: 06ec6351: Spread Spectrum and CdmarcherrPas encore d'évaluation

- Visualizing Statistical RelationshipDocument1 pageVisualizing Statistical RelationshiprcherrPas encore d'évaluation

- Automatic Language ID of Phone Speech in Under 40Document30 pagesAutomatic Language ID of Phone Speech in Under 40rcherrPas encore d'évaluation

- List of Books On Science Activities by Arvind GuptaDocument6 pagesList of Books On Science Activities by Arvind GuptaMuneeswara MuraliPas encore d'évaluation

- Performance Evaluation of Urban Transport FacilitiesDocument26 pagesPerformance Evaluation of Urban Transport FacilitiesrcherrPas encore d'évaluation

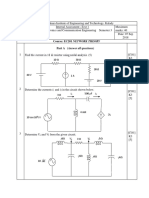

- Course: Ec201 Network Theory Part A (Answer All Questions)Document2 pagesCourse: Ec201 Network Theory Part A (Answer All Questions)rcherrPas encore d'évaluation

- SynchronizationDocument5 pagesSynchronizationrcherrPas encore d'évaluation

- Cosine Modulated FBDocument15 pagesCosine Modulated FBrcherrPas encore d'évaluation

- EC201 Netwok TheoryDocument2 pagesEC201 Netwok TheoryrcherrPas encore d'évaluation

- Mel ProgDocument2 pagesMel ProgrcherrPas encore d'évaluation

- ADCT SyllabusDocument4 pagesADCT SyllabusrcherrPas encore d'évaluation

- DC Test 1 - Answer KeyDocument1 pageDC Test 1 - Answer KeyrcherrPas encore d'évaluation

- SynchronizationDocument5 pagesSynchronizationrcherrPas encore d'évaluation

- Mel ProgDocument2 pagesMel ProgrcherrPas encore d'évaluation

- SS GATE QnsDocument2 pagesSS GATE QnsrcherrPas encore d'évaluation

- Automatic Language ID of Phone Speech in Under 40Document30 pagesAutomatic Language ID of Phone Speech in Under 40rcherrPas encore d'évaluation

- Atomic Layer Deposition (ALD) : Myo Min TheinDocument28 pagesAtomic Layer Deposition (ALD) : Myo Min TheinrcherrPas encore d'évaluation

- DSP Assignment TestDocument1 pageDSP Assignment TestrcherrPas encore d'évaluation

- YegnaMurtyK S R 2009Document11 pagesYegnaMurtyK S R 2009rcherrPas encore d'évaluation

- Atomic Layer Deposition (ALD) : Myo Min TheinDocument28 pagesAtomic Layer Deposition (ALD) : Myo Min TheinrcherrPas encore d'évaluation

- ISSPA Paper From IEEE SiteDocument4 pagesISSPA Paper From IEEE SitercherrPas encore d'évaluation

- Application Form Faculty 2014Document3 pagesApplication Form Faculty 2014rcherrPas encore d'évaluation

- SS GATE QnsDocument2 pagesSS GATE QnsrcherrPas encore d'évaluation

- Atomic Layer Deposition (ALD) : Myo Min TheinDocument28 pagesAtomic Layer Deposition (ALD) : Myo Min TheinrcherrPas encore d'évaluation

- ScheduleDocument1 pageSchedulercherrPas encore d'évaluation

- Finite Precision EffectsDocument3 pagesFinite Precision EffectsrcherrPas encore d'évaluation

- Shannon LimitDocument1 pageShannon LimitrcherrPas encore d'évaluation

- DSP Assignment TestDocument1 pageDSP Assignment TestrcherrPas encore d'évaluation

- Ijset 2013 712Document6 pagesIjset 2013 712rcherrPas encore d'évaluation

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel990Pas encore d'évaluation

- Mechanical Design II Clutches, Brakes, Couplings & FlywheelsDocument19 pagesMechanical Design II Clutches, Brakes, Couplings & FlywheelsterratempestPas encore d'évaluation

- Dwarf Mast Foundation Design - 11.05.20Document8 pagesDwarf Mast Foundation Design - 11.05.20SM ConsultantsPas encore d'évaluation

- Thin andDocument43 pagesThin andAnnisa TurrahmahPas encore d'évaluation

- Measuring Principles Lecture on Sources of ErrorDocument18 pagesMeasuring Principles Lecture on Sources of ErrorAbhinav SinglaPas encore d'évaluation

- Non-linear solubility-temperature plots and their pharmaceutical interpretationDocument14 pagesNon-linear solubility-temperature plots and their pharmaceutical interpretationZaira CardenasPas encore d'évaluation

- PlateHangingList NA NADocument3 pagesPlateHangingList NA NAHaris Fadillah AlhudaPas encore d'évaluation

- Chapter 14 - GiancoliDocument4 pagesChapter 14 - GiancoliHectorCabzPas encore d'évaluation

- RooftankDocument1 pageRooftankwennycantikPas encore d'évaluation

- P&I Diagram Ri-Fliessbild: MWM Beijing / Voith Paper 1329360 Tem Evo, Akr / Nox 500 T 4513Document1 pageP&I Diagram Ri-Fliessbild: MWM Beijing / Voith Paper 1329360 Tem Evo, Akr / Nox 500 T 4513周庆卓Pas encore d'évaluation

- Production of BioemulsifierDocument4 pagesProduction of BioemulsifierSwateja ManglePas encore d'évaluation

- Surfaces in Precision Engineering, Microengineering and NanotechnologyDocument17 pagesSurfaces in Precision Engineering, Microengineering and NanotechnologyAdnan TorlakovićPas encore d'évaluation

- FiltrationDocument7 pagesFiltrationKers CelestialPas encore d'évaluation

- Calculating Wavelength of Light Using Single Slit DiffractionDocument30 pagesCalculating Wavelength of Light Using Single Slit DiffractionRajneilPas encore d'évaluation

- Space TrussDocument74 pagesSpace Trussomer1299Pas encore d'évaluation

- Integriwise Assessment Report: Project InformationDocument3 pagesIntegriwise Assessment Report: Project Informationsanu patilPas encore d'évaluation

- Relativistic Velocity and Acceleration Transformations From Thought ExperimentsDocument8 pagesRelativistic Velocity and Acceleration Transformations From Thought ExperimentssanniaPas encore d'évaluation

- TAMUQReport PlasticsinAsphaltDocument27 pagesTAMUQReport PlasticsinAsphaltZahraa Hashim Mashaallah - زهراء هاشم ماشاء الله أحمد الهاشميPas encore d'évaluation

- Forms of Corrosion: CHE-545-172 DR Ime B.ObotDocument17 pagesForms of Corrosion: CHE-545-172 DR Ime B.ObotAnonymous NxpnI6jCPas encore d'évaluation

- Motor Size SelectionDocument4 pagesMotor Size SelectionArnoah RamirezPas encore d'évaluation

- Marshall Stability and Flow of Asphalt ConcreteDocument2 pagesMarshall Stability and Flow of Asphalt ConcreteadePas encore d'évaluation

- 11.2-Length Time-Cie Igcse Physics Ext-Theory-qpDocument4 pages11.2-Length Time-Cie Igcse Physics Ext-Theory-qpTalaPas encore d'évaluation

- Catalog 2023 FinalDocument55 pagesCatalog 2023 FinalHana VũPas encore d'évaluation