Académique Documents

Professionnel Documents

Culture Documents

Best Bakeshop

Transféré par

Leilanie BagarinaoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Best Bakeshop

Transféré par

Leilanie BagarinaoDroits d'auteur :

Formats disponibles

1.

Project Location

Political Jurisdiction The BEST BAKESHOP is situated along diversion road Barangay Buhangin proper, Buhangin District, Davao City. It is approximately 500 meters from Orange Grove Hotel and less than 100 meters from the intersection going to Tigatto on the west and Davao City (in the east). It is located adjacent to Pag-asa Homes.

Delineation of Impact Zones The primary impact zone is the project site, the adjacent residential subdivision in the east, the Ananda Marga area on the southern part and the immediate vicinity because these will be directly affected with the operation of the bakeshop. Barangay Buhangin proper is delineated as the secondary impact zone. While the rest of Davao City, Panabo City, Tagum City, Municipality of Sta. Cruz and Digos City are the tertiary impact areas. The secondary and tertiary impact zones will indirectly benefit in terms of employment and services. These areas are the target markets of the products.

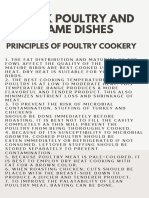

Bread Manufacturing All ingredients required for the production of bread and buns are premixed. Flour will be delivered to the plant in 25-kg sack. Flour yeast and water are mixed mechanically to produce sponge within a period of fifteen minutes. The sponge is then discharged to a through container and placed inside a Fermentation room where it is fermented in 2.5 hours. The sponge is then discharged to another vertical mechanical mixer where shortening, liquid sugar, salt and betacarotene are added to produce dough. The dough is then divided into smaller pieces and rounded. Afterwhich it is flattened using a sheeter. Greased pans are then inserted in the panning equipment where the flattened dough is paced. Proofing by the addition of we steam at 90% relative humidity and 41.5 degrees Celsius will make dough rise within 70 minutes. Figure 4 reflects the process flow diagram of bread and buns making adopted by Earth Grain Inc.

Preparing of Ingredients

Intermediate Proofing

Sponge Mixing

Final Proofing

Fermenting

Baking

Dough Mixing

Cooling

Dividing/Rounding

Packaging

Figure 4 : Process Flow of Bread Making

Cake Manufacturing All the materials for a days production are pulled from the main warehouse. The ingredients are checked and weighed according to a recipes standard batch weight prior to mixing and baking in the premix-scaling room. The eggs are cleaned and prepared in the egg room. All the prepared ingredients are then mixed and baked following the steps reflected in Figure 5. The baked cakes and rolls are transferred to the icing room for the icing layout. The iced/frosted cakes and rolls pass the finishing or final decoration before packaging and dispatch.

Raw materials Delivery /Storage

Packing

Mixing

Storage

Tempering

Dispatching

Baking

Icing/Cooling

Figure 5 : Cake Making Process Diagram

Vous aimerez peut-être aussi

- Keto Bread Machine Cookbook: Homemade Easy and Delicious Keto Bread Recipes in The Bread MachineD'EverandKeto Bread Machine Cookbook: Homemade Easy and Delicious Keto Bread Recipes in The Bread MachinePas encore d'évaluation

- The Perfect Blending CookbookD'EverandThe Perfect Blending CookbookÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Production PlanDocument2 pagesProduction PlanJunbert Harold De GuzmanPas encore d'évaluation

- Castronuevo, Rogelio Iii - Tem Act. 3 MidtermDocument10 pagesCastronuevo, Rogelio Iii - Tem Act. 3 Midtermit.rjcastronuevoPas encore d'évaluation

- Production and Operations ManagementDocument17 pagesProduction and Operations ManagementSamra SiddiquiPas encore d'évaluation

- Indomie SiwesDocument11 pagesIndomie SiwesAdebisi EmmanelPas encore d'évaluation

- 12 Steps of BakingDocument7 pages12 Steps of Bakingzoltan2010100% (1)

- Nafdac Sop For Topmost Butter BreadDocument11 pagesNafdac Sop For Topmost Butter BreaddebeamvibesPas encore d'évaluation

- Sliced Bread: The Science ofDocument4 pagesSliced Bread: The Science ofGayatri PrameswariPas encore d'évaluation

- Gardenia RedddDocument44 pagesGardenia RedddYasmin Yvonne De Chavez100% (1)

- English ProcessDocument11 pagesEnglish ProcessHamzah ChPas encore d'évaluation

- Project On Parle Biscuit MakingDocument21 pagesProject On Parle Biscuit MakingSneha Bhosale67% (3)

- Bakery Products and Rice MillingDocument19 pagesBakery Products and Rice Millingabhishek.ajmaniPas encore d'évaluation

- Project Report On Parle-G Biscuits - 129282158Document25 pagesProject Report On Parle-G Biscuits - 129282158linesh rewale75% (4)

- Factors That Contribute To Successful BakingDocument8 pagesFactors That Contribute To Successful BakingErrol San Juan100% (1)

- Operation Process of "Nabisco Biscuit & Bread Factory LTD": MethodologyDocument6 pagesOperation Process of "Nabisco Biscuit & Bread Factory LTD": MethodologyAli Haider MohammadullahPas encore d'évaluation

- Topic BreadDocument13 pagesTopic BreadDhruvi gosaviPas encore d'évaluation

- Techninal StudyDocument26 pagesTechninal StudyGorski RonquilloPas encore d'évaluation

- Technical AspectDocument16 pagesTechnical Aspectjulie anne mae mendozaPas encore d'évaluation

- Module 4 - Technical Aspect PDFDocument59 pagesModule 4 - Technical Aspect PDFJustin ManzanoPas encore d'évaluation

- Process of GardeniaDocument8 pagesProcess of Gardeniarickstagrams67% (3)

- Hierarchy of Parle ProductsDocument16 pagesHierarchy of Parle ProductsMonika Wadhel0% (1)

- Process FlowDocument3 pagesProcess FlowMaheen AlamPas encore d'évaluation

- Production Plan SampleDocument36 pagesProduction Plan SampleAidan CervantesPas encore d'évaluation

- Module 4 PFS Technical AspectDocument60 pagesModule 4 PFS Technical AspectShiela MayPas encore d'évaluation

- Bread Factory Set Up IdeaDocument3 pagesBread Factory Set Up IdeaKartik GoyalPas encore d'évaluation

- Thesis On Bread MakingDocument7 pagesThesis On Bread MakingJill Brown100% (2)

- Written Quiz SITHCCC041Document15 pagesWritten Quiz SITHCCC041ryanmai2804Pas encore d'évaluation

- Report On Industrial Visit: Fore School of ManagementDocument12 pagesReport On Industrial Visit: Fore School of Managementmanish_readsPas encore d'évaluation

- Seatwork 2 - Flow Chart Process (Repaired)Document5 pagesSeatwork 2 - Flow Chart Process (Repaired)Loren SalanguitPas encore d'évaluation

- Toastmaster BreadBox 1154 - 1156Document23 pagesToastmaster BreadBox 1154 - 1156drtzap80% (5)

- Dolce e Croccante Banana ChipDocument10 pagesDolce e Croccante Banana ChipRhoda Mae JapsayPas encore d'évaluation

- A Project Feasibility Study On Sweet PotDocument35 pagesA Project Feasibility Study On Sweet PotYvonne Dale V. DaceraPas encore d'évaluation

- PPM Dough DRDocument2 pagesPPM Dough DRNike NurjannahPas encore d'évaluation

- Technical Article Onf Extrusion Process For Preparation of Instant CerealDocument10 pagesTechnical Article Onf Extrusion Process For Preparation of Instant Cerealgurusamy kandasamyPas encore d'évaluation

- BAKING SCIENCE v1.0Document7 pagesBAKING SCIENCE v1.0Ed MolinaPas encore d'évaluation

- Tips For Making BreadDocument2 pagesTips For Making BreadvlovelainblessPas encore d'évaluation

- Business Plan Report Writing 2019Document20 pagesBusiness Plan Report Writing 2019Sushwet AmatyaPas encore d'évaluation

- Chimebere IT ReportDocument21 pagesChimebere IT Reportarinze nwakwudoPas encore d'évaluation

- Name: Gupta Gungun Semester: BBA SEM 4 Roll No:175 College: Asia Pacific College Topic: Parle-G ProductionDocument8 pagesName: Gupta Gungun Semester: BBA SEM 4 Roll No:175 College: Asia Pacific College Topic: Parle-G ProductionGungun GuptaPas encore d'évaluation

- Chapter One 1.0Document19 pagesChapter One 1.0Sbm D GreatPas encore d'évaluation

- Gardenia Bakeries Philippines IncDocument33 pagesGardenia Bakeries Philippines IncTrisha CabralPas encore d'évaluation

- Moulinex User ManualDocument12 pagesMoulinex User Manualpali_pe0% (1)

- PrintDocument7 pagesPrintertgsjvlkdghcPas encore d'évaluation

- Industrial Trip: Manufacturing Unit of PARLE Raipur (C.G.)Document3 pagesIndustrial Trip: Manufacturing Unit of PARLE Raipur (C.G.)Suhail KhanPas encore d'évaluation

- TA RIKA B InggrisDocument14 pagesTA RIKA B InggrisRosma YulisaPas encore d'évaluation

- Etp Farah Arisha Binti Shahrom DF170134Document3 pagesEtp Farah Arisha Binti Shahrom DF170134Farah ArishaPas encore d'évaluation

- AENG 95 - Learning Activity 1Document19 pagesAENG 95 - Learning Activity 1Rufina RiveraPas encore d'évaluation

- RempeyekDocument7 pagesRempeyekelyasliaPas encore d'évaluation

- Company Profile: Aquino, R., Lleva, C., Mabansag M., Reano, C., Tigas, A. ACT143 BS Accountancy 2 Sem A.Y. 2016-2017Document15 pagesCompany Profile: Aquino, R., Lleva, C., Mabansag M., Reano, C., Tigas, A. ACT143 BS Accountancy 2 Sem A.Y. 2016-2017Christian Blanza LlevaPas encore d'évaluation

- Sih TRPDocument4 pagesSih TRPKarthi PrabhakaranPas encore d'évaluation

- FHGJDocument16 pagesFHGJChienna Sabandon OmolonPas encore d'évaluation

- Bakery Products ProcessDocument13 pagesBakery Products ProcessrakhigoelPas encore d'évaluation

- Web DevelopmentDocument6 pagesWeb Development770joshuasamPas encore d'évaluation

- Application of Industrial Ingineering TechniqueDocument14 pagesApplication of Industrial Ingineering TechniquebunskygirlPas encore d'évaluation

- TLE10 Q4 SLM Ep4Document6 pagesTLE10 Q4 SLM Ep4Jelly Ace Almond TeaPas encore d'évaluation

- Process 1 - NoodlesDocument5 pagesProcess 1 - NoodlesNgoc VoPas encore d'évaluation

- Chapter IV g2 4ie2Document12 pagesChapter IV g2 4ie2Ma Kathleen Laude - DuranPas encore d'évaluation

- E Portfolio Food4022Document19 pagesE Portfolio Food4022FranPas encore d'évaluation

- House Cleaning ScheduleDocument1 pageHouse Cleaning ScheduledenfanPas encore d'évaluation

- Class2021 4Document12 pagesClass2021 4vikash KumarPas encore d'évaluation

- Kelas 11Document7 pagesKelas 11Jakaria SajaPas encore d'évaluation

- VanakkamDocument5 pagesVanakkamSivanathan AnbuPas encore d'évaluation

- Balaji WafersDocument4 pagesBalaji WafersMukesh RaoPas encore d'évaluation

- Brown and White Doodle Marketing Proposal Report Cover A4 DocumentDocument7 pagesBrown and White Doodle Marketing Proposal Report Cover A4 DocumentKingking alcosebaPas encore d'évaluation

- Quarter 3 Module 1Document16 pagesQuarter 3 Module 1Angel KrizylPas encore d'évaluation

- Banana Lime Coconut CakeDocument1 pageBanana Lime Coconut CakemmaftuhinPas encore d'évaluation

- Unit Test 7A: Has WorkedDocument3 pagesUnit Test 7A: Has WorkedMaria Fernanda Naranjo Garzon50% (2)

- Lib0128683 G5Document288 pagesLib0128683 G5Davide FabrianesiPas encore d'évaluation

- Rice Milling: Poonam DhankharDocument9 pagesRice Milling: Poonam DhankharWeare1_busyPas encore d'évaluation

- Active and PassiveDocument5 pagesActive and PassiveFasilo YatsePas encore d'évaluation

- A Temporary Matter (Lahiri)Document9 pagesA Temporary Matter (Lahiri)Ruben 24 :DPas encore d'évaluation

- Mix-and-Match Quick BreadDocument16 pagesMix-and-Match Quick BreadRaul RamosPas encore d'évaluation

- Modal Verbs Joan Paaez 10-ADocument8 pagesModal Verbs Joan Paaez 10-Ajoan paezPas encore d'évaluation

- Water Absorption, Hard Shell and Cooking Time of Common Beans (Phaseolus Vulgaris L.)Document8 pagesWater Absorption, Hard Shell and Cooking Time of Common Beans (Phaseolus Vulgaris L.)Mulubrhan OkbaiPas encore d'évaluation

- Modern Advanced Accounting in Canada Canadian 7th Edition Hilton Solutions Manual 1Document36 pagesModern Advanced Accounting in Canada Canadian 7th Edition Hilton Solutions Manual 1nicholasmcdowellqzogitybxs100% (22)

- Tugas Basing 1.Document3 pagesTugas Basing 1.mesiwulandaryy1Pas encore d'évaluation

- Curso: Ingles Profesor Titular Del Curso: Alan Daniel Lazo de La Vega Ramos Nombre de La Actividad Semana Código de La Clase: 01708Document3 pagesCurso: Ingles Profesor Titular Del Curso: Alan Daniel Lazo de La Vega Ramos Nombre de La Actividad Semana Código de La Clase: 01708ELIZABETH COAGUILA AÑARIPas encore d'évaluation

- Pizza Place CombinationsDocument14 pagesPizza Place CombinationsNicolas Santiago Garzon BautistaPas encore d'évaluation

- Curso: Ingles Ii Docente: Gina Antonella Buitriago Mendez Alumno: - Ayrton Fernando Torrejon Santillan Codigo: - U20249783Document3 pagesCurso: Ingles Ii Docente: Gina Antonella Buitriago Mendez Alumno: - Ayrton Fernando Torrejon Santillan Codigo: - U20249783Ayrton Fernando TorrejónPas encore d'évaluation

- Harvest Moon: Friends of Mineral Town GBA Items GuideDocument12 pagesHarvest Moon: Friends of Mineral Town GBA Items GuideAnnMargaretNunagPas encore d'évaluation

- ĐỀ SỐ 2 - VOCABDocument5 pagesĐỀ SỐ 2 - VOCABlvietanh289Pas encore d'évaluation

- Math & Pasta AHS FinalDocument30 pagesMath & Pasta AHS Finaldavisfc50Pas encore d'évaluation

- Shift Shop Meal Plan Week 1Document1 pageShift Shop Meal Plan Week 1Brenda AldoPas encore d'évaluation

- RYR Chocolates Price ListDocument15 pagesRYR Chocolates Price ListGianna Poblete-villaluzPas encore d'évaluation

- He Cookery Gr9 q2 Module-3 TrueDocument6 pagesHe Cookery Gr9 q2 Module-3 TrueLeah Rizza CabaliwPas encore d'évaluation

- ProcedureDocument11 pagesProcedureEka Subekti67% (3)

- Manual Masina de Spalat Vase Incorporabila HeinnerDocument61 pagesManual Masina de Spalat Vase Incorporabila HeinnerPerfectreviewPas encore d'évaluation

- Future Continuous PracticeDocument2 pagesFuture Continuous PracticeAC English100% (1)