Académique Documents

Professionnel Documents

Culture Documents

Bitelli BB781

Transféré par

Dem HasiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bitelli BB781

Transféré par

Dem HasiDroits d'auteur :

Formats disponibles

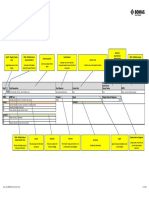

PAVER FINISHER BB 781

2000

2700

1670

500

1020

200

300

940 3125 730

2300 2500

100

6520

DIMENSIONS: mm

3545

CARRIAGE: tracked machine with two rubber shoe crawlers. Track tension is assured by a grease piston with a shock absorbing system. TRANSMISSION: two hydrostatic transmissions are each fitted with a variable displacement pump feeding fixed displacement axial piston motors directly splined to a two speed gearbox. Planetary final reduction gears in oil bath. An electro-proportional servo-control consents machine starting and stopping (for asphalt supply, etc.) with no pre-set working speed variation. Machine steering is operated by a steering wheel that acts an electronic digital device that consequently adjusts the right and left track motion guaranteeing a constant speed and direction. SCREED RB 4700 and RB 5700: the screed plate axis allows modifications of shapes (V W ) with different camber angles between +4.5% and -2.5%. Tamper and vibrator are operated automatically when the machine advances following a preset ramp. The tamper stopping and starting ramp can be adjusted electronically. During operation tamper and vibrator adjustment are electrically controlled and can be individually adjusted using potentiometers. Both screeds are fitted with electronic ignition and automatic adjustment of the smoothing plate temperature for central and each mobile plate. ELECTRIC HEATED SCREED RB 4700 E: with automatic adjustment of the smoothing plate and tamper bar temperature for central and each mobile plate. Rapid screed preheating is obtained at low engine rpm for quiet operation. Heavy-duty, user friendly screed heating control unit with selfdiagnostic control. SCREED ASSIST: the screed is equipped with an electro-hydraulic device maintaining a constant screed pressure on the bituminous mix, independently from the mix bearing capacity and the paving width. It is also possible to transfer part of the screed weight to the tracks of the machine, thus increasing machine traction. Whenever the machine is stopped in "stand-by" (for asphalt supply, etc.) a weight relief pressure is automatically inserted to avoid the screed for marking the mat. BRAKES: the hydrostatic drive acts as the service brake; the safety and parking brakes are mechanical multi-disk brakes with negative hydraulic control. Parking brake is automatically applied with the machine in STAND-BY mode. When required the brakes can be released manually. DRIVING POSITION AND CONTROLS: fitted with a folding canopy and two sliding seats. Operator seats and console panel are mounted on pivoting pedestals that permit the operator to rotate to the left or right for enhanced visibility. The console panel is fully equipped with all main operating controls, propel lever, a multifunctional LCD-display, warning lights and can be positioned in both driving positions. The multifunctional LCD-display provides detailed information regarding the operating parameters of the engine. HOPPER AND FEEDING SYSTEM: the independent movement of the two side wings is obtained by means of two hydraulic cylinders. The bottom plate of the hopper is built of abrasion-proof steel. Two reversible conveyors, made of wear-resisting steel, are independently

controlled and proportionally driven by two sonic wave detectors. Material conveyed to both sides is spread by two independently controlled augers. Rotation speed can be varied automatically to ensure a homogeneous distribution of material before the screed. Two sonic wave detectors control proportional auger movement. The augers are reversible and their height can be adjusted hydraulically. A pair of auger extensions are supplied with the machine. ELECTRIC-ELECTRONIC SYSTEM: electronic circuits governing and operating the hydraulic system ensure an exceptional machine selfgovernment allowing the operator to concentrate on driving. An onboard generator is fitted when the paver is equipped with the RB 4700 E electric screed. The generator provides 25 kW output to power screed heating and also optional lighting assemblies. ON REQUEST: - Hydraulic canopy with electric control - Automatic leveling devices: - Grade control - mechanical - Grade control - digital and mechanical - Digital ultrasound grade control - Digital ultrasound grade control - 5 ultrasound sensors - Combined ultrasound grade control - electronic and mechanical - Sonic ski grade control - Laser scanner grade control - Slope control - Digital slope control - 6.00 m rigid ski for grade control - 6.00 m or 9.00 m auto-leveling ski for grade control - Mechanical extension 3 m for auto-levelling ski - Mechanical extension elements with tamper and auger extensions for laying widths up to 5.20 m (for RB 4700 and RB 4700 E screeds) and laying widths up to 6.20 m (for RB 5700 screed) - Mechanical extension elements with tamper, vibrator, auger extensions and wind bracing for laying widths 6.10m and 7.50 m (for RB 4700 E screed) - Mechanical extension elements with tamper, vibrator, auger extensions, wind bracing and electronic ignition for laying widths 6.10 m, 6.70 m and 7.50 m (for RB 4700 screed) - Mechanical extension elements with tamper, vibrator, auger extensions, wind bracing and electronic ignition for laying widths 7.10m, 7.70m, 8.50 m and 9.10 m (for RB 5700 screed) - Mechanical extension elements of 1.50 m, 0.75 m and 0.25 m with auger extensions, electronic ignition kit and wind bracing for paving widths up to 13.00 m (RMB 13000 mechanical screed) - Rotating side screed bulkheads (for RB 4700 and RB 4700 E screeds) - Motorized camber adjustment - Infrared joint heater (for RB 4700 screed) - Supplementary working lights package with xenon lights (24V) - Supplementary working lights package with halogen lights (230V) - Centralized and automatic lubrication system for tractor and screed - Refueling pump - Biodegradable hydraulic oil

3000

3745

350

Via IV Novembre, 2 - 40061 MINERBIO (Bologna) - ITALY Tel. +39-051-6607111 - Fax +39-051-6607115 www.bitelli.com Nr 50 100 1344 Certified

UNI EN ISO 9001:2000 Specs and data are subject to change without notice or obligation. Illustrations shown may show the machine fitted with additional equipment.

260-00-0104-GB

W V

BB 781

TRACKED PAVER FINISHER

ENGINE Make 6 cylinders Output at 2300 rpm (ISO 1585) Fuel consumption Electric system SCREED RB 4700 E Hydraulically extending screed width with 2 extensions (0.25 m each) (optional) with 2 extensions (0.70 m each) (optional) with 4 extensions (0.70 m each) (optional) Electric heating with thermostatic electronic control SCREED RB 4700 Hydraulically extending screed width with 2 extensions (0.25 m each) (optional) with 2 extensions (0.70 m each) (optional) with 2 extensions (1.00 m each) (optional) with 4 extensions (0.70 m each) (optional) SCREED RB 5700 Hydraulically extending screed width with 2 extensions (0.25 m each) (optional) with 2 extensions (0.70 m each) (optional) with 2 extensions (1.00 m each) (optional) with 4 extensions (0.70 m each) (optional)

260-00-0104-GB

TECHNICAL SPECS Caterpillar 3126B ATAAC liquid cooling system 149 kW (200 HP) 221.6 g/kWh 24 V 2.504.70 m max 5.20 m max 6.10 m max 7.50 m Transmission Track base Track width Ground pressure (empty weight with RB 5700) Steering Inside turning radius Operating weight with RB 4700 with RB 5700 Hopper capacity (tunnel included) Hopper discharge height - at centre at sides 2.504.70 m max 5.20 m max 6.10 m max 6.70 m max 7.50 m 3.005.70 m max 6.20 m max 7.10 m max 7.70 m max 8.50 m SPEED 1st gear (work) 2nd gear (travel) PERFORMANCES Max. production Mat thickness TANK CAPACITIES Fuel Hydraulic oil Ecological liquid 295 l 200 l 35 l 820 t/h 5350 mm 026 m/min 06 km/h Augers hydrostatic 3125 mm 300 mm 1.15 kg/cm2 electronically controlled by altering the speed of each track 1.00 m 20900 kg 21600 kg 12 t 500 mm 600 mm 360 mm

with 2 x 0.70 m and 2 x 1.00 m extensions (optional) max 9.10 m LPG heating Tamper vibration frequency Smoothing plate vibration frequency 8 burners with electronic ignition 01700 rpm 03400 rpm (028.3 Hz) (056.7 Hz)

The BB 781 is also available with RMB 13000 mechanical screed with LPG heating.

The machine shown can be fitted with additional equipment

Vous aimerez peut-être aussi

- Catalogo de Peças H40-H70FT - Sub Serie L177Document970 pagesCatalogo de Peças H40-H70FT - Sub Serie L177Suziane Sousa Victor80% (5)

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoPas encore d'évaluation

- Tg5390-5470 Operation ManualDocument176 pagesTg5390-5470 Operation ManualAnonymous 8THg7TgPPas encore d'évaluation

- Vision 5203-2 Us VogeleDocument14 pagesVision 5203-2 Us VogeleRobinson Guaneme0% (1)

- BW213DH-4 BVC PDFDocument2 pagesBW213DH-4 BVC PDFVlad SuteuPas encore d'évaluation

- SUPER700-3 - EN - 2513779 - 0216 - MPW - VOGELEDocument18 pagesSUPER700-3 - EN - 2513779 - 0216 - MPW - VOGELERobinson GuanemePas encore d'évaluation

- Ahb L544-L580Document44 pagesAhb L544-L580sanches pitaPas encore d'évaluation

- 18 T To 19 T Road Paver BF 691/BF 691 CDocument8 pages18 T To 19 T Road Paver BF 691/BF 691 CAliPas encore d'évaluation

- Diagrama Electrico de Camion Cat 777DDocument2 pagesDiagrama Electrico de Camion Cat 777DPedro Ruiz100% (2)

- Manual Book XQ29-1.8B Sucker Rod Power Tong PDFDocument31 pagesManual Book XQ29-1.8B Sucker Rod Power Tong PDFadi Julianto100% (1)

- DNEPR M72 Manual EnglishDocument76 pagesDNEPR M72 Manual Englishdaemonium666100% (2)

- 27 StabilizerDocument32 pages27 StabilizerTarik Benzineb100% (1)

- Brochure Variomatic Screed en 21 20000043 DDocument12 pagesBrochure Variomatic Screed en 21 20000043 DHaris100% (1)

- Bomag bw219Document2 pagesBomag bw219ZabdyRA YT0% (1)

- BW24RH / BW27RHDocument4 pagesBW24RH / BW27RHVlad SuteuPas encore d'évaluation

- AP Vs Vogele Competitive Update (QELQ9951)Document14 pagesAP Vs Vogele Competitive Update (QELQ9951)firman manalu100% (1)

- Dynapac PaverDocument158 pagesDynapac PaverMamta Raybage100% (1)

- Cold Milling Machine W 2100: Technical SpecificationDocument8 pagesCold Milling Machine W 2100: Technical SpecificationAliPas encore d'évaluation

- Roadtec Cold Planers BrochureDocument24 pagesRoadtec Cold Planers BrochureKuntawee100% (1)

- Dynapac PaverDocument27 pagesDynapac Paverirfan ammar100% (3)

- SUPER 1603-3: Universal ClassDocument22 pagesSUPER 1603-3: Universal ClassBurazBurazPas encore d'évaluation

- Freza BrošuraDocument32 pagesFreza BrošurahamzapfkPas encore d'évaluation

- Failure Code of The PLC From SAUER For The BF / MF 571 C BF / MF 691 C CrawlerDocument15 pagesFailure Code of The PLC From SAUER For The BF / MF 571 C BF / MF 691 C CrawlerTeknik MakinaPas encore d'évaluation

- Dynapac Large Tracked Paver Range: Dynapac SD2500C / SD2500CS SD2550C / SD2550CSDocument16 pagesDynapac Large Tracked Paver Range: Dynapac SD2500C / SD2500CS SD2550C / SD2550CSsobirin100% (1)

- C-10 Deutz English Hyd DRGDocument1 pageC-10 Deutz English Hyd DRGbercketowzhenyaPas encore d'évaluation

- 6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Document6 pages6 Finisor de Asfalt Pe Senile Volvo Abg9820 47542Farkas Pal100% (1)

- DYNAPAC F 150 C 769130 - SpecificationDocument254 pagesDYNAPAC F 150 C 769130 - Specificationhoan100% (2)

- Системы нивелирования MOBADocument32 pagesСистемы нивелирования MOBAHadi Bendj100% (1)

- Kenr5125kenr5125-02 SisDocument13 pagesKenr5125kenr5125-02 Sisygor valdezPas encore d'évaluation

- E-Teile Winter10 enDocument12 pagesE-Teile Winter10 enVladimir Illich Pinzon BallenPas encore d'évaluation

- Bb681ci Du-259a010105gbDocument150 pagesBb681ci Du-259a010105gbEvgeniy BPas encore d'évaluation

- Vogelle S1600-3iDocument22 pagesVogelle S1600-3ijhonycvzPas encore d'évaluation

- Writ GenDocument475 pagesWrit Genagus tiwansyah50% (2)

- Terex Finlay J-1160Document4 pagesTerex Finlay J-1160eaglego00Pas encore d'évaluation

- 3705 Brochure Bf800 CDocument4 pages3705 Brochure Bf800 CAbdul Khaliq100% (1)

- Screeds: A Wirtgen Group CompanyDocument29 pagesScreeds: A Wirtgen Group CompanyMichael Forrest100% (1)

- En - 1676 - Hydraulic Systems For Truck TractorsDocument4 pagesEn - 1676 - Hydraulic Systems For Truck TractorsAli ShdiefatPas encore d'évaluation

- AP-1000b Vs Blow Knox Pf-3200 (Qexq9702)Document27 pagesAP-1000b Vs Blow Knox Pf-3200 (Qexq9702)firman manaluPas encore d'évaluation

- 3414HT TCD2012L04 3414HTP TCD2012L04 W V4 en-GBDocument2 pages3414HT TCD2012L04 3414HTP TCD2012L04 W V4 en-GBJovanka Jadrovska100% (2)

- Lubrication Hose DiagramDocument8 pagesLubrication Hose Diagramvic13rPas encore d'évaluation

- Vogele PB S1800Document9 pagesVogele PB S1800Pappa Anton Florin100% (2)

- Control and Monitoring Systems For Road Paving Machines: Parts Catalogue 2018Document27 pagesControl and Monitoring Systems For Road Paving Machines: Parts Catalogue 2018Romica CiorneiPas encore d'évaluation

- Paver Super 1800 3Document12 pagesPaver Super 1800 3Yasar100% (1)

- 3D Machine Control Systems: Innovative Solutions From VÖGELE For Working With 3D SystemsDocument8 pages3D Machine Control Systems: Innovative Solutions From VÖGELE For Working With 3D SystemsAbdulmajeed KandakjiPas encore d'évaluation

- PL2000LS Maintenance 900981071enDocument120 pagesPL2000LS Maintenance 900981071enHussein SayedPas encore d'évaluation

- Bobcat 853 Operator ManualDocument20 pagesBobcat 853 Operator ManualAbdul KhaliqPas encore d'évaluation

- 386 - 200 Ultrasonic Sensor Auger 13962097 PDFDocument1 page386 - 200 Ultrasonic Sensor Auger 13962097 PDFDmitryPas encore d'évaluation

- 1675BW Ed201408Document354 pages1675BW Ed201408PEPE100% (2)

- 3520HT TCD2012L06 3520HTP TCD2012L06 W V4 en-GBDocument2 pages3520HT TCD2012L06 3520HTP TCD2012L06 W V4 en-GBJovanka Jadrovska100% (1)

- Bomag Single Drum Rollers 40Document12 pagesBomag Single Drum Rollers 40Alex TanPas encore d'évaluation

- 7 Finisoare de Asfalt Pe Senile Volvo p7820c p8820c 47543Document16 pages7 Finisoare de Asfalt Pe Senile Volvo p7820c p8820c 47543Farkas PalPas encore d'évaluation

- Wirtgen SP15Document324 pagesWirtgen SP15Nguyen AlmiraPas encore d'évaluation

- DF135 OmDocument270 pagesDF135 Omvan long Bui100% (1)

- Service Information Systems: Know How For Your Success.: Road and Mineral TechnologiesDocument32 pagesService Information Systems: Know How For Your Success.: Road and Mineral TechnologiesFelipe HernandezPas encore d'évaluation

- BF600-2 P, BF800 P - Error Code List: Actuator / Input Device / Sensor Device BSPNDocument228 pagesBF600-2 P, BF800 P - Error Code List: Actuator / Input Device / Sensor Device BSPNJuan PerezPas encore d'évaluation

- VF500 VF600 VR600Document24 pagesVF500 VF600 VR600Mehdi FarrokhiPas encore d'évaluation

- SB250 PDFDocument24 pagesSB250 PDFJose Manuel Paredes GarciaPas encore d'évaluation

- SUPER 1900-3i: Highway ClassDocument22 pagesSUPER 1900-3i: Highway ClassТракия Билд0% (2)

- CS54 Cs533e en PDFDocument16 pagesCS54 Cs533e en PDFXavier Millan100% (1)

- BB681C Du-258069906gbDocument158 pagesBB681C Du-258069906gbEvgeniy BPas encore d'évaluation

- V Ec360 212 1620 0009 PDFDocument12 pagesV Ec360 212 1620 0009 PDFJessica NoriegaPas encore d'évaluation

- SUPER 1800-3i EN 2723056 MPW 0219Document22 pagesSUPER 1800-3i EN 2723056 MPW 0219karim khorsi100% (1)

- R155Document1 pageR155Francisco Javier López BarrancoPas encore d'évaluation

- Paver Finisher: Engine Technical SpecsDocument2 pagesPaver Finisher: Engine Technical SpecszlPas encore d'évaluation

- Grove 60 Ton PDFDocument24 pagesGrove 60 Ton PDFFabrizzio ZuñigaPas encore d'évaluation

- GMK4115Document38 pagesGMK4115tincho_0026Pas encore d'évaluation

- BROCHURE TENSA MODULAR LR CH enDocument8 pagesBROCHURE TENSA MODULAR LR CH enDem HasiPas encore d'évaluation

- ST-3 Sonic Tracker: DescriptionDocument8 pagesST-3 Sonic Tracker: DescriptionDem HasiPas encore d'évaluation

- Shrinkage and Cracking Behavior of Cement Stabilized MaterialDocument6 pagesShrinkage and Cracking Behavior of Cement Stabilized MaterialDem HasiPas encore d'évaluation

- Integral Bridge Design To EN 1992-2Document58 pagesIntegral Bridge Design To EN 1992-2Dem HasiPas encore d'évaluation

- Design Manual For Roads and BridgesDocument32 pagesDesign Manual For Roads and BridgesDem HasiPas encore d'évaluation

- Construction ManagementDocument63 pagesConstruction ManagementDem Hasi100% (2)

- Bernhard Hofko 1Document19 pagesBernhard Hofko 1Dem HasiPas encore d'évaluation

- Cold AsphaltDocument440 pagesCold AsphaltDem Hasi100% (1)

- Building A Cold FrameDocument9 pagesBuilding A Cold FrameDem HasiPas encore d'évaluation

- Građevinar 61Document9 pagesGrađevinar 61Dem HasiPas encore d'évaluation

- Map KosovoDocument1 pageMap KosovoDem HasiPas encore d'évaluation

- The Basics of GPSDocument35 pagesThe Basics of GPSDem HasiPas encore d'évaluation

- DTSDocument26 pagesDTSvijayakumarPas encore d'évaluation

- Trans PDFDocument28 pagesTrans PDFRamon CasillasPas encore d'évaluation

- 1996 - 1999 Nissan Pathfinder (R50) Automatic To Manual Transmission Conversion ManualDocument24 pages1996 - 1999 Nissan Pathfinder (R50) Automatic To Manual Transmission Conversion ManualDiegoAlejandroCuadrosPas encore d'évaluation

- 2 Stroke Maintenance SchedulesDocument3 pages2 Stroke Maintenance SchedulesGeo PalPas encore d'évaluation

- FFB - Custom - Settings - Pure Feel V5 (NEW)Document3 pagesFFB - Custom - Settings - Pure Feel V5 (NEW)JustinVoPas encore d'évaluation

- ATR FCOM 1-16 Power PlantDocument44 pagesATR FCOM 1-16 Power PlantoscarPas encore d'évaluation

- Plano Electrico 420E Pra0917Document4 pagesPlano Electrico 420E Pra0917Luis Gustavo Escobar Machado0% (1)

- Brochures Manual IRIZARDocument26 pagesBrochures Manual IRIZAREmebeizaPas encore d'évaluation

- Automotive Design and Production - August 2019Document52 pagesAutomotive Design and Production - August 2019Ivan IvanovPas encore d'évaluation

- Key Features Key Specifications: Adr 80/03 ModelDocument4 pagesKey Features Key Specifications: Adr 80/03 ModelAndrew RegaPas encore d'évaluation

- Mett July 2017Document60 pagesMett July 2017Muhammad SiddiuqiPas encore d'évaluation

- HYSTER TransmissionDocument30 pagesHYSTER Transmissioncristian faundes0% (1)

- Cat d9r BrochureDocument20 pagesCat d9r Brochureayush bansalPas encore d'évaluation

- GP N Brochure ProdriveDocument7 pagesGP N Brochure ProdriveTc Mrt Çap TmlPas encore d'évaluation

- ATOX Inspection Brochure 7Document4 pagesATOX Inspection Brochure 7taghdirimPas encore d'évaluation

- Hydraulic Oil Contamination - Engineering For Hydr+Document9 pagesHydraulic Oil Contamination - Engineering For Hydr+Pinky DeyPas encore d'évaluation

- Volvo Trucks MID Fault CodeDocument1 pageVolvo Trucks MID Fault CodeJan Svein HammerPas encore d'évaluation

- RSJ PartsDocument32 pagesRSJ PartsAmit Chopra Amit100% (1)

- Treadmill Bicycle Using Solar and Manual PoweredDocument41 pagesTreadmill Bicycle Using Solar and Manual PoweredKushal MalikPas encore d'évaluation

- Top Drive 750 Product SheetDocument3 pagesTop Drive 750 Product SheetPedro RiveraPas encore d'évaluation

- Prime Line Industrial Controls CatalogDocument32 pagesPrime Line Industrial Controls CatalogMaria Clara Ybarra CesaroPas encore d'évaluation

- Theory of Machines - I: Question Bank (Numericals) Velocity and Acceleration Analysis of Mechanisms: Graphical MethodsDocument18 pagesTheory of Machines - I: Question Bank (Numericals) Velocity and Acceleration Analysis of Mechanisms: Graphical Methodsvijaykumar327Pas encore d'évaluation

- 09e 1Document24 pages09e 1ruslan1580100% (1)