Académique Documents

Professionnel Documents

Culture Documents

Metal Table-2865 - 2866

Transféré par

kastelaninTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Metal Table-2865 - 2866

Transféré par

kastelaninDroits d'auteur :

Formats disponibles

Metal Table JIS - EN 2

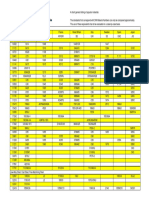

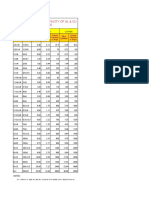

JIS Material EN Material No. No. S30C S30C S35C S35C S40C S40C S45[CD] S45C S45C S45C S45-D S50C S50C S53C S55C S55C S58C S58C S58C SCM415[H] SCM418[H] SCM418[H] SCM418[H] SCM420 SCM420 SCM420 SCM420H SCM421 SCM430 SCM430 SCM430 SCM430 SCM435[H] SCM440 SCM440H SCM440H SCM445 SCM822 SCr415[H] SCr415[H] SCr420[H] SCr430 SCr430[H] SCr435[H] SCr440 SCr440[H] SCS13 SCS22 SGP SGPW SK1 SK2 SK3 SK3 SK4 SK5 SK5 SK6 SK7 SKD1 SKD11 SKD12 SKD4 SKD5 SKD6 SKD61 SKD7 SKD8 SKH10 SKH2 SKH51/SUH3 SKH52/SKH53 SKH55 SKH57 SKH59 SKS11 SKS2/3/31 SKS21 SKS3 SKS41 SKS41 SKS42 SKS43 1.1178 1.1178 1.0501 1.1181 1.0511 1.0511 1.1191 1.0503 1.0503 1.0503 1.1191 1.1206 1.1213 1.1210 1.0535 1.1203 1.0601 1.1221 1.1223 1.7242 1.7243 1.7243 1.7243 1.7264 1.7264 1.7264 1.7258 1.7264 1.7218 1.7218 1.7218 1.7218 1.7220 1.7220 1.7223 1.7225 1.7262 1.7350 1.7015 1.7016 1.7027 1.7033 1.7033 1.7034 1.7035 1.7035 1.4308 1.4401 1.0035 1.0035 ISO ISO 1.1545 1.1645 ISO 1.1525 1.1830 1.1625 1.1740 1.2080 1.2379 1.2363 1.2567 1.2581 1.2343 1.2344 1.2365 (JIS) 1.3202 1.3355 1.3343 1.3344 1.3243 1.3207 1.3247 (JIS) 1.2419 (JIS) 1.2510 1.2541 1.2542 1.2552 1.2833 EN Denomination C30 C30 1C35 (C35) C35E (Ck35) C40 C40 C45E (Ck45) C45 C45 C45 C45E C50E (Ck50) C50 C53E (Ck53) C55 C55E (Ck55) C60 C60E (Ck60) C60R 16CrMo4 18CrMo4 18CrMo4 18CrMo4 20CrMo5 20CrMo5 20CrMo5 24CrMo5 20CrMo5 25CrMo4 25CrMo4 25CrMo4 25CrMo4 34CrMo4 34CrMo4 41CrMo4 42CrMo4 16CrMo4 22CrMo44 15Cr3 17Cr3 20Cr4 34Cr4 34Cr4 37Cr4 41Cr4/42Cr4 41Cr4/42Cr4 G-X6CrNi18-9 G-X5CrNiMo17-12-2 S185 (St.33) S185 (St.33) TC140 TC120 C105W1 C105W2 TC90 C80W1 C85W C80W2 C60W X210Cr12 X155CrVMo12-1 X100CrMoV5-1 X30WCrV5-3 X30WCrV9-3 X38CrMoV5-1 X40CrMoV5-1 X32CrMoV3-3 untranslateable S12-1-4-5 S18-0-1 S6-5-2 S6-5-3 S6-5-2-5 S10-4-3-10 S2-10-1-8 untranslateable 105WCr6 untranslateable 100MnCrW4 (~~) 35WCrV7 45WCrV7 80WCrV8 100V1 Material Description unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment [cold drawn] unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment unalloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / case hardening steel alloyed construction steel / case hardening steel alloyed construction steel / case hardening steel alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / case hardening steel alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment / higher carbon content alloyed construction steel / / for quenching and tempering / for heat treatment / for ame-induction hardening alloyed construction steel / / for quenching and tempering / for heat treatment / for ame-induction hardening alloyed construction steel / / for quenching and tempering / for heat treatment / for ame-induction hardening alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment stainless steel casting stainless steel casting unalloyed construction steel / pipe steel unalloyed construction steel / pipe steel / galvanized unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for hot work unalloyed tool steel for hot work unalloyed tool steel for cold work unalloyed tool steel for cold and hot work unalloyed tool steel for hot work unalloyed tool steel alloyed high speed steel with Co alloyed high speed steel without Co alloyed high speed steel without Co alloyed high speed steel without Co alloyed high speed steel with Co alloyed high speed steel with Co alloyed high speed steel with Co unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work Re-Rp0,2 Condition min. max. in MPa annealed QT QT annealed annealed 16 QT 16 QT case hardened annealed 40 QT 16 16 280 400 430 270~300 320 460 490 305~340 340~390 520 16 40 QT 370 550 550 340~380 580 450~580 850 690 600 600 500 400 Rm in MPa 510 600~750 630~780 520 580 650~800 700~850 650~800 580 640~790 750 640 630~780 800~950 800~950 670~710 850~1000 800~950 1100~1350 950~1300 800~1150 1000 850 750 800~950 900~1100 550~700 800~950 700~850 1000~1200 980 980~1180 1100~1300 A Hardness Hardness in % Unit Value JIS Material EN Material No. No. SKS44 SKS5 SKS7 SKS8 SKS93 SKS94 SKS95 SKT3/SKT4 SMF5040 SMn420[H] SMn433[H] SMn433[H] SMn438[H] SMn443[H] SMnC420[H] SMnC420[H] SNB16 SNB21 [1-5] SNB22 [1-5] SNB23 [1-5] SNB7 SNC236 SNC415[H] SNC631[H] SNC631[H] SNC631[H] SNC815[H] SNC836 SNC836 SNC836 SNC836 SNCM220[H] SNCM240 SNCM415 SNCM420[H] SNCM431 SNCM439 SNCM447 SNCM447 SNCM616 SNCM625 SNCM630 SNCM815 SPCC[SD] SPHC SS330 SS400[D] SS400[D] SS400[D] SS490 SS540 SSPR SSPSR STKM11A STKM12[A/C] STKM13A STPG370 STPS2 STPT370 STPT370 SUH1 SUH11 SUH3 SUH309 SUH31 SUH310 SUH310 SUH35/SUH36 SUH37 SUH38 SUH4 SUH409[L] SUH409[L] SUH446 SUH600 SUH616 SUH660 SUH661 SUJ1 SUJ2 SUJ2 SUJ2 SUJ3 (JIS) (JIS) (JIS) 1.2008 (JIS) (JIS) (JIS) 1.2713 (JIS) 1.1160 1.1165 1.1166 1.1167 1.1175 1.1133 1.7147 1.7711 1.7223 1.7223 1.6562 1.7225 1.5710 1.5732 1.5736 1.5736 1.5736 1.5752 1.3565 1.5755 1.5755 1.5755 1.6523 1.6546 1.7262 1.6587 1.6580 1.6582 1.6511 1.6511 1.6565 (JIS) (JIS) 1.6657 1.0330 1.0320 1.0028 1.0040 1.0042 1.0136 1.0050 1.0060 (JIS) (JIS) 1.0034 1.0038 1.0480 1.0254 (JIS) 1.0255 1.0305 1.4718 (JIS) 1.4731 1.4828 1.4873 1.4841 1.4845 1.4871 (JIS) (JIS) 1.4747 1.4512 1.4720 1.4762 (JIS) 1.4935 1.4943 1.4971 (JIS) 1.2067 1.3505 1.3505 (JIS) EN Denomination untranslateable untranslateable untranslateable 140Cr3 (~~) untranslateable untranslateable untranslateable 55NiCrMoV6 C43 (~~) 22Mn6 30Mn5 34Mn5 36Mn5 41Mn4 20Mn5 20MnCr5 40CrMoV4-7 41CrMo4 41CrMo4 40NiCrMo8-4 42CrMo4 36NiCr6 14NiCr10 36NiCr10 36NiCr10 36NiCr10 14NiCr14 48CrMo4 31NiCr14 31NiCr14 31NiCr14 20NiCrMo2-2 40NiCrMo2-2 16CrMo4 17CrNiMo8 30CrNiMo8 34CrNiMo6 36CrNiMo4 36CrNiMo4 40NiCrMo6 untranslateable untranslateable 14NiCrMo34 DC01 (St.12) St.22 S205G1T (USt.34) Ust.42.2 RSt.42.2 St.42.3 E295 (St.50.2) E335 (St.60.2) untranslateable untranslateable S205G2T (RSt.34) S235JRG2 (RSt.37.2) H240LA S235 (St.37) untranslateable St.37-4 P235G1TH (St.35.8) X45CrSi9-3 untranslateable X40CrSiMo10-2 X15CrNiSi20-12 X45CrNiW18-9 X15CrNiSi25-20 X12CrNi25-21 X53CrMnNiN21-9 untranslateable untranslateable X80CrNiSi20 X5CrTi12 X6CrTI12 X10CrAlSi25 untranslateable X20CrMoWV12-1 X4NiCrTi25-15 X12CrCoNi21-20 untranslateable 102Cr6 100Cr6 100Cr6 untranslateable Material Description unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold work unalloyed tool steel for cold and hot work sintered carbon mould steel structural / heat treatment steel [increased Carbon content] structural / nitriding steel / heat treatment steel [increased Carbon content] structural / nitriding steel / heat treatment steel [increased Carbon content] structural / heat treatment steel [increased Carbon content] structural / heat treatment steel [increased Carbon content] structural / heat treatment steel [increased Carbon content] structural / heat treatment steel [increased Carbon content] alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed structural steel alloyed construction steel / case hardening steel / higher carbon content alloyed construction steel / for quenching and tempering / for heat treatment / higher carbon content alloyed construction steel / for quenching and tempering / for heat treatment / higher carbon content alloyed construction steel / for quenching and tempering / for heat treatment / higher carbon content alloyed construction steel / case hardening steel / higher carbon content unalloyed bearing steel alloyed bearing steel alloyed bearing steel alloyed bearing steel alloyed construction steel / for quenching and tempering / for heat treatment / higher carbon content alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment / higher carbon content alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment alloyed construction steel / for quenching and tempering / for heat treatment unalloyed steel / deep drawable / [solid drawn] unalloyed steel / deep drawable / [hot coiled] unalloyed mild steel unalloyed structural steel unalloyed mild steel unalloyed mild steel unalloyed mild steel unalloyed mild steel structural steel structural steel unalloyed mild steel unalloyed mild steel unalloyed construction steel / pipe steel unalloyed construction steel / pipe steel seamless pipe for hydraulic uids unalloyed construction steel / pipe steel for high temperature unalloyed construction steel / pipe steel for high temperature alloyed valve steel / heat resistant alloyed valve steel / heat resistant alloyed high speed steel without Co heatresistant steel alloyed stainless steel / valve steel / heat resistant alloyed stainless steel / acid proof / heat resistant alloyed stainless steel / acid proof / heat resistant alloyed stainless steel / valve steel / highly heat resistant alloyed stainless steel / acid proof / heat resistant alloyed stainless steel / acid proof / heat resistant alloyed stainless steel / acid proof / heat resistant alloyed stainless steel / acid proof / heat resistant alloyed stainless steel / acid proof / heat resistant alloyed stainless steel / acid proof / heat resistant alloyed construction steel / for quenching and tempering / for heat treatment / heat resistant alloyed stainless steel / valve steel / highly heat resistant alloyed stainless steel / valve steel / highly heat resistant / weldable without treatment alloyed stainless steel / valve steel / highly heat resistant unalloyed tool steel (~SUJ2 however 0.9-1.2%cr) unalloyed tool steel / ball bearing steel unalloyed tool steel / ball bearing steel unalloyed tool steel / ball bearing steel unalloyed tool steel (~SUJ2 however 0.4-0.7%Si) Re-Rp0,2 Condition min. max. in MPa Rm in MPa A Hardness Hardness in % Unit Value

19 16 14 HRc 16 49~55

930~1420

HRc

55~60

16

<900 750~950 800 <800 1080~1370 850~1000 980~1180 700~900 900~1200 575 1030~1180 880~1030 740~880 930~1230 1080 980~1130 880~1030 790~930 980~1270

annealed QT case hardened 16 case hardened 40 case hardened 100 case hardened 16 40 100

11 13 9 9 10 12 14 16 HRc 49~55

QT QT QT 16 40 QT

685 470~700 880 450~700 650~900

8 14

HB

215

11

HRc

38

16 40 16 40

40 40 100 100 250

QT QT QT

780 690 590

16 40

16 16 40 100

QT QT QT QT

700 680 600 450 800 835 880 900

18 12 14 15 12

HRc HB HB HB

58 215~260 215~260 215~260

40 40 100 100 250

QT QT QT

840 740 590 590

11 12 14 10

QT QT QT QT

1050 700~900 800~1000 1000

1250~1450 1000~1200 1100~1300 1200~1400

11 10 9

HB

355~410

450 635 700~740 650 785 780

16 16

40 40

QT QT

800~1050 <1000 780 880~1000 880~1080 930 950~1150

11 18 15 13 11

QT 140~280 195 unkilled

1150

10

HRc HB

35 90~120

175~185

290 290

265~295

270~410 28~39 270 27~31 330~430 26 400~510 400~510 400~510 470~610 20 >540

HRc

52~58

killed

215 240~310 180

340~470 340 450

HB 27 30

120

HRc 1000 HRc HRc

52~58

>68 >68

(<350C) (<350C) C M A A A 230~290 230~300 230~300 500~750 30~40 550~750 30~40 550~750 30~40 HB 130~220

1550 1180~1770

HRc

>68

hardened

1000

HRc

60~68

hardened

<1000

HRc

58~64

C F F F M C A A annealed annealed hardened

280

520~720

10

675 675 850

HB HB HRC

230 230 58~65

<1000

2865

JIS denomination is binding for orders. EN denominations are started as comparative material. (Partly there is no existing equivalent EN material for JIS material existing or contrary). All information ist based on values and properties which are achieved typically and are only for assessment of materials (typical values). Properties herein shall not be located directly to a product and there is no supposition that any product achieves these values. For proof values own checks are necessary or you may request the direct related value from Misumi.

JIS denomination is binding for orders. EN denominations are started as comparative material. (Partly there is no existing equivalent EN material for JIS material existing or contrary). All information ist based on values and properties which are achieved typically and are only for assessment of materials (typical values). Properties herein shall not be located directly to a product and there is no supposition that any product achieves these values. For proof values own checks are necessary or you may request the direct related value from Misumi.

2866

Vous aimerez peut-être aussi

- Ball ValvesDocument34 pagesBall ValvesalexescPas encore d'évaluation

- BGA-EnG-MATL-TS-0008 Materials of Construction Requirements Rev 01Document38 pagesBGA-EnG-MATL-TS-0008 Materials of Construction Requirements Rev 01Gururaj P KundapurPas encore d'évaluation

- STP 619-1977Document74 pagesSTP 619-1977Anonymous pSozzNFc100% (1)

- Air Conditioning Plant (BSME 5B)Document128 pagesAir Conditioning Plant (BSME 5B)Marvin ArnaizPas encore d'évaluation

- PI734DDocument8 pagesPI734Deng_hopaPas encore d'évaluation

- 04 WPS Atp Asme 2012 (A312 304) (A312 310)Document6 pages04 WPS Atp Asme 2012 (A312 304) (A312 310)lailatul kodriPas encore d'évaluation

- Asme Awareness Program - DesignDocument126 pagesAsme Awareness Program - DesignGaurav KhamkarPas encore d'évaluation

- Multiconductor TechnicalDocument24 pagesMulticonductor TechnicalJuan Felipe Vieira GaviriaPas encore d'évaluation

- 21071-S-0000-3600-0013 - O - Underground Piping System For Pressure LinesDocument32 pages21071-S-0000-3600-0013 - O - Underground Piping System For Pressure LinesHadi SuagungPas encore d'évaluation

- Steel Pipes - Pipe Schedule ChartDocument1 pageSteel Pipes - Pipe Schedule ChartAlzaki AbdullahPas encore d'évaluation

- Klenger GasketDocument23 pagesKlenger Gasketjayhuacat7743Pas encore d'évaluation

- EarthingDocument17 pagesEarthingtangouzePas encore d'évaluation

- Valves Jouka Product-GuideDocument28 pagesValves Jouka Product-GuideJenniffer Almánzar100% (2)

- Quenched and Tempered BarDocument7 pagesQuenched and Tempered Barpulilatha100% (1)

- Equivalent SteelDocument2 pagesEquivalent SteelJustin MorrisPas encore d'évaluation

- Metal Table JISDocument1 pageMetal Table JISNakkolopPas encore d'évaluation

- TechnicalDocument36 pagesTechnicalshahzad afzal100% (1)

- Hot Rolled Steel SheetsDocument14 pagesHot Rolled Steel SheetssuvraPas encore d'évaluation

- Diagramas TT de Ferro e Aço - Aço de Alta ResistênciaDocument111 pagesDiagramas TT de Ferro e Aço - Aço de Alta ResistênciaFernando VenceslauPas encore d'évaluation

- Specification For Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceDocument18 pagesSpecification For Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceSofiaJabadanEspulgarPas encore d'évaluation

- LS G100 Quick SettingDocument8 pagesLS G100 Quick SettingtrunghieutcPas encore d'évaluation

- Toez C736 70.1Document27 pagesToez C736 70.1Marius BarPas encore d'évaluation

- Hardness ConversionDocument11 pagesHardness ConversionSimon RisteskiPas encore d'évaluation

- ATC - Automatic Air Conditioner PDFDocument134 pagesATC - Automatic Air Conditioner PDFbenPas encore d'évaluation

- Caustic Soda Flake MSDS PDFDocument3 pagesCaustic Soda Flake MSDS PDFFajar RamadhanPas encore d'évaluation

- Metal Equivalent GradesDocument2 pagesMetal Equivalent GradesMarcelo CostaPas encore d'évaluation

- Stress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanDocument9 pagesStress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanGANESANMECH05Pas encore d'évaluation

- ASTM-A53-B Carbon Steel Pipes Working PresureDocument3 pagesASTM-A53-B Carbon Steel Pipes Working PresureAndres Giraldo MorenoPas encore d'évaluation

- Gate Valve (Z45X)Document1 pageGate Valve (Z45X)lnacerPas encore d'évaluation

- ABB BrakeMotorsDocument32 pagesABB BrakeMotorsDuy Anh TrầnPas encore d'évaluation

- Datasheet - Pig Signallers: Product Description and FunctionsDocument2 pagesDatasheet - Pig Signallers: Product Description and FunctionsMurli ramchandranPas encore d'évaluation

- Valve Selection Guide D 35Document2 pagesValve Selection Guide D 35arrikanPas encore d'évaluation

- LPI Stormaster ESE Air TerminalDocument8 pagesLPI Stormaster ESE Air TerminaleekamaleshPas encore d'évaluation

- Hopper Calculation-9Document1 pageHopper Calculation-9Ujwal KhandokarPas encore d'évaluation

- Misumi Golbal Tool Steel Equivalents by ManufacturerDocument1 pageMisumi Golbal Tool Steel Equivalents by Manufacturerwulfgang66Pas encore d'évaluation

- Klingersil: Optimum Flange SecurityDocument7 pagesKlingersil: Optimum Flange SecurityjbertralPas encore d'évaluation

- Groundfos CR 10-10Document8 pagesGroundfos CR 10-10defriyantoPas encore d'évaluation

- Upvc Price ChartDocument4 pagesUpvc Price ChartbewithkiranPas encore d'évaluation

- Mitsubishi v500 VFD Instruction ManualDocument119 pagesMitsubishi v500 VFD Instruction ManualMROstop.com100% (1)

- Kitz GraphiteDocument48 pagesKitz GraphitejjdPas encore d'évaluation

- ACW Booster Pump CalculationDocument7 pagesACW Booster Pump CalculationgreenenergykolkataPas encore d'évaluation

- ASTM A53 B Carbon Steel Pipes - Allowable PressureDocument8 pagesASTM A53 B Carbon Steel Pipes - Allowable PressureAizat Najib100% (1)

- ArchiCAD Canopy GuideDocument15 pagesArchiCAD Canopy GuideFellow9Pas encore d'évaluation

- Chemical Solution Density & ViscosityDocument18 pagesChemical Solution Density & ViscosityLee JianPas encore d'évaluation

- Material GradesDocument2 pagesMaterial GradesDvs RameshPas encore d'évaluation

- Calculation Book Cathodic Protection Input ParametersDocument4 pagesCalculation Book Cathodic Protection Input ParametersLuis SuarezPas encore d'évaluation

- Why Switch To Chemical Electrode Earthing ?Document9 pagesWhy Switch To Chemical Electrode Earthing ?gohilnarendraPas encore d'évaluation

- Centrifugal Pump Data SheetDocument8 pagesCentrifugal Pump Data SheetCarlos GomezPas encore d'évaluation

- Bus Bars Current Ratings For Al, CuDocument1 pageBus Bars Current Ratings For Al, CuMJ PrabhuPas encore d'évaluation

- Tightening Torques For Imperial (U.S.) Bolts of Yield Strength (Sy) 80%Document2 pagesTightening Torques For Imperial (U.S.) Bolts of Yield Strength (Sy) 80%Serj DavidPas encore d'évaluation

- Pt. Indexim Coalindo Pt. Jakarta Prima CranesDocument1 pagePt. Indexim Coalindo Pt. Jakarta Prima Cranesfajar kristantiPas encore d'évaluation

- D2 KNLDocument1 pageD2 KNLmini p shendePas encore d'évaluation

- Pipe Schedule Asme 36.10Document1 pagePipe Schedule Asme 36.10manojPas encore d'évaluation

- Fittings Catalogue 2010Document218 pagesFittings Catalogue 2010sixuletPas encore d'évaluation

- Price ListDocument5 pagesPrice ListSharafat AliPas encore d'évaluation

- HFDSR - 1500kw 6kv Drwg.Document4 pagesHFDSR - 1500kw 6kv Drwg.Sulistyono SulistyonoPas encore d'évaluation

- Reinforcement: Industrial Training Report Tudawe Brothers LimitedDocument8 pagesReinforcement: Industrial Training Report Tudawe Brothers Limitedymanfas100% (1)

- Klinger - Gasket FactorsDocument1 pageKlinger - Gasket FactorsAnonymous q2HC0zyfa2Pas encore d'évaluation

- Common Materilas For CS PipingDocument2 pagesCommon Materilas For CS PipingValiullah SarpanchPas encore d'évaluation

- OpeningCalculator v1 0Document4 pagesOpeningCalculator v1 0PROYECTOMSPas encore d'évaluation

- Caustic Soda Liquid 48-50%Document12 pagesCaustic Soda Liquid 48-50%wongpengchiong7205Pas encore d'évaluation

- Wall Thickness CalcDocument2 pagesWall Thickness Calcpbao_12Pas encore d'évaluation

- Outokumpu Stainless - Steel GradesDocument1 pageOutokumpu Stainless - Steel GradesNshuti Rene FabricePas encore d'évaluation

- Materials FerrousDocument3 pagesMaterials Ferrousjohnson_regoPas encore d'évaluation

- NipponDocument12 pagesNipponLalit SharmaPas encore d'évaluation

- Mot So Loai Van Hay DungDocument14 pagesMot So Loai Van Hay DungNguyễn Xuân NamPas encore d'évaluation

- Chains and Buckets Etc.Document6 pagesChains and Buckets Etc.dariusiasdasdPas encore d'évaluation

- MD ElementsDocument13 pagesMD ElementsJosue RicaldePas encore d'évaluation

- Improved Life of Die-Casting Dies (H-13 Steel) by Heat Treatment (US DOE, 1998) WWDocument255 pagesImproved Life of Die-Casting Dies (H-13 Steel) by Heat Treatment (US DOE, 1998) WWapi-3729703100% (2)

- Astm 400Document9 pagesAstm 400JOSEPH REFUERZOPas encore d'évaluation

- A TEM Study of Precipitation in Al-Mg-Si AlloysDocument6 pagesA TEM Study of Precipitation in Al-Mg-Si AlloysHarood NishatPas encore d'évaluation

- VTT-009 QuenchPatternCharacteristicsDocument3 pagesVTT-009 QuenchPatternCharacteristicstroyel99Pas encore d'évaluation

- Rewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceDocument21 pagesRewetting and Boiling in Jet Impingement On High Temperature Steel SurfaceH. LEOCADIOPas encore d'évaluation

- Rolling of Steel Plates in A Plate Rolling MillDocument20 pagesRolling of Steel Plates in A Plate Rolling MillKASHIFPas encore d'évaluation

- Vacuum Hardening HssDocument6 pagesVacuum Hardening Hssharanus2000Pas encore d'évaluation

- CarTech® Custom 465® StainlessDocument14 pagesCarTech® Custom 465® StainlessElkin ColoradoPas encore d'évaluation

- AAMRADocument50 pagesAAMRARona Khairol Pratama100% (1)

- JMATPRO Ifhtse 2008Document4 pagesJMATPRO Ifhtse 2008FahrgerustePas encore d'évaluation

- Revised Draft Ammendment To IRS T29 MAR13Document11 pagesRevised Draft Ammendment To IRS T29 MAR13Shipra MishraPas encore d'évaluation

- Hodge JM Orehoski MA Trans AIME 1946 167 502 PDFDocument11 pagesHodge JM Orehoski MA Trans AIME 1946 167 502 PDFPablo CollantesPas encore d'évaluation

- Emm Heat Treatment Process QuizDocument3 pagesEmm Heat Treatment Process QuizNarinder Kumar67% (6)

- Wear Plate PDFDocument19 pagesWear Plate PDFNorma SalazarPas encore d'évaluation

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 pagesRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456Pas encore d'évaluation

- European Steel and Alloy Grades: S235JRG2 (1.0038)Document2 pagesEuropean Steel and Alloy Grades: S235JRG2 (1.0038)farshid KarpasandPas encore d'évaluation

- Varmebehandling 3Document28 pagesVarmebehandling 3Ahamed Saleel CPas encore d'évaluation

- KATALOG SHACKLE in MM PDFDocument12 pagesKATALOG SHACKLE in MM PDFRay HerlambangPas encore d'évaluation

- HeattreatmentDocument21 pagesHeattreatmentroyalmechnoPas encore d'évaluation

- Presentacion TTA PDFDocument48 pagesPresentacion TTA PDFdavid peralesPas encore d'évaluation

- Forced Circulation of Nitrogen Gas For AcceleratedDocument14 pagesForced Circulation of Nitrogen Gas For Acceleratedحسن عرقسوسيPas encore d'évaluation

- Cooksongold Advanced Metal Powders 2016Document8 pagesCooksongold Advanced Metal Powders 2016mariaPas encore d'évaluation